Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

779results about How to "Reduce positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

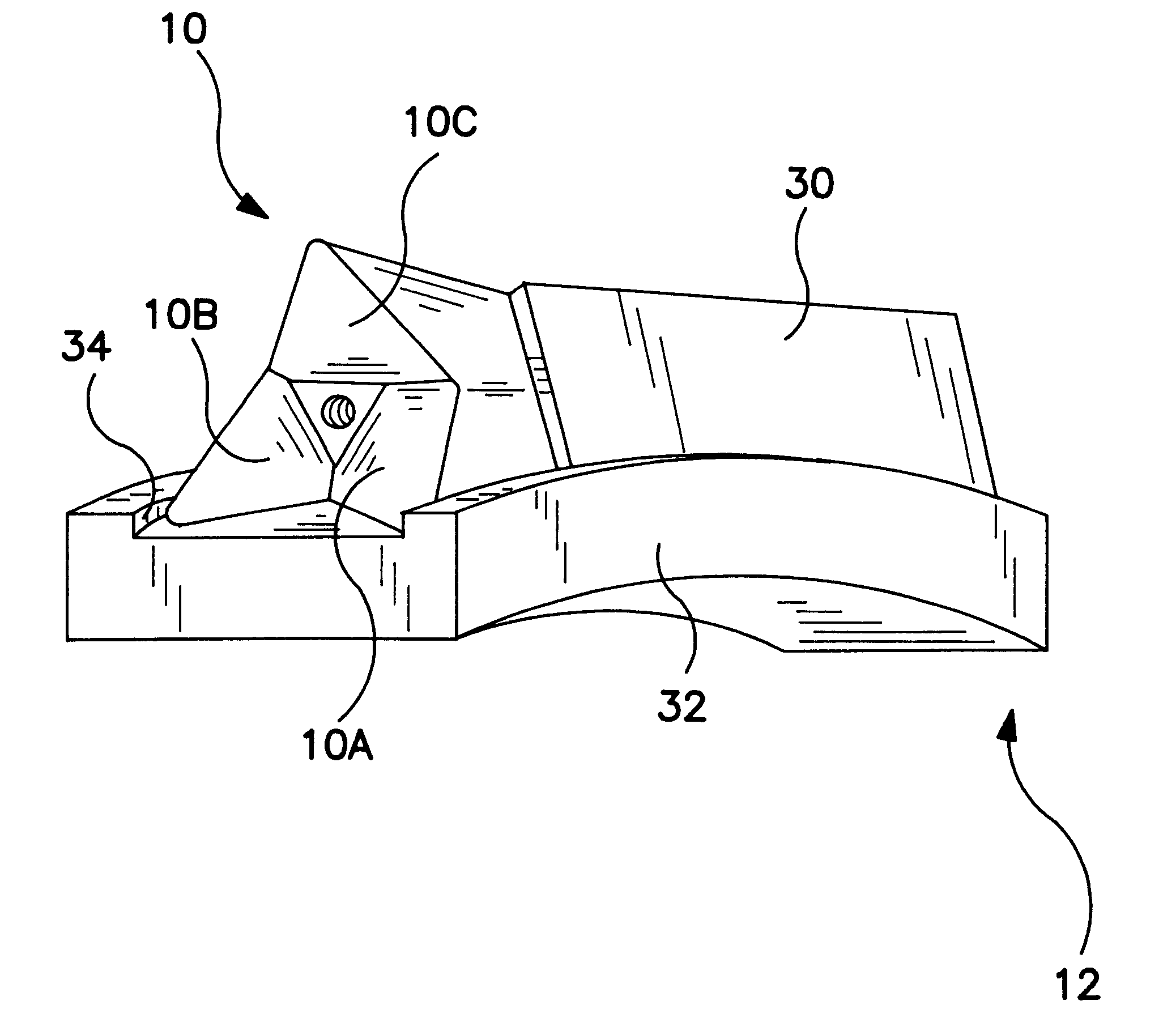

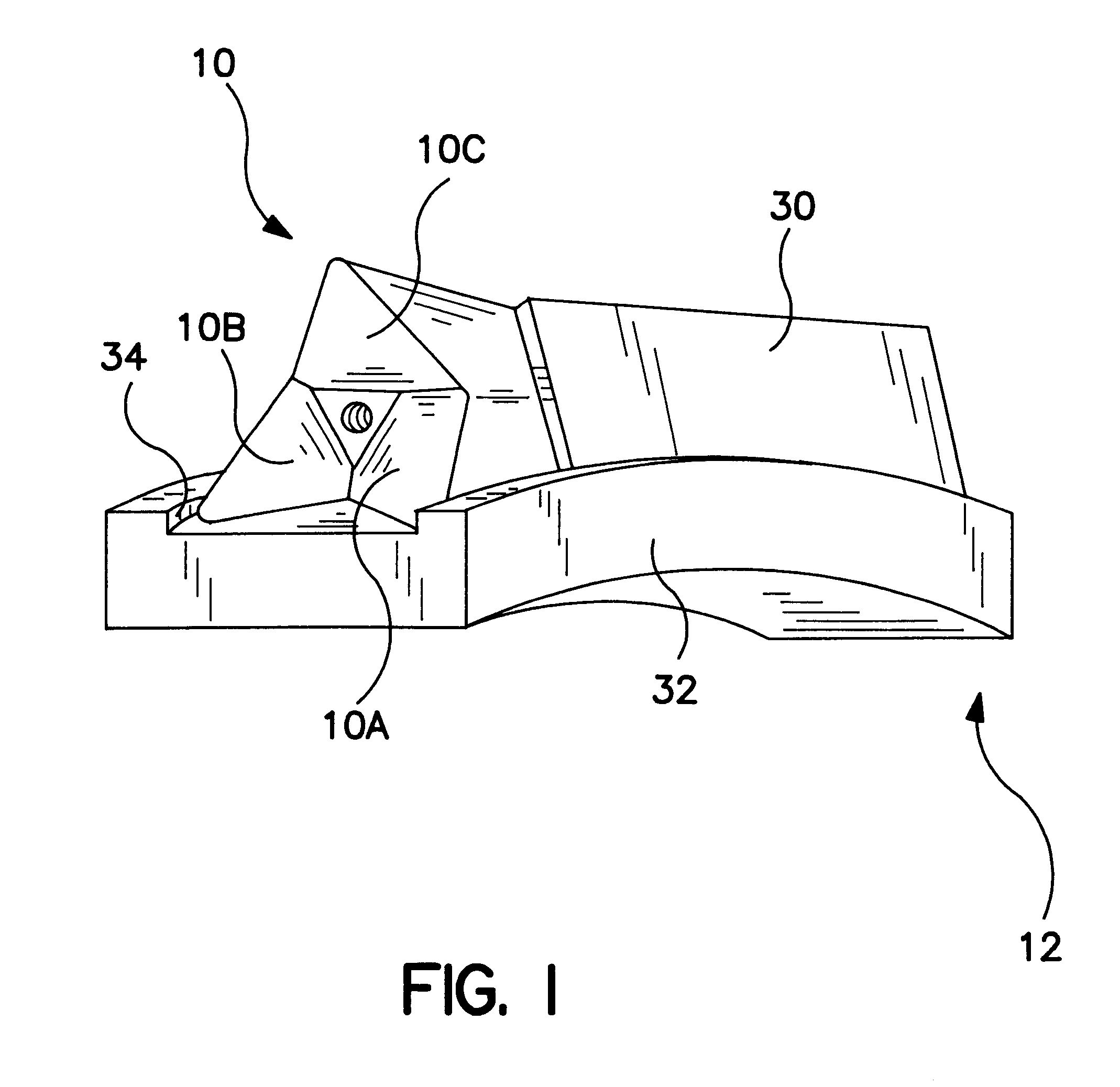

Total joint arthroplasty system

ActiveUS20090131941A1Precise alignmentImprove visualizationMedical simulationProgramme controlJoint arthroplastyTotal hip arthroplasty

A method and system for performing a total joint arthroplasty procedure on a patient's damaged bone region. A CT image or other suitable image is formed of the damaged bone surfaces, and location coordinate values (xn,yn,zn) are determined for a selected sequence of bone surface locations using the CT image data. A mathematical model z=f(x,y) of a surface that accurately matches the bone surface coordinates at the selected bone spice locations, or matches surface normal vector components at selected bone surface locations, is determined. The model provides a production file from which a cutting jig and an implant device (optional), each patient-specific and having controllable alignment, are fabricated for the damaged bone by automated processing. At this point, the patient is cut open (once), the cutting jig and a cutting instrument are used to remove a selected portion of the bone and to provide an exposed planar surface, the implant device is optionally secured to and aligned with the remainder of the bone, and the patient's incision is promptly repaired.

Owner:HOWMEDICA OSTEONICS CORP

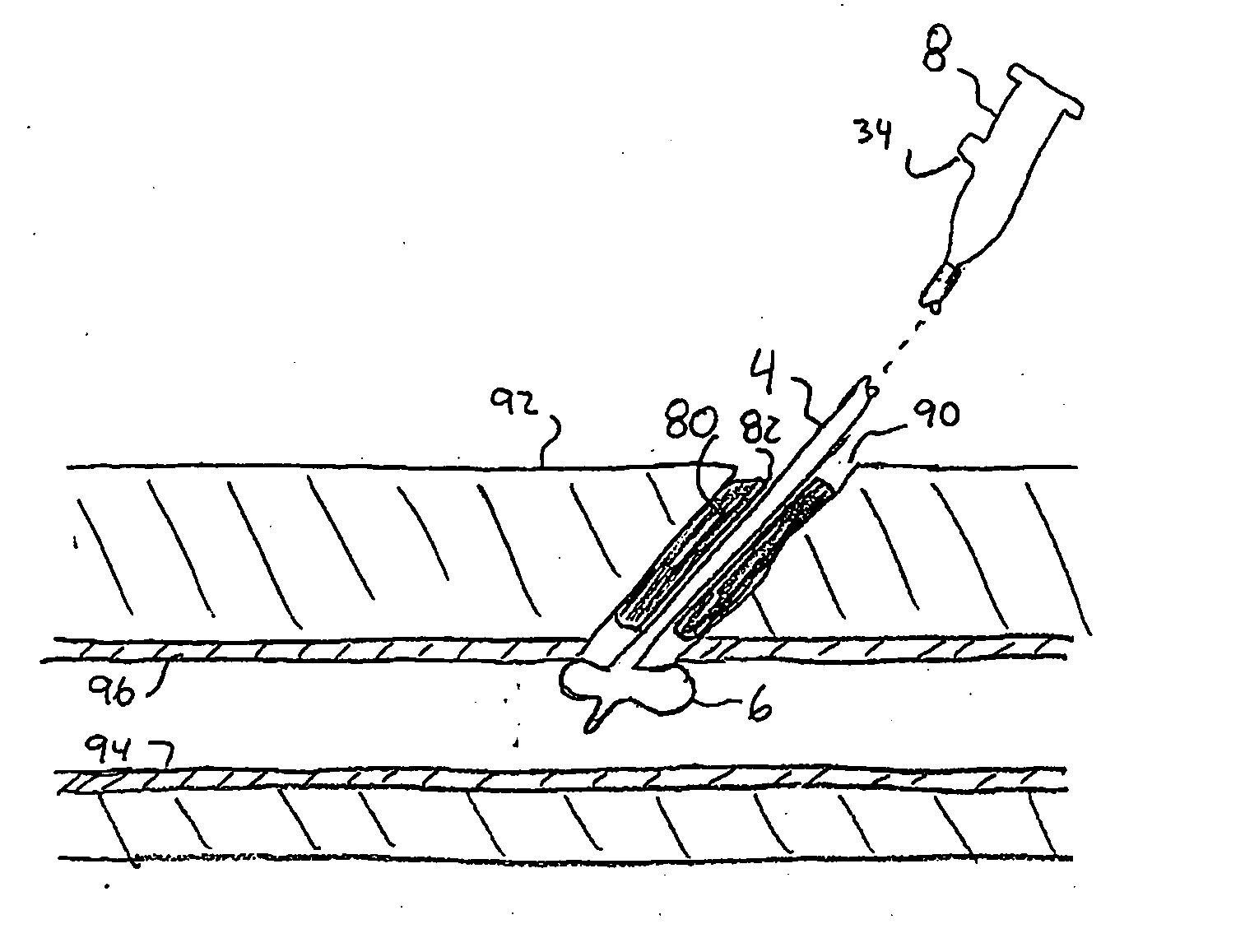

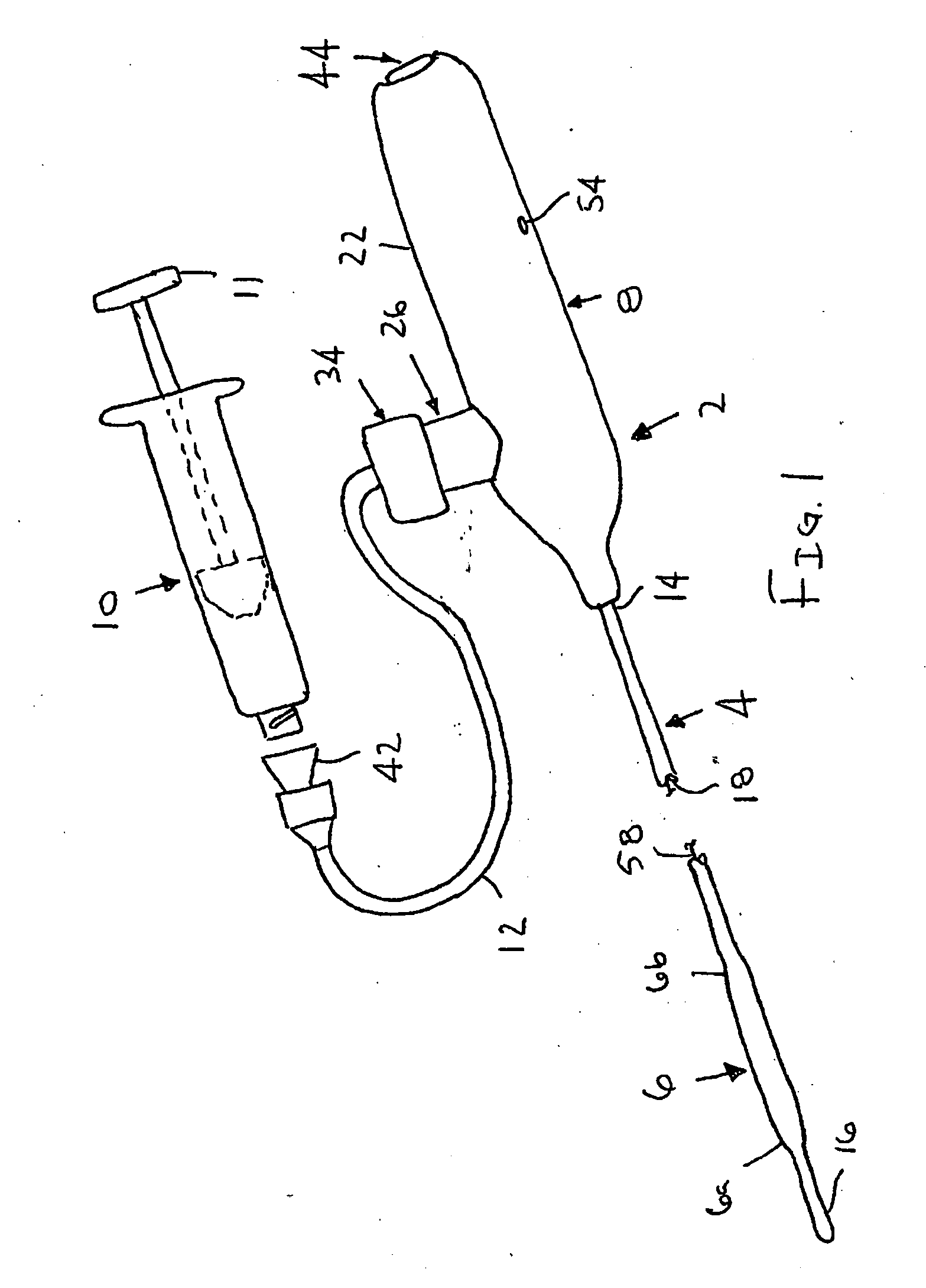

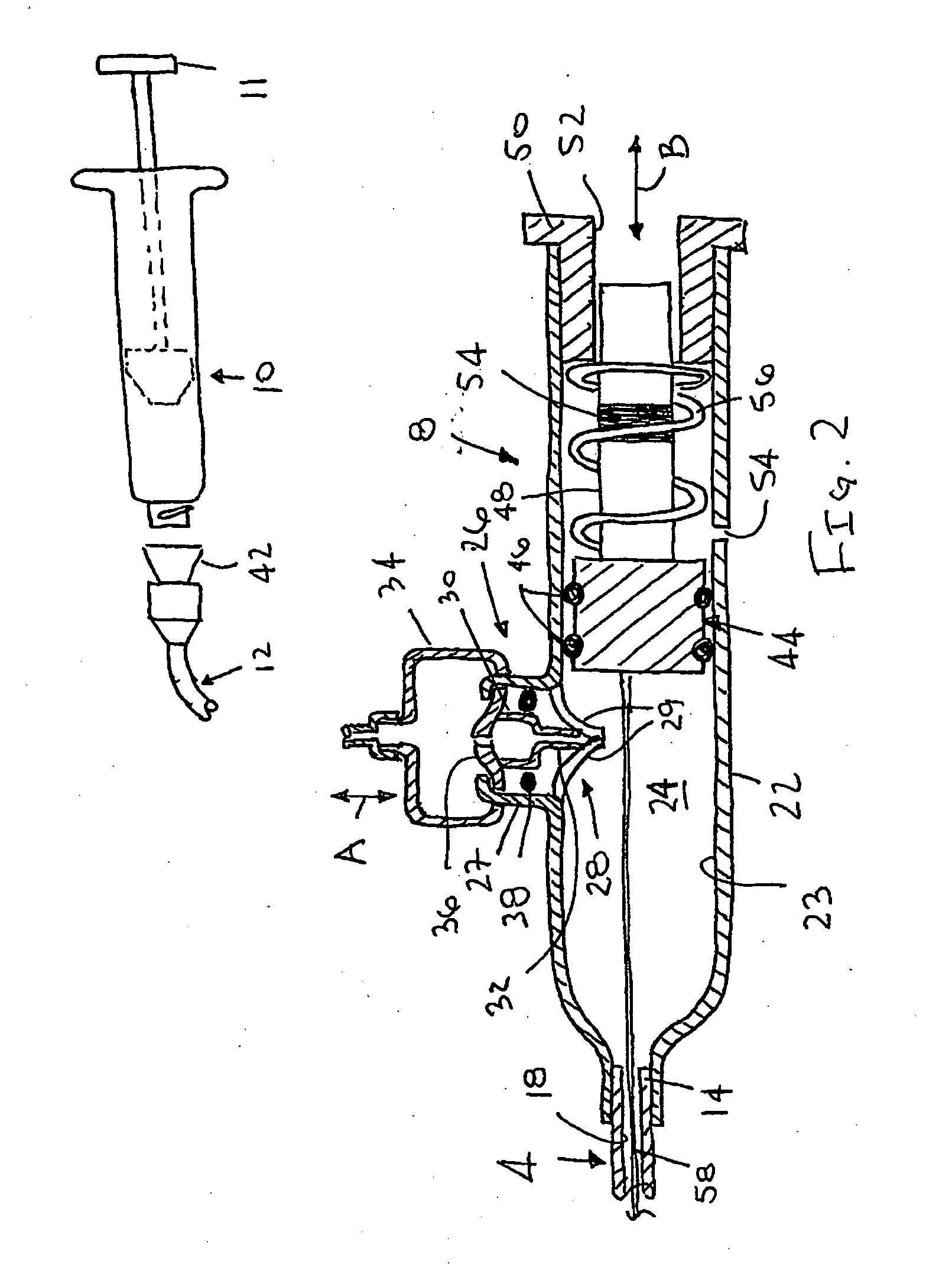

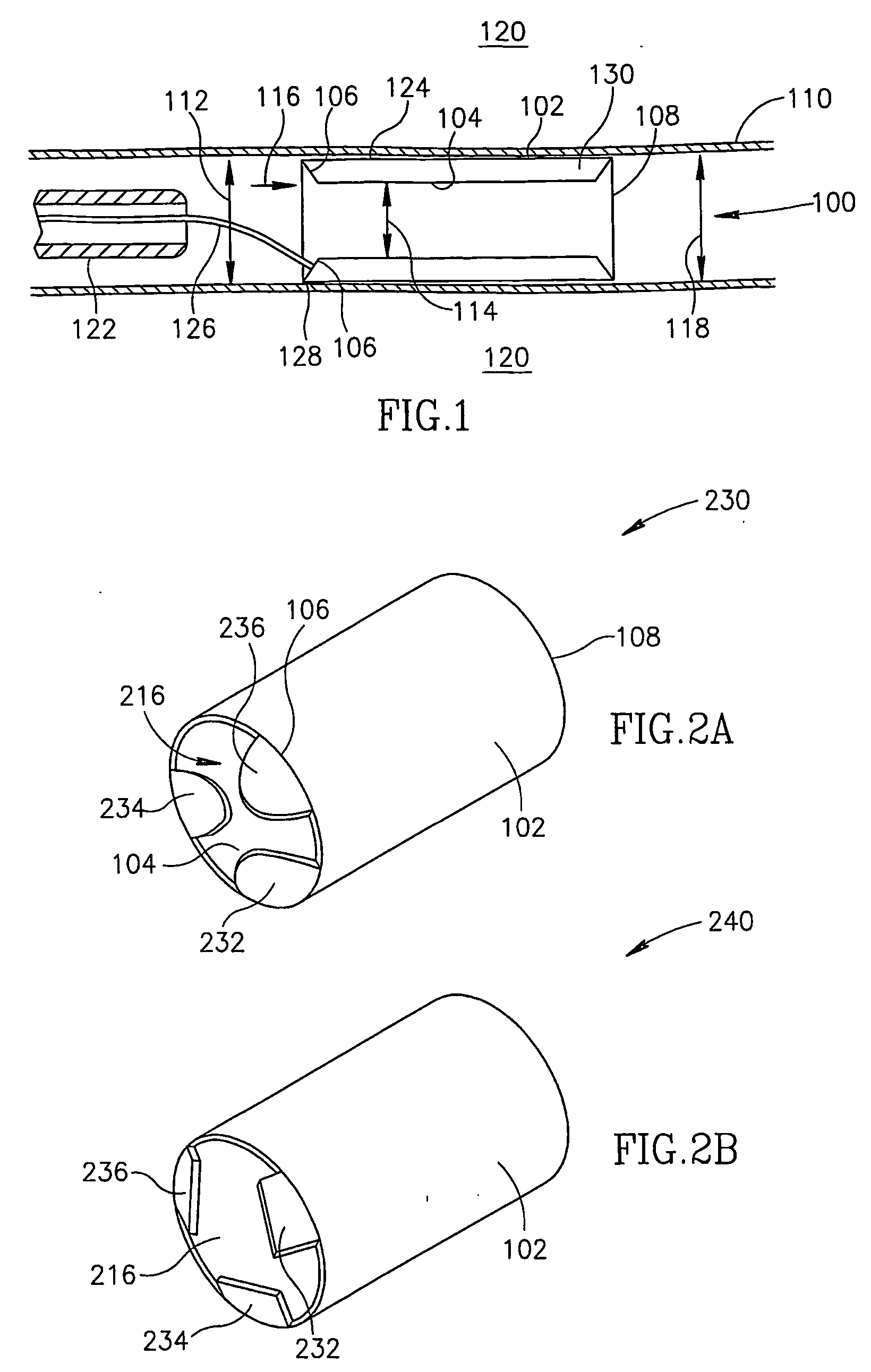

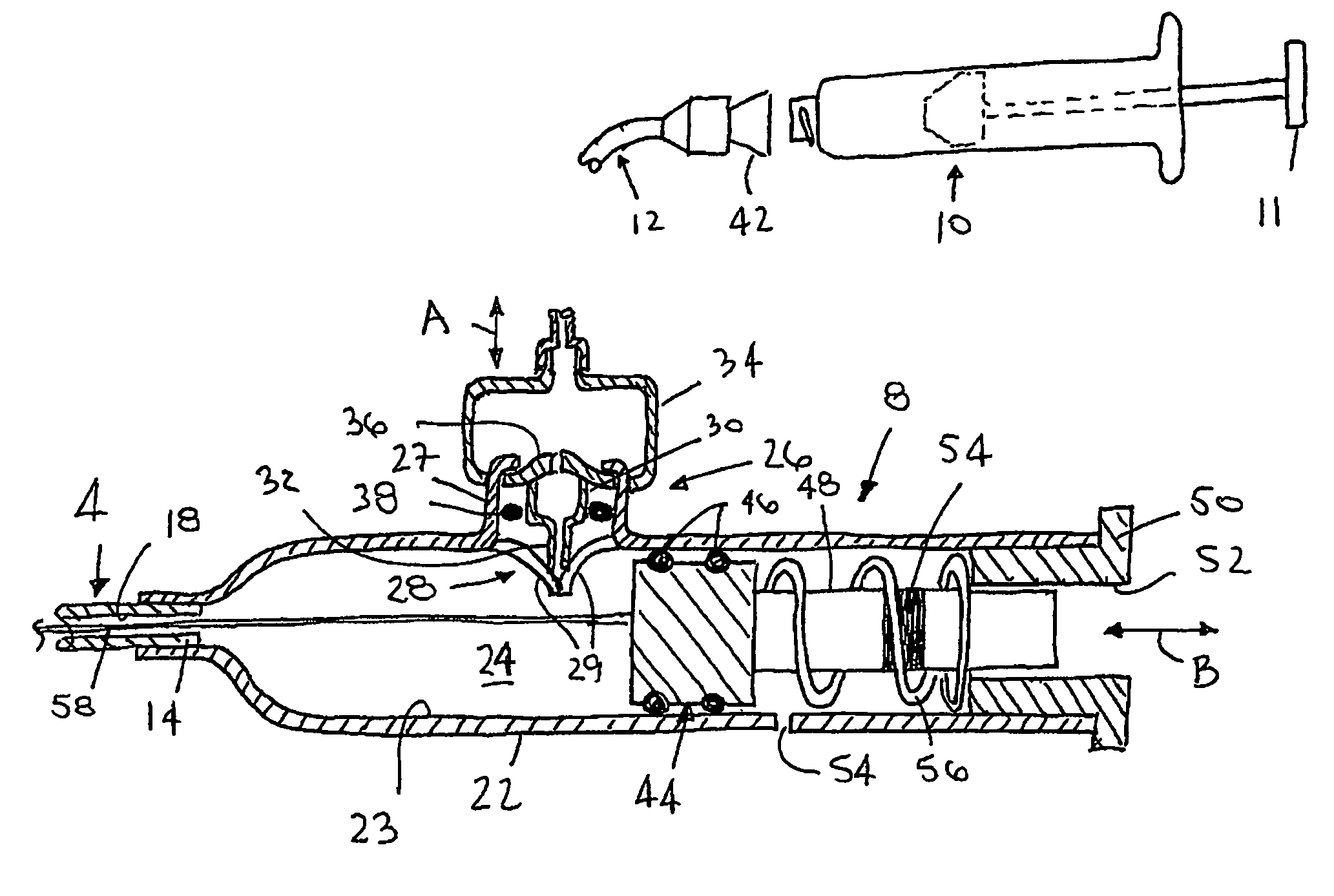

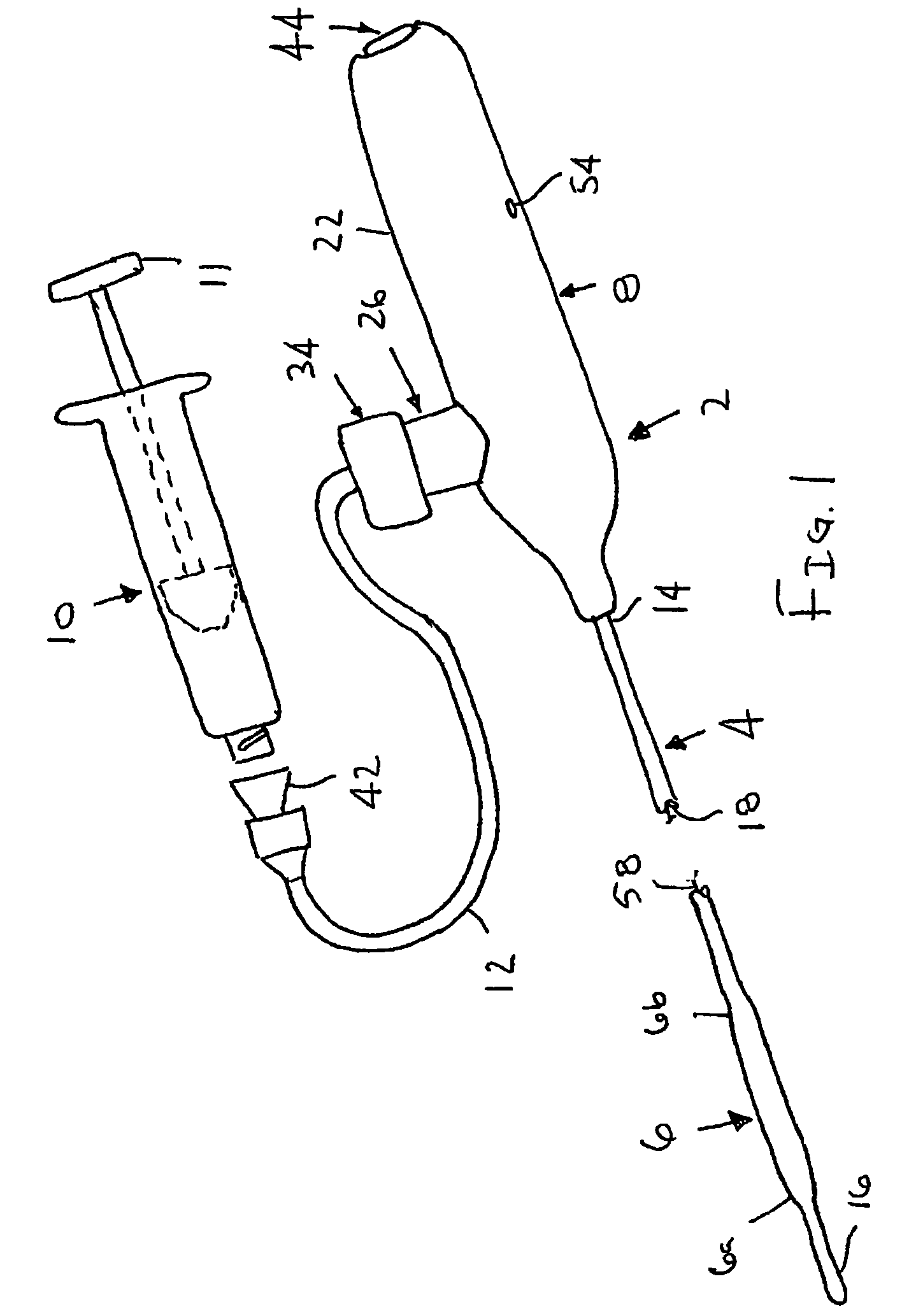

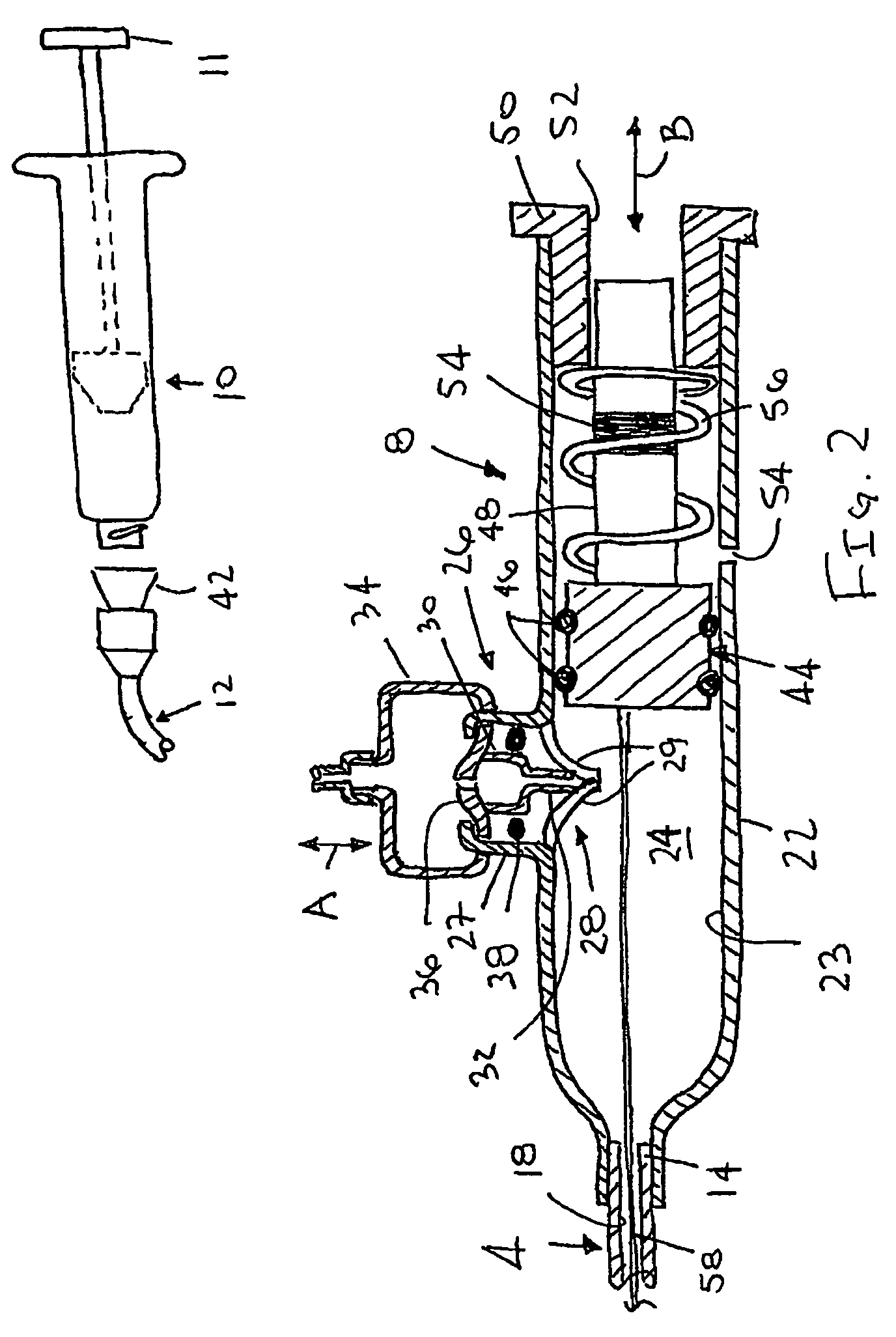

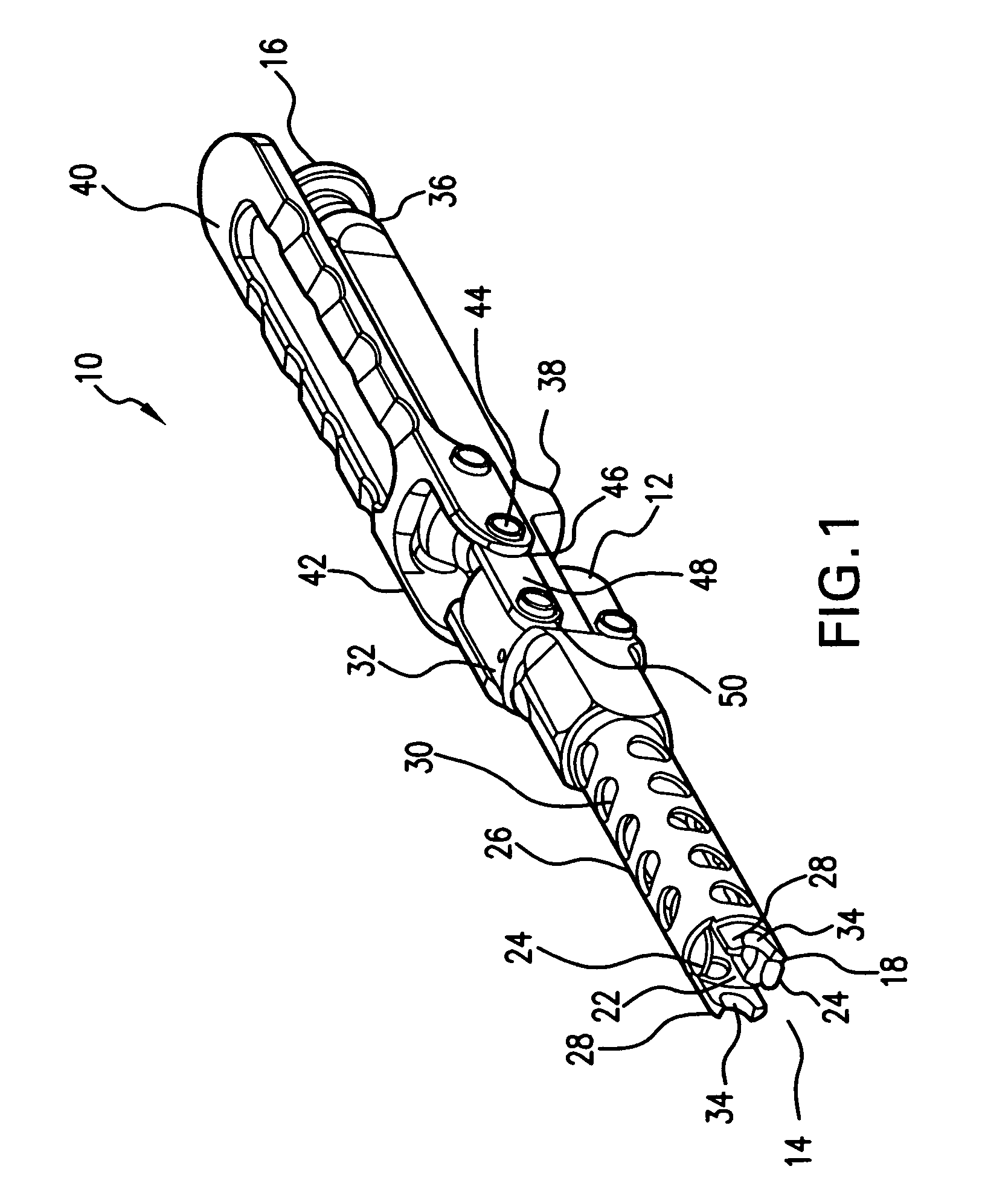

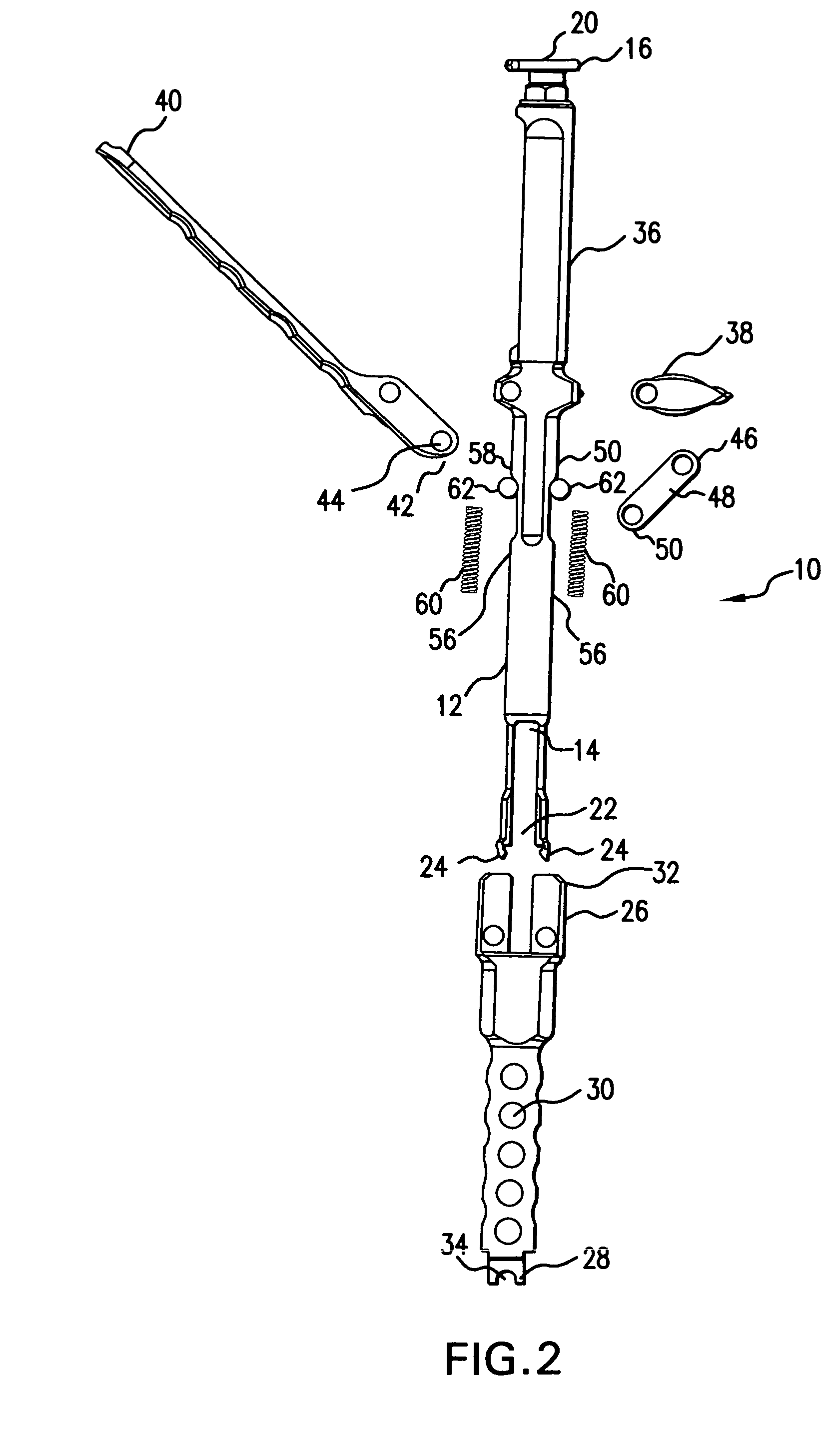

Apparatus and method for temporary hemostasis

ActiveUS20080009794A1Good hemostasisPrevent over-pressurizationBalloon catheterSurgeryVALVE PORTPlunger

An apparatus for providing hemostasis within a puncture through tissue includes an elongate member having a lumen extending between proximal and distal ends thereof, an expandable member carried on the distal end and a housing on the proximal end, the housing including an interior communicating with the lumen, and further including a valve assembly with a one-way valve allowing access into the housing interior upon application of a pressure differential across the valve, and a movable plunger for overriding and opening the valve.

Owner:ACCESSCLOSURE

System and Method of Prioritizing Items in a Queue

A system and method of prioritizing items in a queue is provided. The system and method includes the creation of a document queue comprising a plurality of items and the assignment of a queue position to each of the plurality of items based upon one or more determining factors, such as the date of receipt of each item. A fee can be calculated for moving an item to a different priority queue position and a right-of-first refusal can be provided for one or more items that would have their respective queue positions changed as a result of payment of the fee.

Owner:LEVIATHAN ENTERTAINMENT

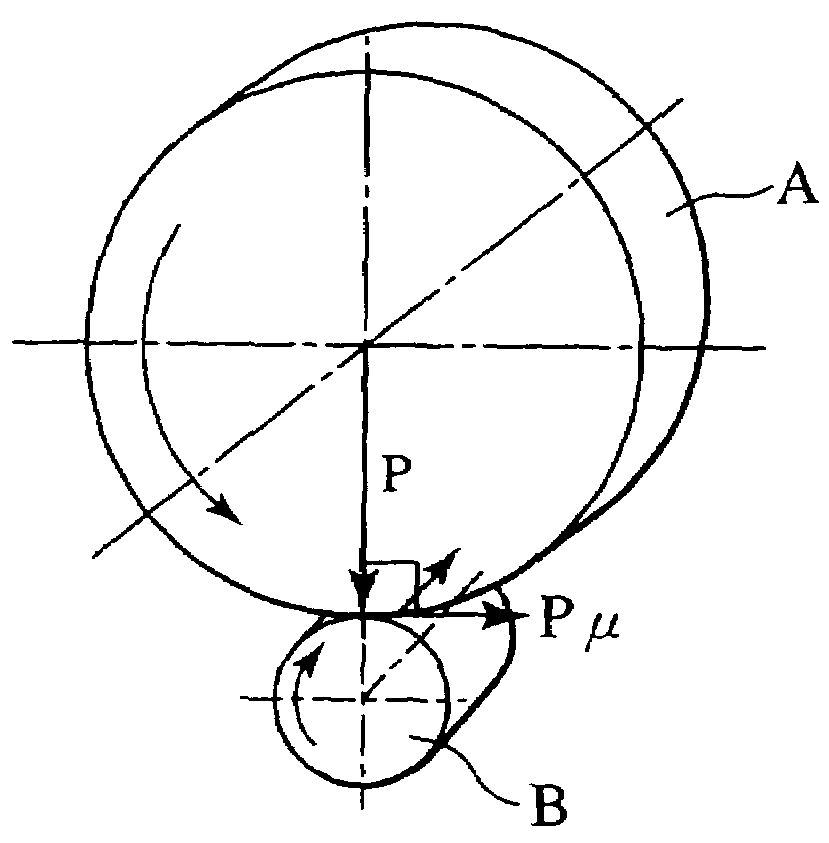

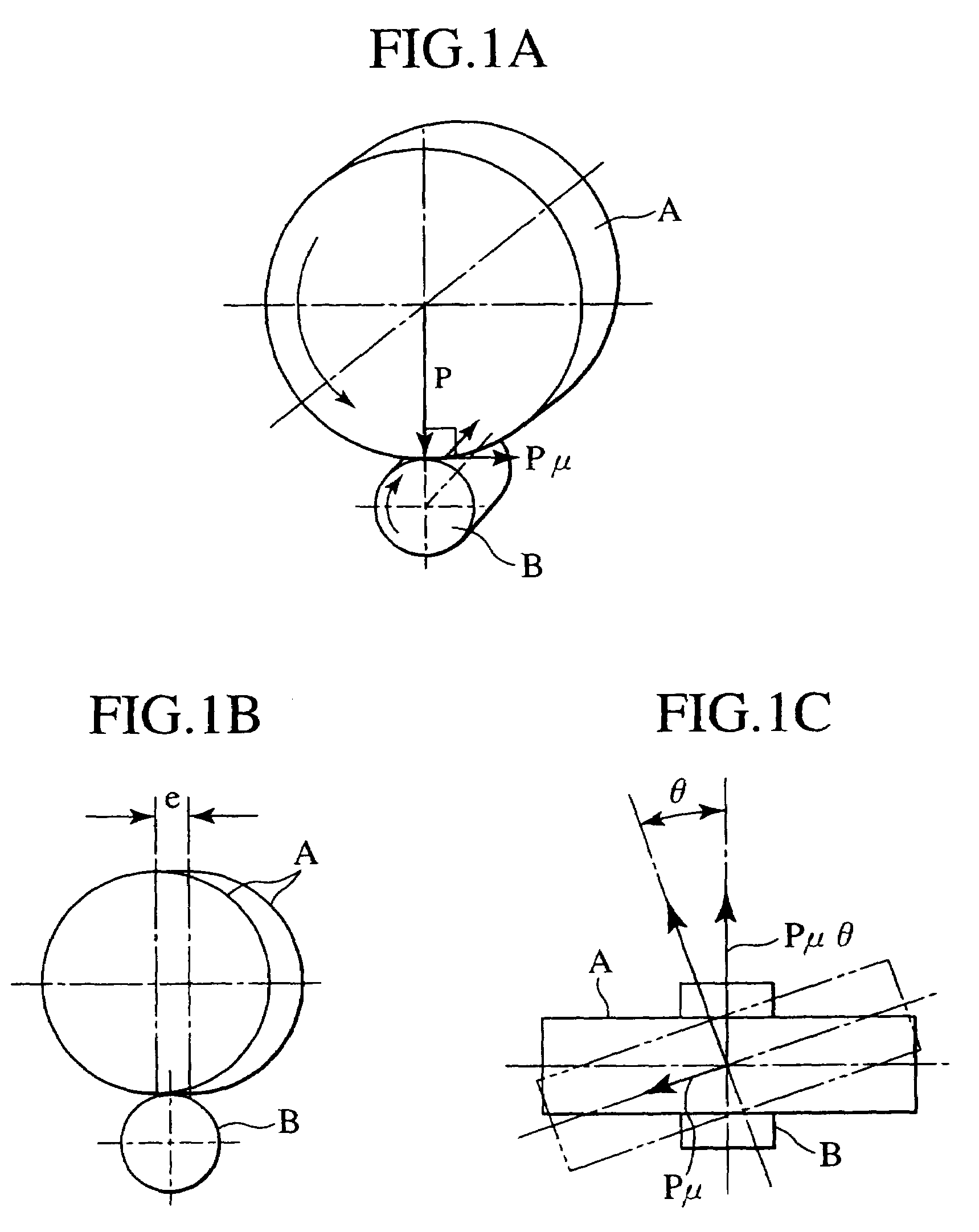

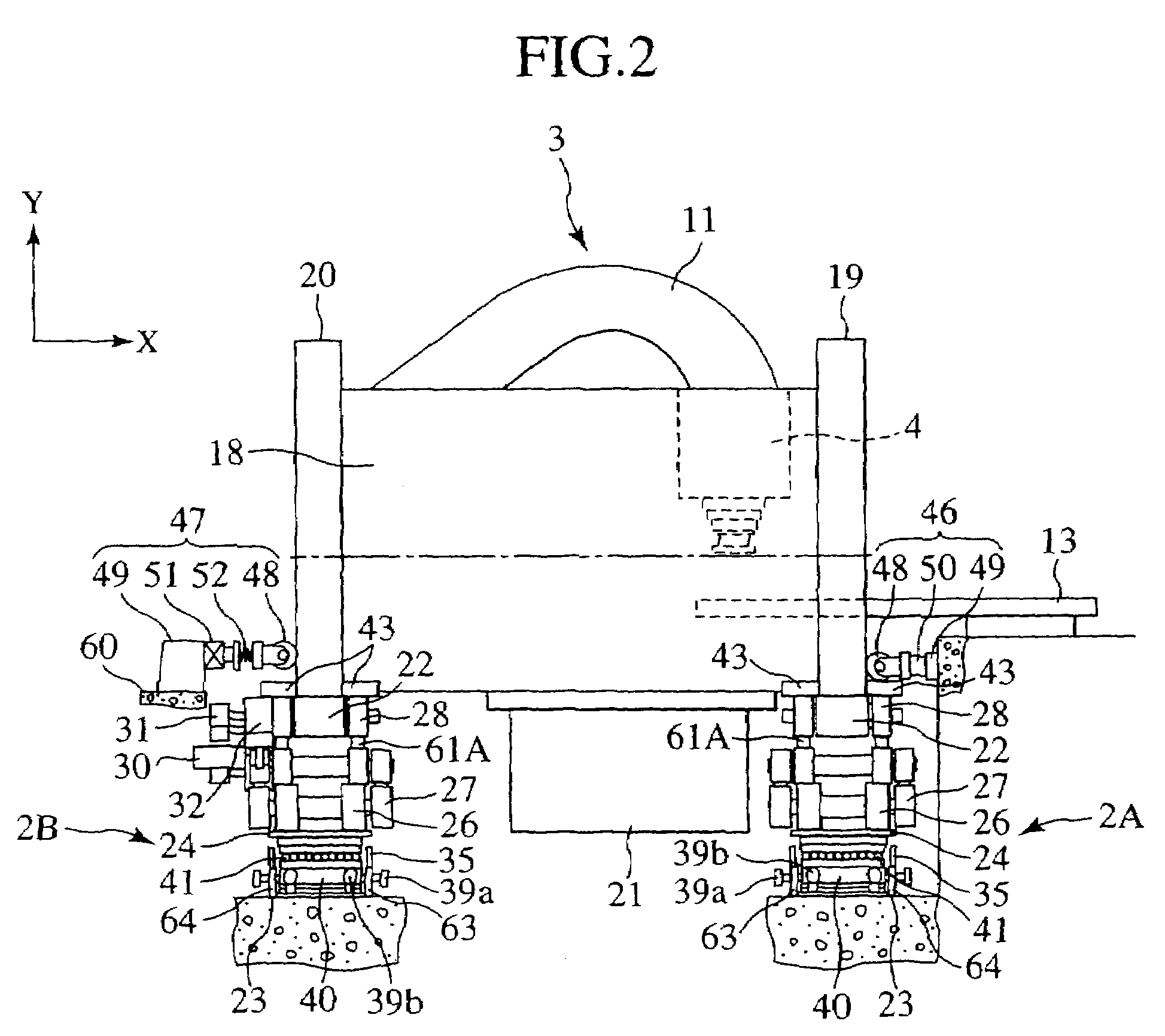

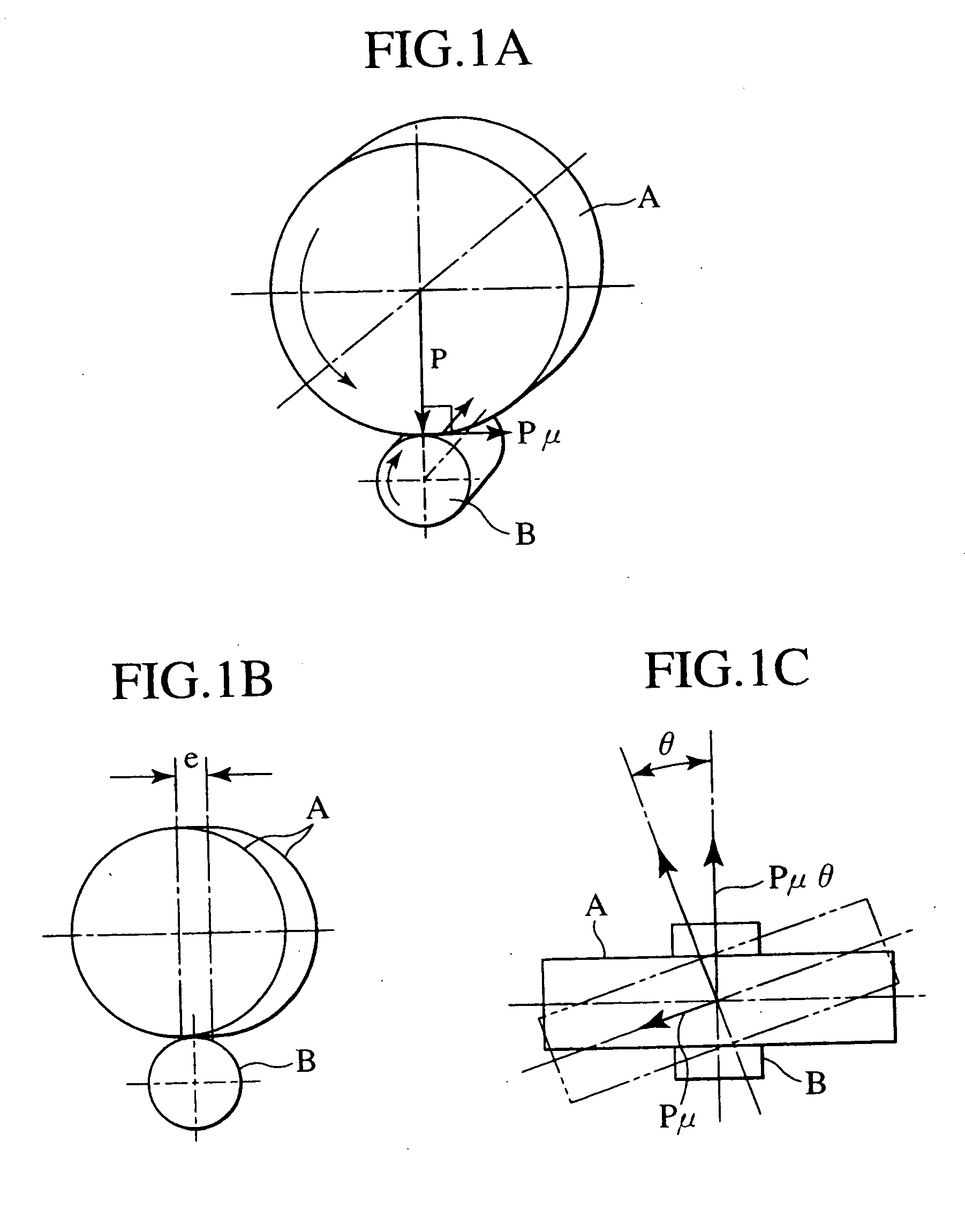

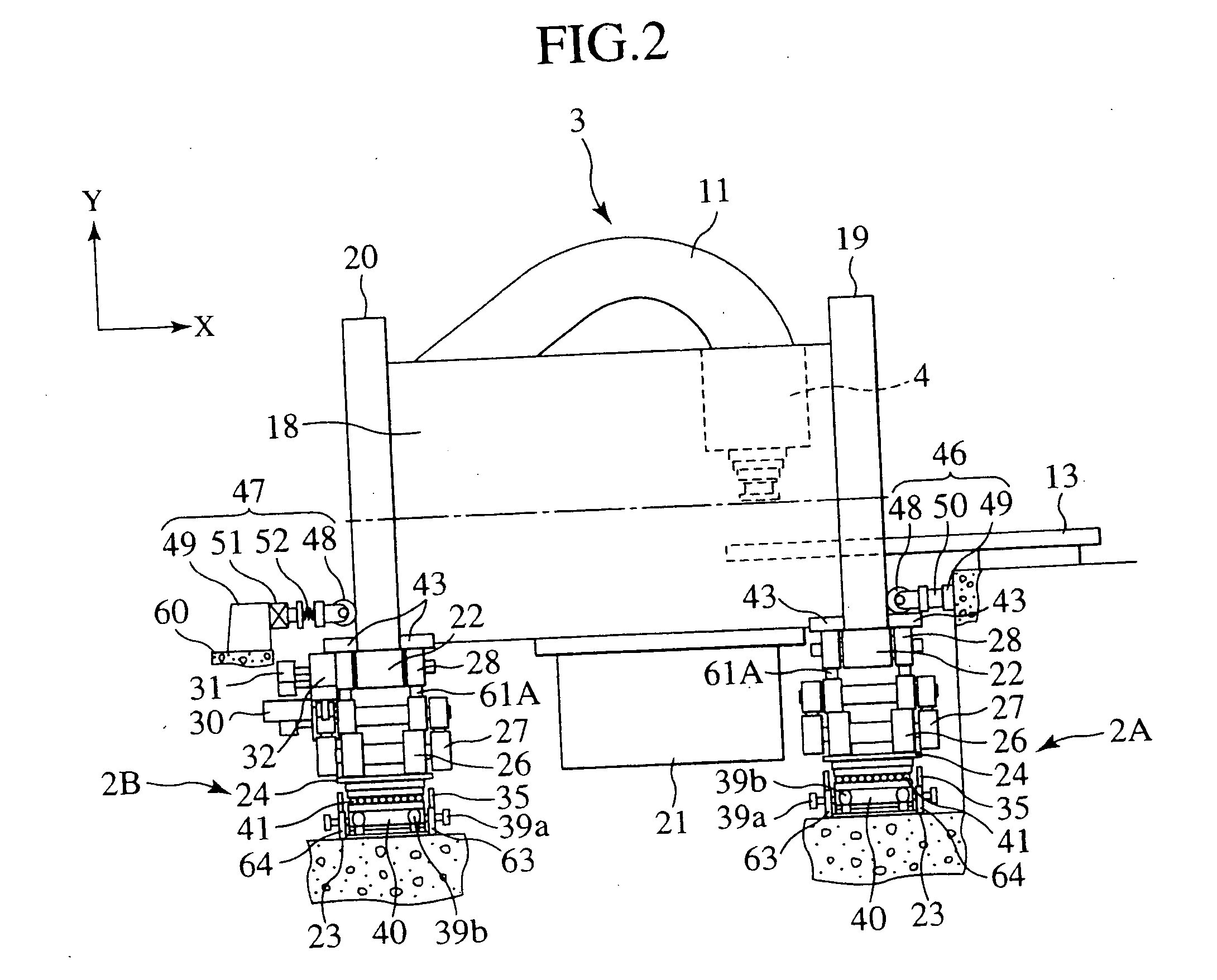

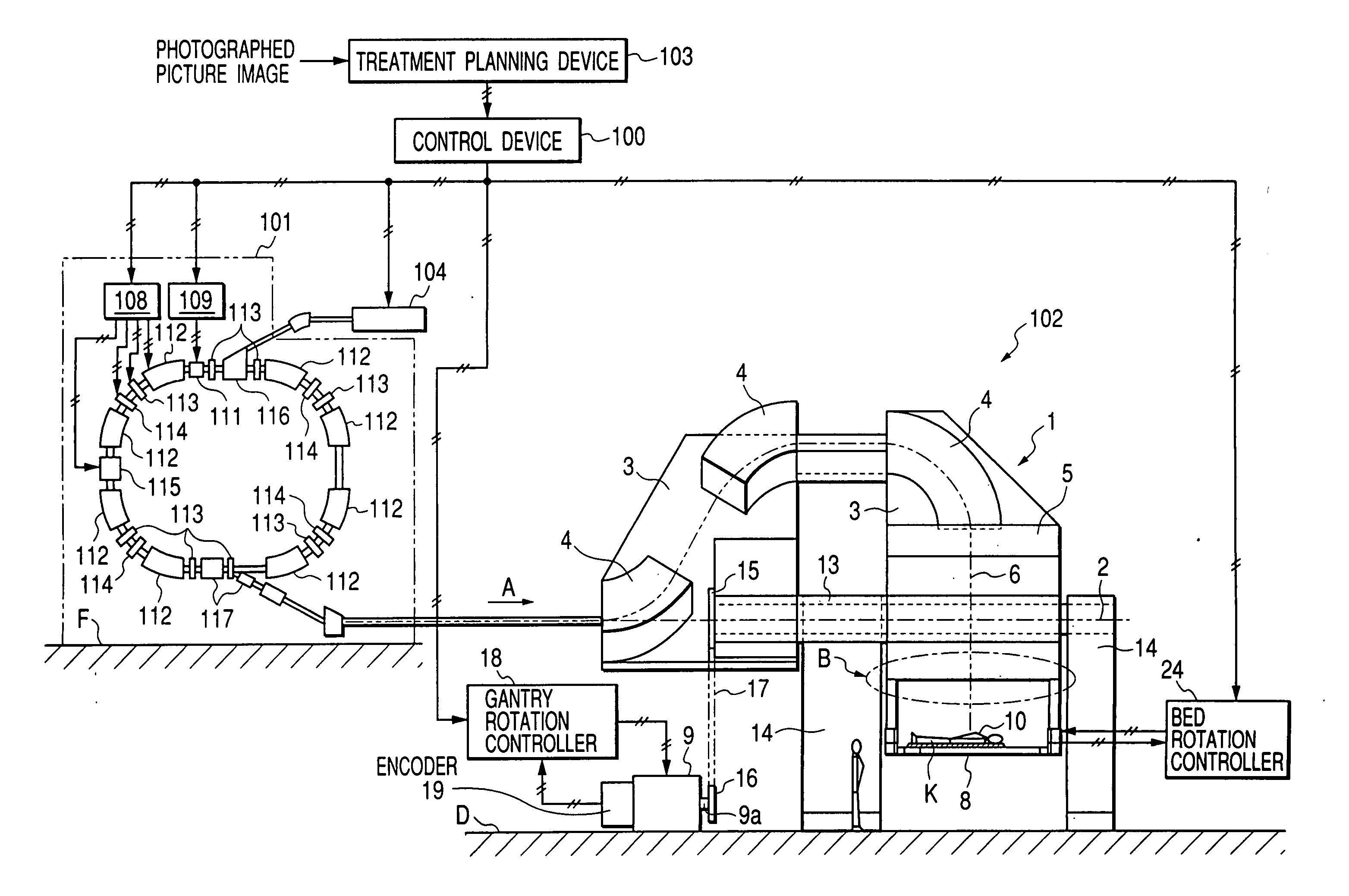

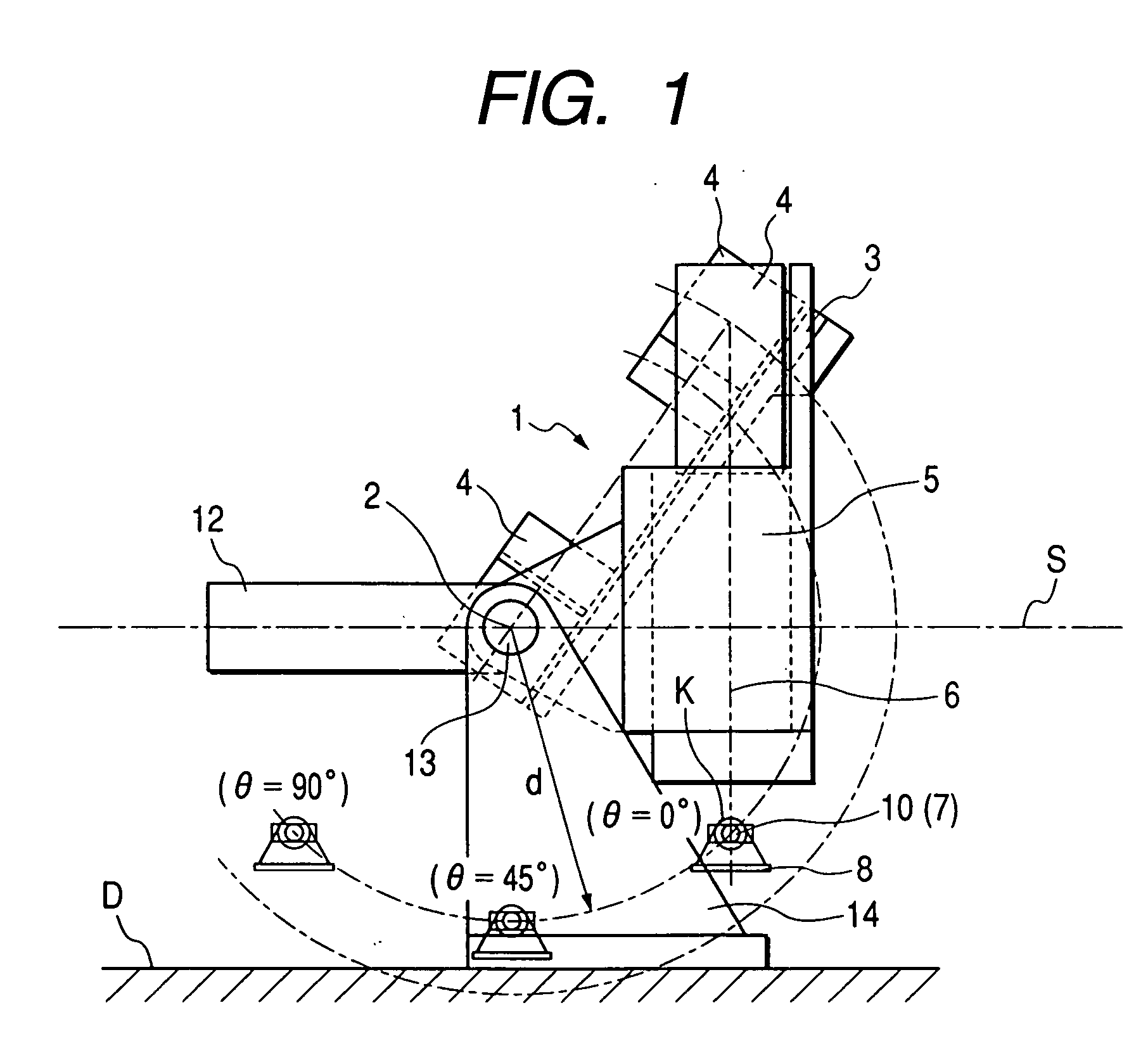

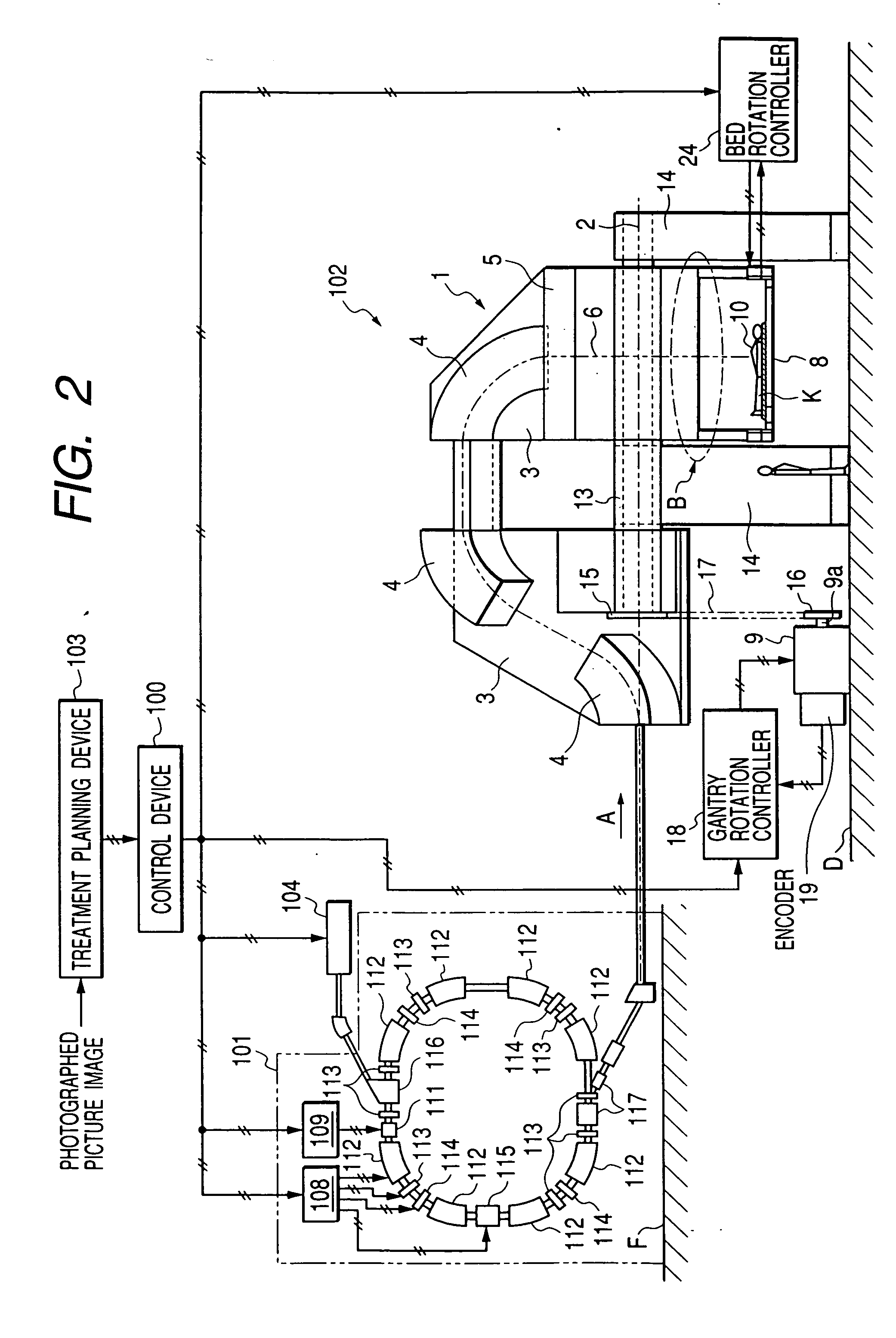

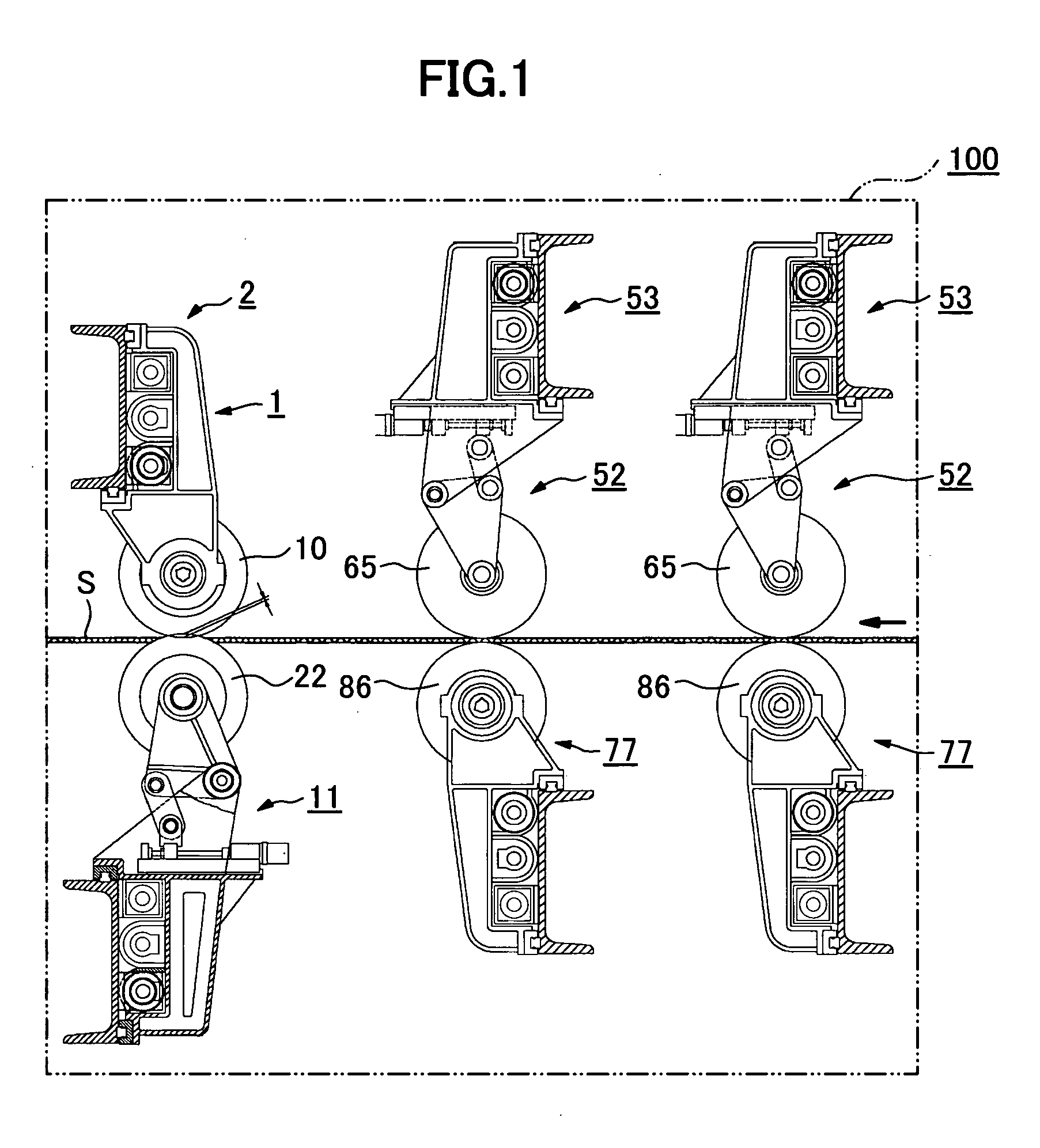

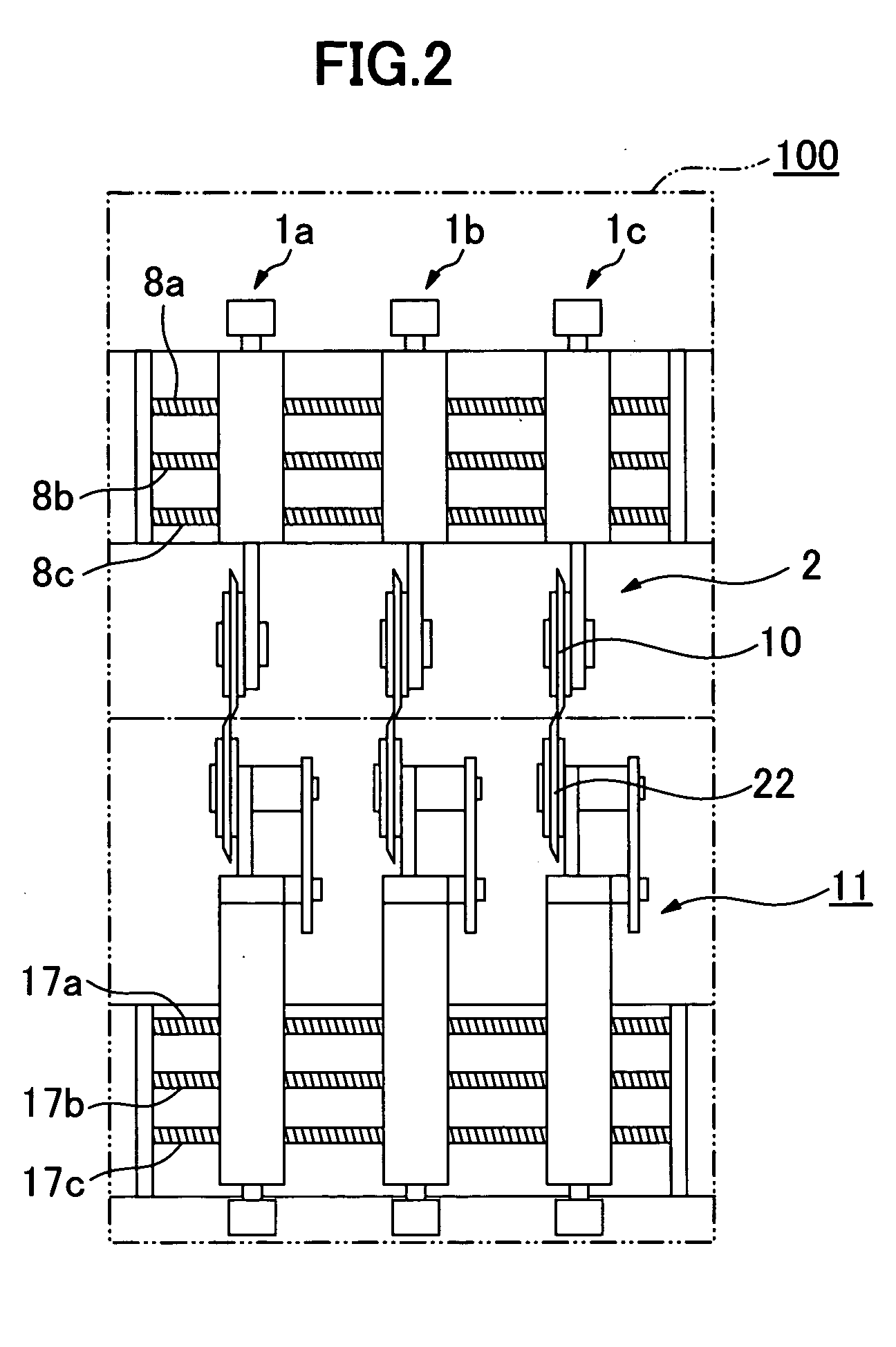

Rotating irradiation apparatus

ActiveUS7381979B2Increase the number ofHigh positioning accuracyRadiation/particle handlingElectrode and associated part arrangementsParticle radiotherapyRotational axis

A rotating irradiation apparatus includes a rotating gantry 3 including a front ring 19 and a rear ring 20 and is provided with a beam delivery device 11 and an irradiation device 4. The beam delivery device 11 delivers an ion beam used for particle radiotherapy. Radial support devices 61A and 61B support the front ring 19 and radial support devices 61A and 61B support the rear ring 20. Each radial support device includes a linear guide 41, an upper support structure disposed above the linear guide 41, and a lower support structure disposed below the linear guide 41. The upper support structure is movably mounted on the lower support structure and is movable in the direction of the rotational axis of the rotating gantry 3.

Owner:HITACHI LTD

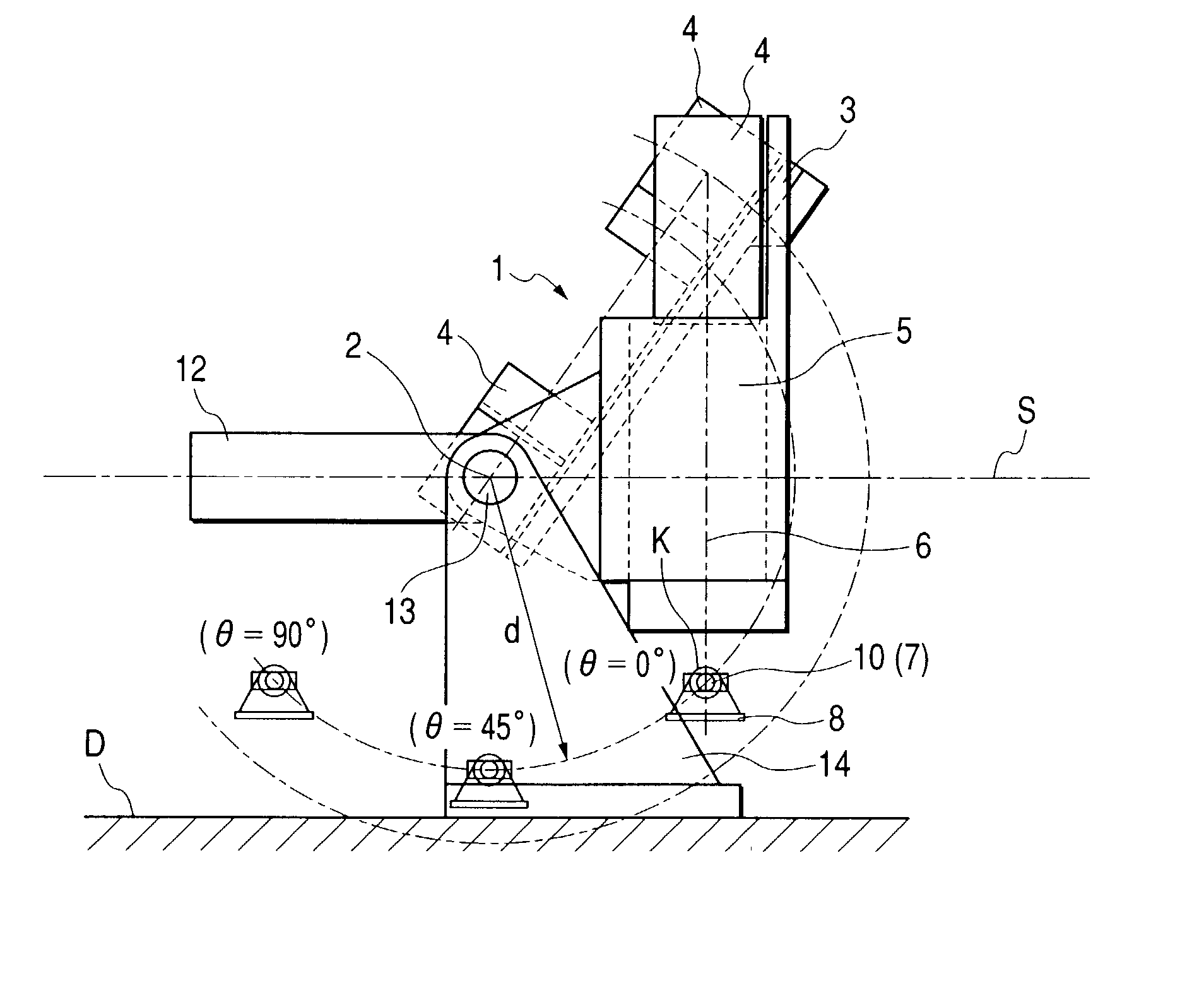

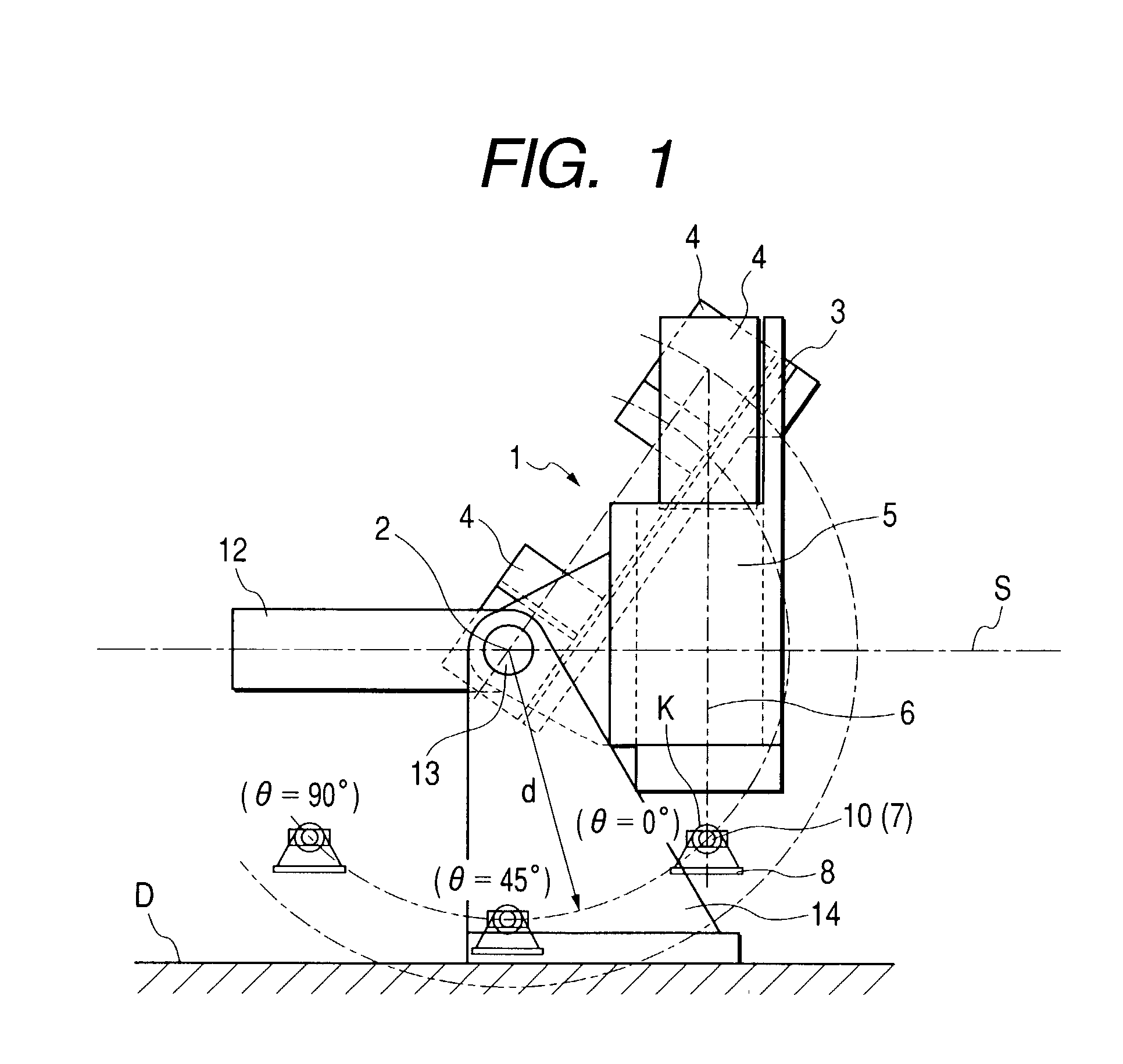

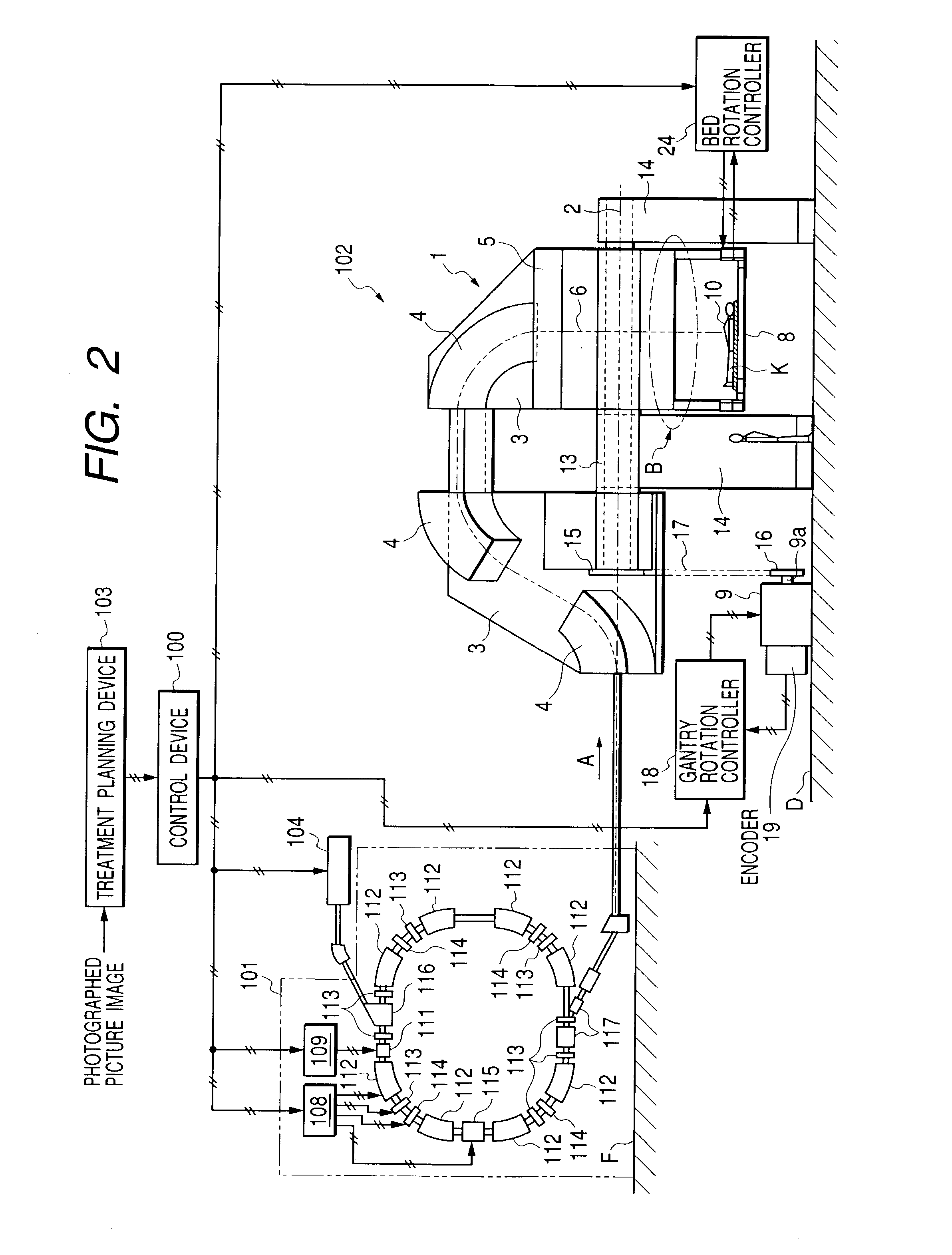

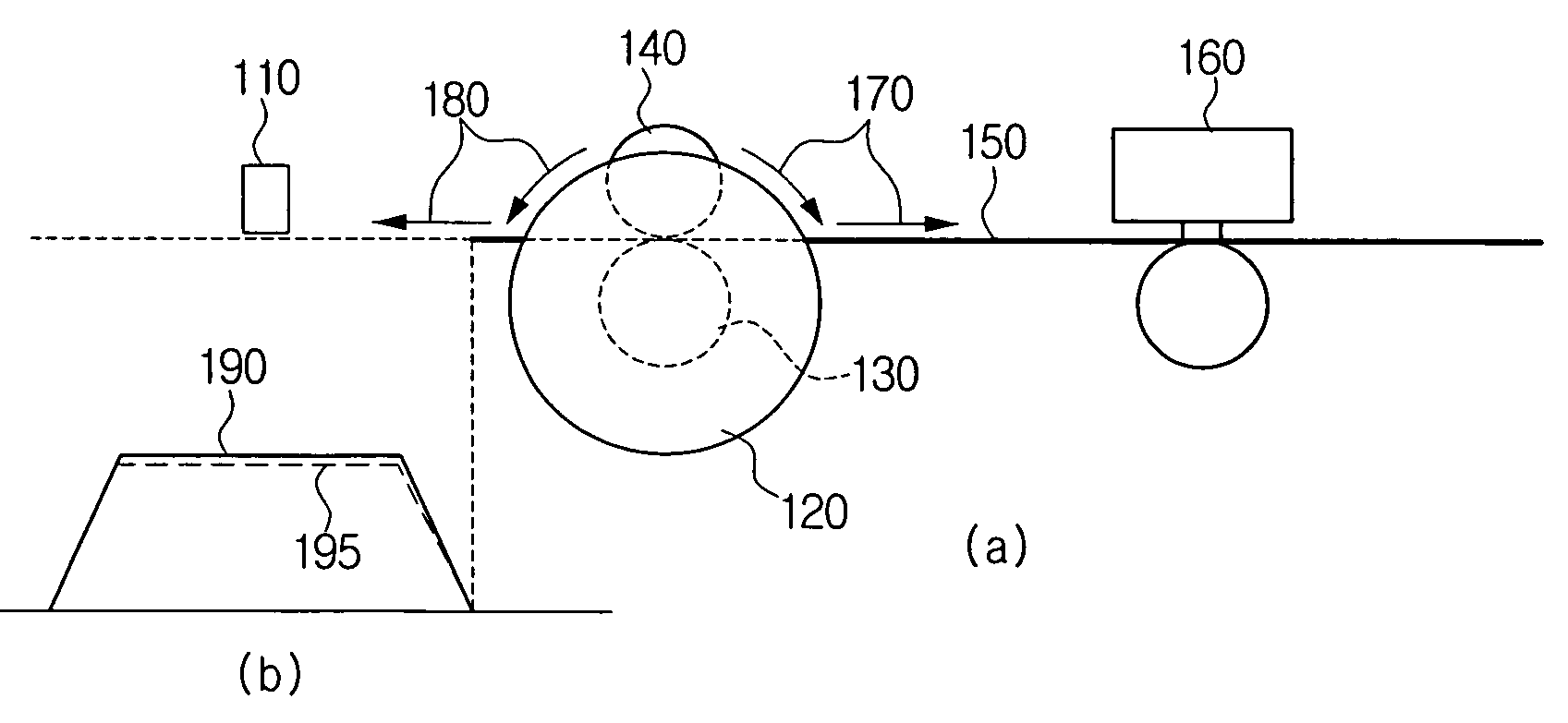

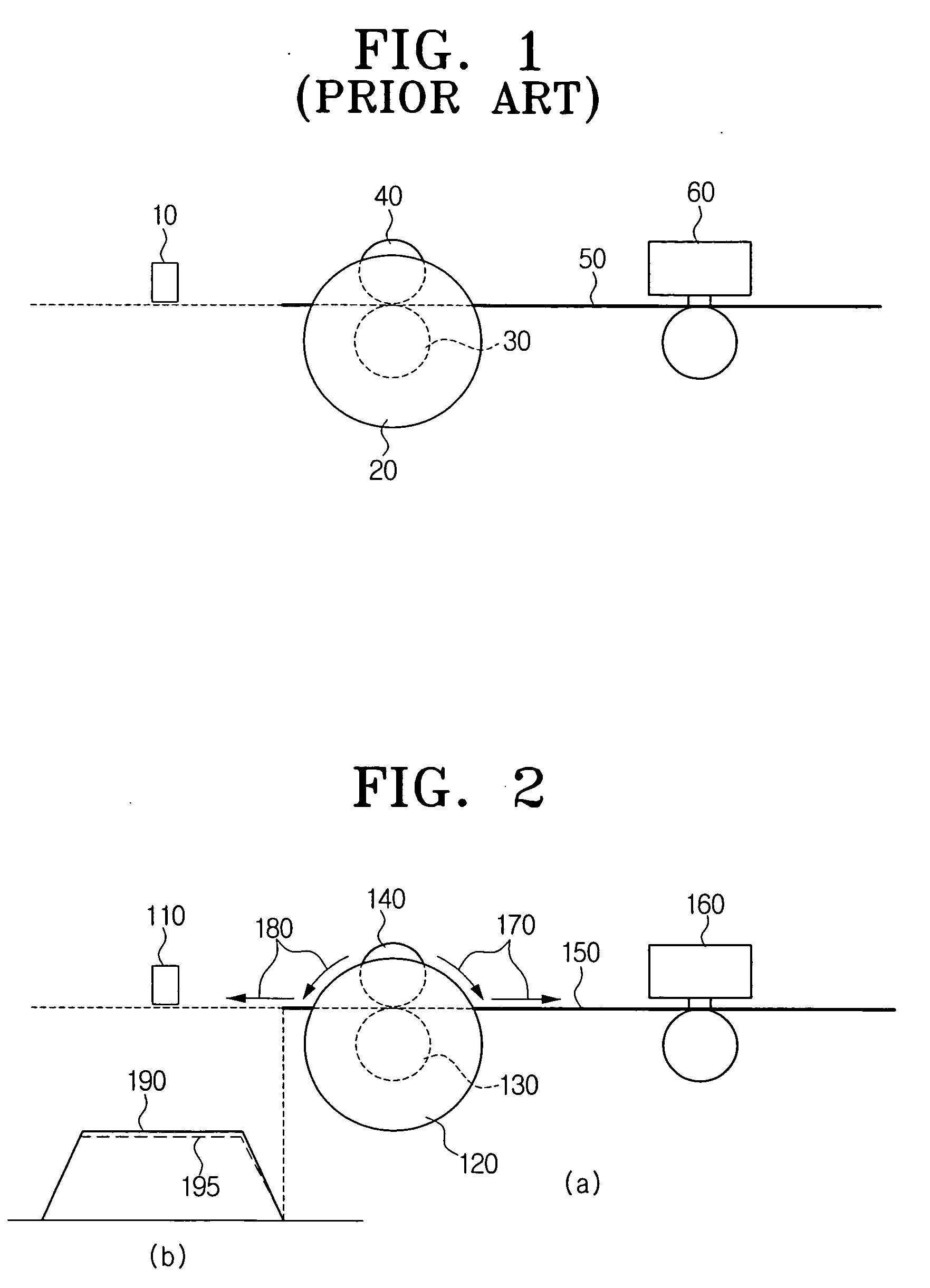

Medical charged particle irradiation apparatus

InactiveUS20030163015A1Reduce positioningImprove irradiation accuracyThermometer detailsBeam/ray focussing/reflecting arrangementsMedical treatmentAtomic physics

A medical charged particle irradiation apparatus capable of irradiation from upward and horizontal directions and performing a preparing / ascertaining work without any separate device such as a moving capsule or the like comprising a patient's bed, on which a patient lies, a transport equipment for injecting and transporting charged particle beams toward the patient's bed, an irradiation field forming device for forming an irradiation field for the beams transported by the transport equipment, and a gantry provided to be rotatable about an axis of rotation, and wherein the irradiation field forming device is eccentrically arranged such that an axis of irradiation passes a position different from the axis of rotation, and the patient's bed is arranged on an opposite side of the transport equipment to a plane, which contains the axis of rotation and is substantially perpendicular to the axis of irradiation.

Owner:HITACHI LTD

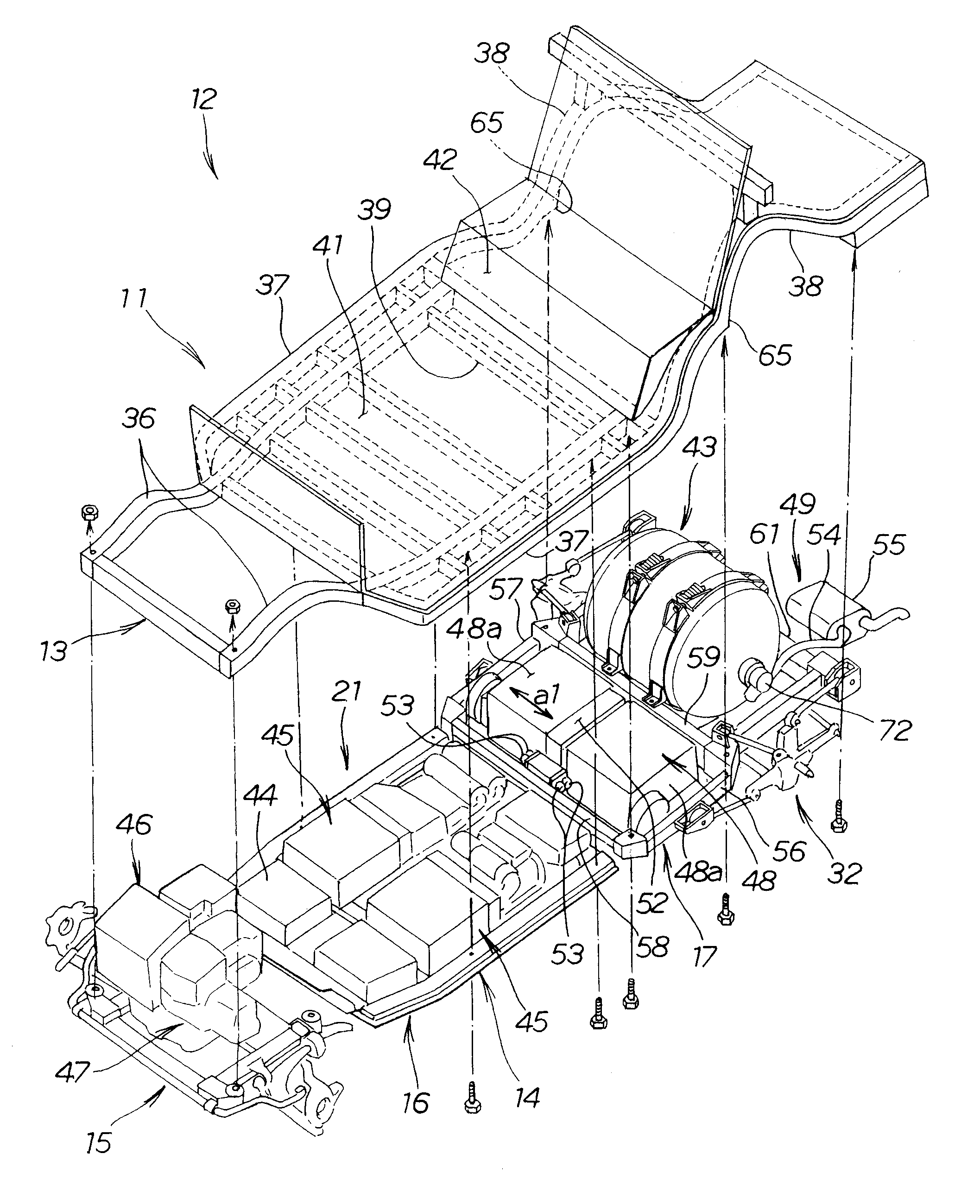

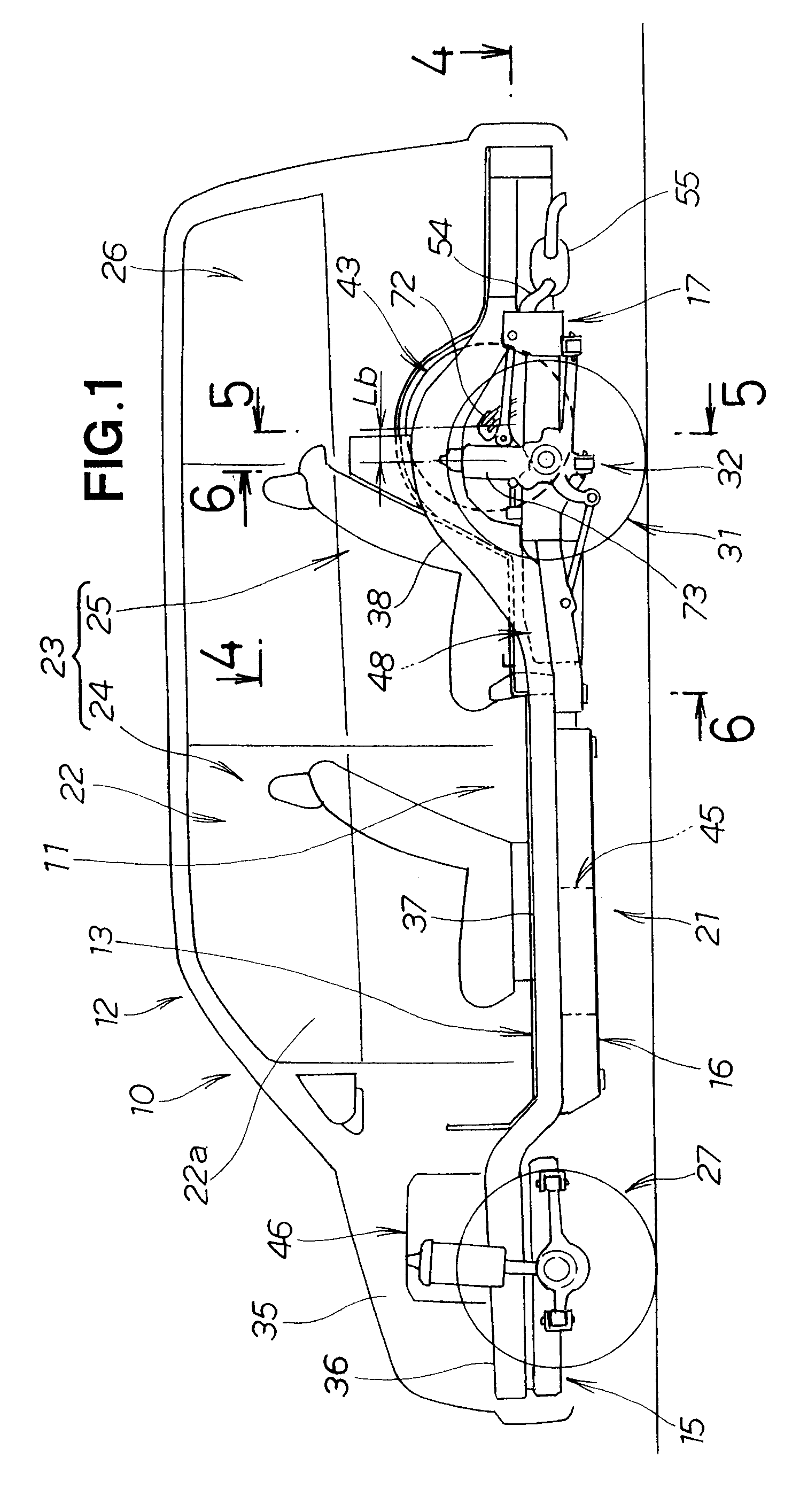

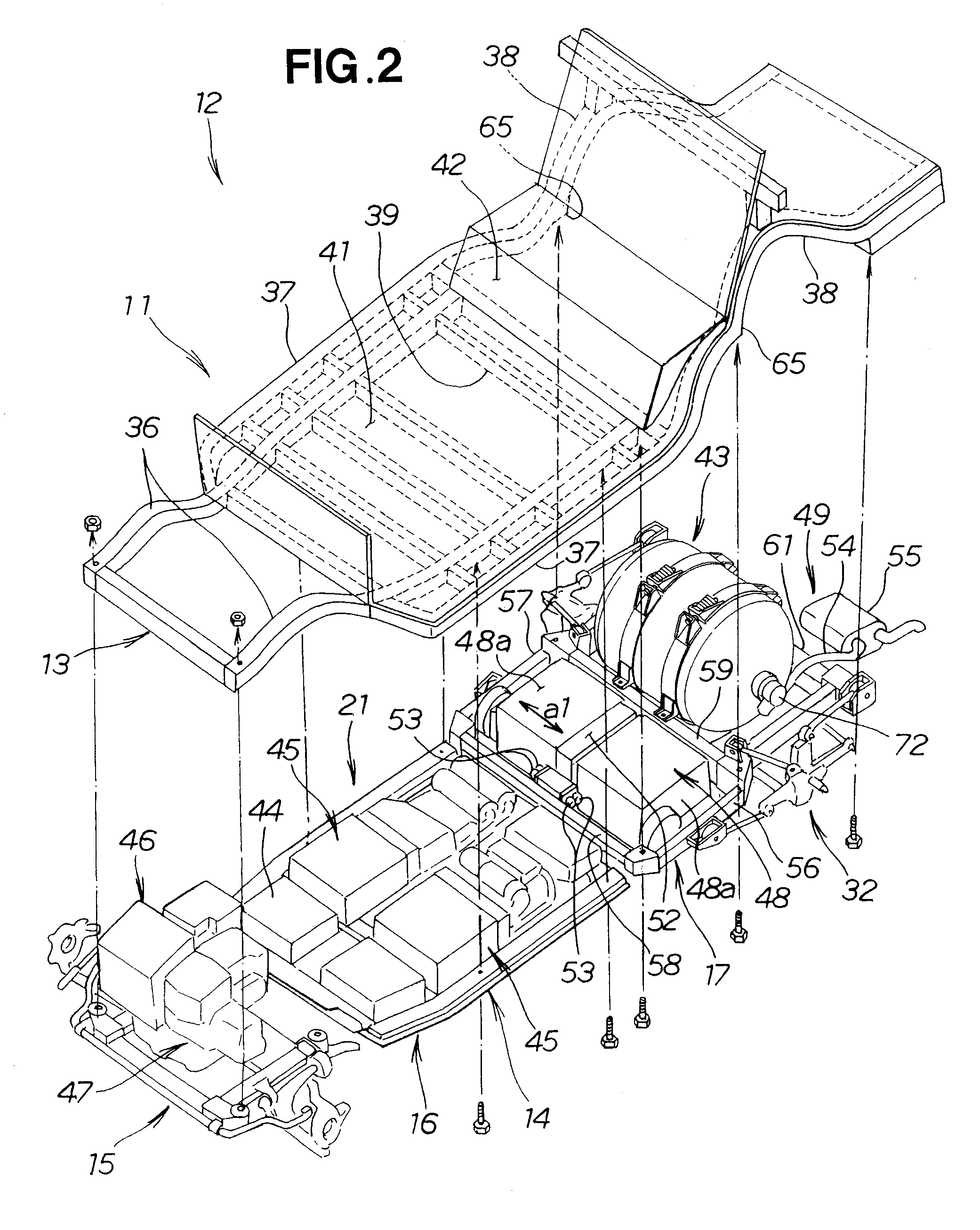

Vehicle body structure

InactiveUS20060289224A1Easy to useLower center of gravityTank vehiclesUnderstructuresVehicle frameFuel tank

A vehicle body structure includes a body frame with a subframe mounted to a lower part of the body frame. The subframe is formed into a rectangular shape and has front, intermediate and rear cross members. A storage battery is designed to be mounted astride the front cross member and the intermediate cross member. A fuel tank is designed to be mounted astride the intermediate cross member and the rear cross member.

Owner:HONDA MOTOR CO LTD

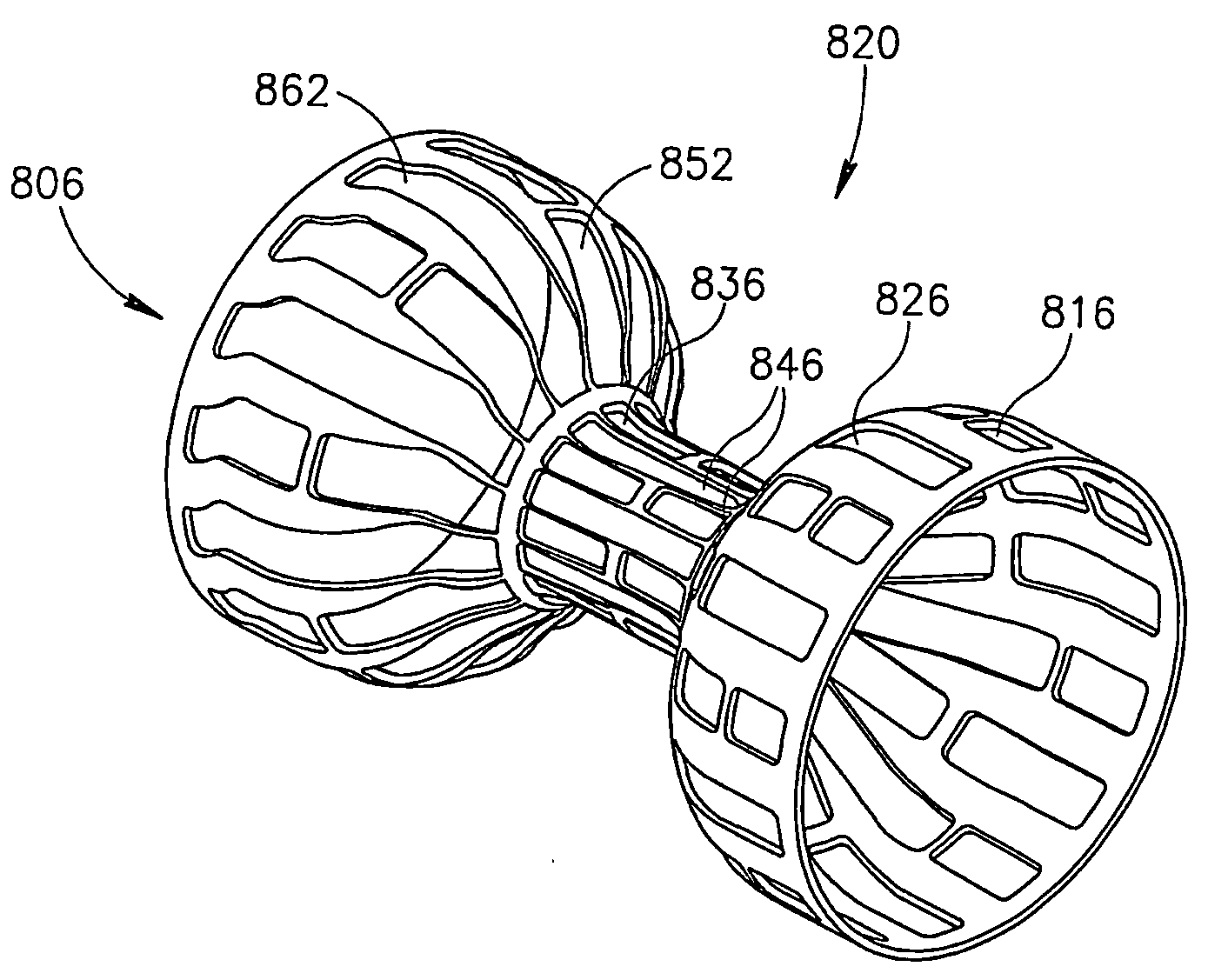

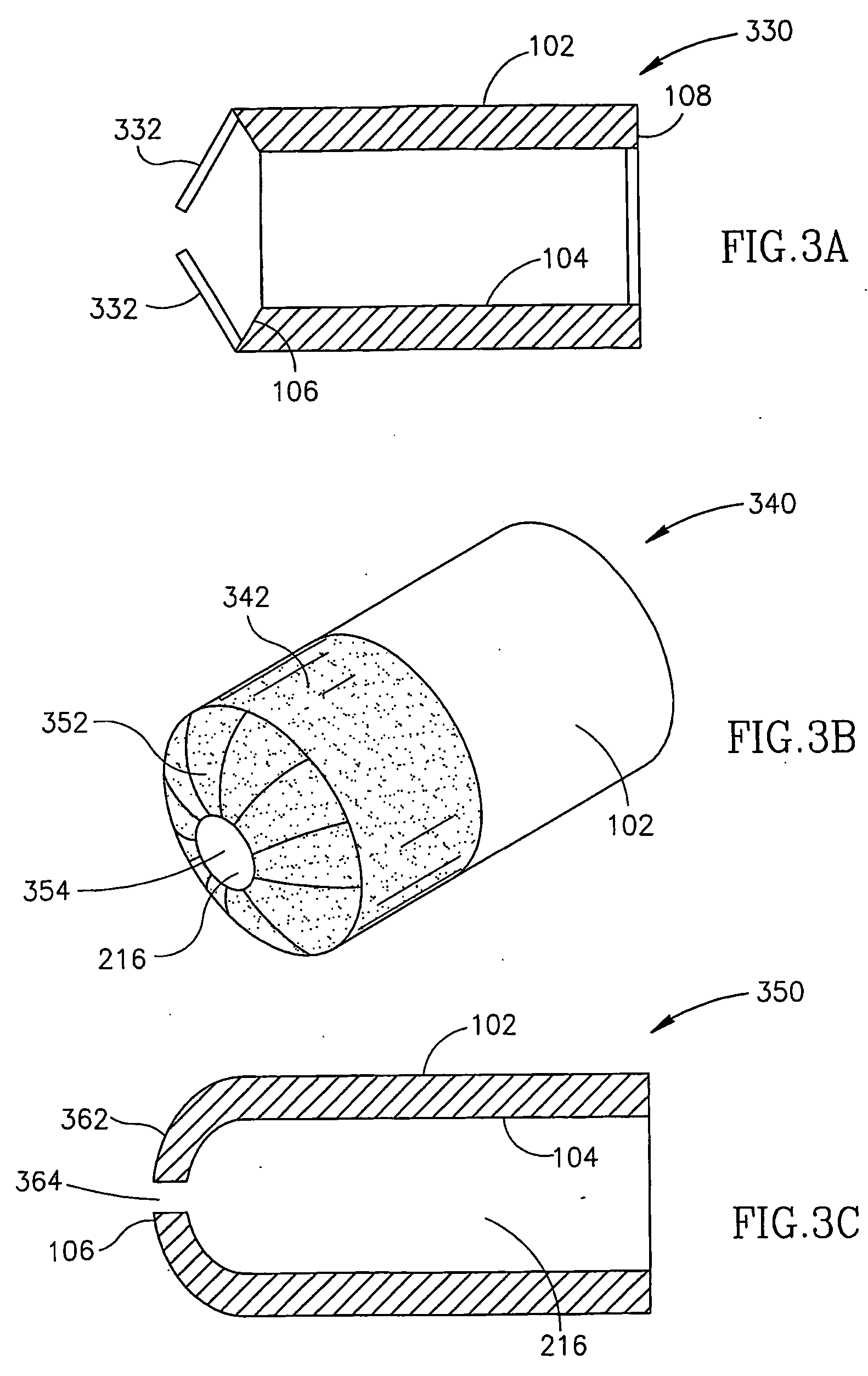

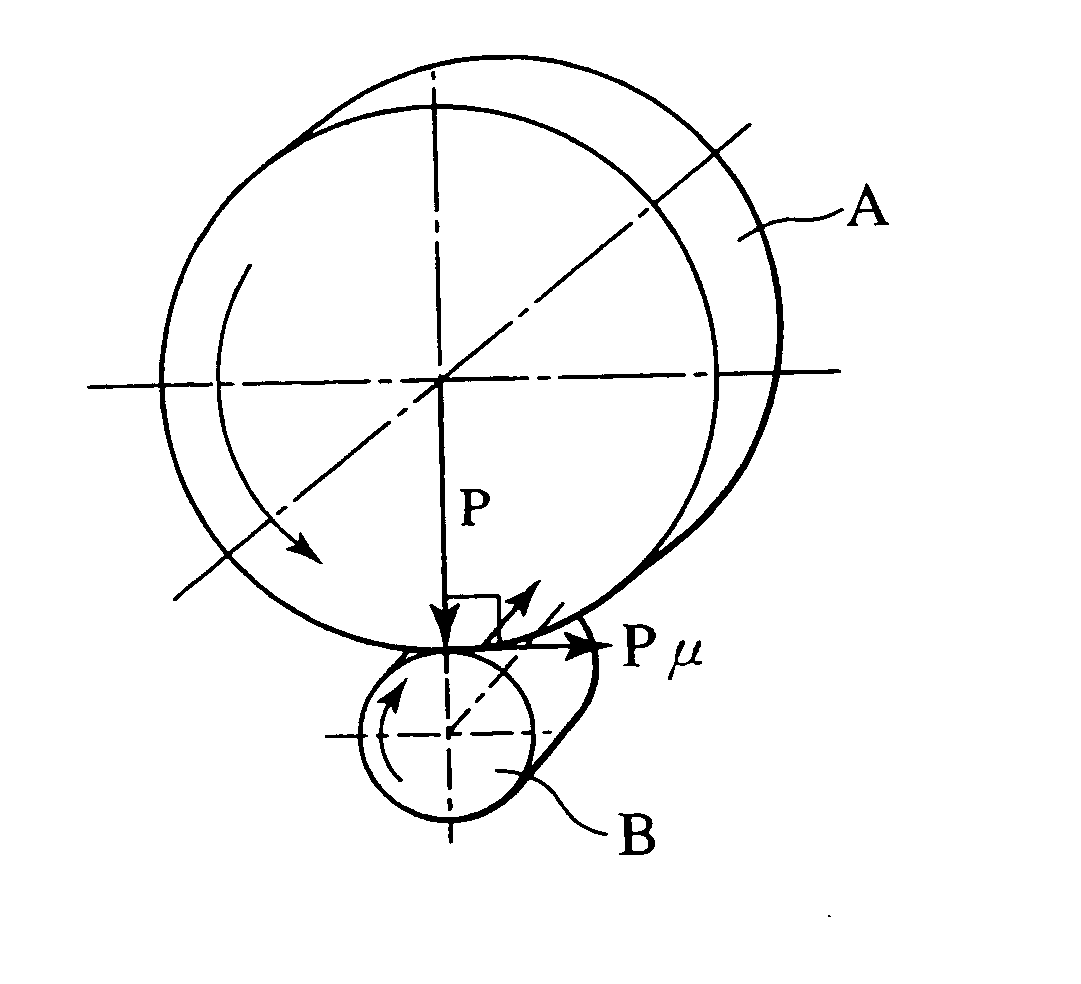

Flow reducing implant

InactiveUS20060106449A1Decreased blood flowPromote angiogenesisStentsDilatorsContact forcePhysical therapy

An intra-vascular balloon (110), comprising a balloon body (1010); and at least one springy and elongate stave (1030) attached to said balloon and conforming to a surface of said balloon, such that said stave can apply contact force to an object in contact with said balloon.

Owner:NEOVASC MEDICAL LTD

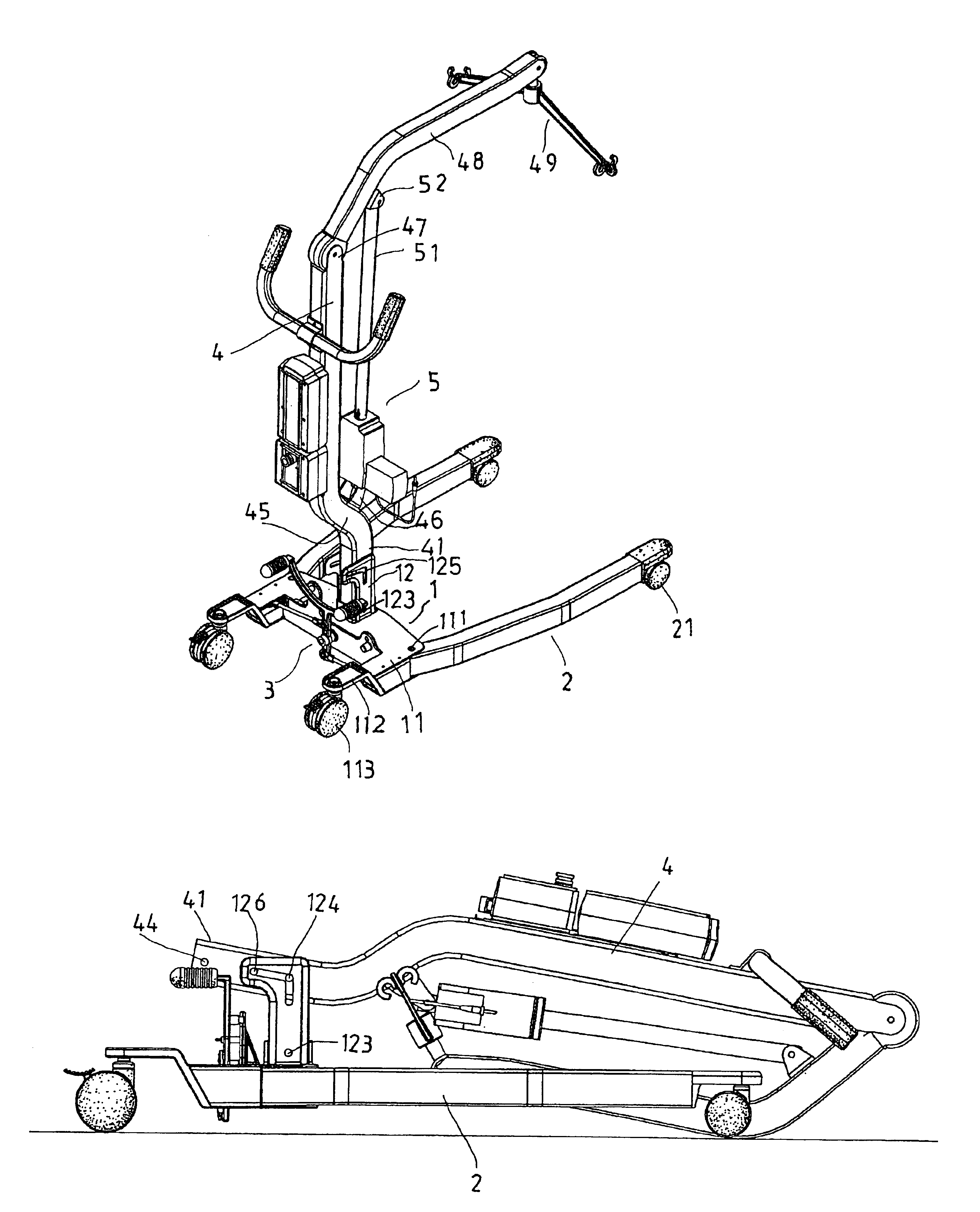

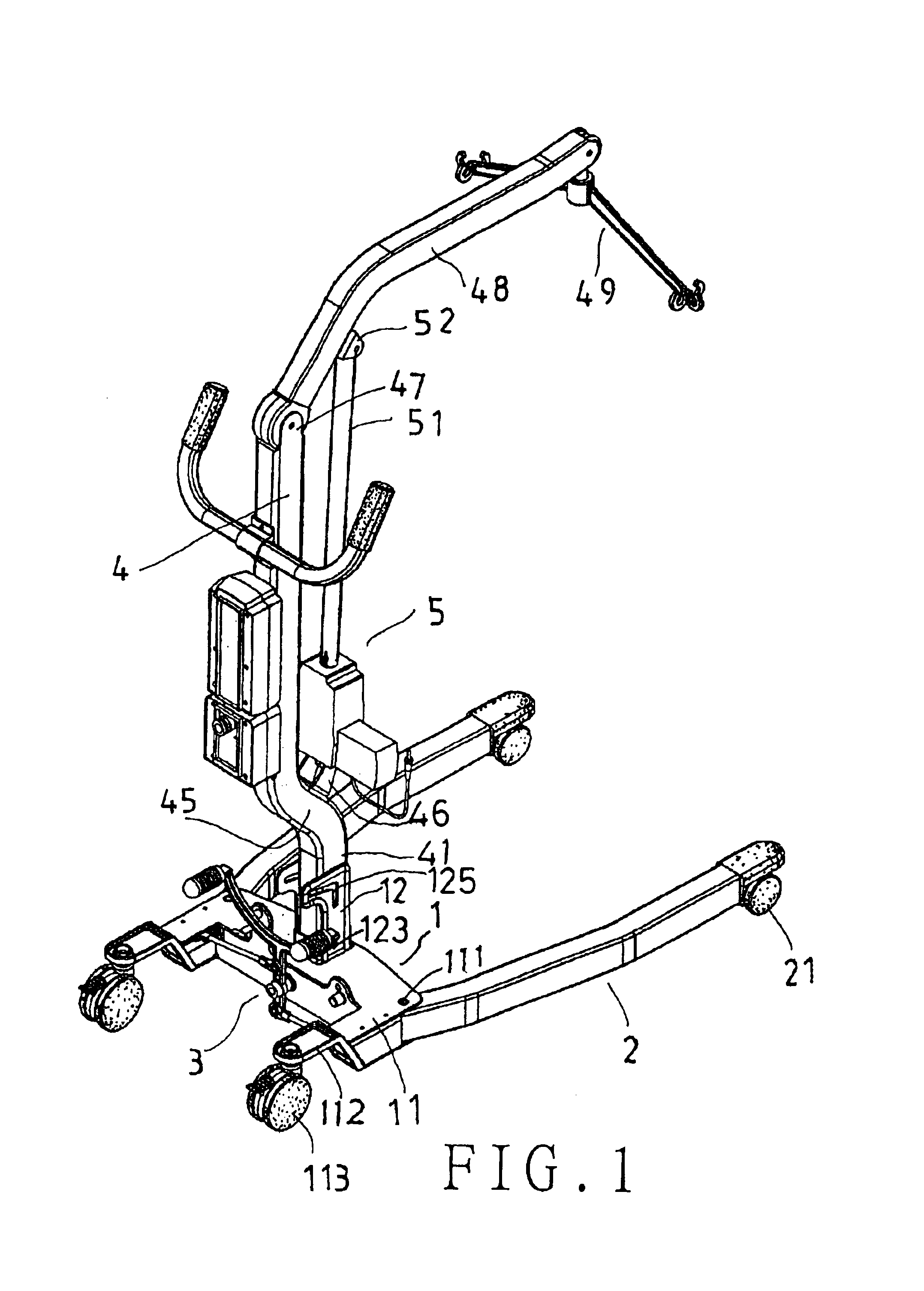

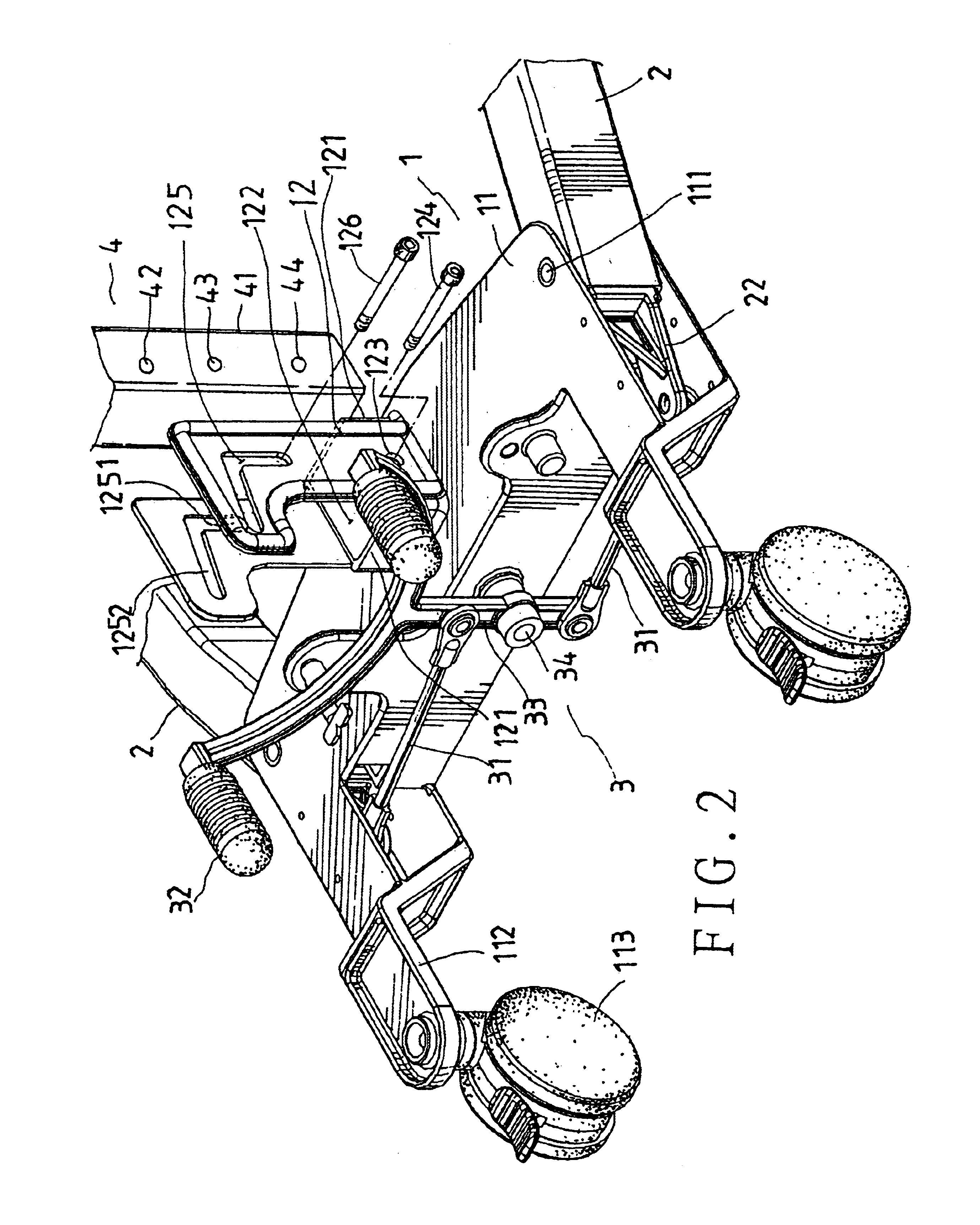

Foldable lift and transfer apparatus for patient

Owner:HUANG CHI TZUNG

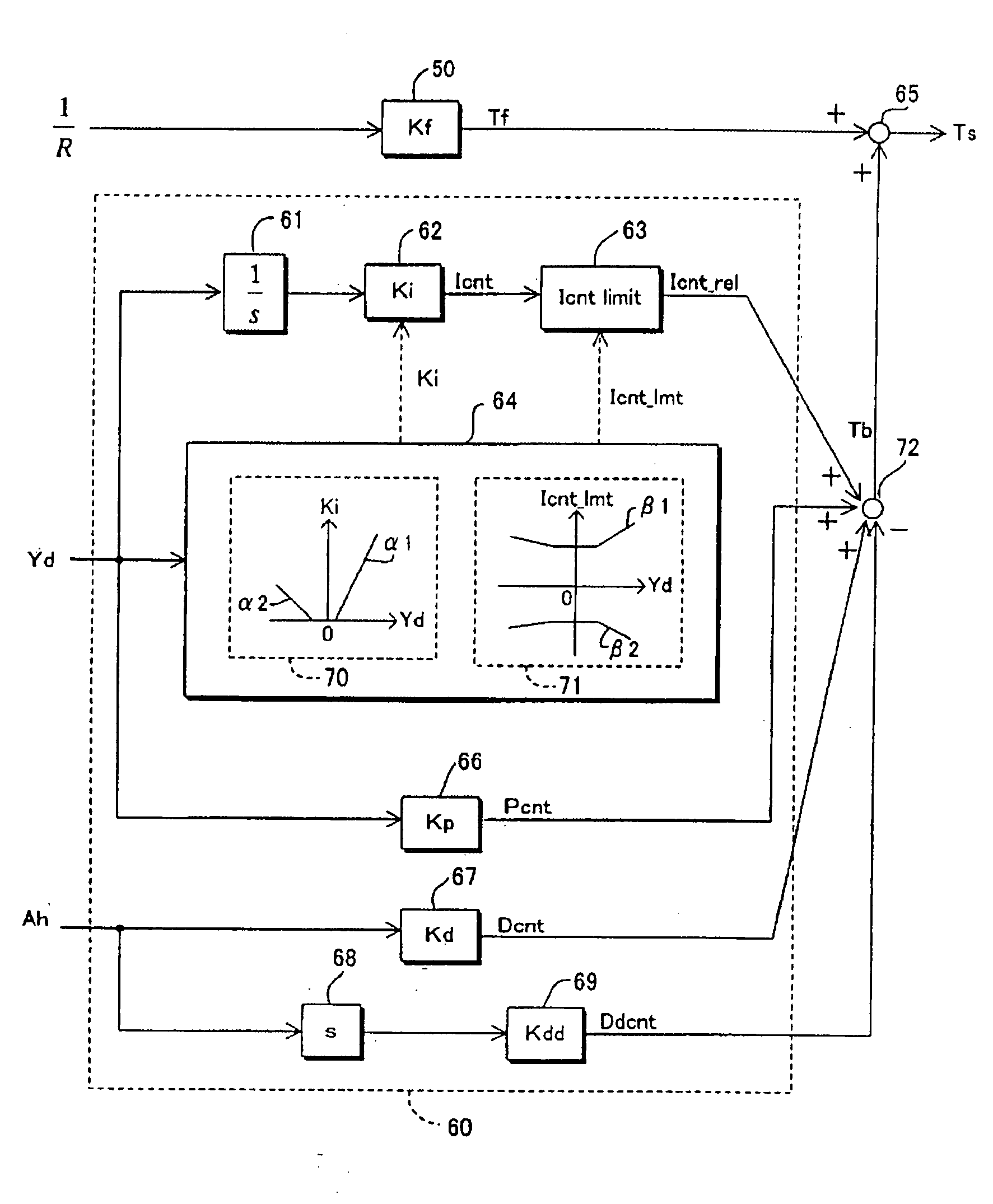

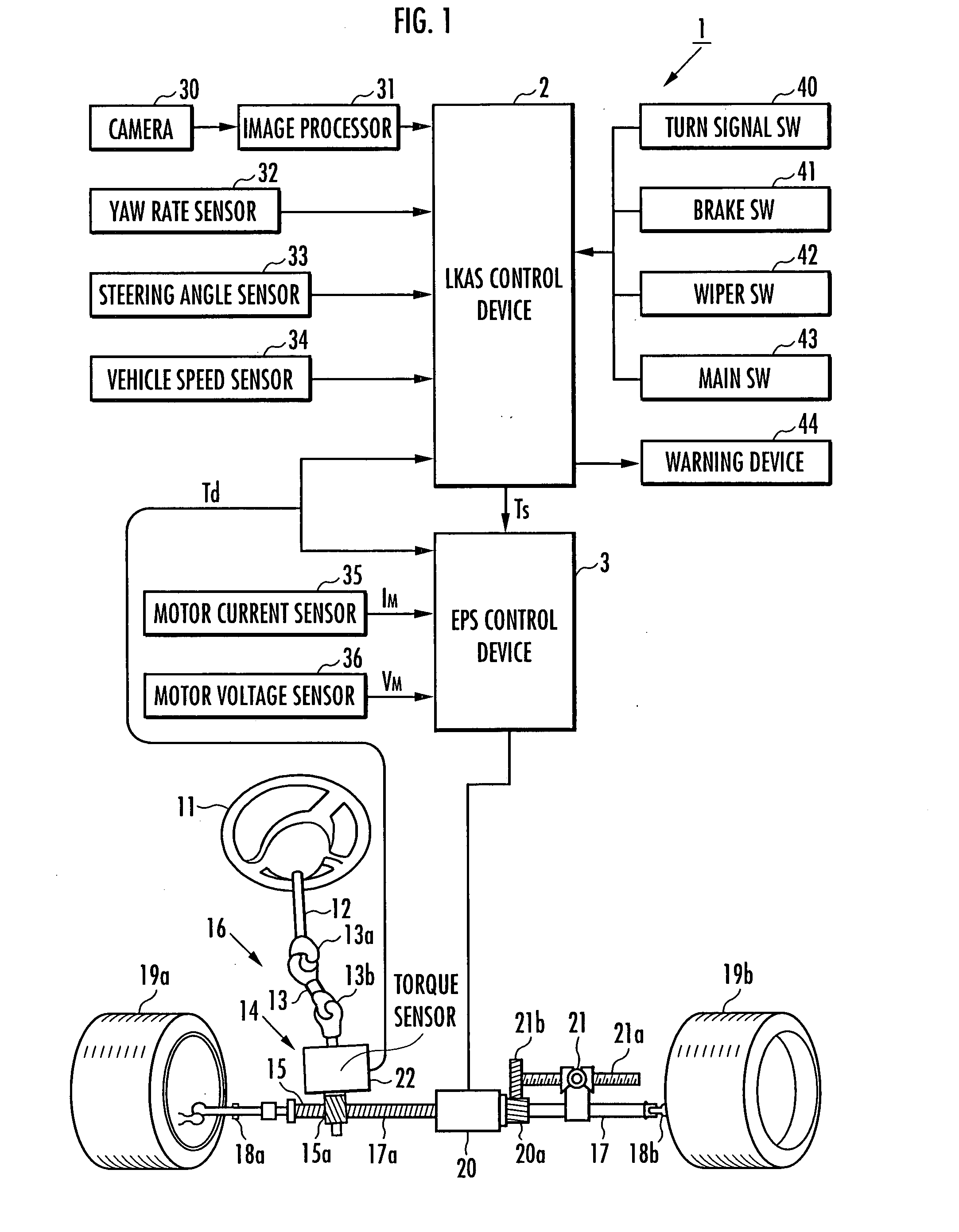

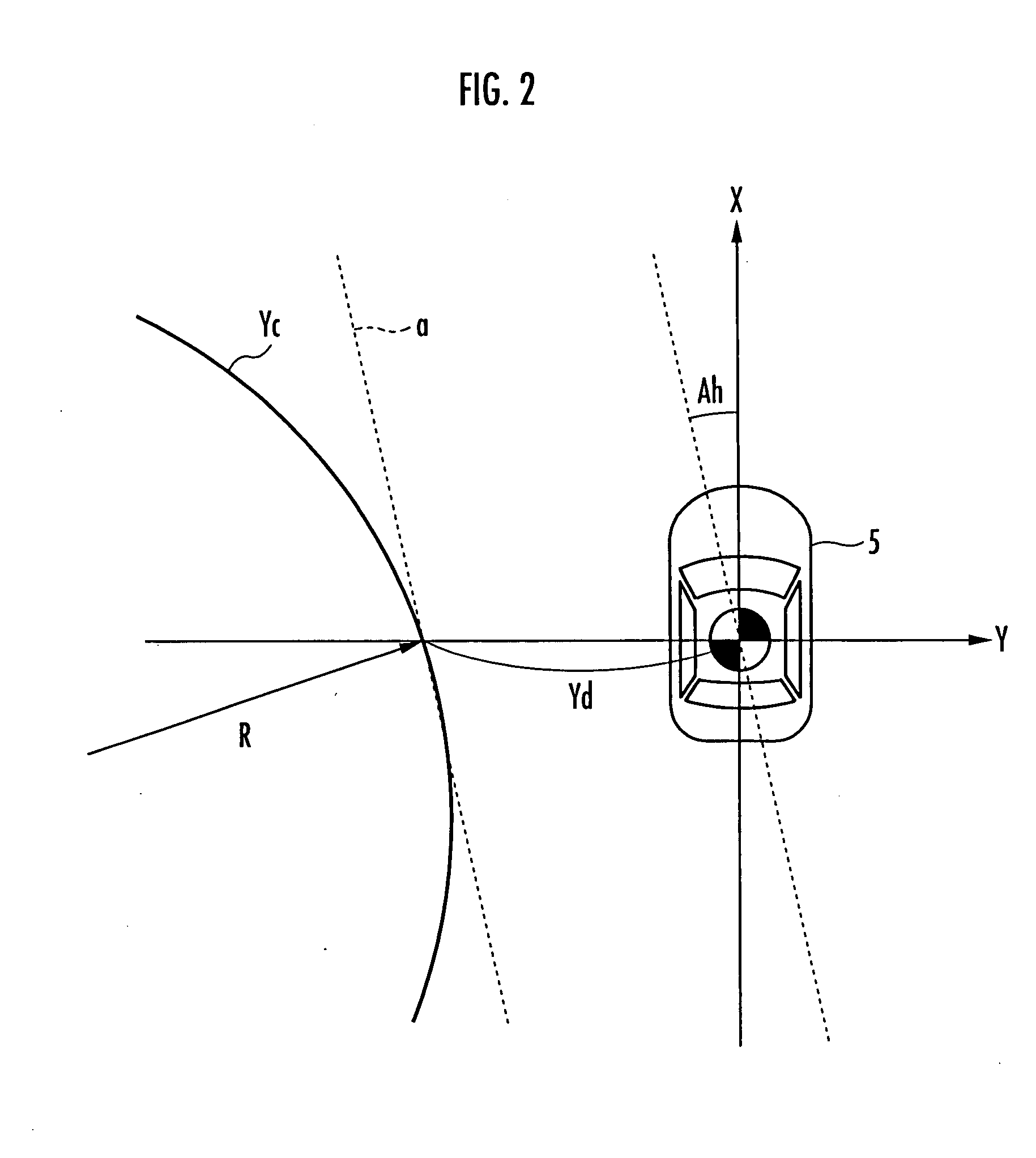

Steering Control Device for Vehicles

InactiveUS20090024278A1Prevent overshootAvoid phase delayDigital data processing detailsSteering initiationsAngular deviationSteering control

A vehicle steering control device which prevents overshoot or a phase delay of a vehicle position from a target position when an actuator of a steering mechanism is controlled so that an integral control reduces a positional deviation of a vehicle from the reference position of a traffic lane. An FB control unit (60) which calculates a corrected steering assist torque (Tb) of a motor so as to reduce a positional deviation (Yd) and an angular deviation (Ah) includes an integral element determination unit (64), which determines an integral gain (Ki), by which the positional deviation (Yd) is multiplied in an integral gain operation unit (62), according to the positional deviation (Yd) and which determines a limit value (Icnt_lmt) of an integral controlled variable (Icnt) according to the positional deviation (Yd), and an integral controlled variable limiting unit (63) which limits the integral controlled variable (Icnt) to within a range set by the limit value (Icnt_lmt) and outputs the current integral controlled variable (Icnt_rel).

Owner:HONDA MOTOR CO LTD

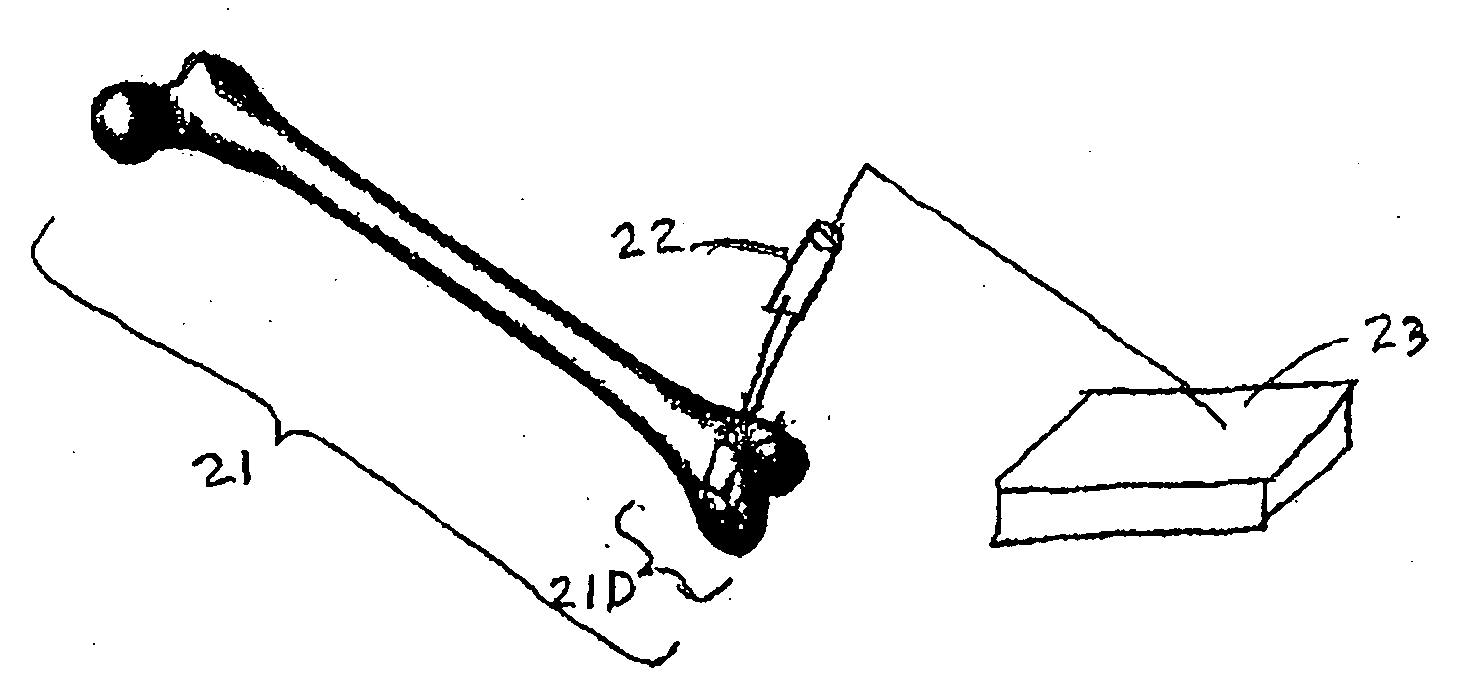

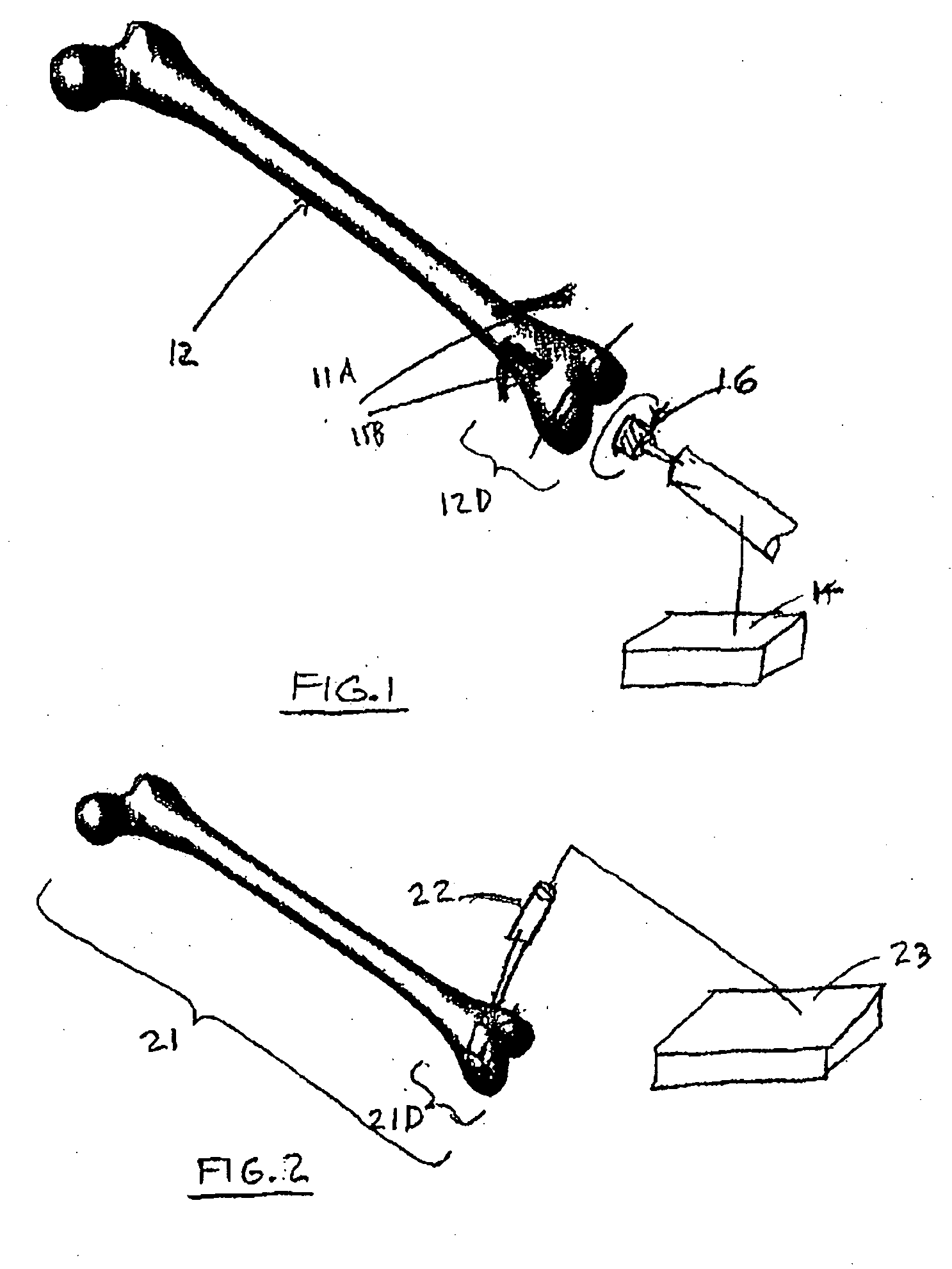

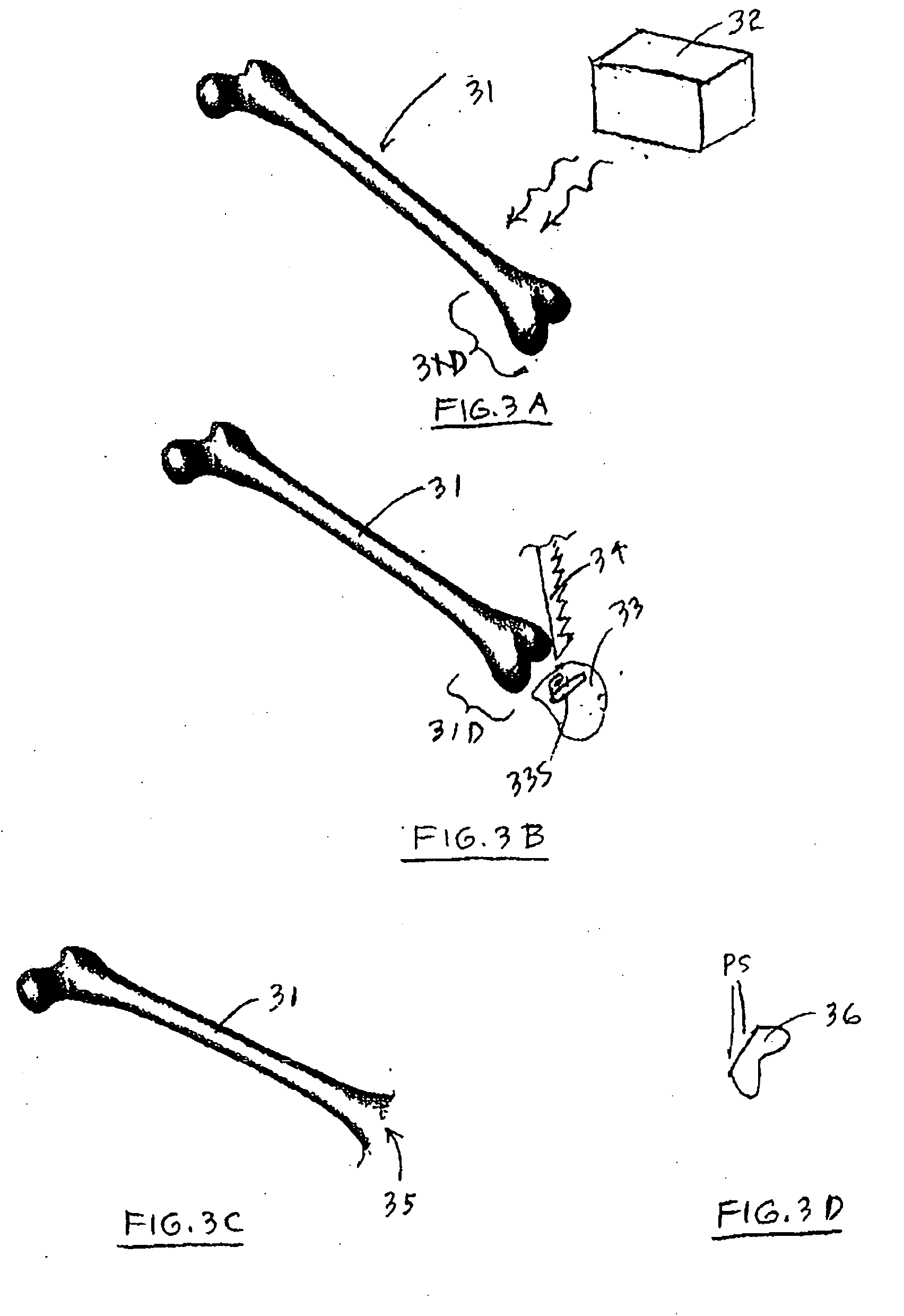

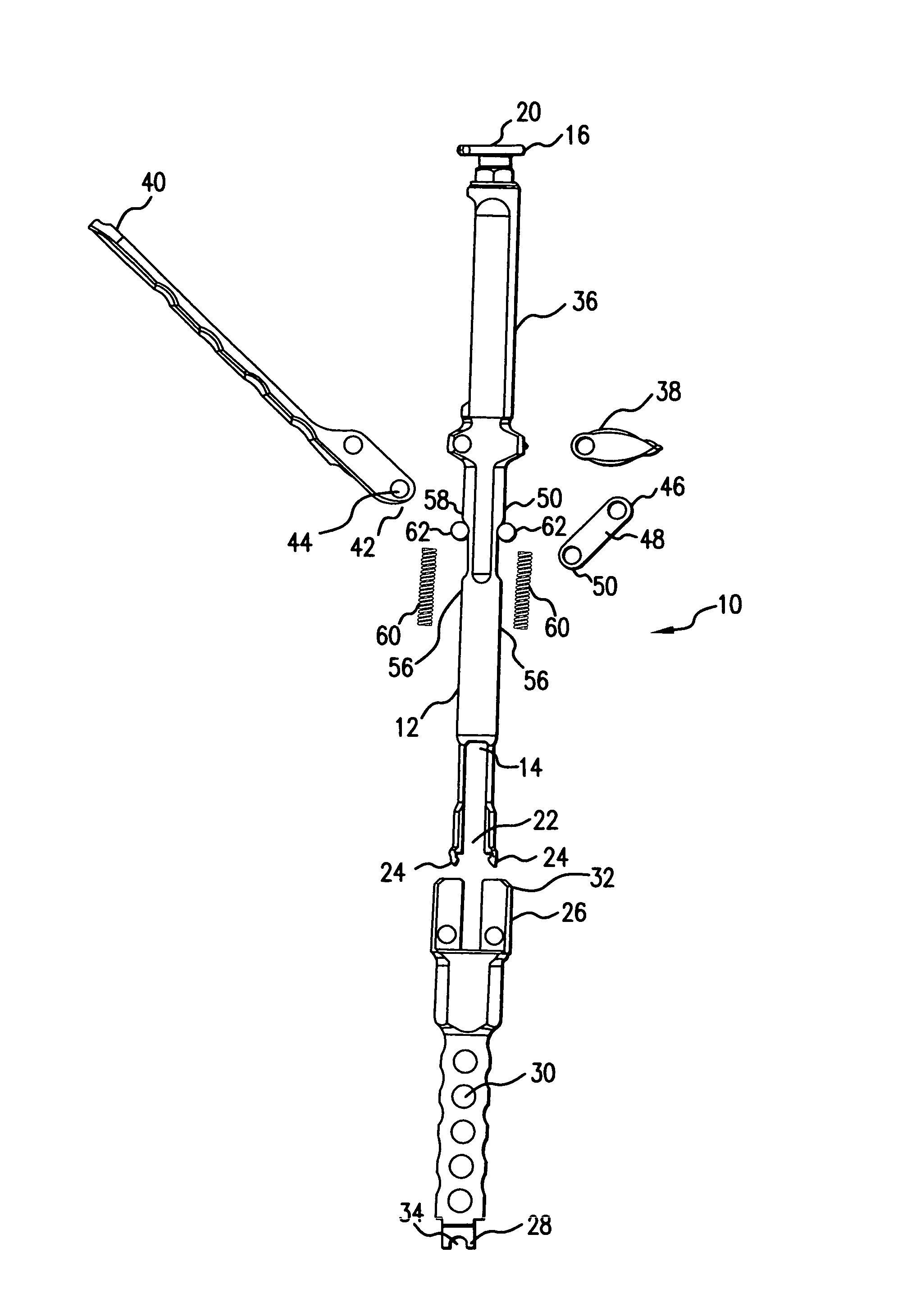

Single action anti-torque rod reducer

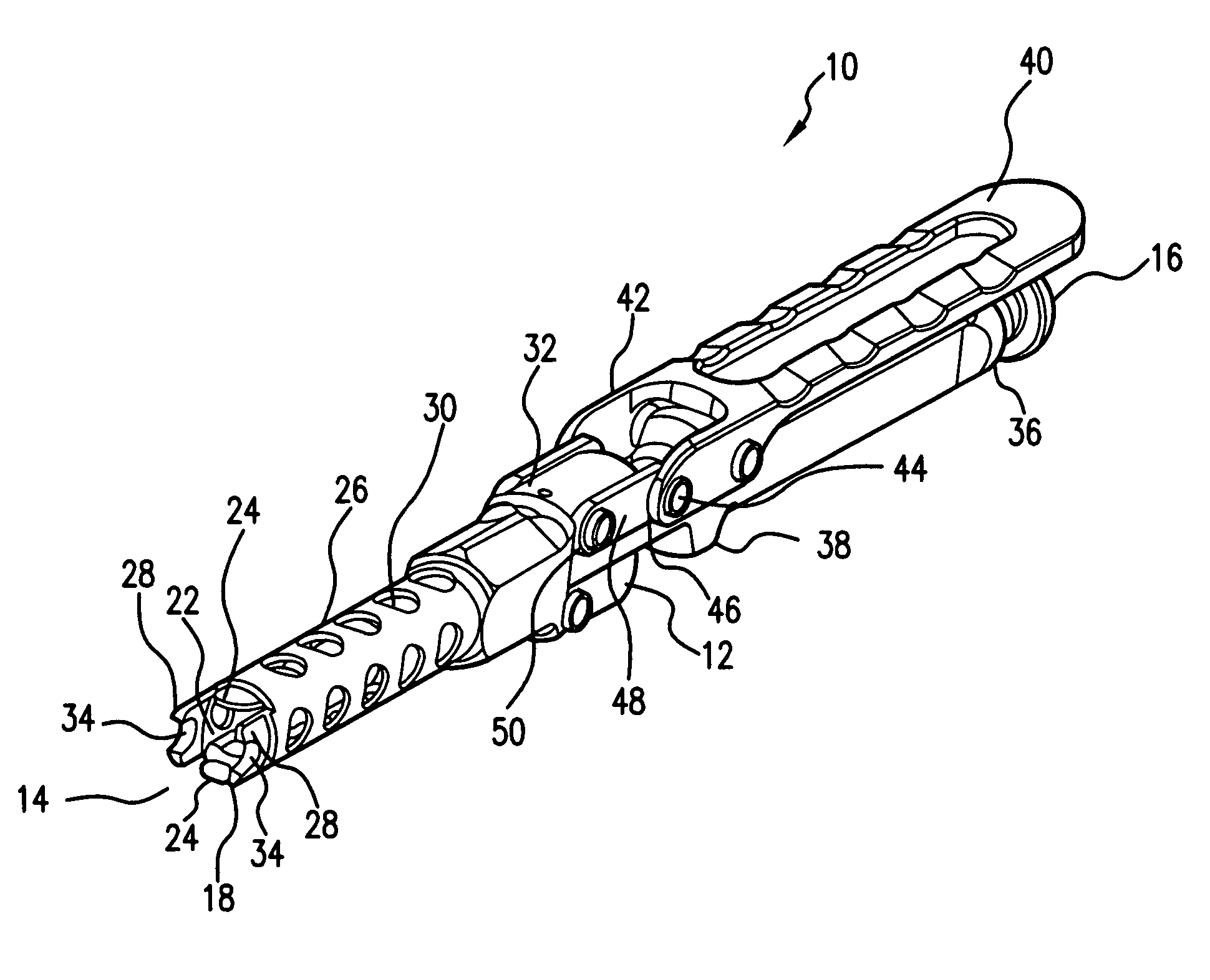

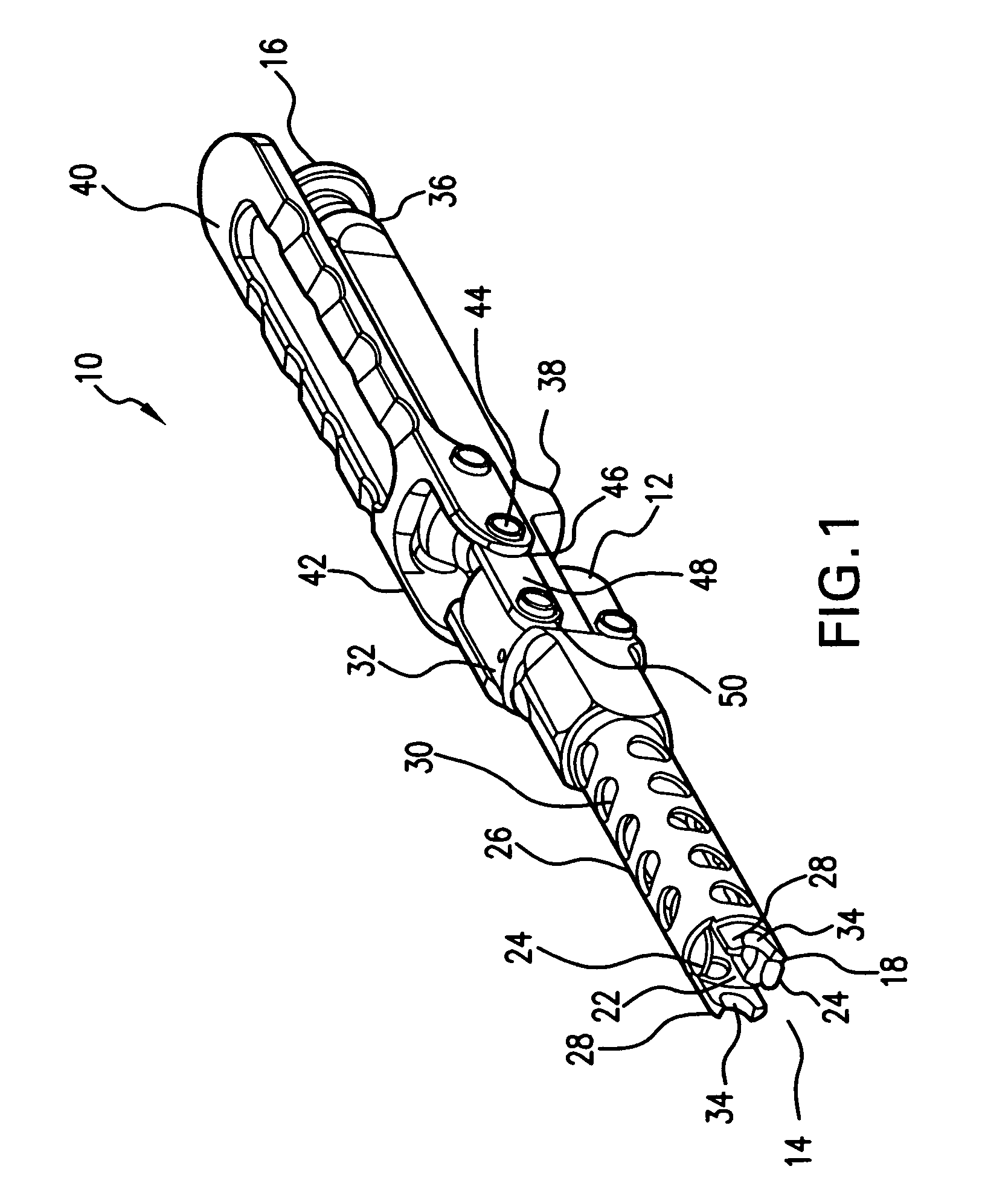

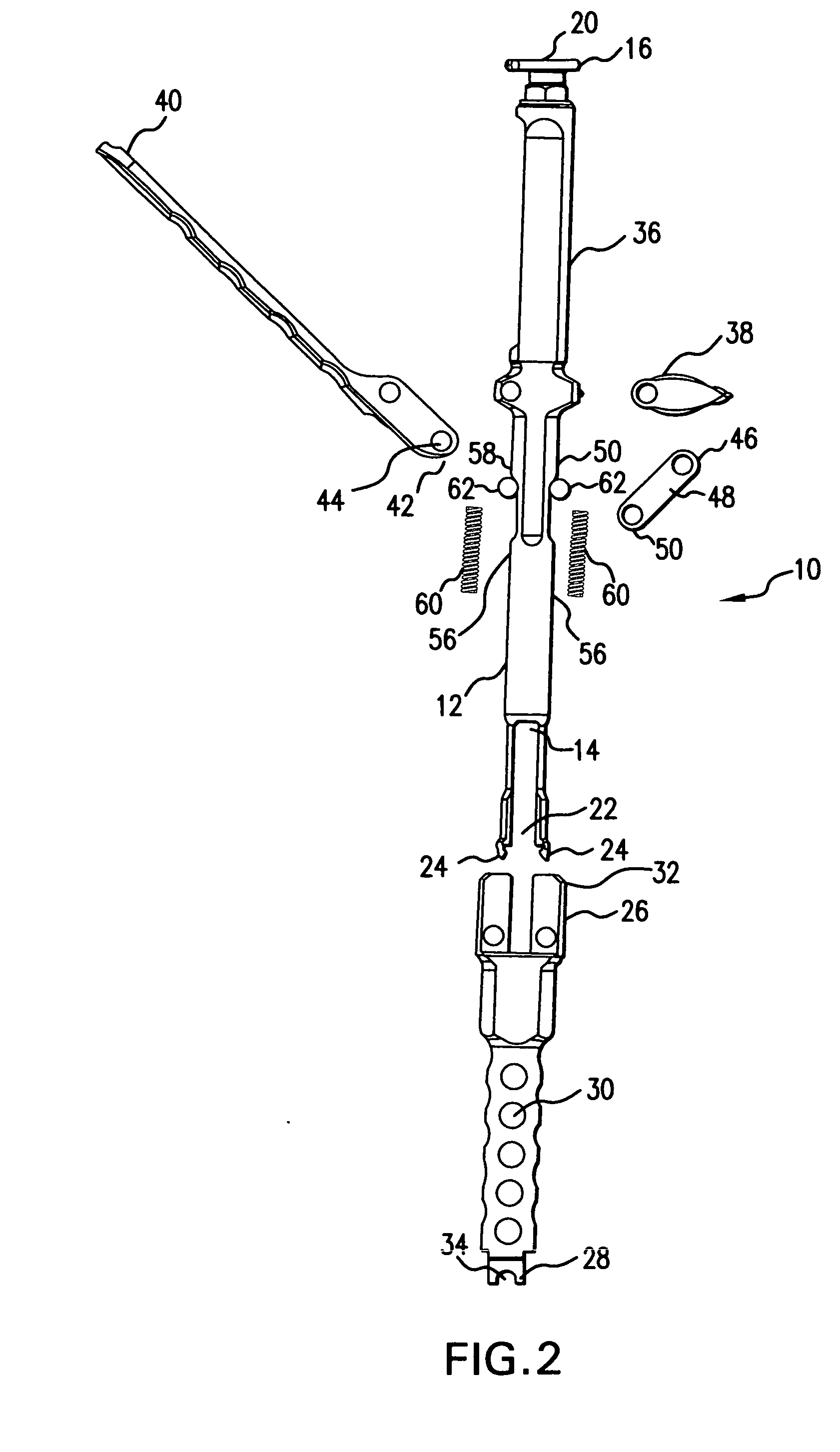

ActiveUS20070093849A1Good effectReduce positioningInternal osteosythesisJoint implantsReducerBiomedical engineering

Owner:K2M

Rotating irradiation apparatus

ActiveUS20070023699A1High positioning accuracyImprove throughputRadiation/particle handlingElectrode and associated part arrangementsParticle radiotherapyRotational axis

Owner:HITACHI LTD

Replaceable cutter tooth with three outwardly diverging cutting tips

A cutter tooth is carried on an outer peripheral surface of a rotatable cutter adapted for clearing, mulching and grinding trees. The cutter tooth includes a tooth body with a front face, sides, and a rear. The face is recessed inwardly and defines three equally spaced-apart and outwardly diverging cutting tips.

Owner:R F SHINN CONTRACTORS

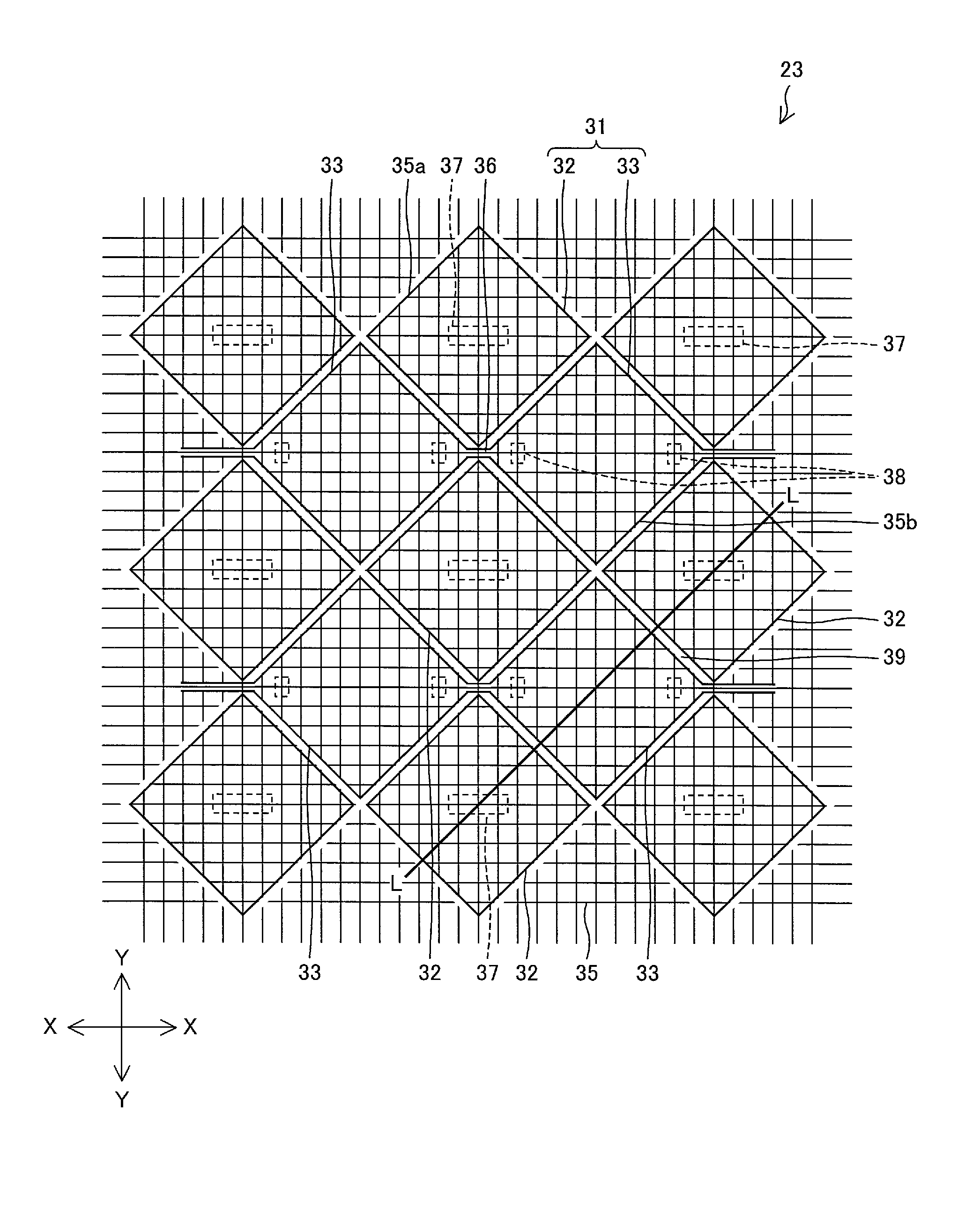

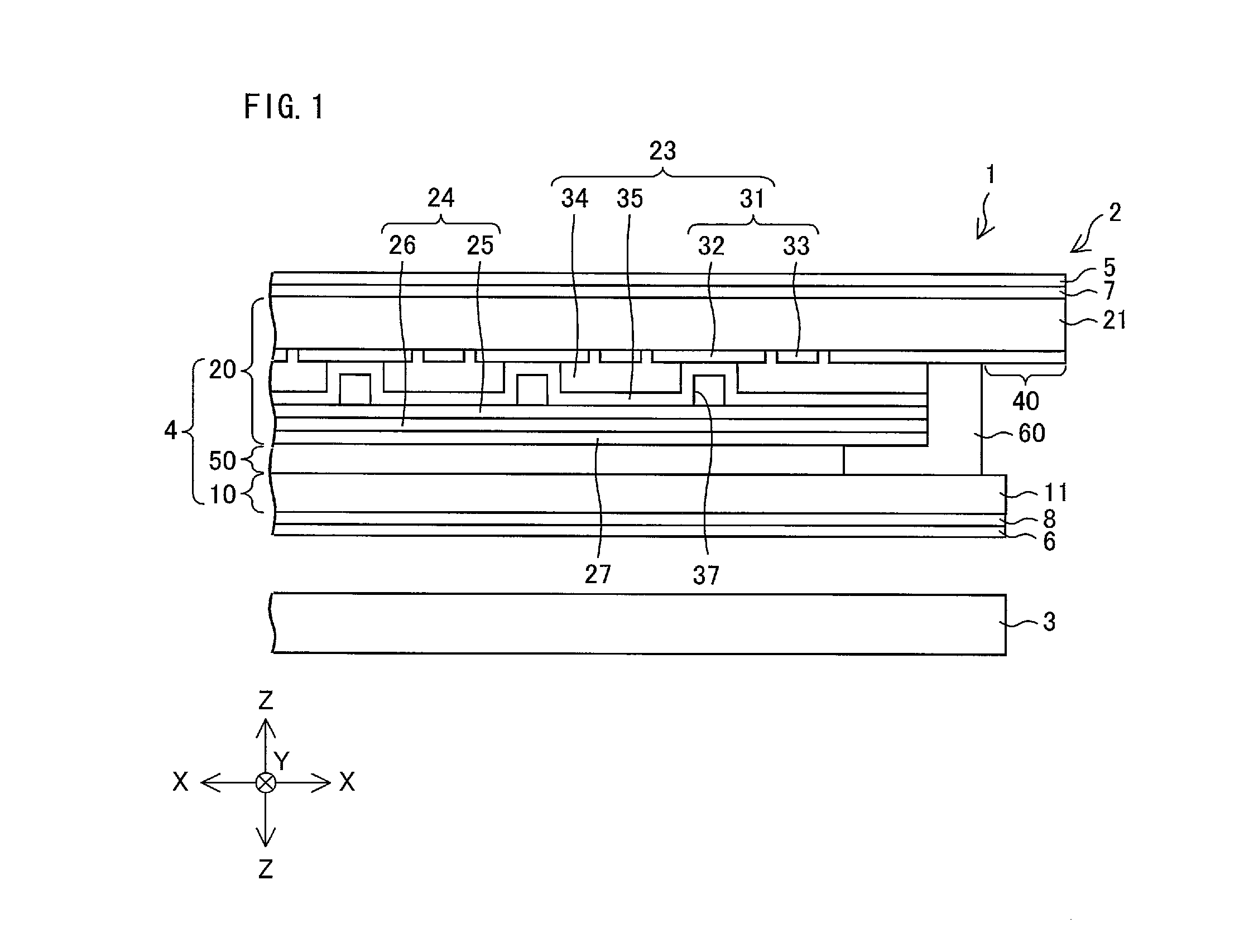

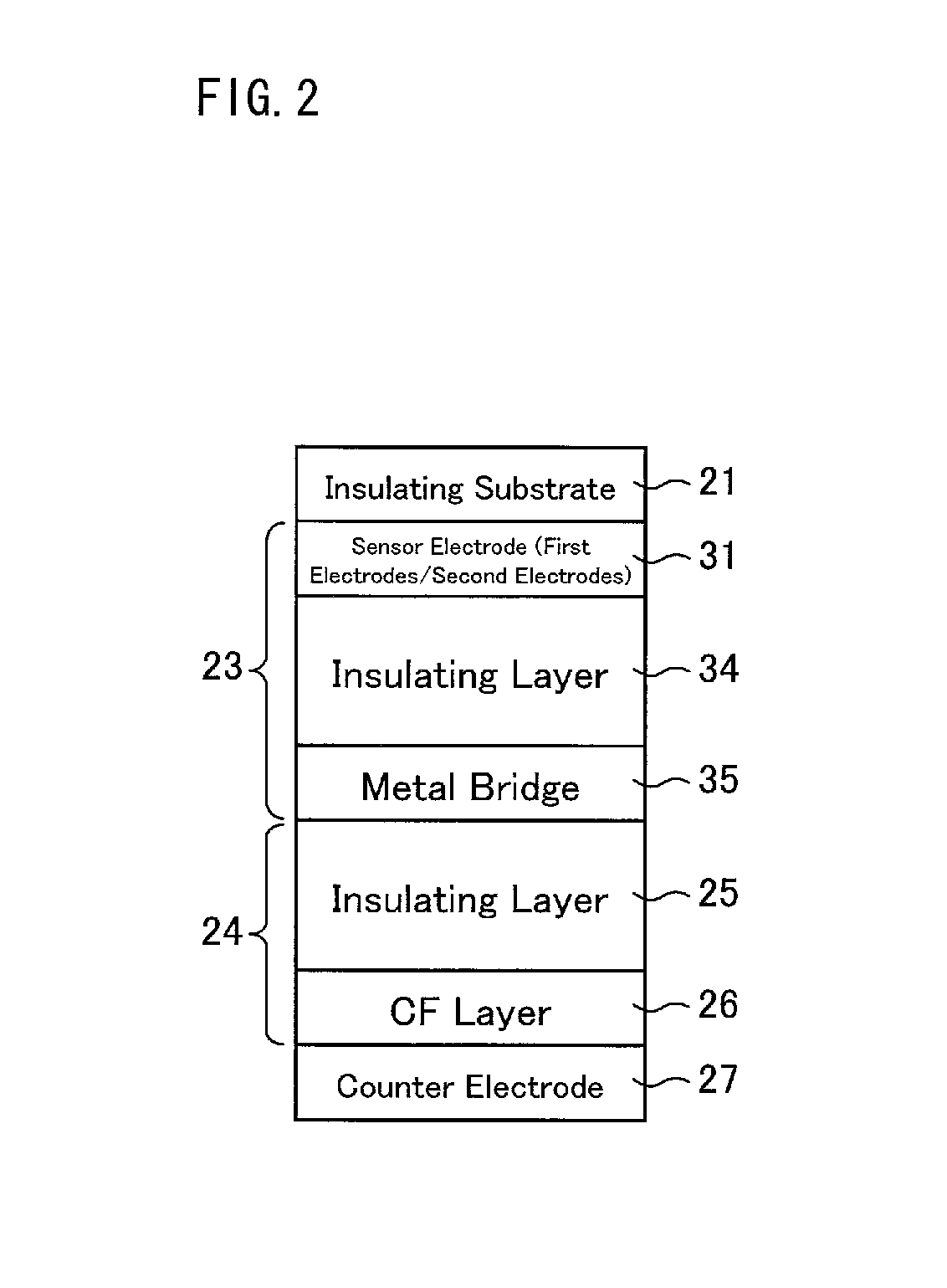

Touch panel substrate and electro-optical device

ActiveUS20140198268A1Reduce of position detectingGain is not constantNon-linear opticsInput/output processes for data processingEngineeringTouch panel

Owner:SHARP KK

Apparatus and method for temporary hemostasis

ActiveUS7806856B2Prevent over-pressurizationReduce positioningBalloon catheterSurgeryPressure differenceVALVE PORT

An apparatus for providing hemostasis within a puncture through tissue includes an elongate member having a lumen extending between proximal and distal ends thereof, an expandable member carried on the distal end and a housing on the proximal end, the housing including an interior communicating with the lumen, and further including a valve assembly with a one-way valve allowing access into the housing interior upon application of a pressure differential across the valve, and a movable plunger for overriding and opening the valve.

Owner:ACCESS CLOSURE INC

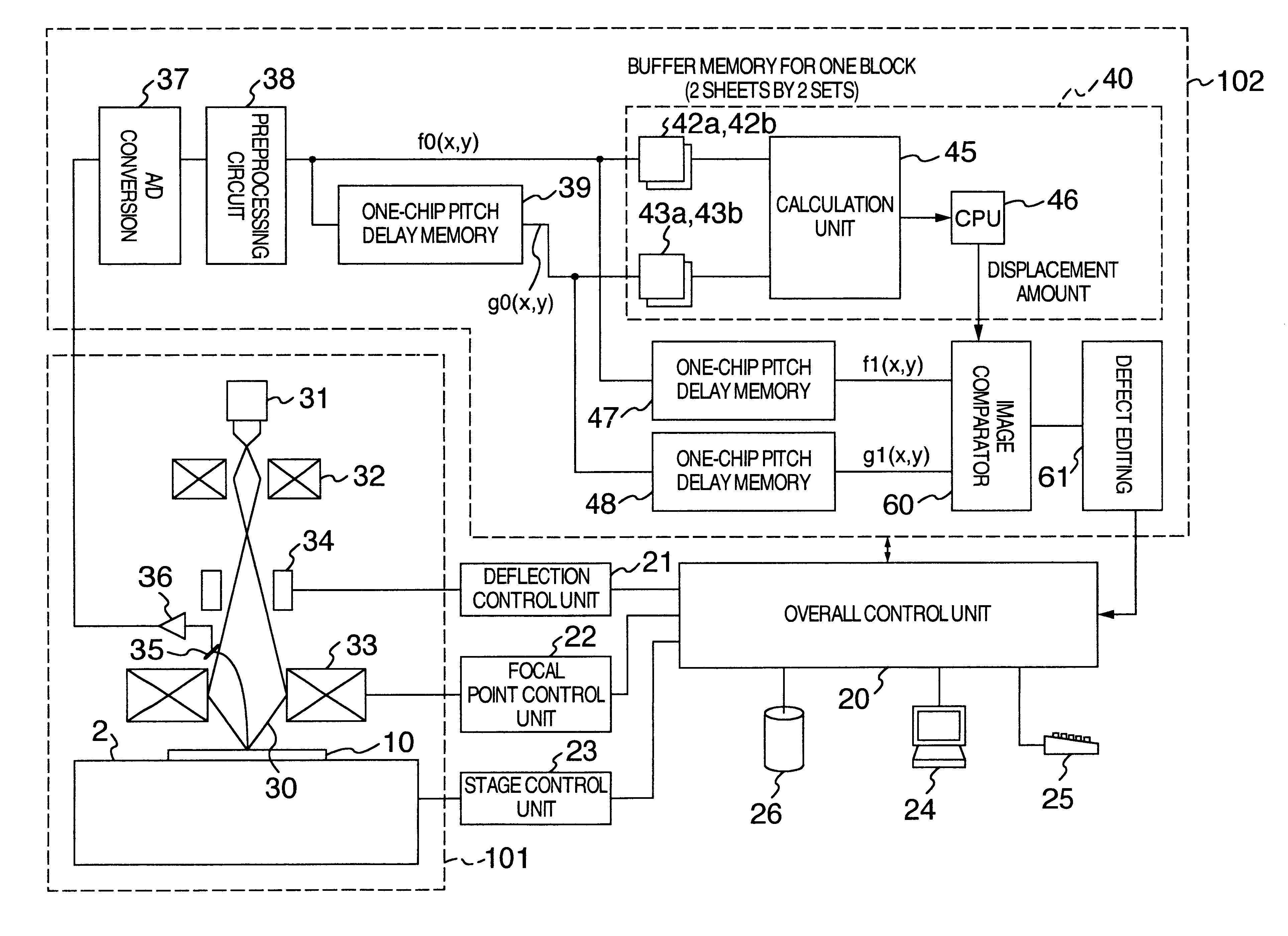

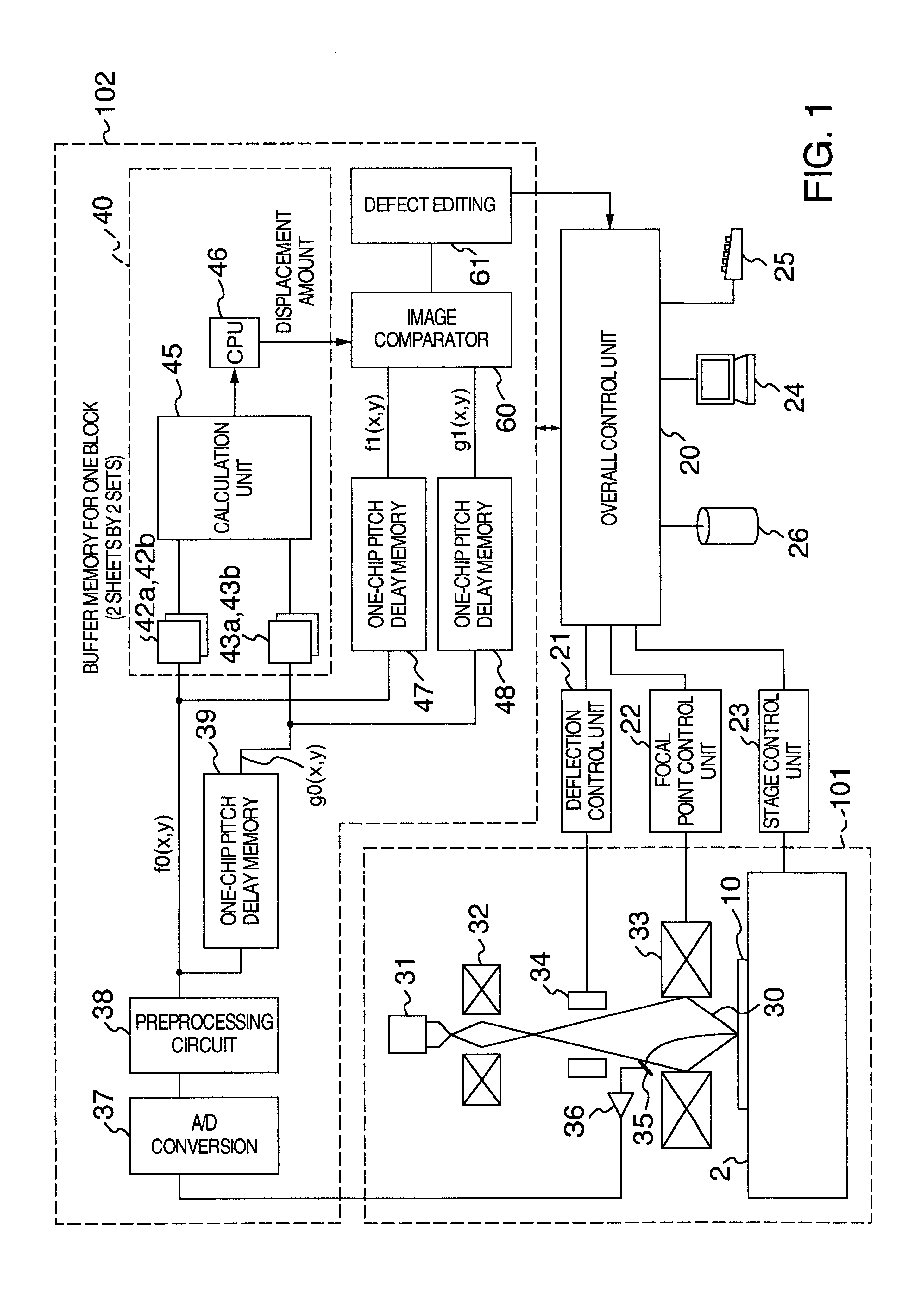

Pattern inspection method and apparatus

InactiveUS6865288B1Inspection is accurateGood chanceImage enhancementImage analysisComputer visionBand shape

A pattern inspection method and apparatus are disclosed, the method has the steps of generating a reference digital image signal to be compared with a detection digital image signal detected continuously from the desired band-shaped inspection area on an object to be inspected, determining zero or one or more candidate , matching positions between the detection digital image signal and the reference digital image signal for each block unit area sequentially cut out and calculating a mass of candidate matching positions over the entire band-shaped inspection area, determining an accurate matching position between the detection digital image signal and the reference digital image signal for each block unit area based on the continuity of the block unit areas from the calculated mass of candidate matching positions over the entire band-shaped inspection area, and determining a defect by matching the positions based on the determined accurate matching position for each block unit area and comparing the images.

Owner:HITACHI LTD

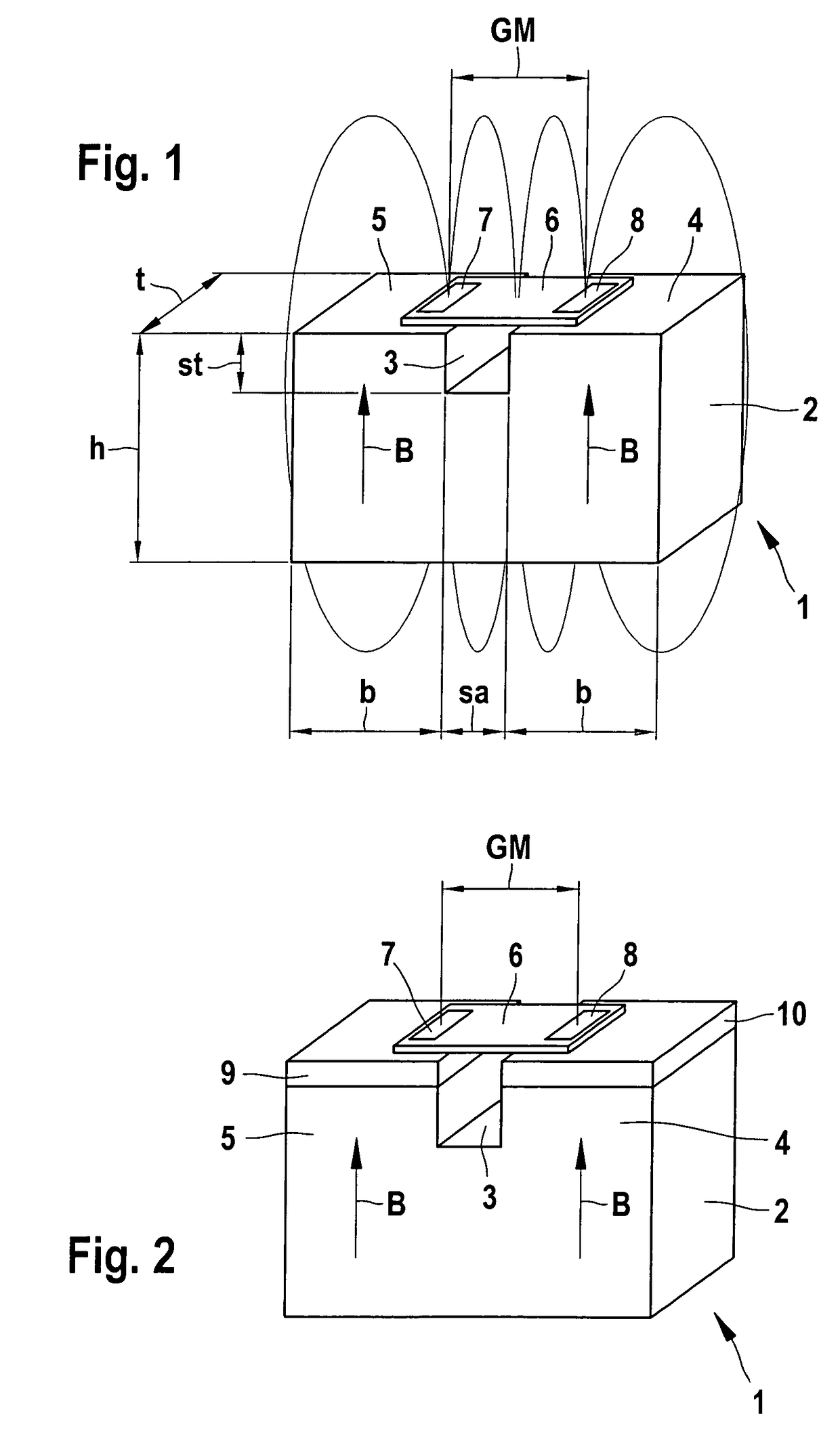

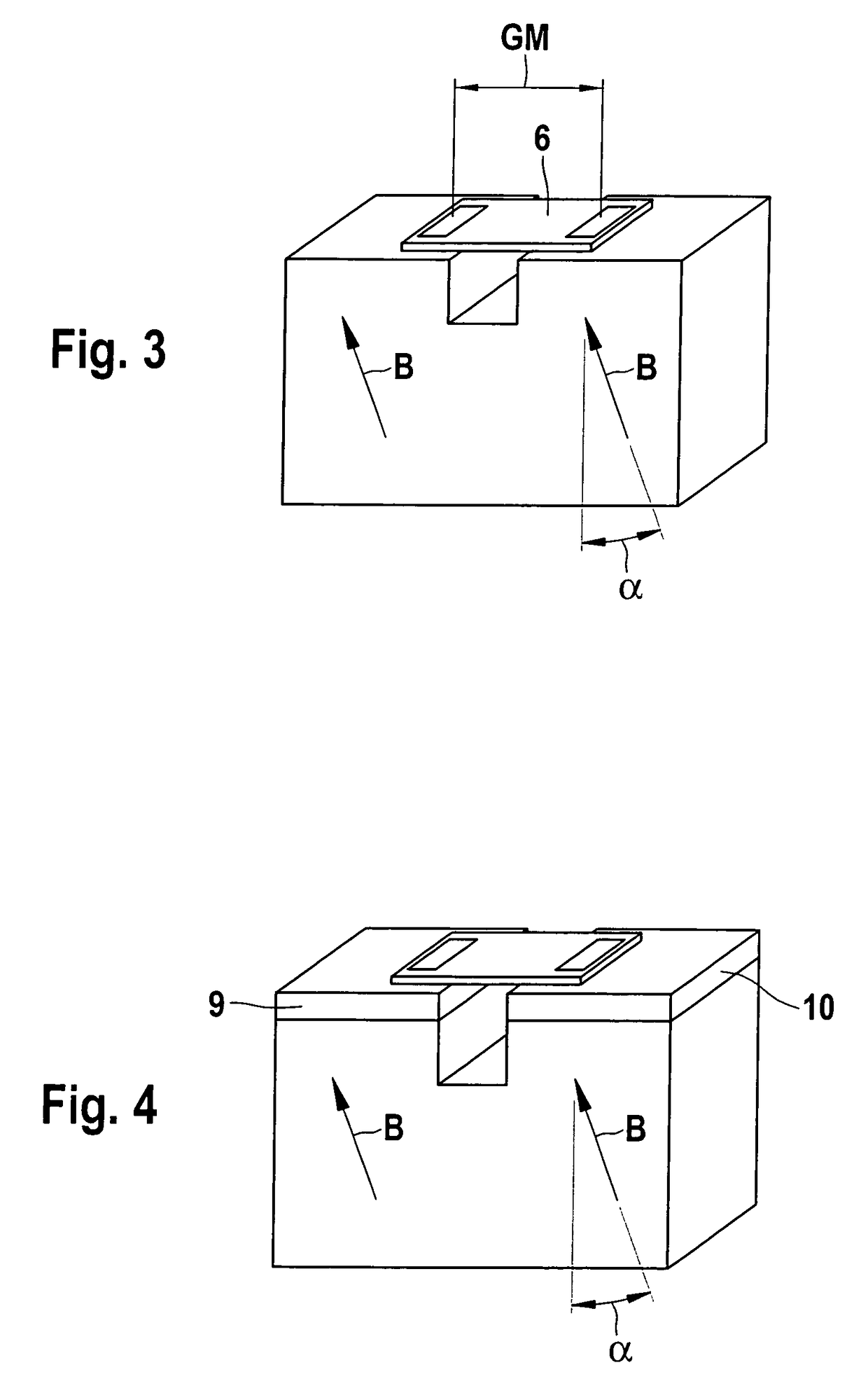

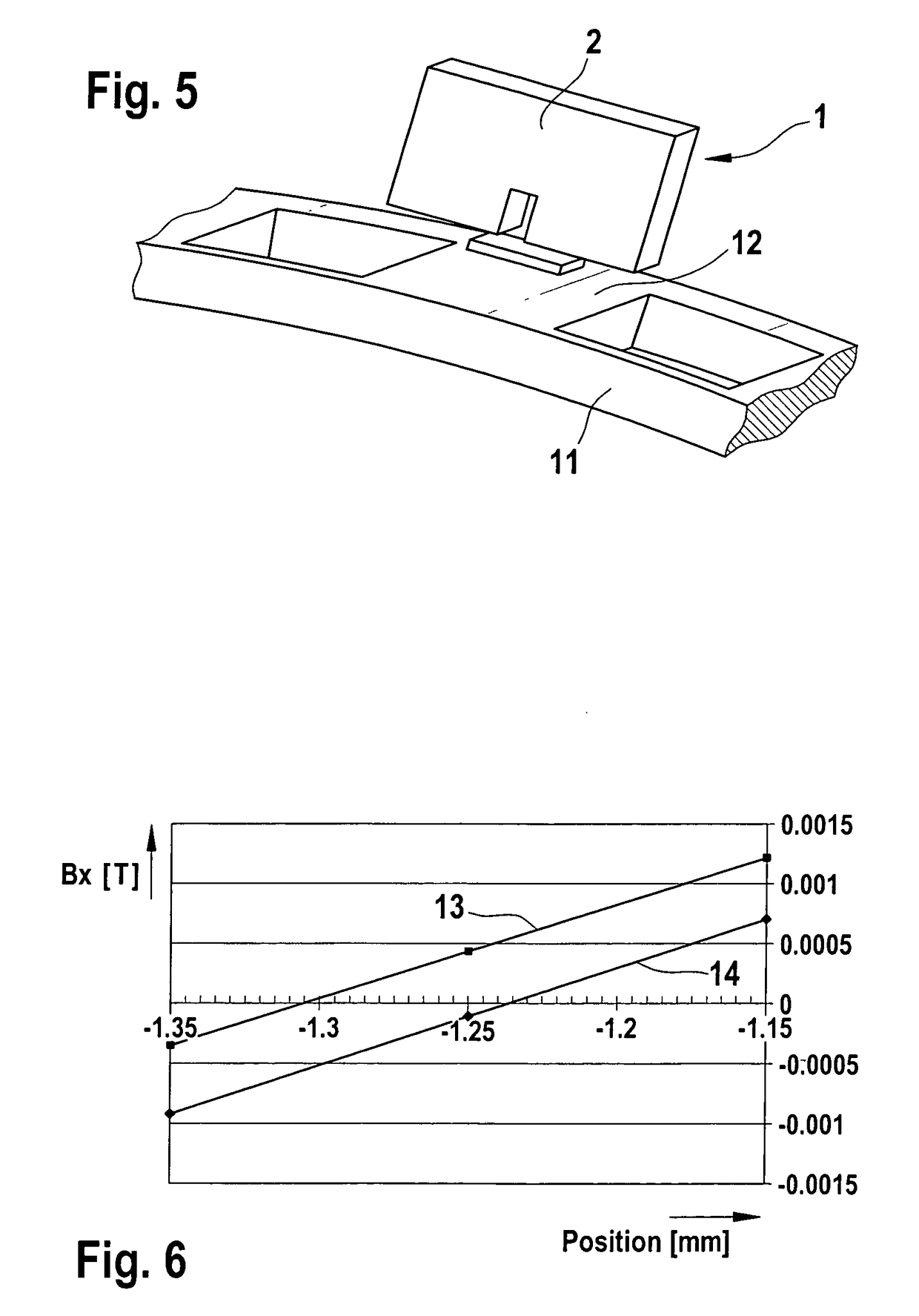

Magnet sensor arrangement for sensing the movement of element moving in linear or rotary fashion

InactiveUS8120351B2Minimize offsetSimple designMagnetic-field-controlled resistorsMagnetic field measurement using flux-gate principleTransmitterMagnet

Owner:ROBERT BOSCH GMBH

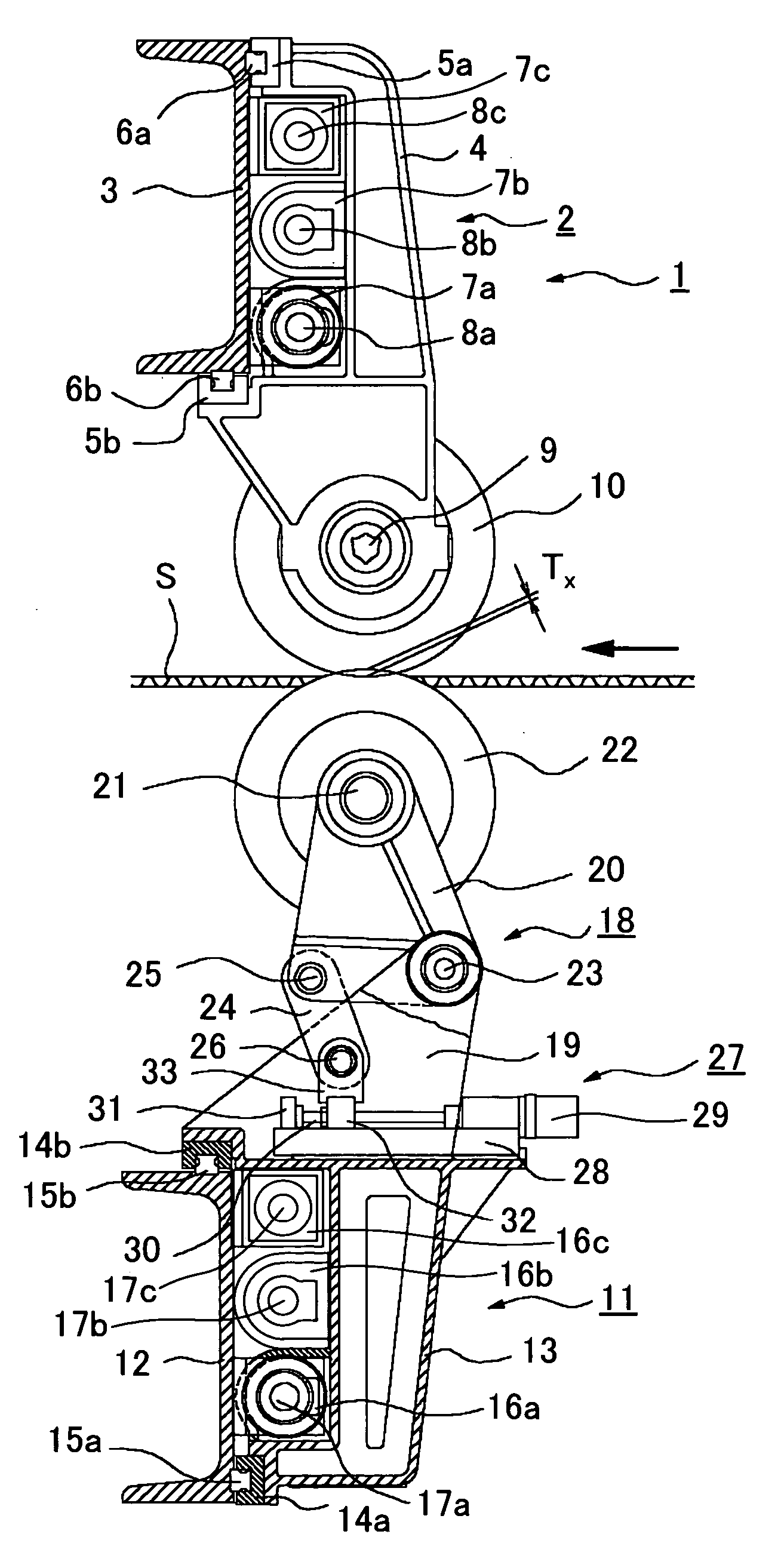

Medical charged particle irradiation apparatus

InactiveUS20040183035A1Reduce positioningImprove irradiation accuracyHandling using diaphragms/collimetersDiagnostic recording/measuringIrradiationMedical treatment

A medical charged particle irradiation apparatus capable of irradiation from upward and horizontal directions and performing a preparing / ascertaining work without any separate device such as a moving capsule or the like comprising a patient's bed, on which a patient lies, a transport equipment for injecting and transporting charged particle beams toward the patient's bed, an irradiation field forming device for forming an irradiation field for the beams transported by the transport equipment, and a gantry provided to be rotatable about an axis of rotation, and wherein the irradiation field forming device is eccentrically arranged such that an axis of irradiation passes a position different from the axis of rotation, and the patient's bed is arranged on an opposite side of the transport equipment to a plane, which contains the axis of rotation and is substantially perpendicular to the axis of irradiation.

Owner:HITACHI LTD

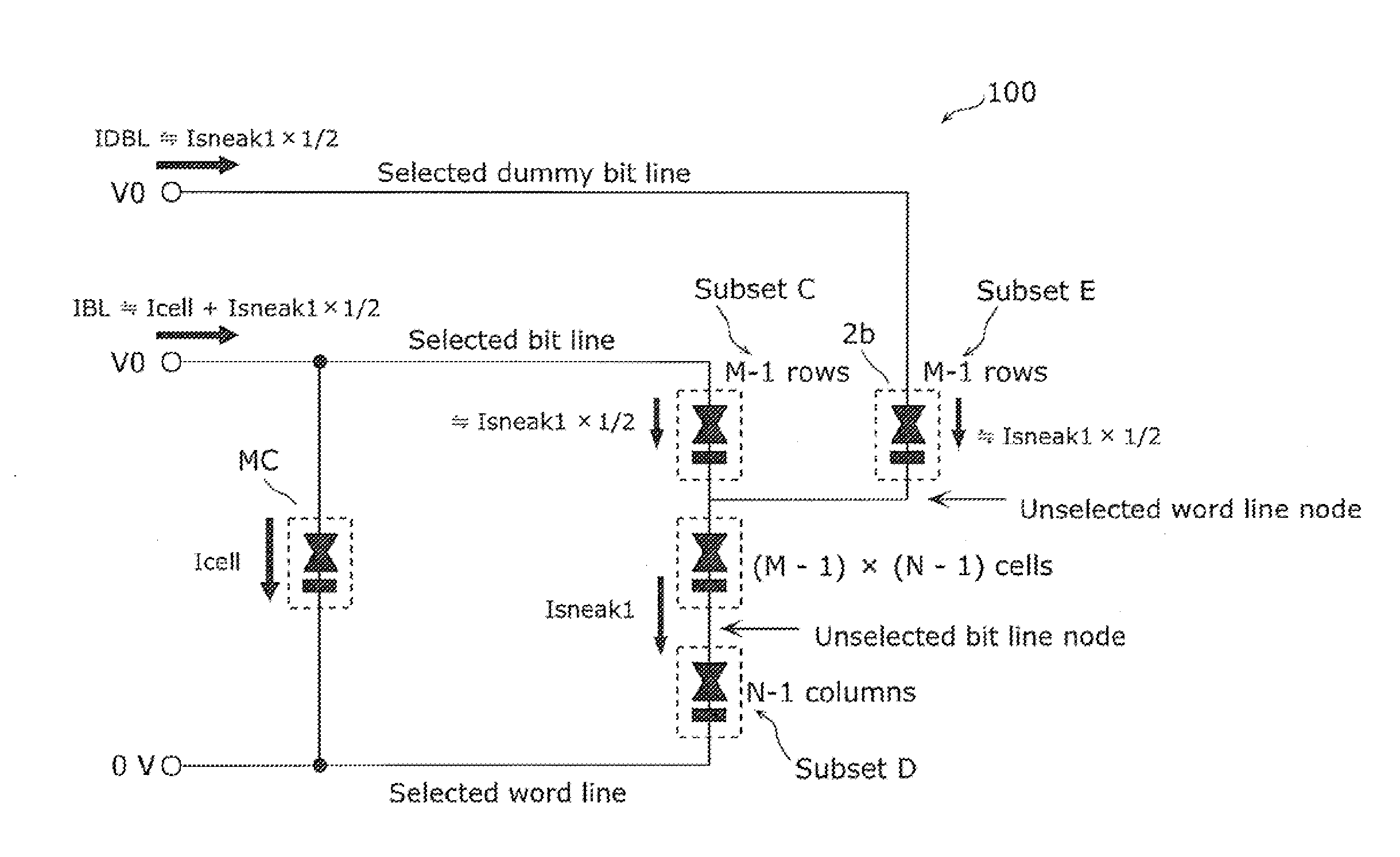

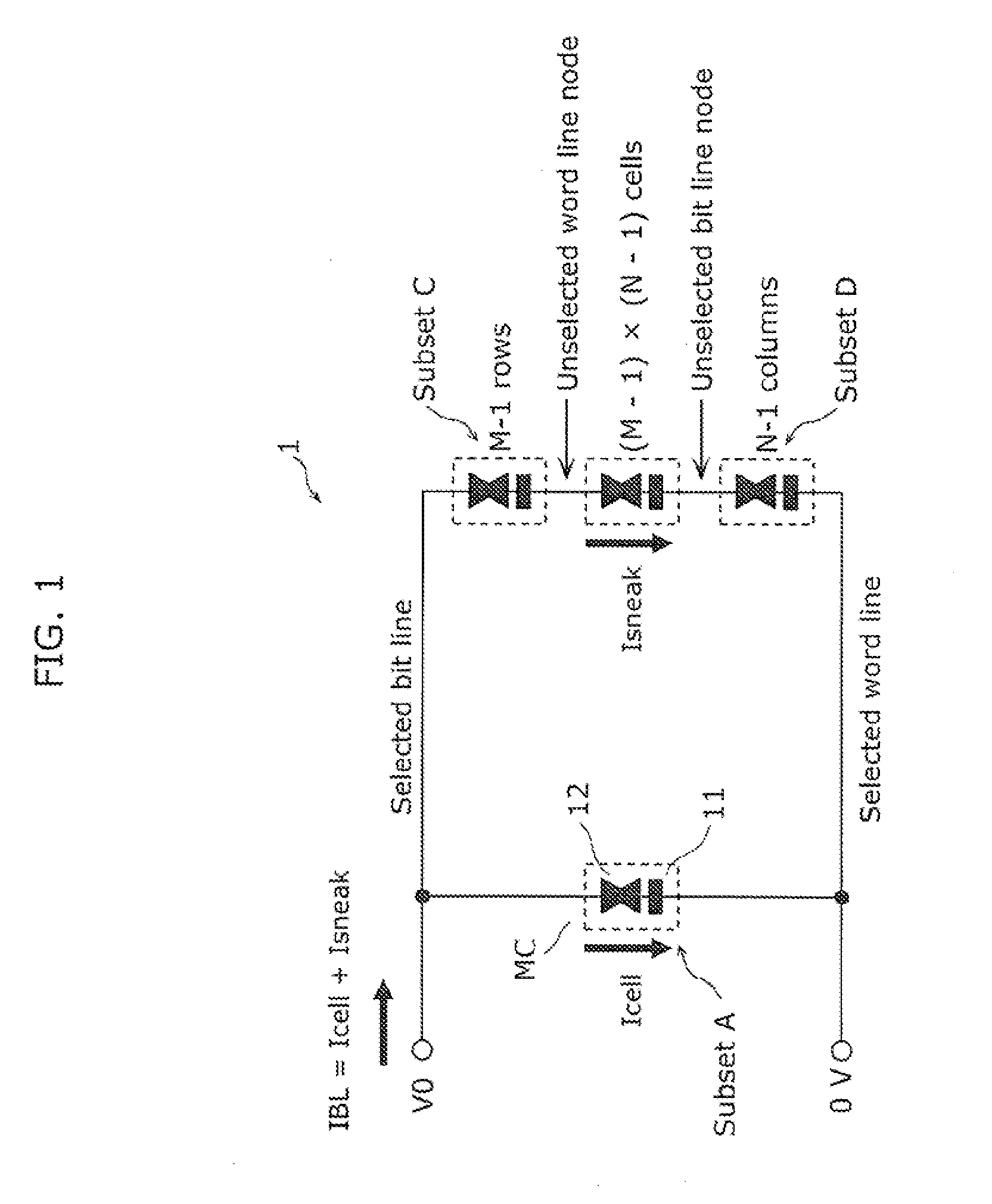

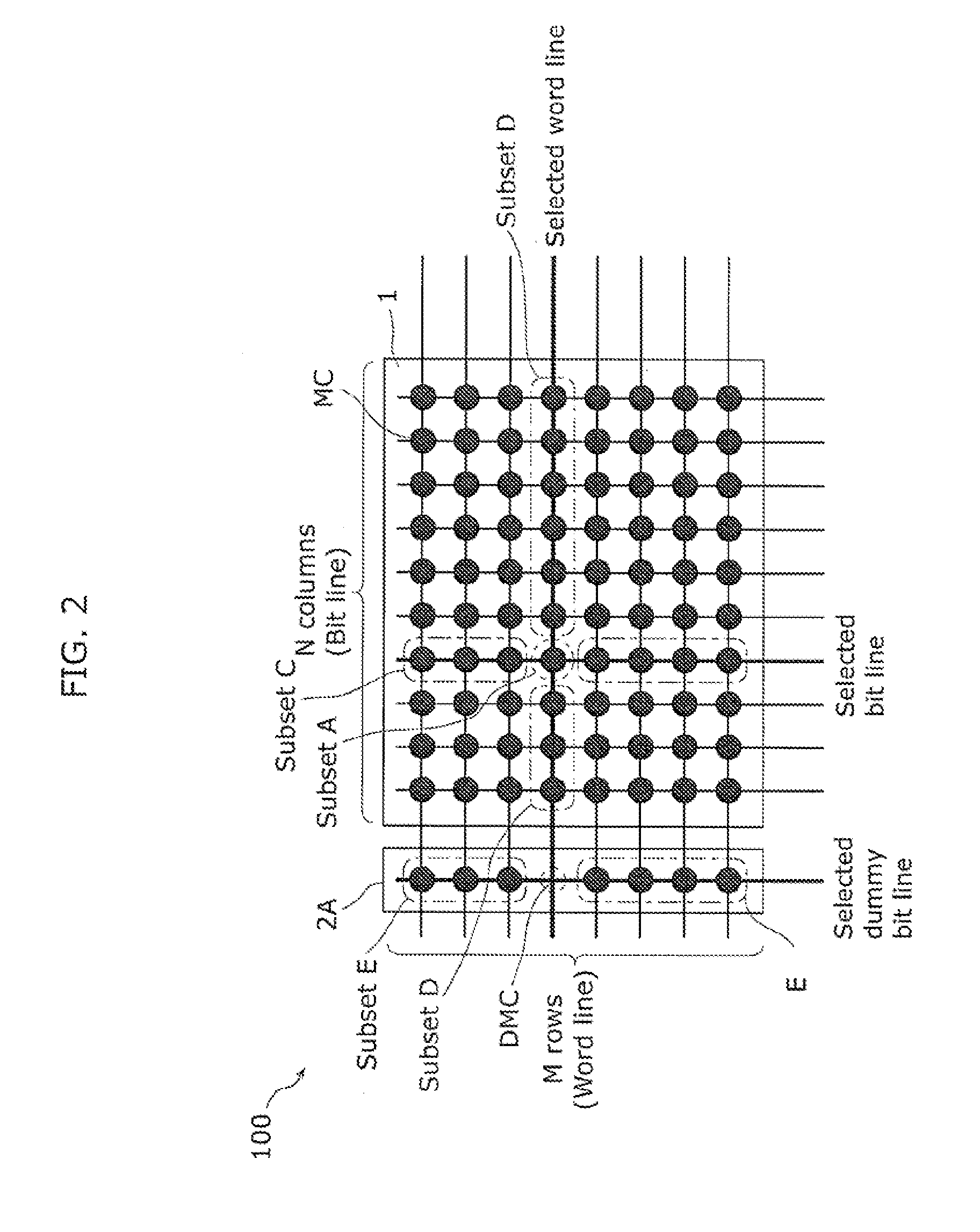

Nonvolatile semiconductor memory device and read method for the same

ActiveUS20130148406A1Low detection sensitivityImprove reading accuracyDigital storageBit lineMemory cell

A cross point nonvolatile memory device capable of suppressing sneak-current-caused reduction in sensitivity of detection of a resistance value of a memory element is provided. The device includes perpendicular bit and word lines; a cross-point cell array including memory cells each having a resistance value reversibly changing between at least two resistance states according to electrical signals, arranged on cross-points of the word and bit lines; an offset detection cell array including an offset detection cell having a resistance higher than that of the memory cell in a high resistance state, the word lines being shared by the offset detection cell array; a read circuit (a sense amplifier) that determines a resistance state of a selected memory cell based on a current through the selected bit line; and a current source which supplies current to the offset detection cell array in a read operation period.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

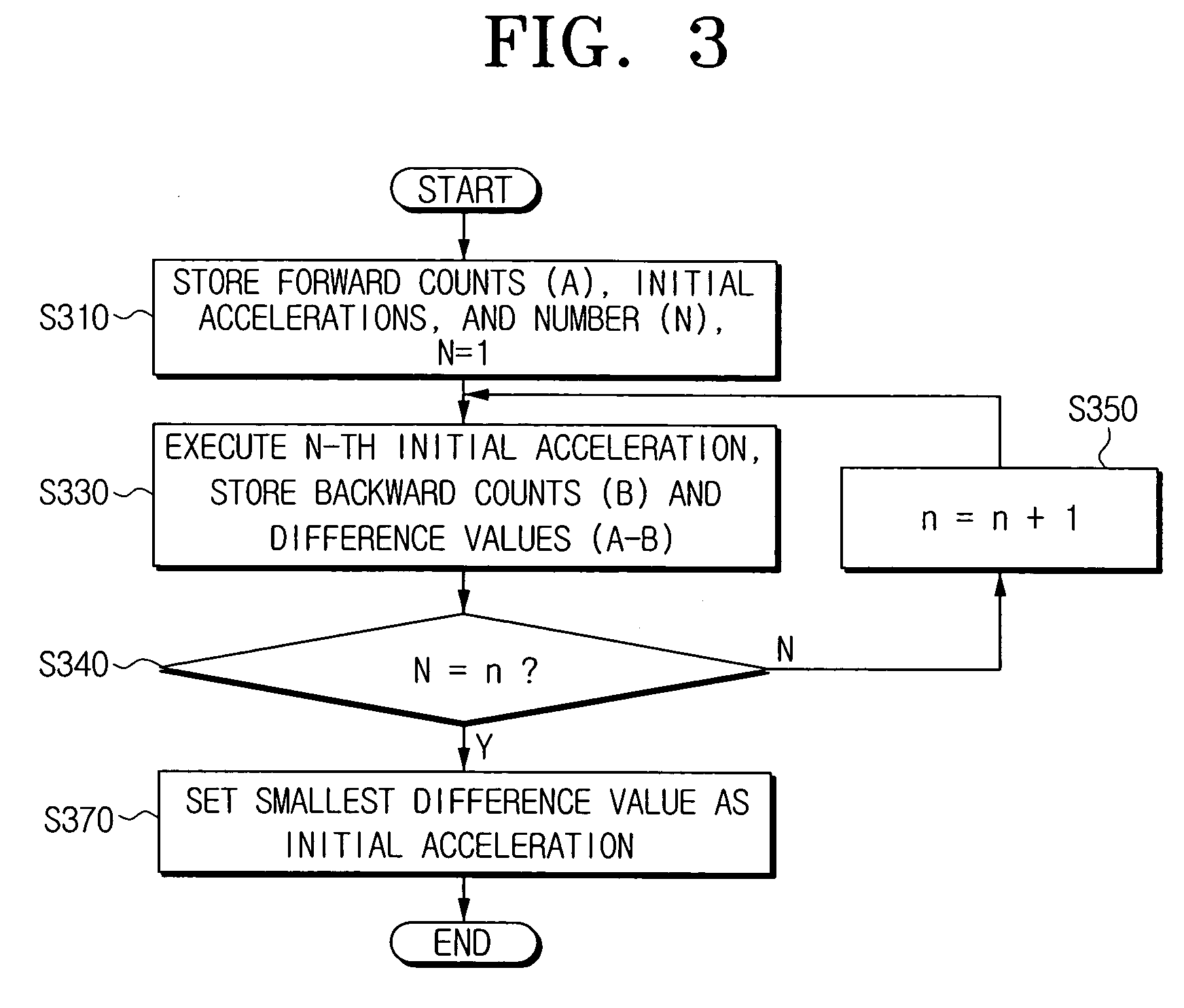

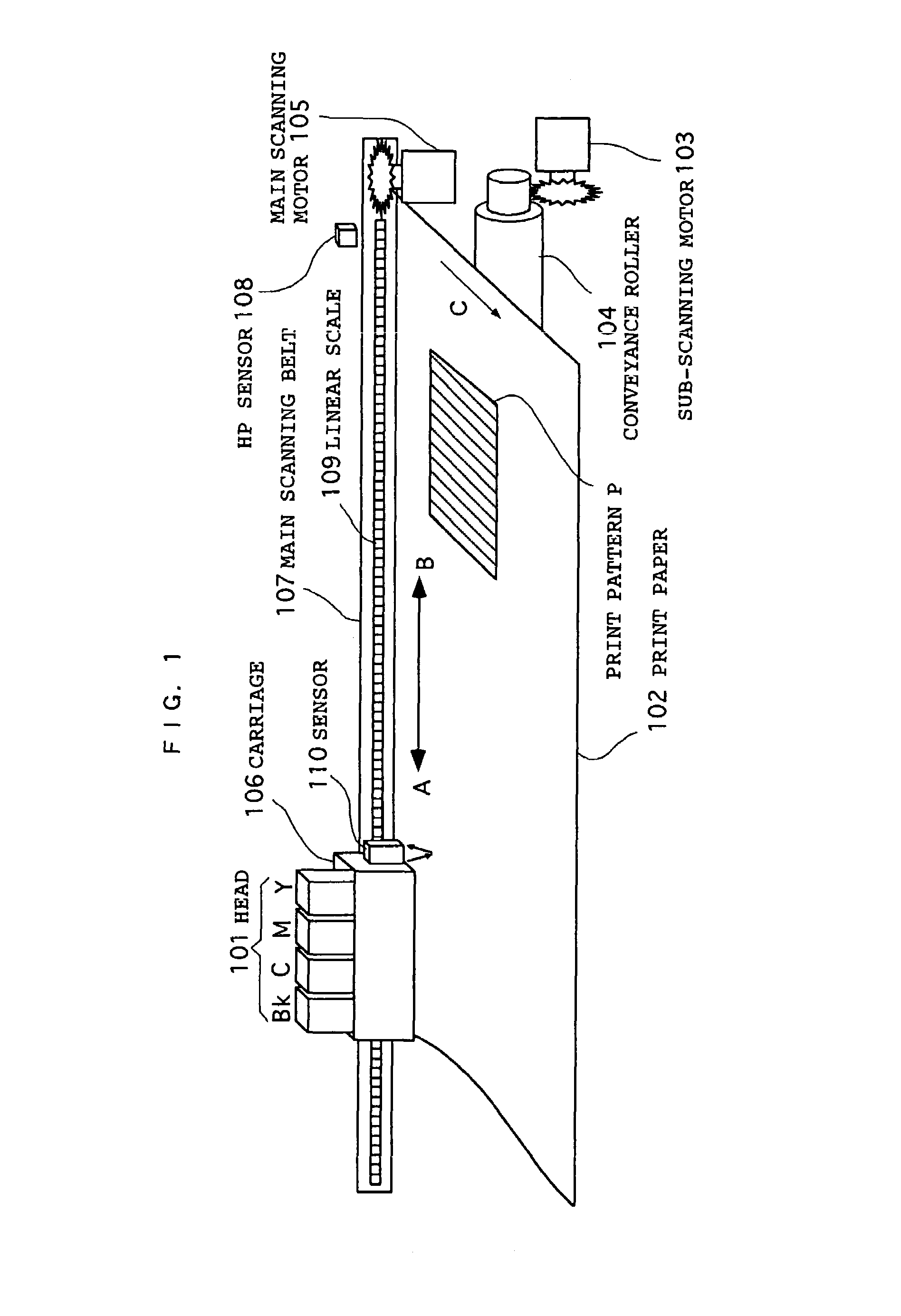

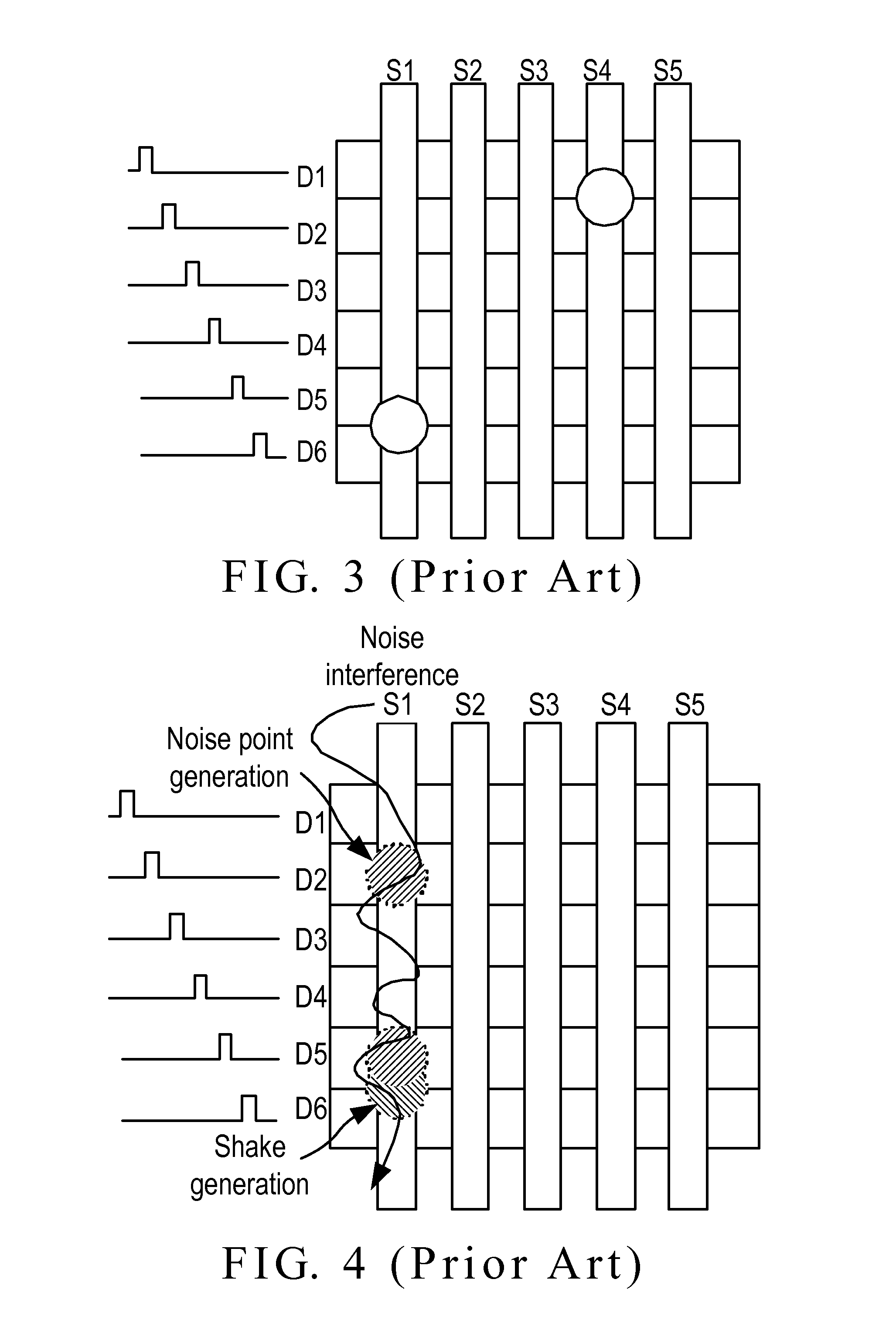

Method for reducing printing position error and image forming apparatus using the same

InactiveUS20060285907A1Reduce errorReduce positioningElectrographic process apparatusOther printing apparatusPosition errorImage resolution

An apparatus and method are provided for reducing a printing position error, in which the method includes the steps of (a) driving an encoder wheel as many times as a predetermined number of forward counts at a predetermined initial acceleration, thereby making the edge of a printing paper become separated from a sensing unit and conveyed in a forward direction, (b) driving the encoder wheel at the predetermined initial acceleration and conveying the printing paper in a backward direction, (c) calculating a difference value between the number of backward counts of the encoder wheel from a start time of the backward driving to a point when the sensing unit detects the edge of the printing paper and the number of forward counts, and (d) repeating the steps (a) through (c) for a designated number of times while varying the predetermined initial acceleration, and setting an initial acceleration corresponding to a smallest value among the difference values as the initial acceleration for driving the encoder wheel. Therefore, in the case of separately printing data on one printing paper several times, the resolution of a printed image can be improved by reducing the printing position error.

Owner:S PRINTING SOLUTION CO LTD

Method for controlling slitter-scorer apparatus

InactiveUS20040159693A1Avoid twists and turnsIncreasing available yield percentageMechanical working/deformationSewerage structuresEngineeringSliding contact

A method for controlling a slitter-scorer apparatus in which a feed line for a paperboard sheet does not need to be stopped when order specification of cutting or scoring for the paperboard sheet has been changed, thereby reducing a setup time, is proposed. A method for controlling a slitter-scorer apparatus including steps of supplying a paperboard sheet along a feed line, and moving a slitter or a scorer in a vertical and / or a widthwise direction to a operative level where the surface of said paperboard sheet is processed thereby wherein: movement of said slitter and / or scorer is controlled such that said slitter and / or scorer either come into sliding contact with or is apart slightly from said surface of the paperboard sheet.

Owner:ISOWA IND CO LTD

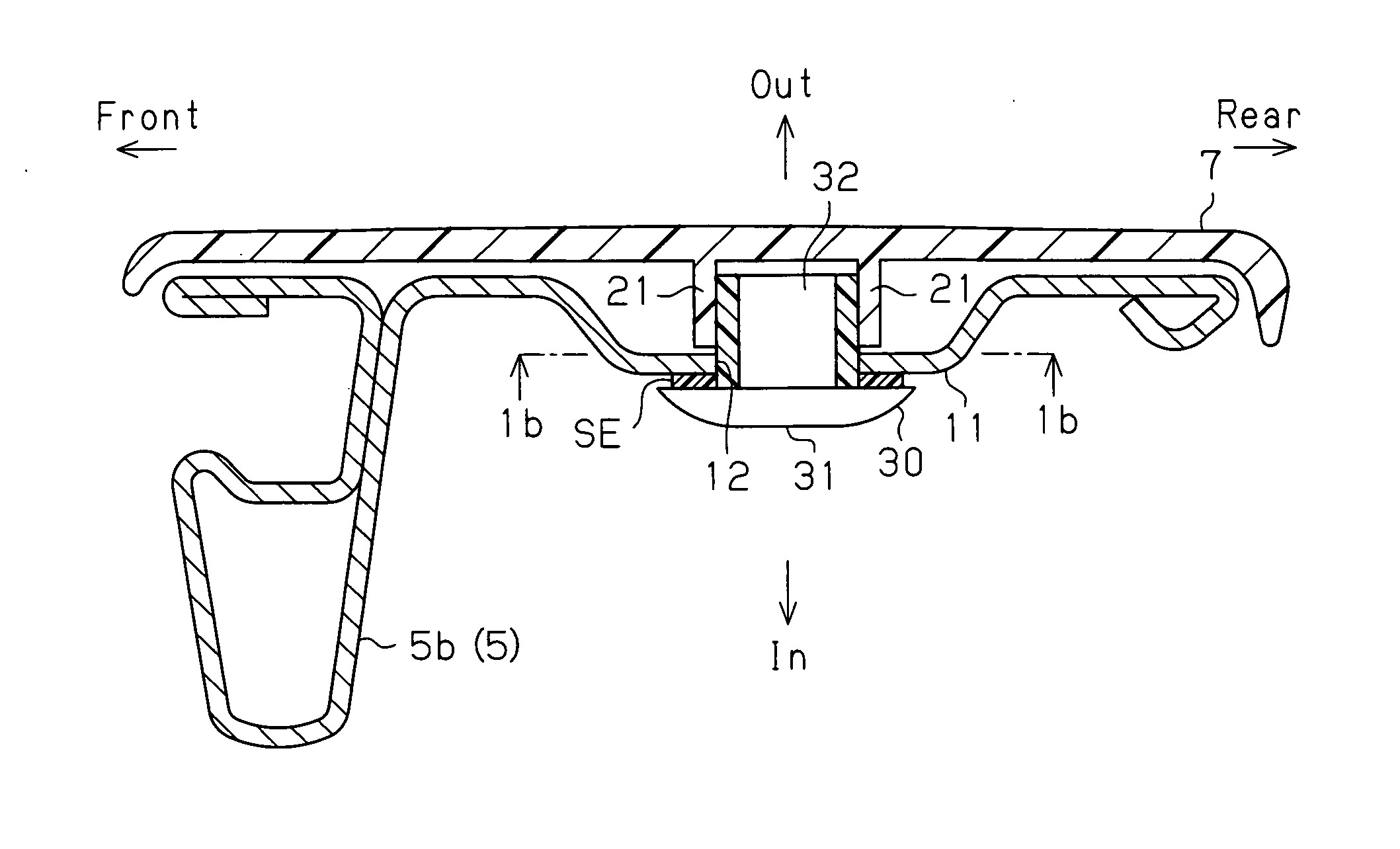

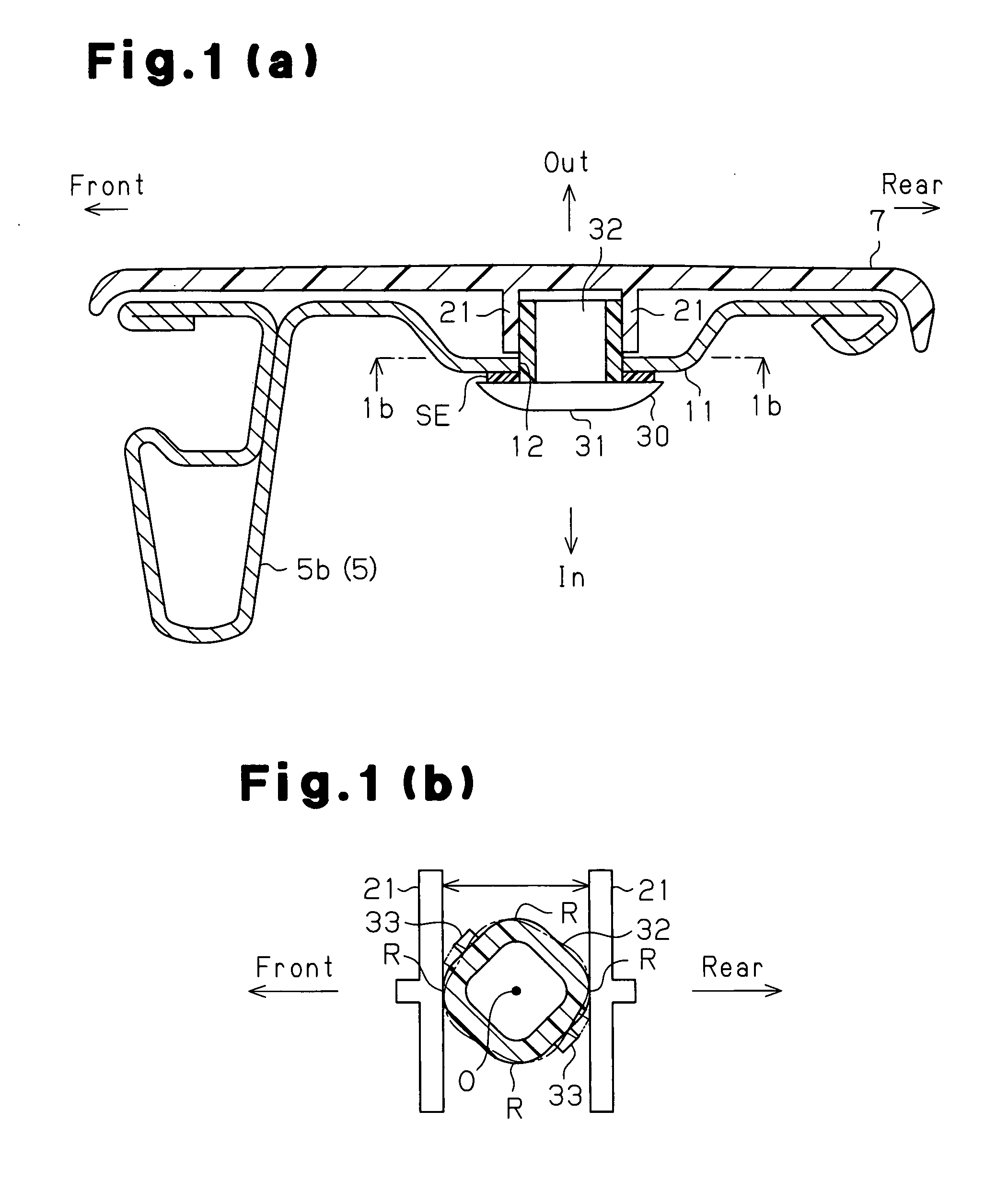

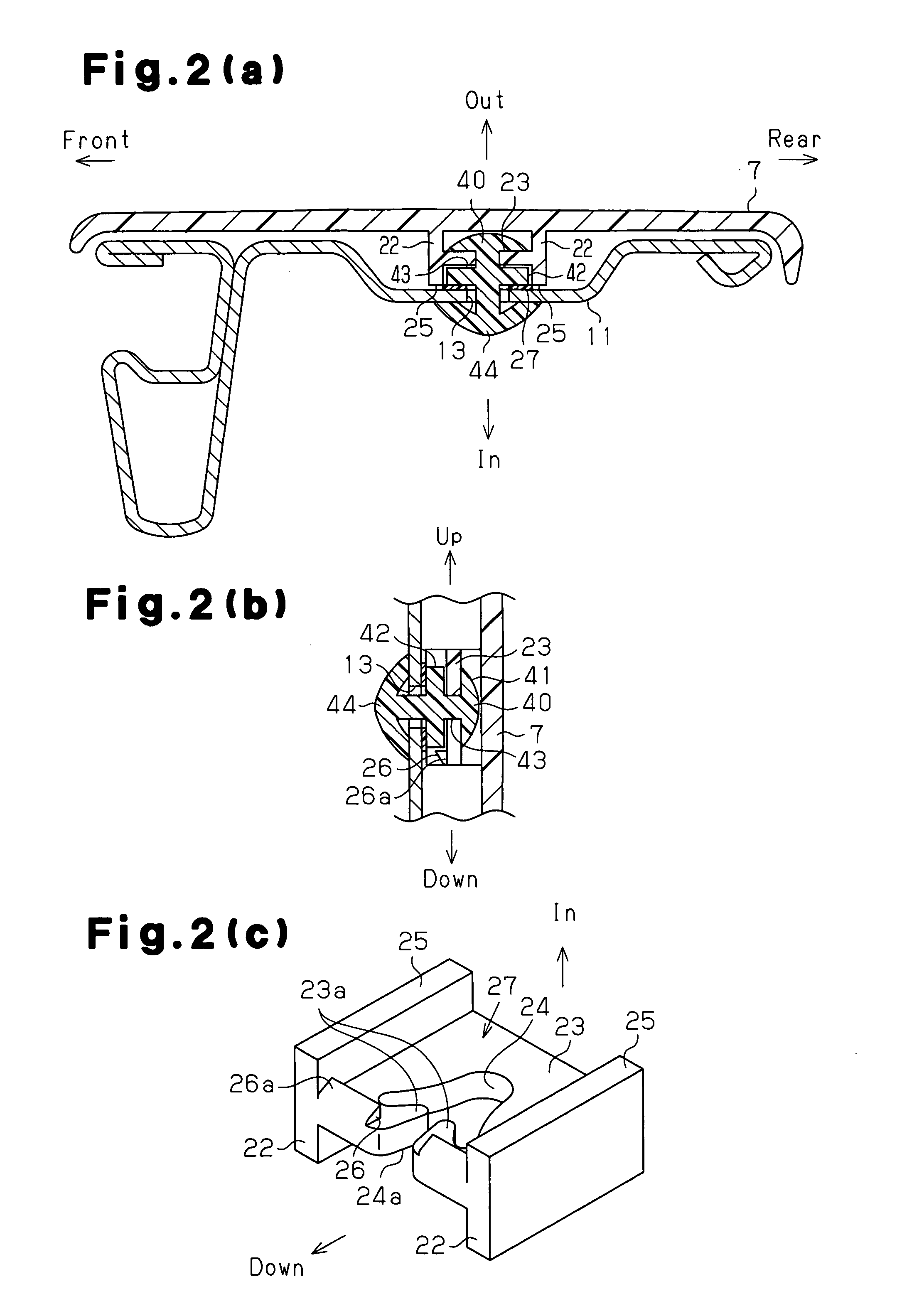

Trim attachment structure

ActiveUS20110296764A1Improves aesthetic appealReduced angular positionSheet joiningFriction grip releasable fasteningsDiagonalSingle plate

A trim attachment structure includes a door frame, trim and a clip. The door frame has an attachment part, which is formed by a single plate, and a fitting hole. The fitting hole has a square shape in which the diagonals thereof are aligned with specific directions. The trim has a pair of ribs which extend towards the inner side in the width direction of the vehicle, respectively facing a pair of end parts of the fitting hole. The clip is installed in the fitting hole. The clip includes a head part, a tube part and a latching hook. The tube part has a tip end part which projects from the fitting hole to the outer side of the attachment part in the width direction of the vehicle. Angled parts of the tip end part are held between the ribs. The latching hook is latched at the peripheral edge of the fitting hole on the outer side of the attachment part in the width direction of the vehicle.

Owner:AISIN SEIKI KK +1

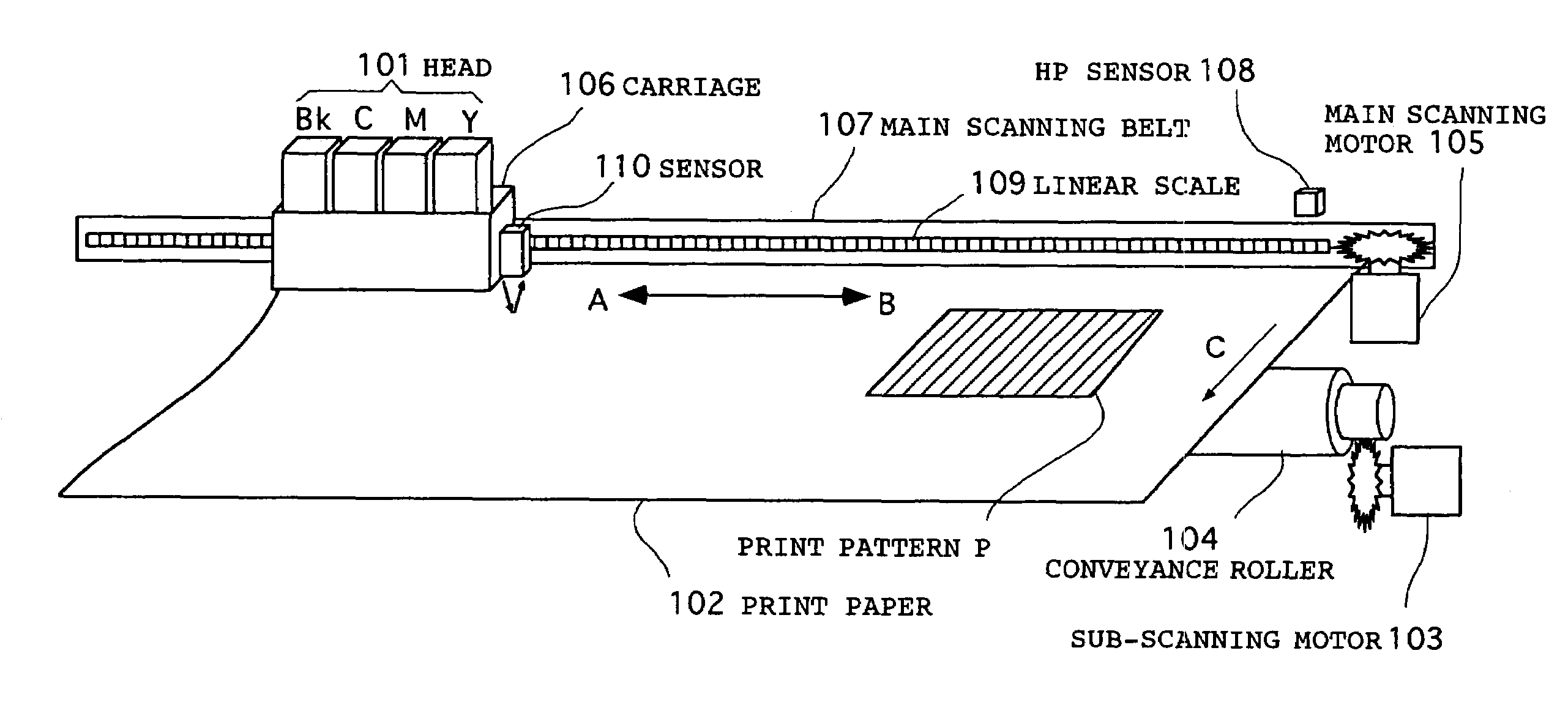

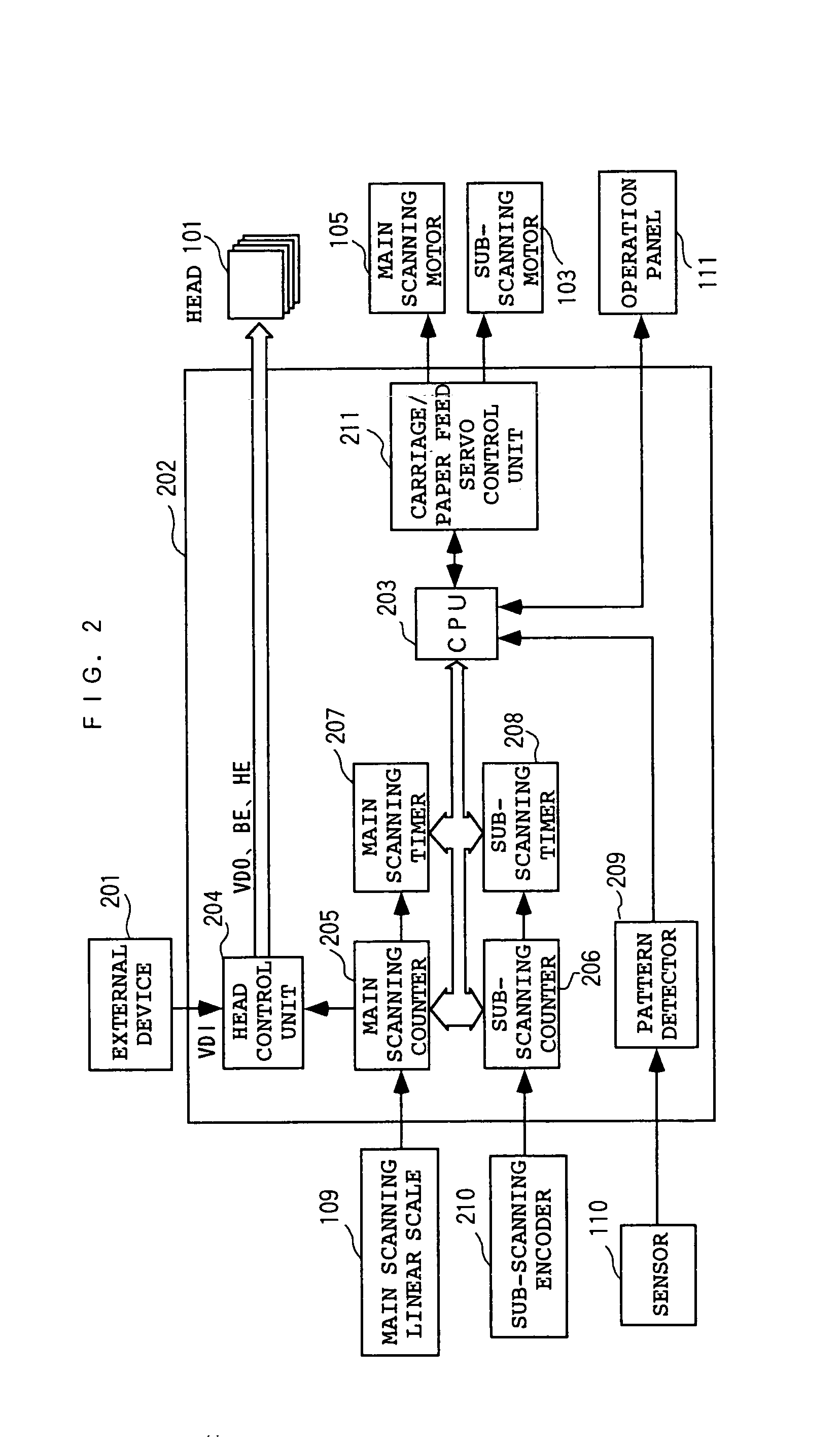

Image forming device

InactiveUS7014289B1Accurate detectionReduce positioningOther printing apparatusVertical barPattern detection

A head (101) prints a predetermined test pattern under the control of a head control unit (204) in order to precisely detect a head deviation when a head has been changed, the printed test pattern is read by a sensor 110 and detected by a pattern detector (209). Every time an interrupt signal corresponding to the edge of a detected pattern element is input to the CPU (203), a value of a main scanning counter (205) / main scanning timer (207) (and / or a sub-scanning counter (206) / sub-scanning timer (208)) is read, the printing position of each pattern element is detected from the value, and the mounting deviation of the head is calculated based on the detection result of the printing position of each pattern element printed by the head. The vertical bar of a test pattern may be printed in multiple passes. A plurality of edges may be detected at different longitudinal positions of the bar and the detected results are averaged to determine an edge position.

Owner:COPYER

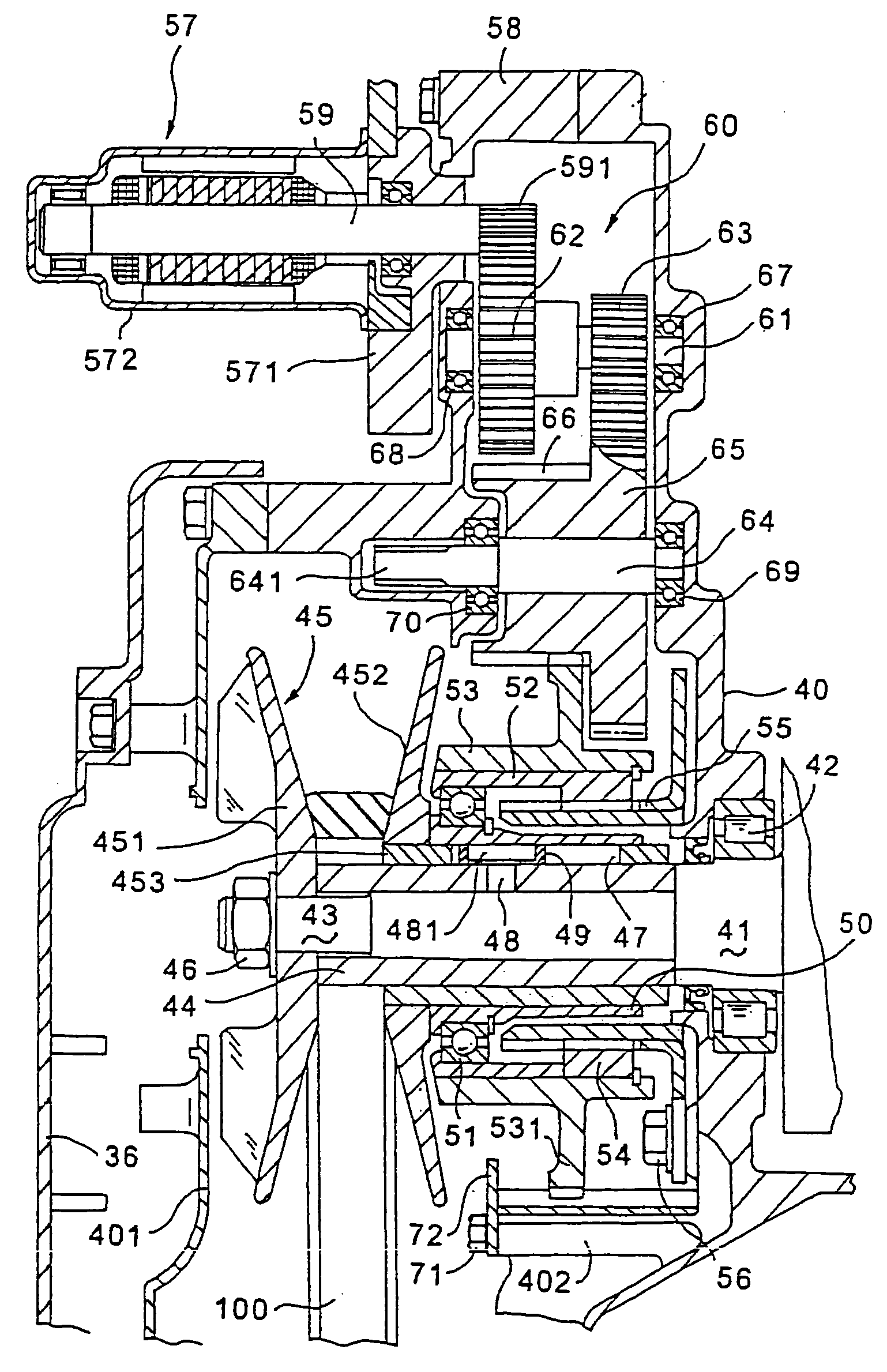

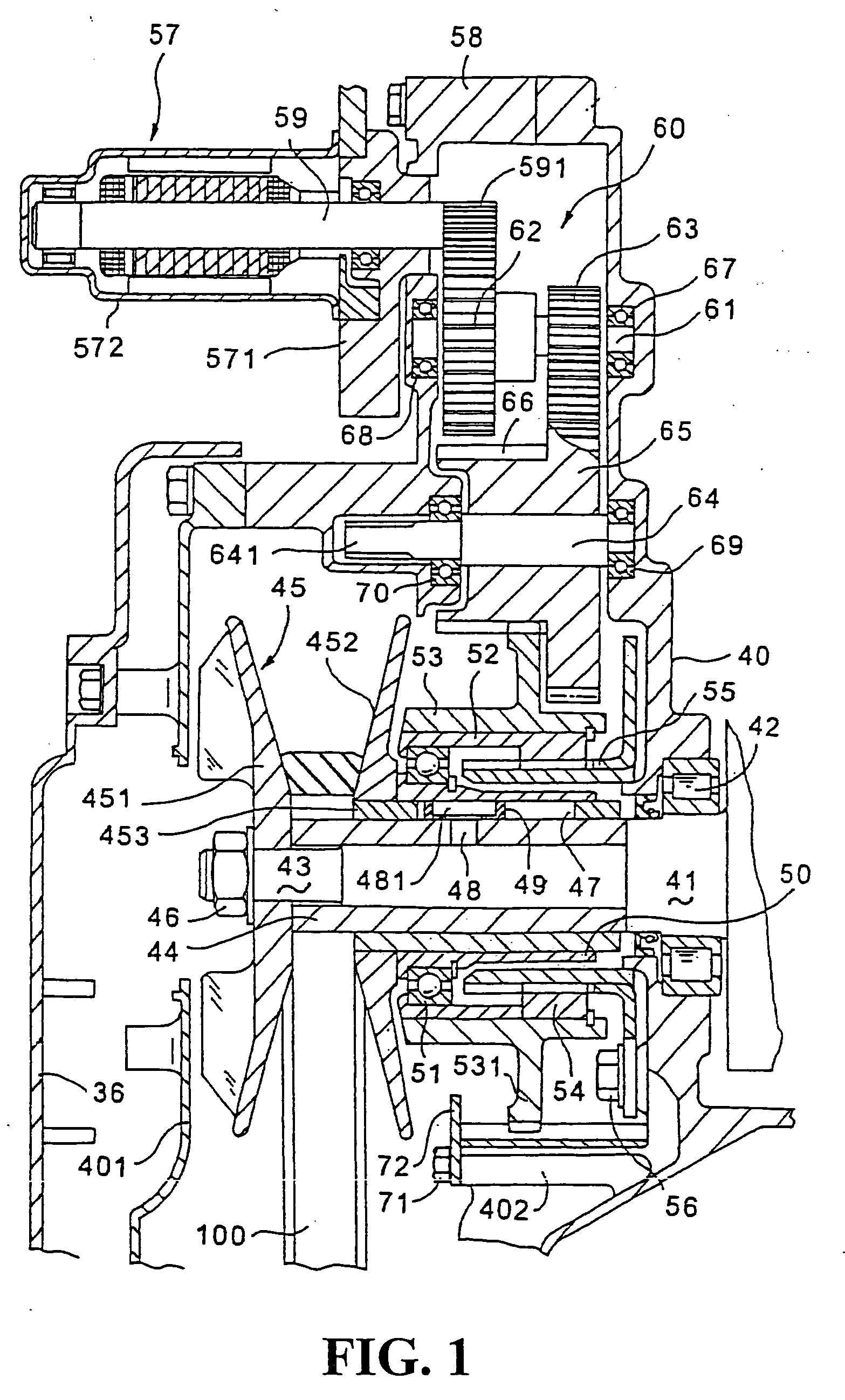

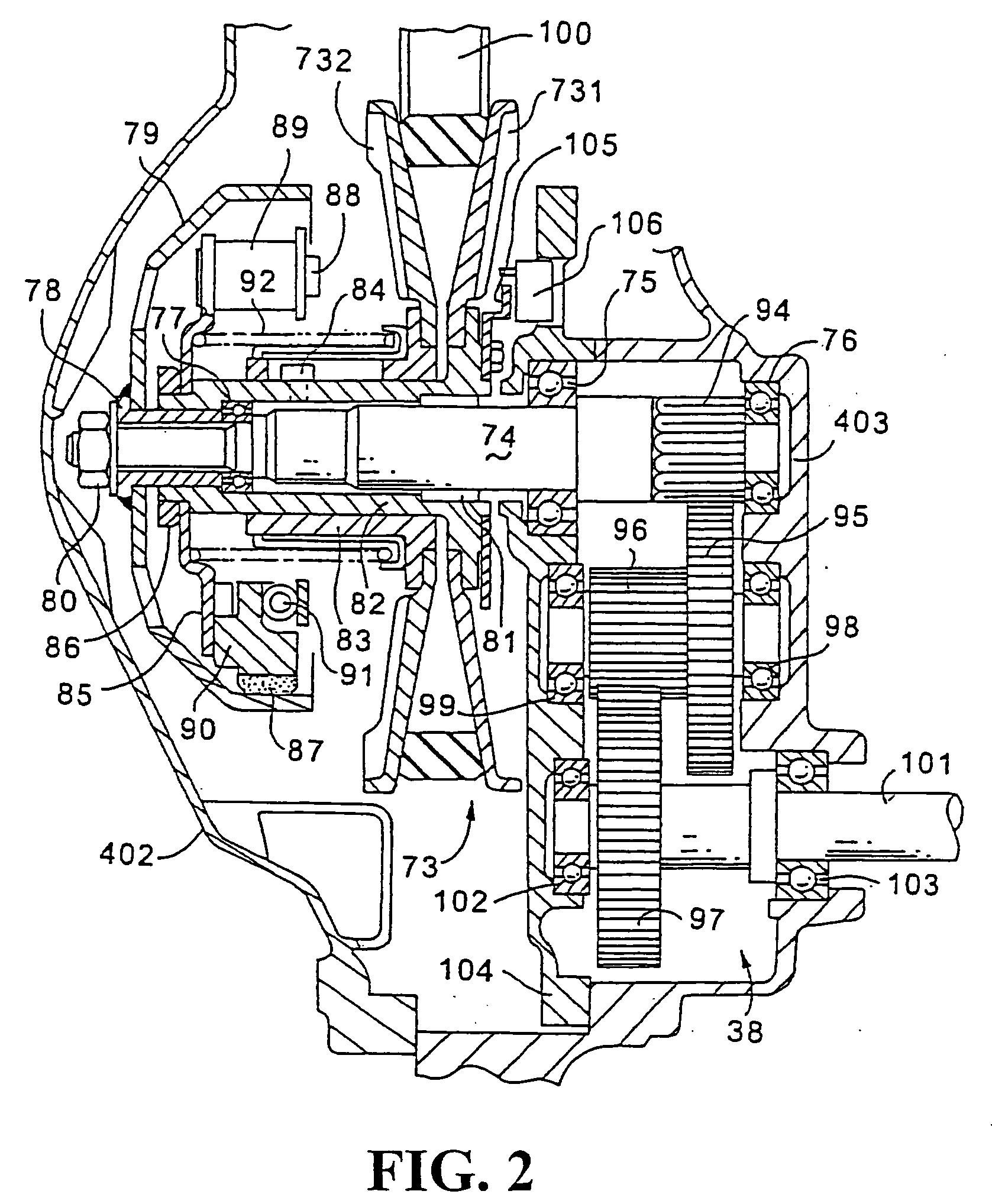

V-belt type continously variable transmission

ActiveUS20050109554A1Simplify the configuration processEasy to manufactureGearboxesGearingGear systemCrankcase

A belt continuously variable transmission apparatus having a case which includes a power transmission case (which is part of a crankcase of an engine), a power transmission case cover, and an actuator cover assembled forwardly of the power transmission case cover (displaced forwardly on a vehicle body). The actuator cover is formed as a separate member from the power transmission case cover, and supports a motor for driving a movable part of a driving pulley. In addition, the actuator cover covers a gear system. The actuator cover is integrated with a cover of the water pump. The resulting configuration improves the assembling of the actuator cover of the belt continuously variable transmission apparatus.

Owner:HONDA MOTOR CO LTD

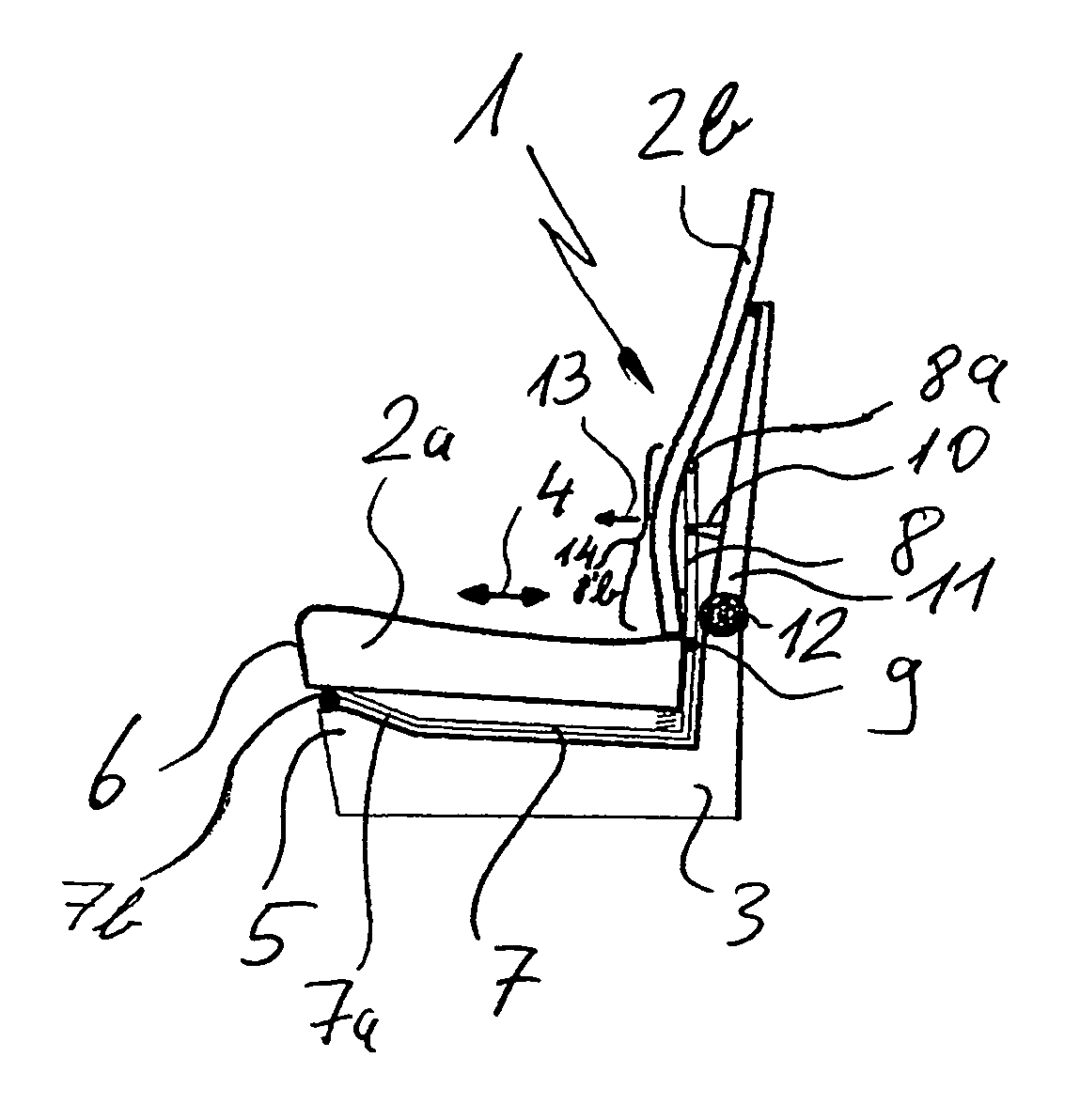

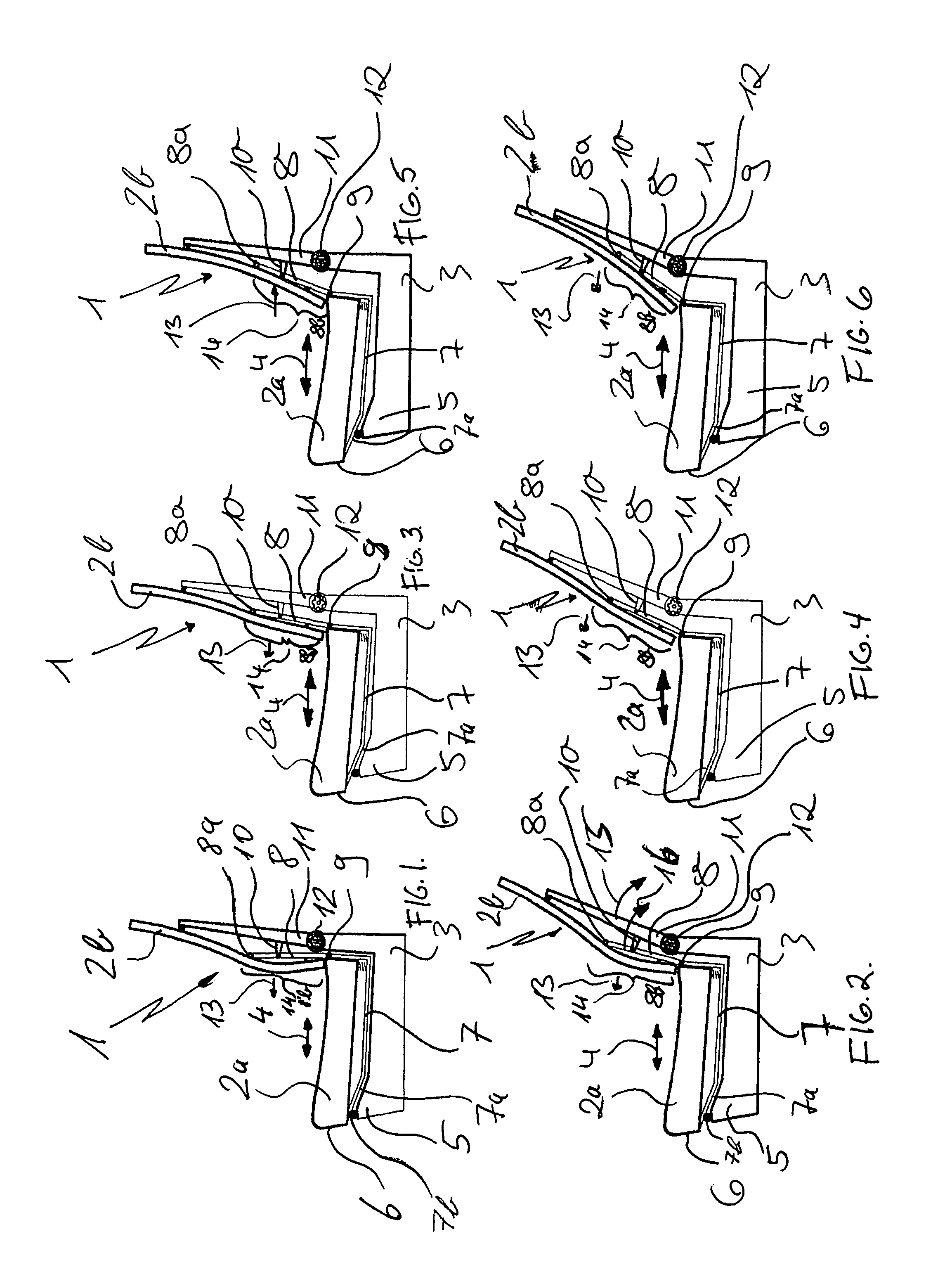

Vehicle seat with a deformable backrest

ActiveUS7874618B2Reduce effectComfortable sittingOperating chairsBack restsEngineeringMechanical engineering

The invention relates to a vehicle seat with a backrest (1) and a seat part (2a), wherein the seat part (2a) can be displaced in the forward and backward direction (4) with respect to a base frame (3, 11) and the backrest (1) has a lumbar spine region (14) which can be deformed in the forward and backward direction (13), wherein a rocker-like element (8) is provided which is arranged in the lumbar spine region (14) such that it can pivot about a horizontally running pivot axle (9), said rocker-like element extending at least partially along the longitudinal direction of the backrest, wherein the pivot axle (9) can be displaced together with the seat part (2a) in the forward and backward direction (4) and a pivotable section (8b) of the rocker-like element (8) is attached to the base frame (3, 11) in a backrest region of the base frame (3, 11).

Owner:GRAMMER AG

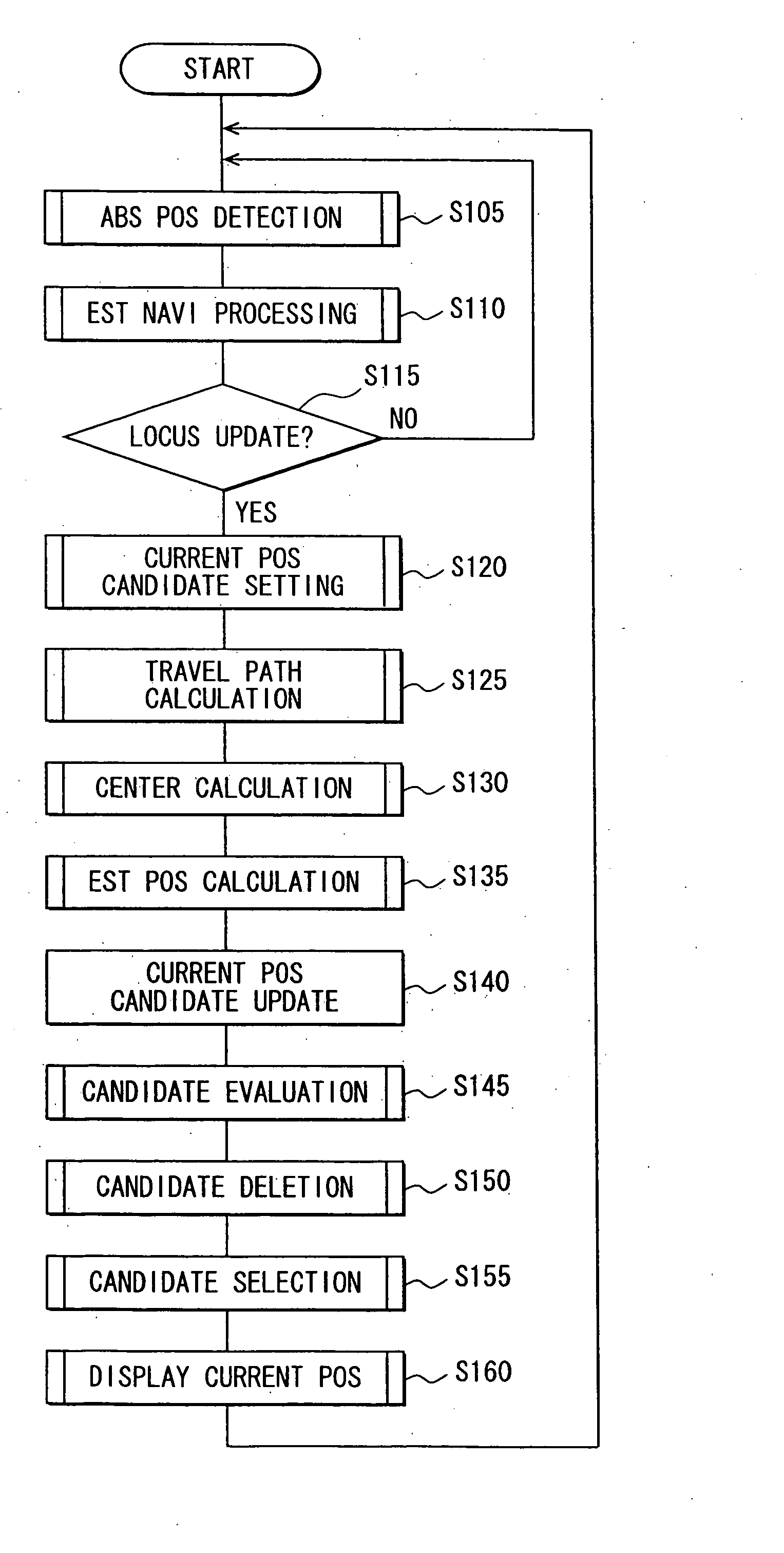

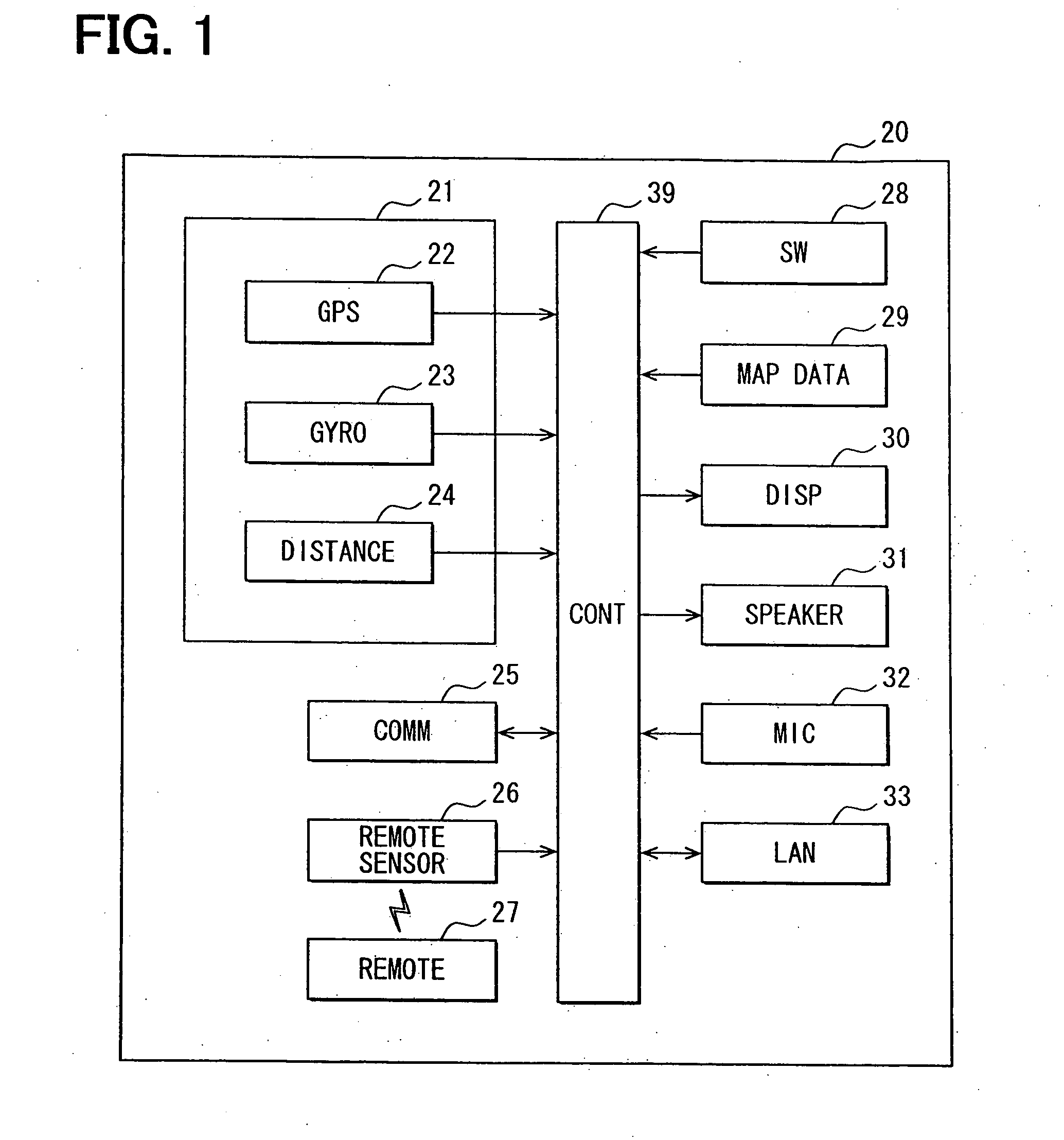

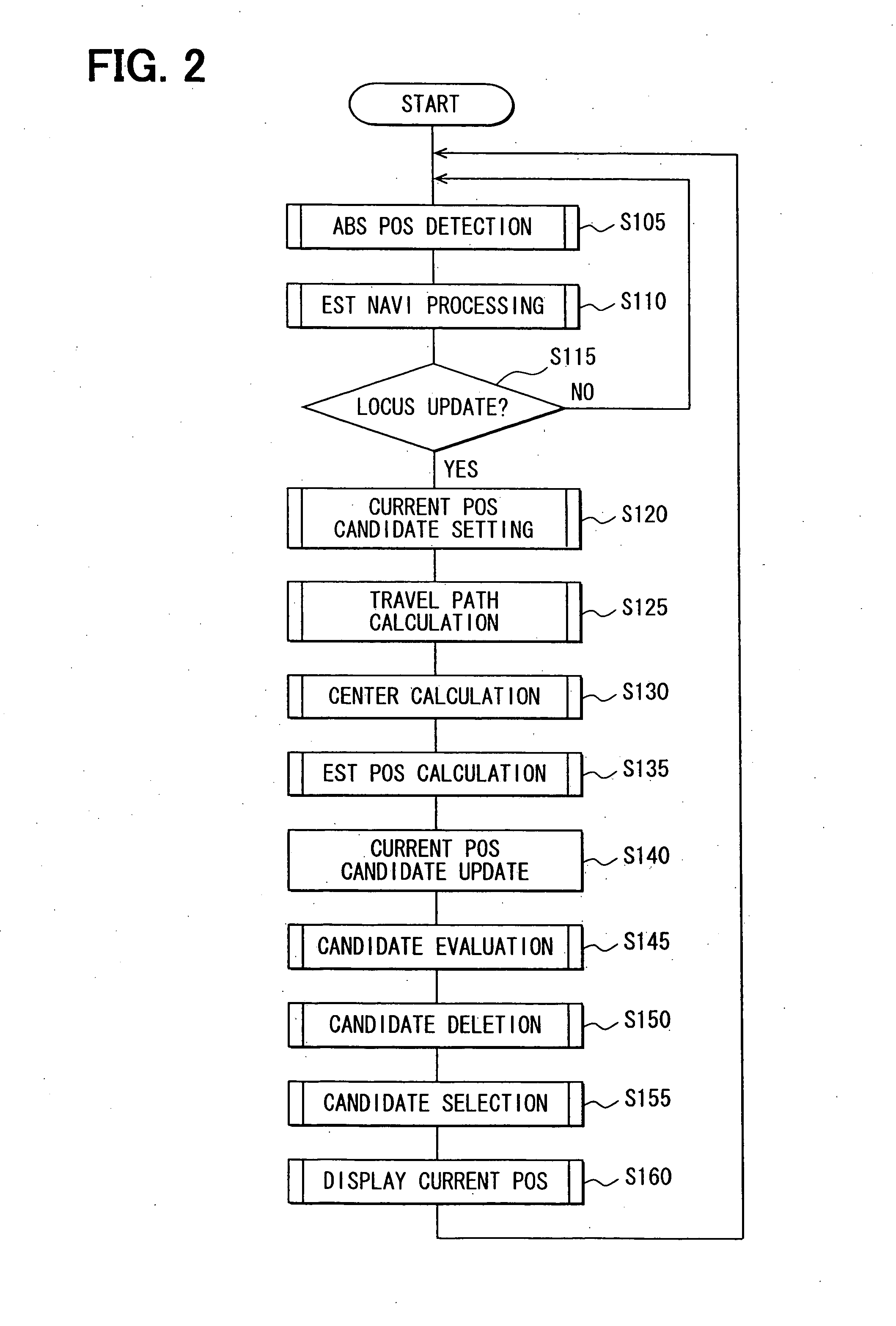

Apparatus and program for finding vehicle position

ActiveUS20090287410A1Reduce computing loadPrecise positioningInstruments for road network navigationRoad vehicles traffic controlMarine navigationEnvironmental geology

Owner:DENSO CORP

Single action anti-torque rod reducer

ActiveUS7771430B2Good effectReduce positioningInternal osteosythesisJoint implantsReducerBiomedical engineering

Owner:K2M

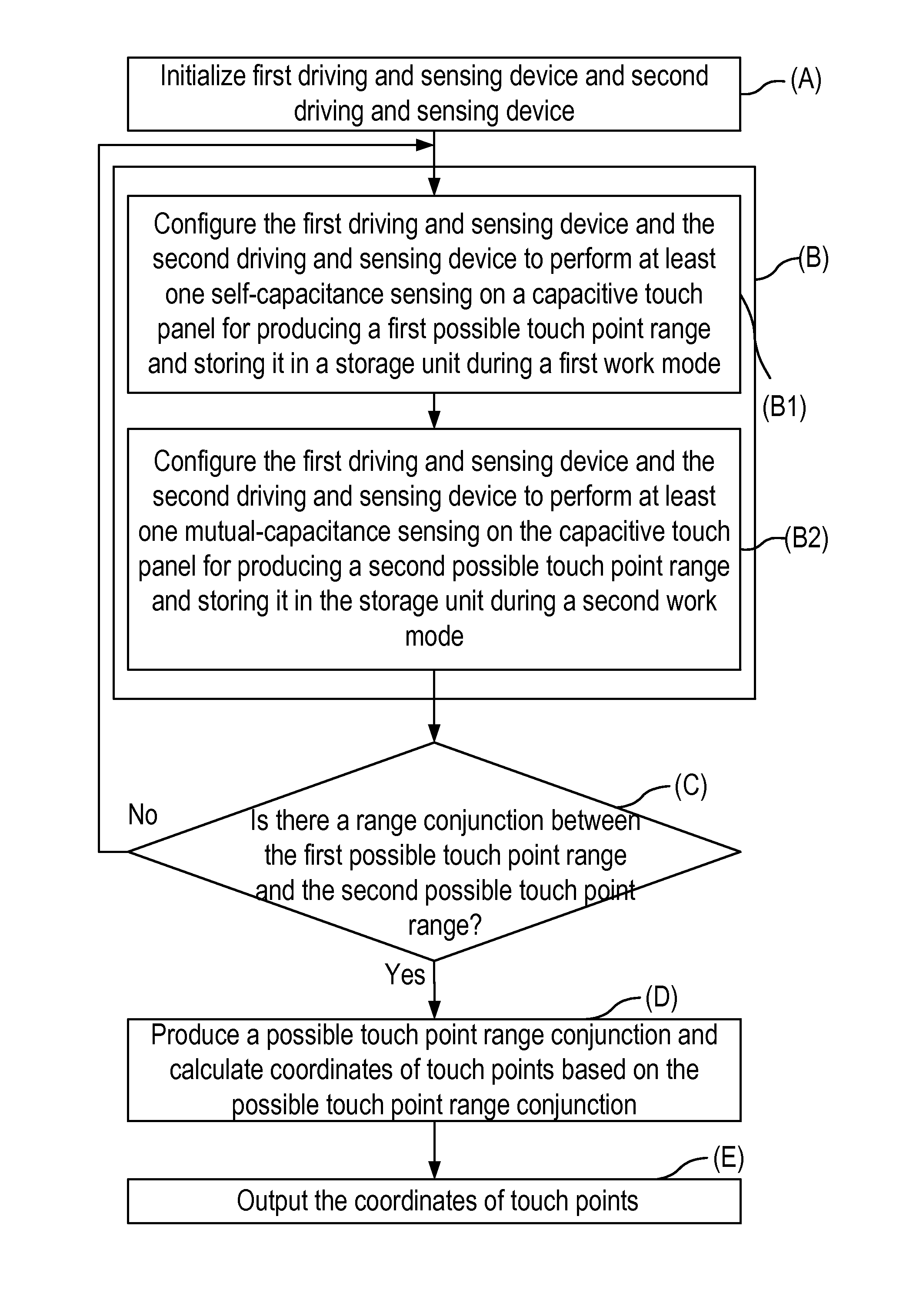

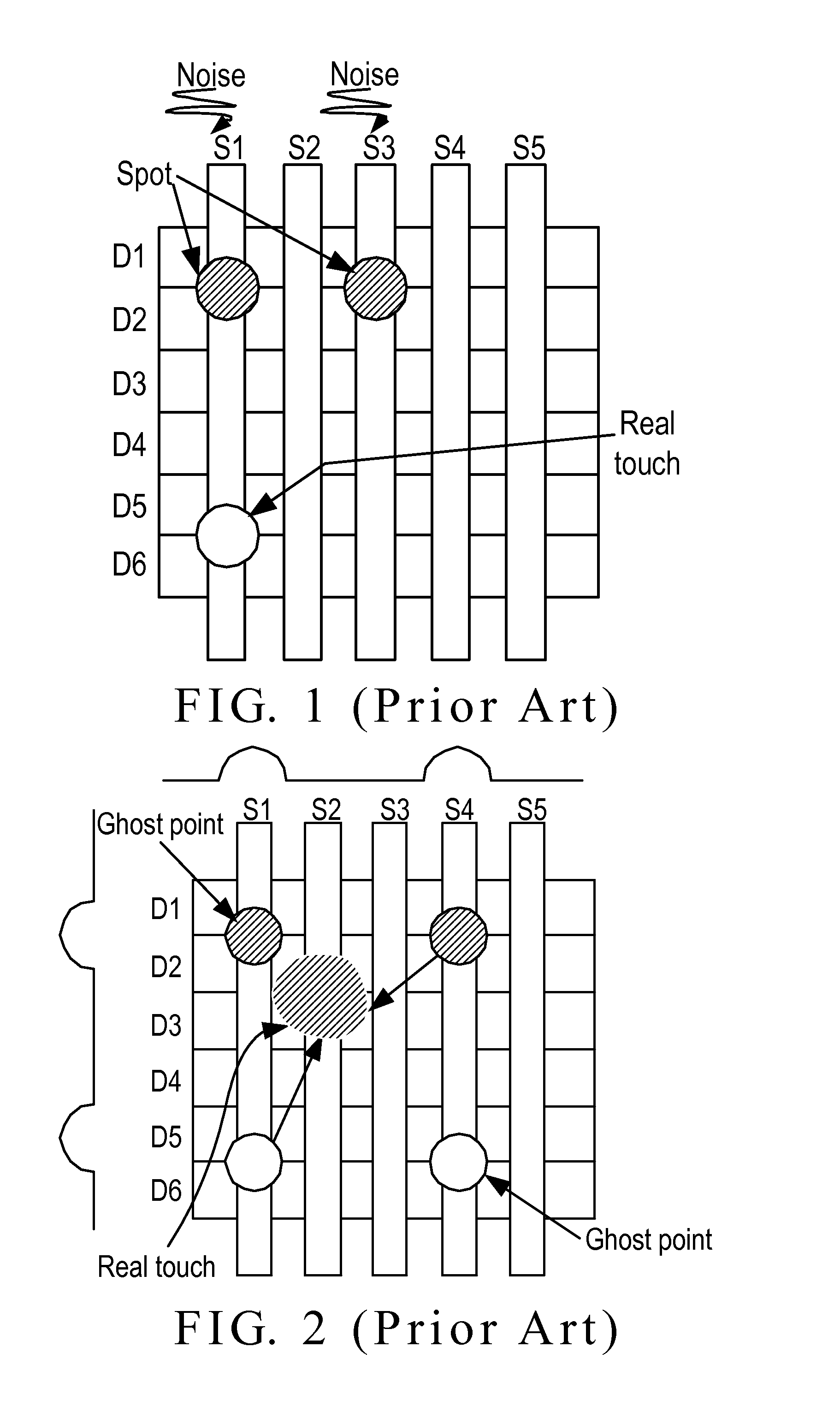

Sensing method using self-capacitance and mutual-capacitance alternatively to reduce touch noises

ActiveUS20140204058A1Reducing touch noiseImprove accuracyInput/output processes for data processingComputer scienceControl equipment

In a sensing method using self-capacitance and mutual-capacitance alternatively to reduce touch noises, a control device configures a first driving and sensing device and a second driving and sensing device to perform an initialization. The control device configures the first and second driving and sensing devices to perform at least one self-capacitance sensing for producing a first possible touch point range during a first work mode. Then, the control device configures the first and second driving and sensing devices to perform at least one mutual-capacitance sensing for producing a second possible touch point range during a second work mode. The control device determines if there is range conjunction between the first and second possible touch point ranges. The control device produces a possible touch point range conjunction and calculates coordinates of touch points based on the possible touch point range conjunction.

Owner:FOCALTECH SYSTEMS LTD

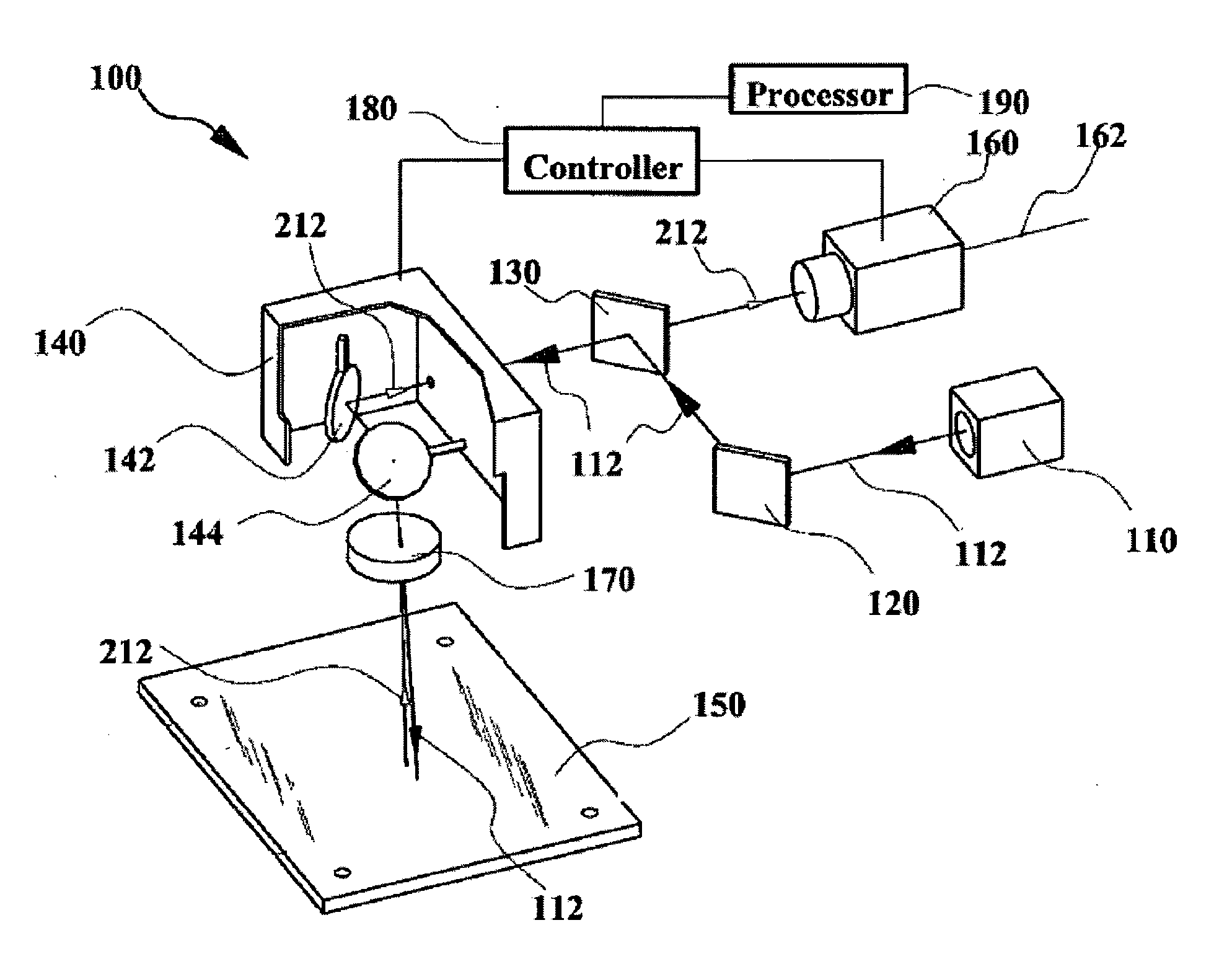

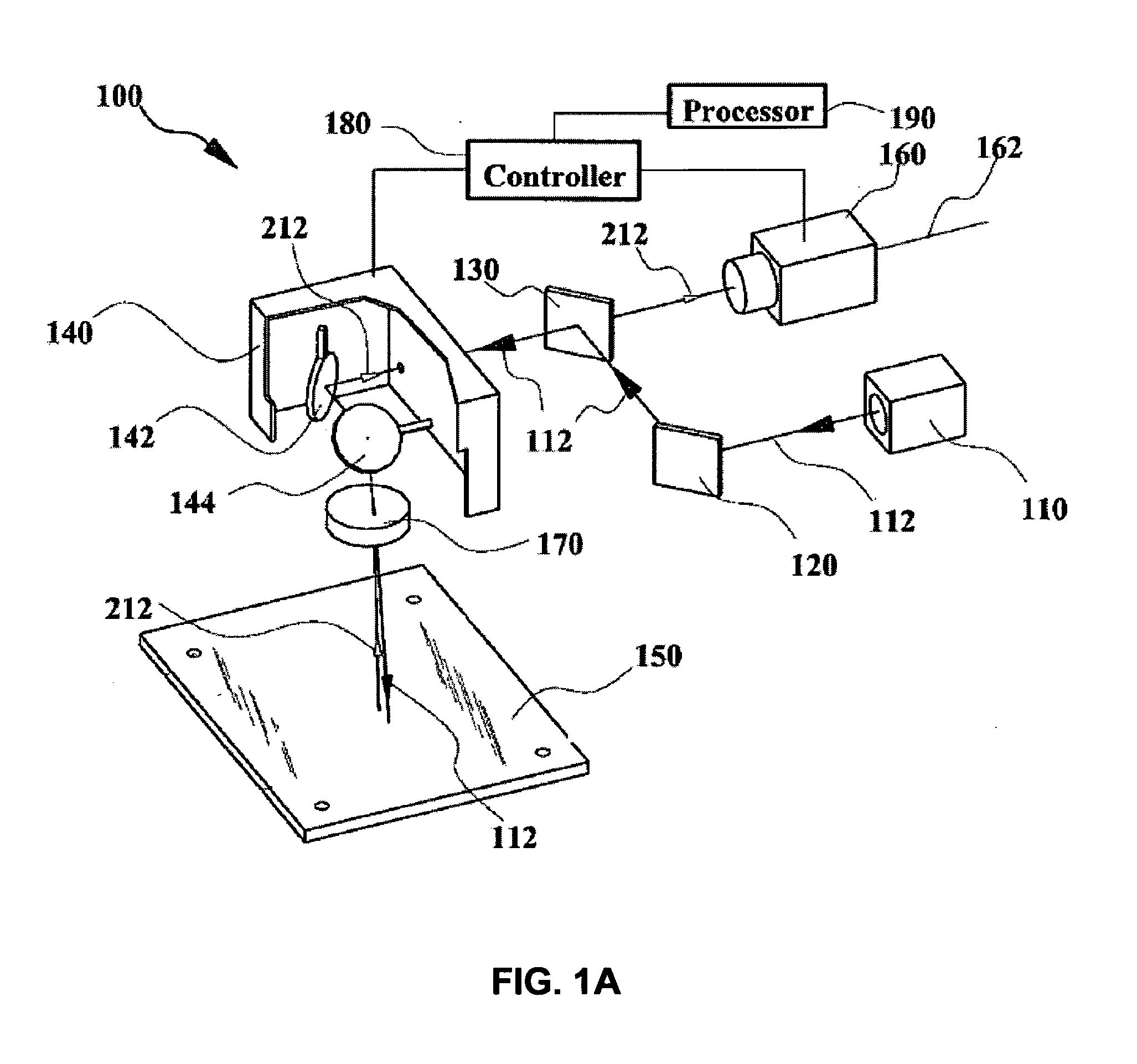

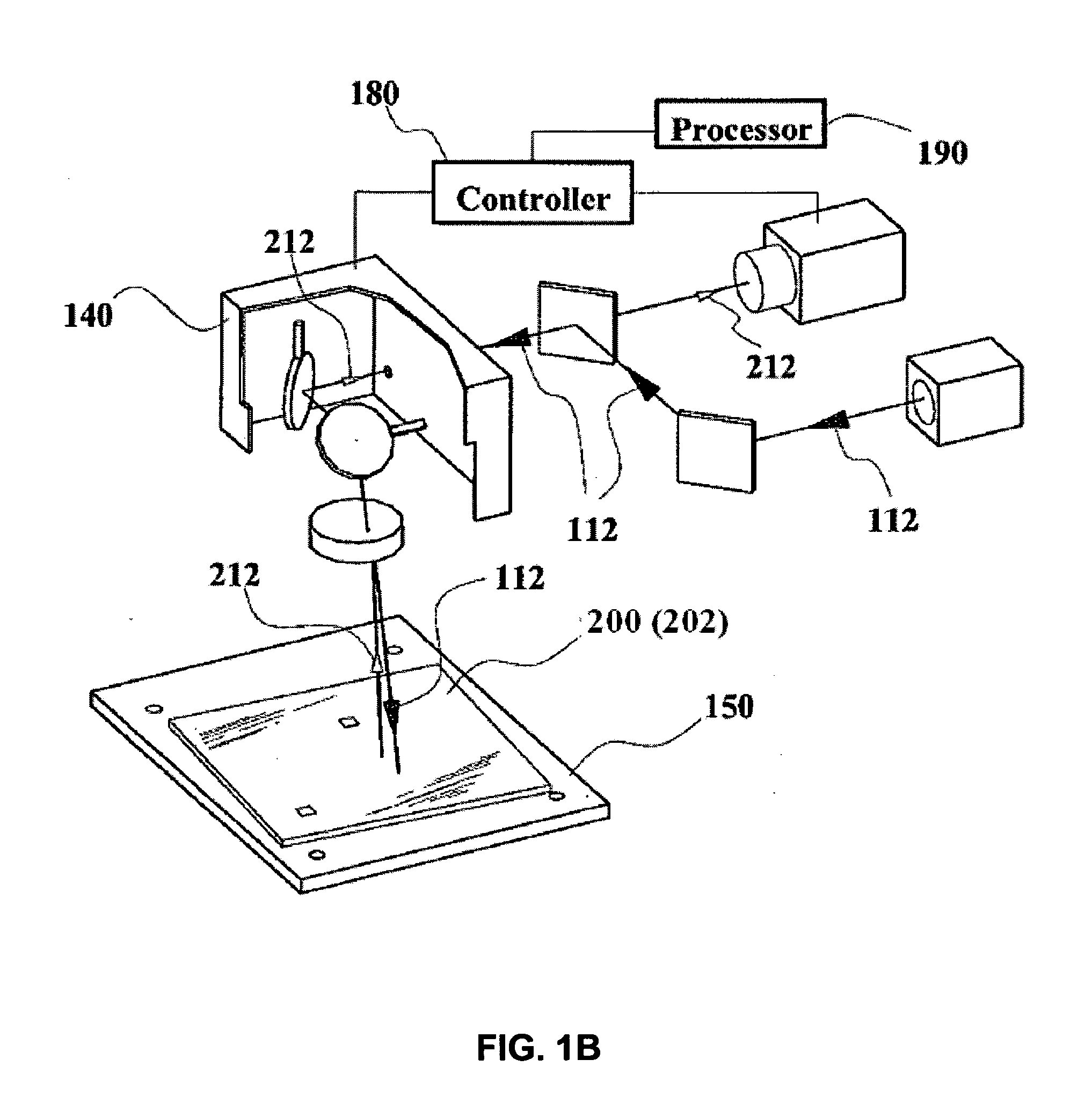

Scan head calibration system and method

InactiveUS20100292947A1Reduce system errorHigh positioning accuracyUsing optical meansTesting/calibration of speed/acceleration/shock measurement devicesVision basedLight beam

A method and system are provided for reducing a positioning error for positioning a light beam either onto or from a workpiece. A calibration mark is provided, and an image of the calibration mark is captured, to compare with a guide mark. The position of the guide mark corresponds to a set of design data or coordinates. The position of the image of the calibration mark is adjusted until the image matches with the guide mark. A set of vision compensating factors can therefore be determined. Thereafter, an image of a laser mark is captured, and adjusted to match the guide mark, to determine a set of scan head compensating factors. The design data can then be modified based on the vision compensating factors and the laser compensating factors, and used to position the laser beam onto the workpiece or capture light from a work piece to form an image.

Owner:COHERENT SINGAPORE PTE

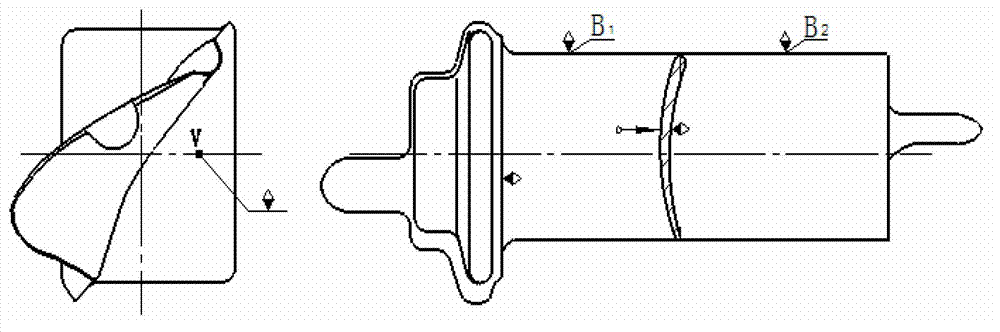

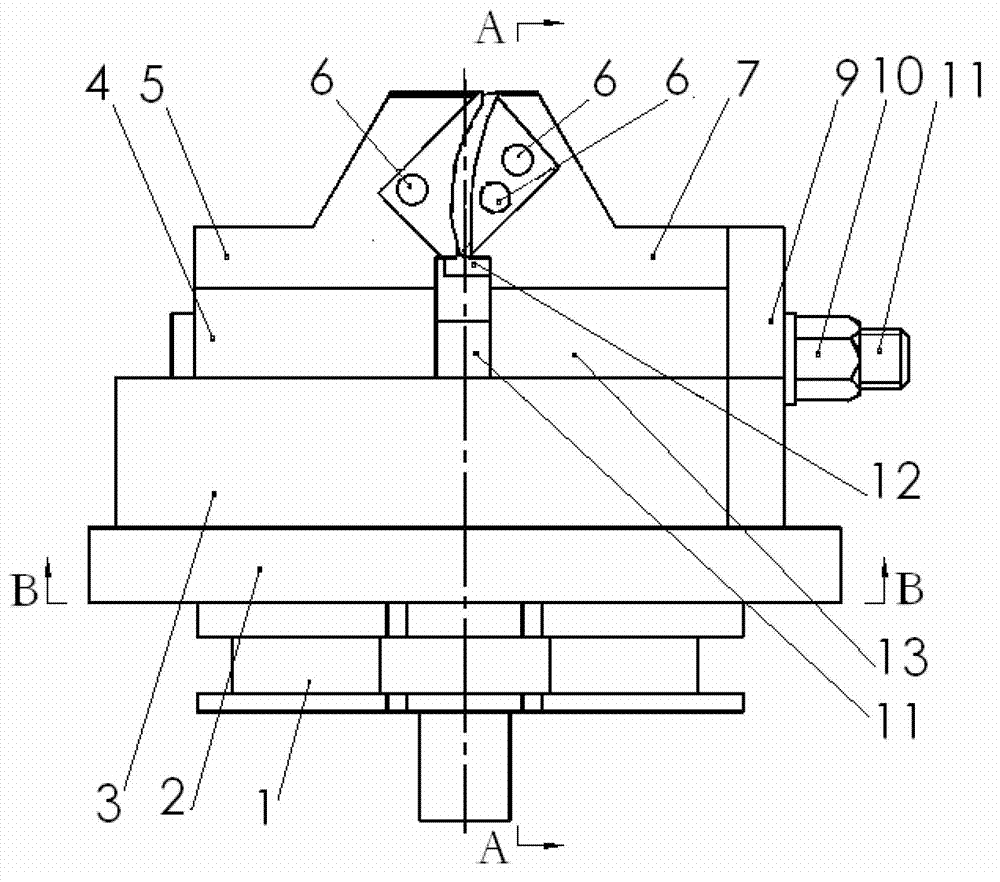

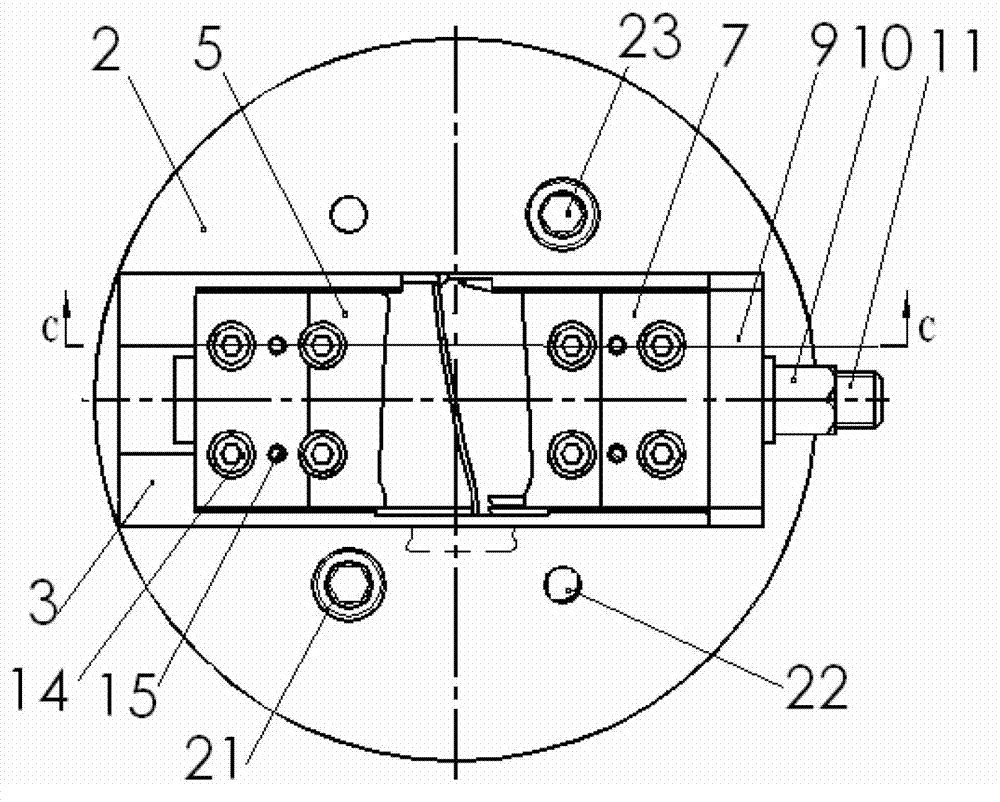

Method and clamp for moulding surface positioning clamping of finish forge blade

ActiveCN102773733AImprove rigidityImprove quality and efficiencyPositioning apparatusMetal-working holdersAdhesiveEngineering

The invention relates to a method and a clamp for moulding surface positioning clamping of a finish forge blade. According to the method, a vane is subjected to positioning clamping through a basin mounding surface of the blade, an inner side moulding surface of a blade root marginal plate, and a V point on the inner side mounting surface of the blade root marginal plate, by the positioning of an air inlet edge, and the clamping of a back mounding surface of the blade, as well as by using a high-accuracy positioning adhesive, and an adhesive coating method, and through a positioning block of the basin moulding surface of the blade and a clamping block of the back moulding surface of the blade. According to the method and the clamp, a satisfying contact area can be obtained by adoption of the high-accuracy adhesive, and the positioning rigidity of the blade is enhanced by adoption of the basin moulding surface of the blade, the inner side moulding surface of the blade root marginal plate and the V point on the inner side moulding surface of the blade root marginal plate for the positioning. According to the method and the device, the problems that the accurate positioning is difficult to realize and the moulding surface of the blade deforms or is damaged because the blade is thin, the blade body is small and the moulding surface is complex are solved. By the method and the device, the positioning accuracy of the mechanical processing of the blade is improved, and the technological process is optimized, so that the processing quality and the production efficiency of the blade are improved, the process is simple, the number of fixtures is reduced, the processing cycle is shortened, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

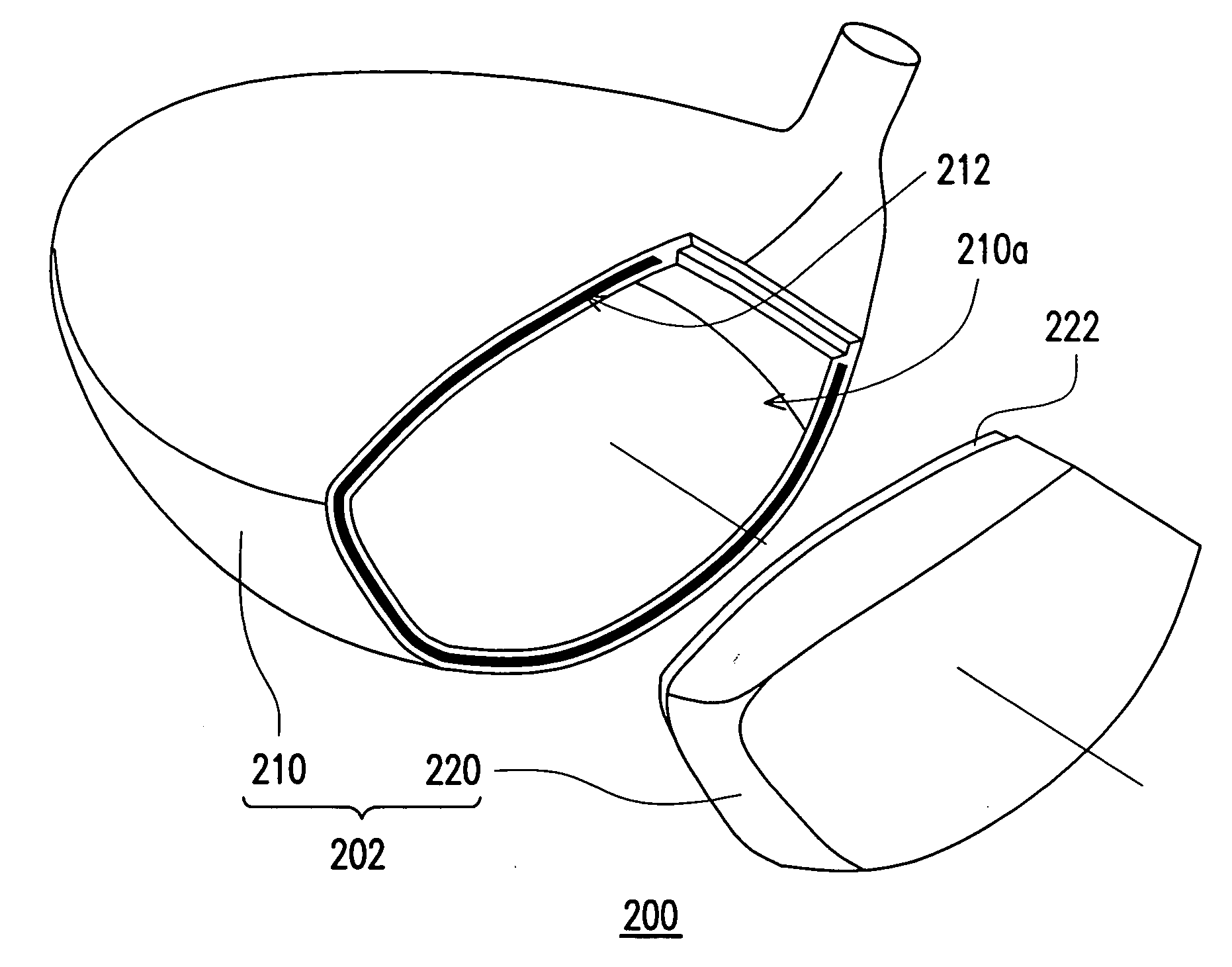

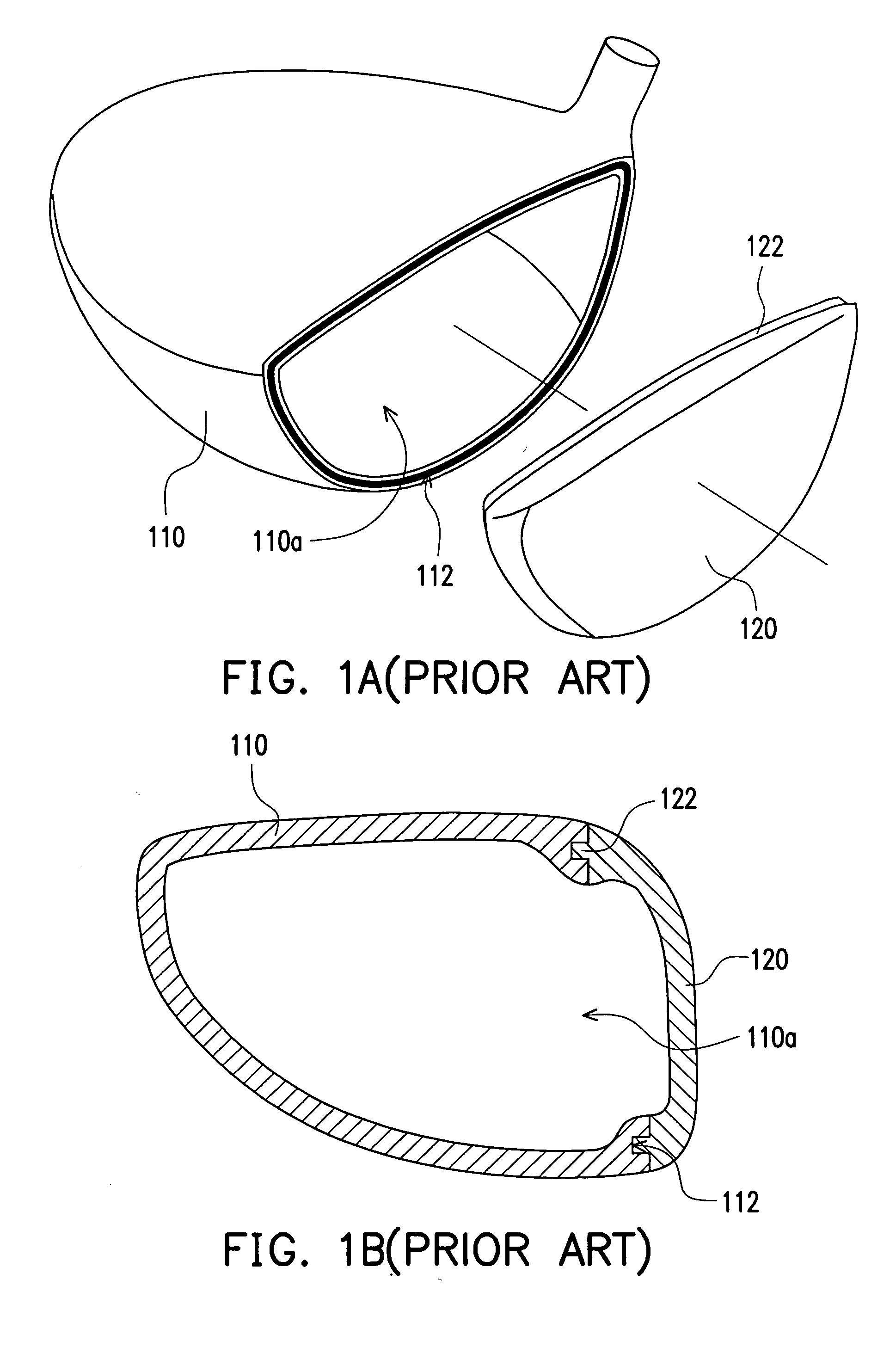

Golf club head

A golf club head which mainly includes a shell and a striking plate is provided. In which, the shell has an opening, and a portion of the edge of the opening of the shell has a first engagement portion. Furthermore, the striking plate is located at the opening, and with the shell forms a golf club head. A portion of the edge of the striking plate has a second engagement portion, which is corresponding to the first engagement portion. The shell and the striking plate are mutually engaged respectively using the first engagement portion and the second engagement portion. The golf club head has superior structural strength and manufacturing yield.

Owner:FUSHENG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com