Horizontal type cyclone combustion biomass burning machine

A cyclone combustion, biomass technology, applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of timing shutdown cleaning, fuel can not be fully burned, can not be used, etc., to achieve long service life, ensure combustion effect, The effect of preventing backfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present technology will be further described below in conjunction with the accompanying drawings.

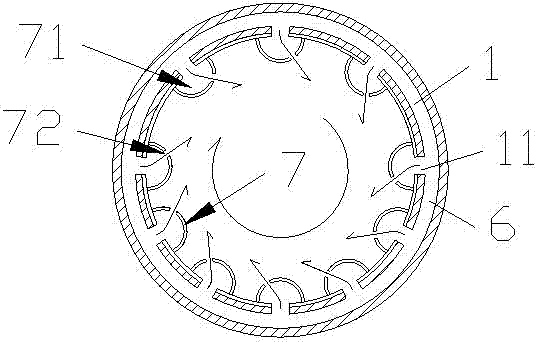

[0019] Such as Figure 1-3 The horizontal cyclone combustion biomass burner shown includes a horizontal cylindrical furnace 1, one end of the furnace is closed, and the closed end 2 has an outlet of a fuel feeding channel 3; a feeding auger is arranged in the fuel feeding channel 4. The fuel feed channel is provided with a tuyere 5 for blowing air toward the outlet of the fuel feed channel; there is an air intake channel 6 in the furnace wall. Both the air inlet passage 6 and the air blast port 5 communicate with the air outlet 9 of the blower. A cyclone tube 7 is arranged on the inner wall of the furnace, and the cyclone tube inner chamber 71 communicates with the air inlet passage 6; an air outlet hole 72 is arranged on the cyclone tube, and the axial direction of the air outlet hole forms an acute angle of 30-60° with the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com