Gas generator propellant grain

A technology of gas generating agent and powder column, which is applied to ammunition, projectiles, cartridge ammunition, etc. It can solve the problems of high temperature of the launch tube, strict thermal design requirements, threat of equipment on the bomb and launch device, etc., and achieve low combustion temperature , compact structure, fast gas production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

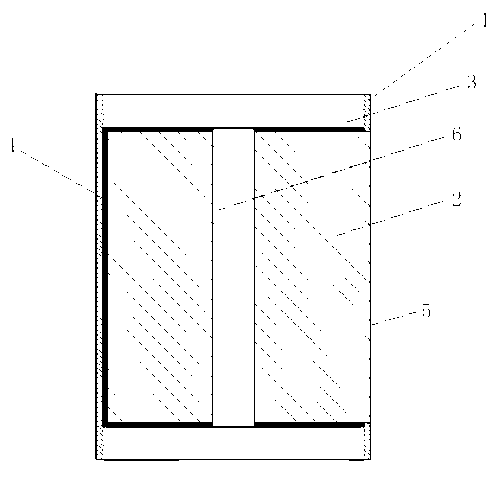

[0026] Embodiments of the gas generant grains according to the invention will be described below with reference to the drawings.

[0027] figure 1 Among them, the present invention is an equipment for providing energy for a power plant, which is composed of the following components: a support cylinder 1 made of any metal such as alloy steel, stainless steel, low carbon steel, and a gas generating agent fixed in the support cylinder 1 2. The supporting cylinder 1 is cylindrical, and has a plurality of axially parallel combustion-supporting holes 5 on its side. The length of the combustion-supporting hole 5 is consistent with the length of the gas generating agent 2 . The gas generating agent 2 has a cylindrical axial through hole 6 with a hole in the axial direction, and the two ends are coated with the limited combustion layer 3 . The gas generating agent 2 covers all the combustion-supporting holes 5 of the support cylinder. The gas generating agent 2 is bonded to the uno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com