High-precision balancing flowmeter

A flow-balanced, high-precision technology, applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure. problems, to reduce the loss of kinetic energy, ensure accuracy, and reduce work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

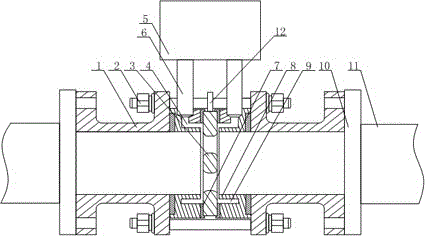

[0020] like figure 1 As shown, this embodiment includes a connecting pipe 1 with a flange, a straight pipe section 11, a sensor, two packing rings 8 and two pressure-taking pipes 6, and the adjacent ends of the two connecting pipes 1 with flanges The ends are connected together by bolts 2, and the other end of the connecting pipe 1 is connected with the straight pipe section 11 through the flange 10. On the opposite end faces of the two connecting pipes 1, packing rings 8 are arranged respectively, and the orifice plate body 3 is arranged between two pack-off rings 8. There are multiple nozzles on the orifice plate body 3, and an air passage 4 communicating with the connecting pipe 1 is opened on one side of the pack-off ring 8, and one end of the pressure-taking tube 6 is It communicates with the air passage 4, and the other end of the pressure-taking pipe 6 communicates with the sensor. On the inner wall of the other side of the packing ring 8, there is a buffer groove 9 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com