Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112 results about "Bulbous bow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bulbous bow is a protruding bulb at the bow (or front) of a ship just below the waterline. The bulb modifies the way the water flows around the hull, reducing drag and thus increasing speed, range, fuel efficiency, and stability. Large ships with bulbous bows generally have twelve to fifteen percent better fuel efficiency than similar vessels without them. A bulbous bow also increases the buoyancy of the forward part and hence reduces the pitching of the ship to a small degree.

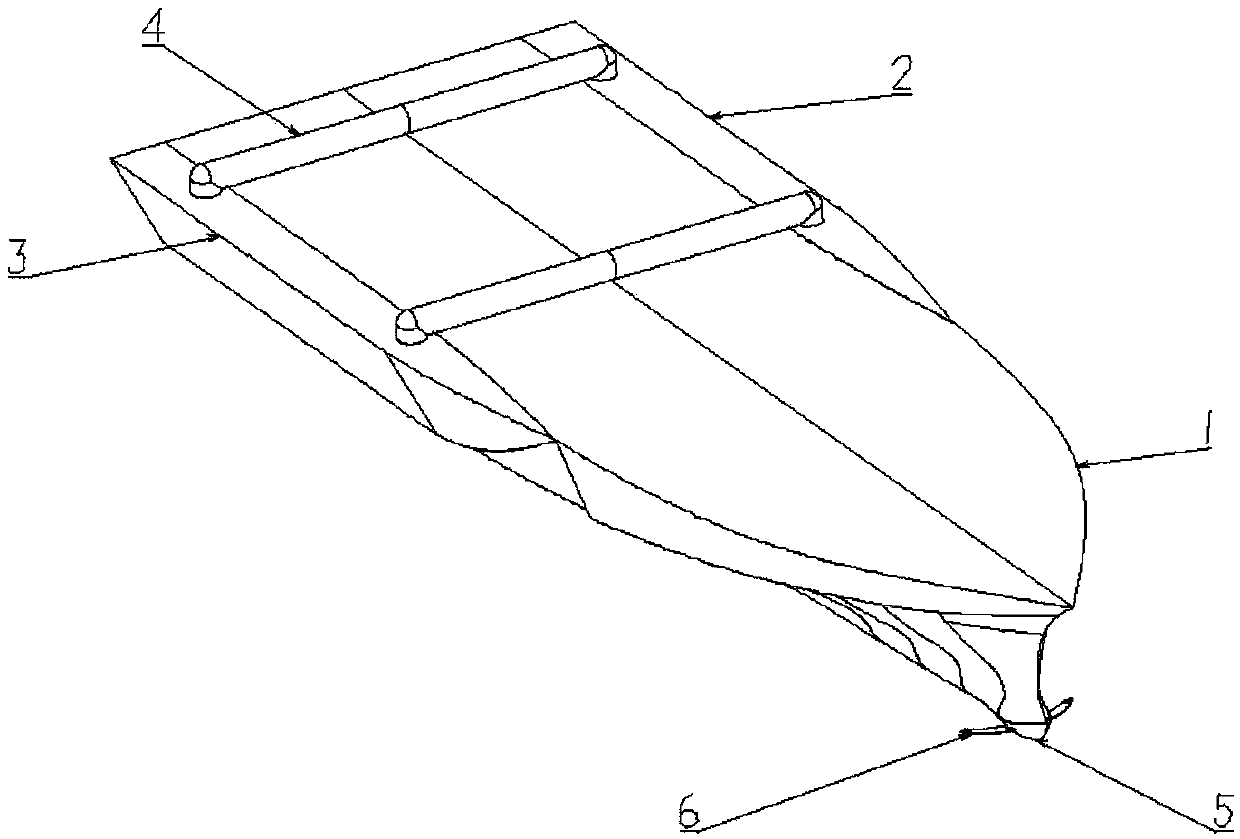

Supercavity-hydrofoil triple-hulled vessel

PendingCN107150760AReduce the impact of wave resistanceStable supercavitationRotary propellersWatercraft hull designVertical vibrationCavitation

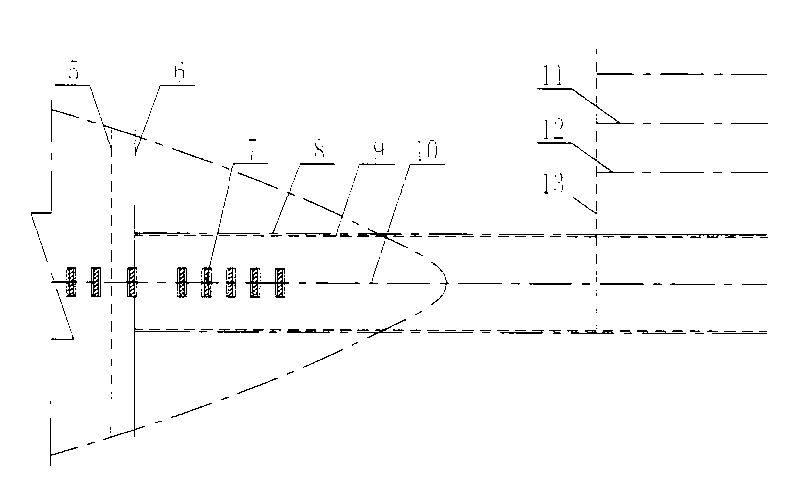

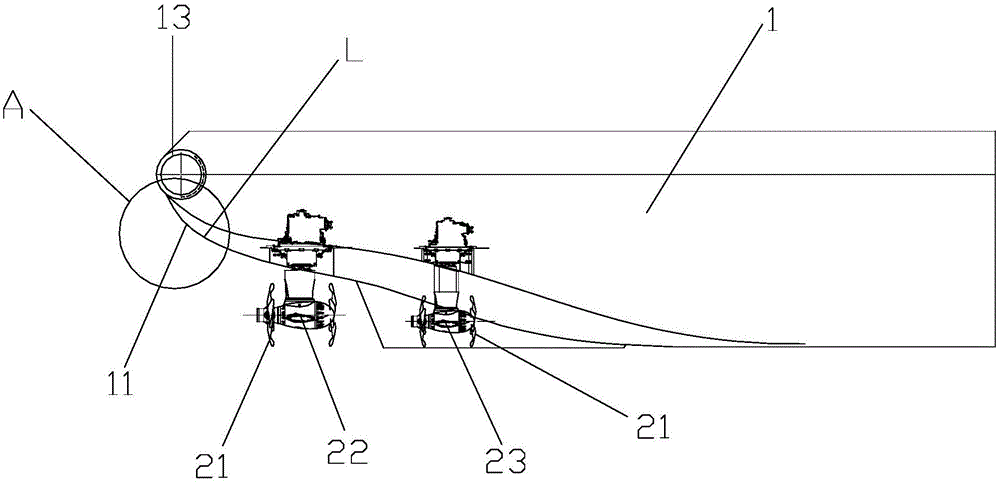

The invention discloses a supercavity-hydrofoil triple-hulled vessel. Double bulbous bows are arranged at the front end of a main hull; a retractable adjusting hydrofoil and a fixed submersible hydrofoil are arranged at the bottom of the main hull; a cavitation device is arranged on each of the retractable adjusting hydrofoil and the fixed submersible hydrofoil; a ducted fan-type propeller is further arranged at the back part of the fixed submersible hydrofoil on the tail part; fixed submersible hydrofoils are arranged at the tail parts of the auxiliary hulls. A medium on the surfaces of the hulls is changed from water into a mixture of water and vapor, so that the sailing speed of the ship is increased, the hulls can be lifted to reduce friction between water and the hulls, longitudinal shaking, vertical vibration and other adverse effects of the hulls to relatively large extent are avoided, and the resistance reducing efficiency of the hydrofoils is greatly improved; the ducted fan-type propeller improves the propulsive efficiency, and the service life of the propeller is significantly prolonged.

Owner:ZHEJIANG UNIV

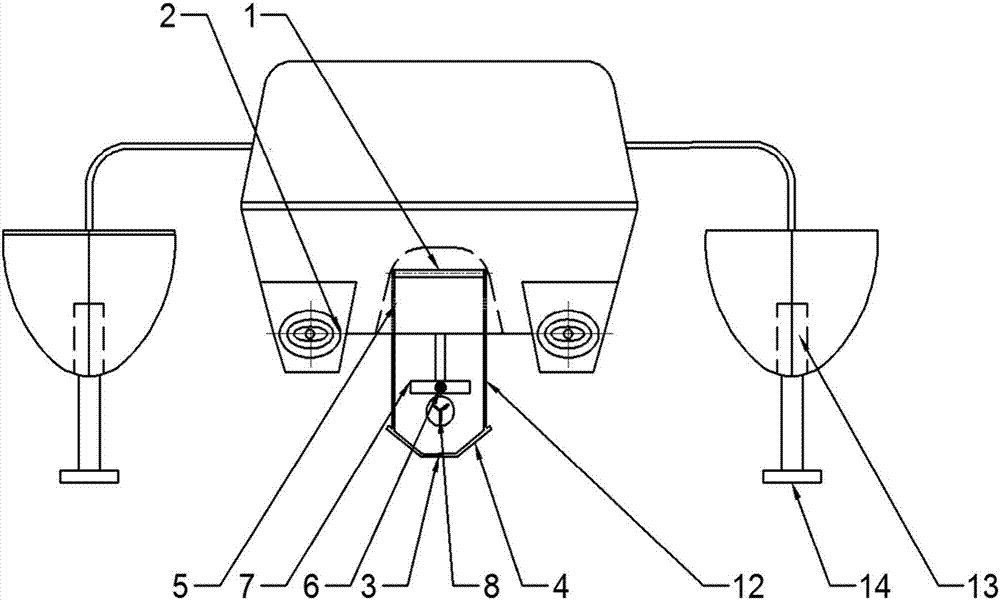

Deformable planing boat with both rapidity and seakeeping ability

InactiveCN107672737AImprove seakeepingVessel designingHydrodynamic/hydrostatic featuresBody shapeSeakeeping

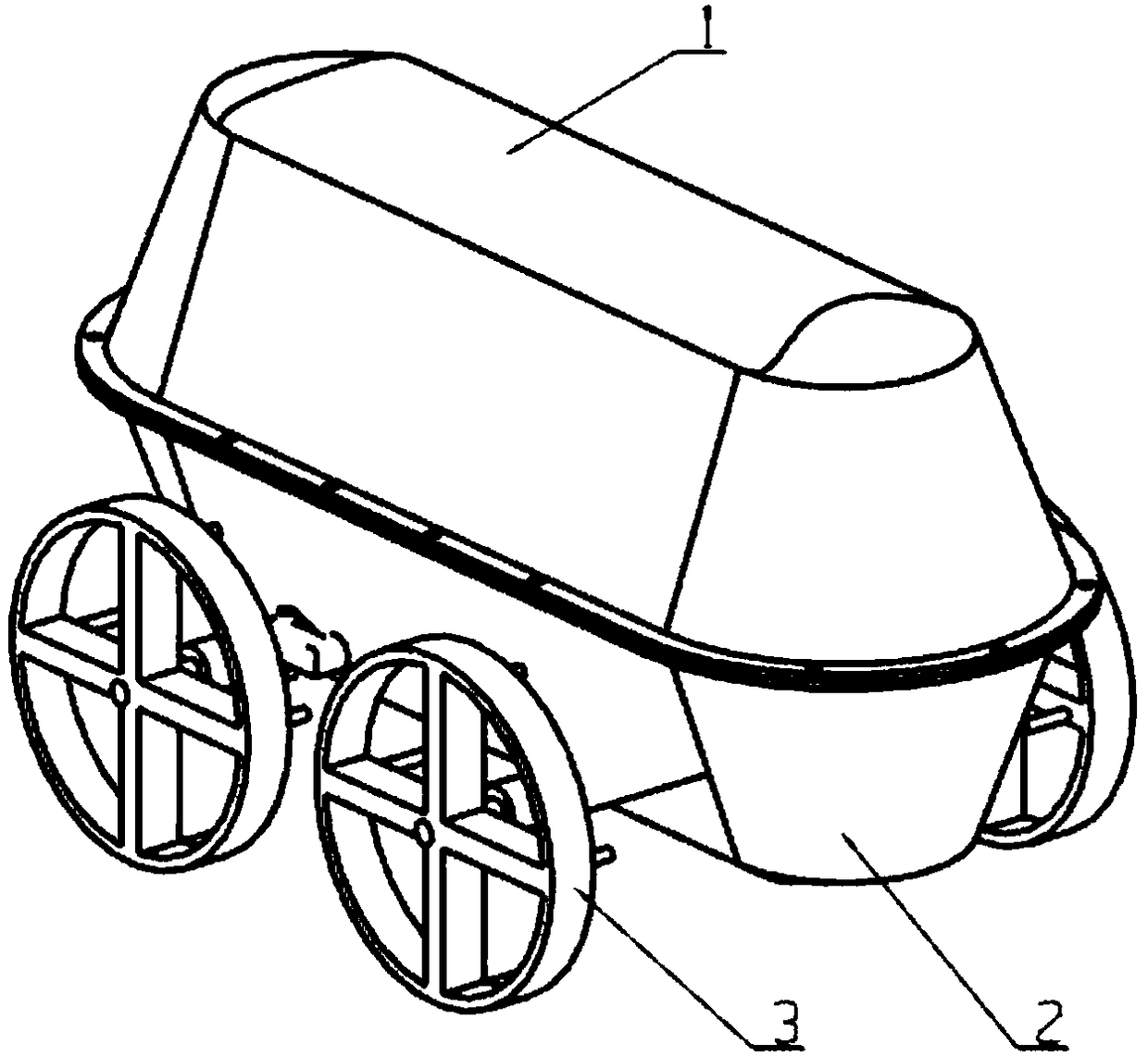

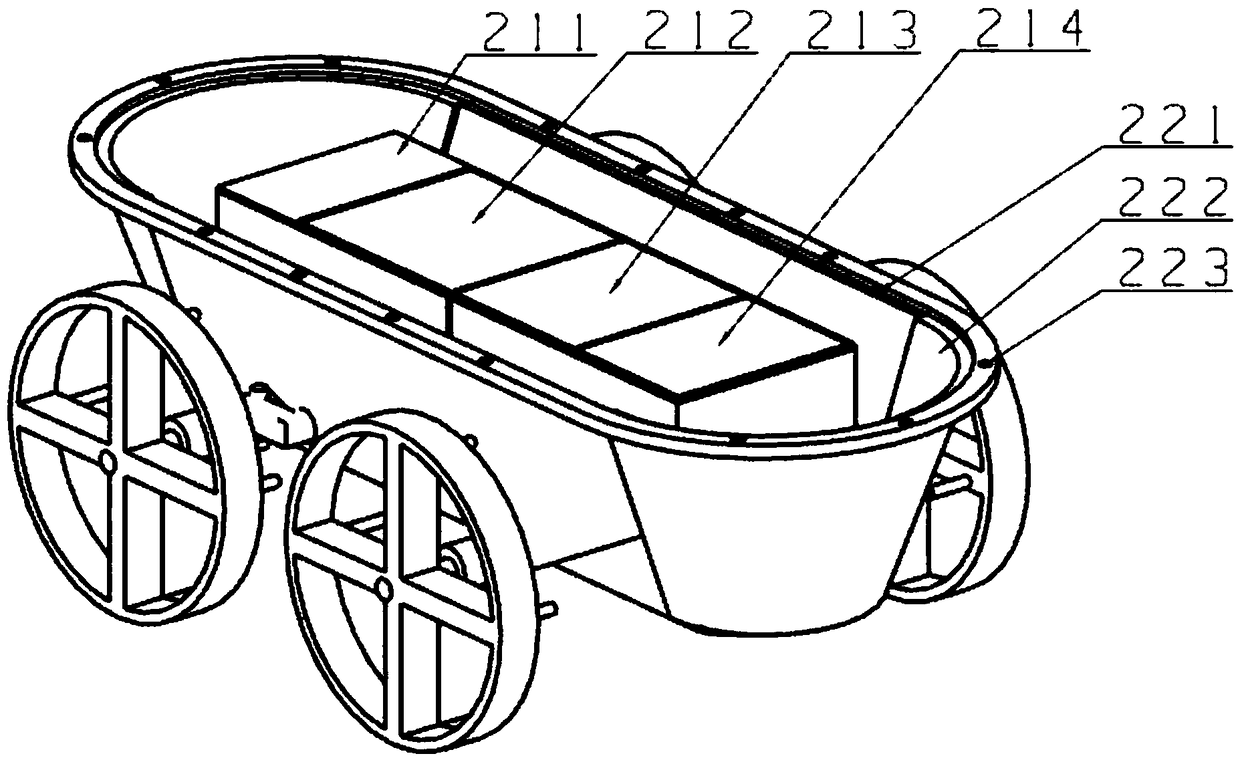

The invention belongs to the field of high-performance ship design and ship moving posture control and particularly relates to a deformable planing boat with both rapidity and the seakeeping ability.The problem that the high speed and the high seakeeping ability cannot be both taken into account in the prior art is solved. The deformable planing boat comprises a main boat body, a first appendage,a second appendage, inverted-U-shaped sliding rails, a bulbous bow and fixed hydrofoils. Each inverted-U-shaped sliding rail comprises vertical guide rails and transverse guide rails. The tail ends of the transverse guide rails are connected with the vertical guide rails, and the vertical guide rails and the transverse guide rails are mutually perpendicular. The first appendage and the second appendage are connected with the ends, close to the water surface, of the vertical guide rails and located on the two sides of the main boat body correspondingly. The bulbous bow is mounted at the bottomof a boat bow of the main boat body, and the fixed hydrofoils are symmetrically mounted on the two sides of the bulbous bow. By changing the boat body shape, the planing boat adapts to the sea conditions of different grades, under the condition that rapidity is not greatly reduced, the good seakeeping ability is obtained, the application range of the planing boat is greatly enlarged, and the taskcarrying-out ability of the planing boat under the severe sea conditions is greatly improved.

Owner:HARBIN ENG UNIV

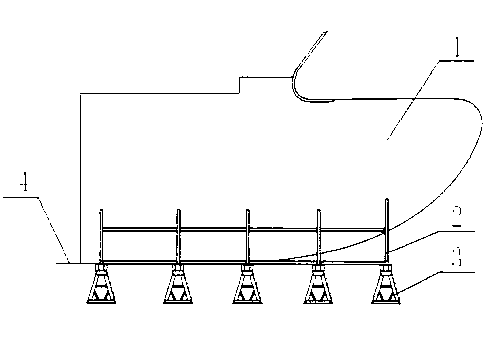

Vehicular bulbous bow integral-replacing process

ActiveCN103192952AShorten docking periodReduce labor intensityVessel partsStructural engineeringMechanical engineering

The invention discloses a vehicular bulbous bow integral-replacing process and belongs to the technical field of ship repair and construction. By sectionally prefabricating and assembling a new bulbous bows and cutting an old bulbous bow, the vehicular bulbous bow integral-replacing process mainly includes steps of marking a positioning line, a datum line and a guide line on a dock bottom surface, arranging and adjusting a docking block, additionally arranging lifting buttresses on two sides of a bow portion, integrally packing the old bulbous bow and the new bulbous bow, disposing a split positioning machine and accurately centering, positioning and folding. The vehicular bulbous bow integral-replacing process has the advantages that docking period is shortened to 15 days from existing 30-40 days; prefabricating and assembling of the new bulbous bow are realized in a machine room, engineer quality and construction accuracy can reach novel shipbuilding level; operation is convenient, reliable and quick, alignment speed and accuracy are greatly increased, workload is greatly reduced, and labor intensity and labor cost are reduced; occupation time of shipyard equipment and facilities is short, and production cost of replacement of the bulbous bow is reduced. The vehicular bulbous bow integral-replacing process can be widely used for the fields of ship repair and construction.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

Process for manufacturing ice zone bulbous bow reinforcing structure by sections

ActiveCN104760662AShorten the construction periodIncrease productivityHull stemsEngineeringMechanical engineering

The invention relates to a process for manufacturing an ice zone bulbous bow reinforcing structure by sections. An angle steel combined horizontal tangent rib frame is adopted during bulbous bow sectioning, and a strong rib frame is used as a reference surface for lying manufacturing. The process for manufacturing by sections comprises the following steps: sectioning; putting a strong rib frame large assembly on a jig; putting a first layer platform large assembly on the jig and assembling; putting a second layer platform large assembly on the jig and assembling; putting a third layer platform large assembly on the jig and assembling: assembling a third layer platform plate and a third strong rib frame assembly into the third layer platform large assembly; putting a fourth layer platform large assembly on the jig and assembling; assembling a third middle longitudinal girder assembly and a fourth middle longitudinal girder assembly into a whole; mounting ribs; mounting an external plate. The process has the advantages that the angle steel combined horizontal tangent rib frame is adopted, and the strong rib frame is used as the reference surface for lying manufacturing, so that the production efficiency is improved, the period for constructing the bulbous bow by sections is shortened, and the shipbuilding speed is increased.

Owner:南通华川交通装备有限责任公司

Amphibious aircraft

InactiveCN108162706ASufficient driving forceEasy to controlAmphibious vehiclesRotational axisWireless control

The invention discloses an amphibious aircraft. The amphibious aircraft comprises a walking mechanism portion, a driving mechanism energy source portion, a control mechanism portion, a blade rotatingportion, a steering mechanism portion, a ballast tank portion, a detection module portion, and an actuator module. The amphibious aircraft is the design of a ship traveling motion mode and uses the wireless control of buttons and touch keys to work together to control the overall movement. The amphibious aircraft preprocesses the collected information, and finally stores the collected data throughwireless transmission of digital signals. The amphibious aircraft is mainly characterized in that a bulbous-bow design is adopted for the outer bulkhead of the whole amphibious aircraft, curved arcsare only available at the top and bottom of amphibious aircraft, each wheel spindle is formed by the connection of two blades and a rotating shaft through a cylindrical cam, and the ballast tank portion adopts the design of controlling the content of ballast water and adopts separated ballast tanks to facilitate the sailing of the amphibious aircraft in the water.

Owner:SHANGHAI OCEAN UNIV

Process for manufacturing bulbous bow in left-right split manner then in combined manner

ActiveCN103407546AReduce manufacturing costReduce labor intensityVessel partsButt weldingEngineering

The invention relates to a process for manufacturing a bulbous bow in a left-right split manner then in a combined manner. The process comprises the steps of left part manufacturing, right part manufacturing and integral manufacturing of the bulbous bow, wherein a left part and a right part are manufactured in a combined manner with a partition board at the most tail end taken as a datum plate; and the integrated bulbous bow is formed; in the left part manufacturing and the right part manufacturing, original aloft operation of framework assembly, framework welding and butt welding of an outer upper plate and an outer plate is changed into normal operation, the left part and the right part are turned horizontally, and fillet welding of the outer plate and the framework is performed. Original difficult operation of the fillet welding of the outer plate and the framework in a narrow space is changed into the normal operation, so that the labor intensity of a constructor is reduced to a large extent, the efficiency is improved by more than 40% at the same time, the processing cycle is shortened, the manufacturing cost of the bulbous bow is saved, and the process has a wide market prospect.

Owner:FUJIAN XINSHENG SHIPBUILDING

Deep diving operation supporting ship

InactiveCN104229082AReasonable arrangementCompact structureHull reinforcementsSpecial purpose vesselsMarine engineeringRemote control

The invention discloses a deep diving operation supporting ship which comprises a bulbous bow, a working deck, a fully-rotating propelling plant, a lifting system, a saturation diving system, an air diving system and a remote control detection working system, wherein the bulbous bow is arranged on a ship foremost region, the working deck is arranged on a ship midship region and a ship tail region, the fully-rotating propelling plant is arranged on the ship tail region, the lifting system is arranged on the ship midship region through stand columns, the saturation diving system is arranged between the ship foremost region and the ship midship region, the air diving system is arranged on a ship side region, and the remote control detection working system is arranged on the ship side region. According to the deep diving operation supporting ship, the fully-rotating propelling plant can be arranged reasonably through the tail shaped line design, and the deep diving operation supporting ship has the advantages that all function regions are compact in structural layout and high in integration level.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

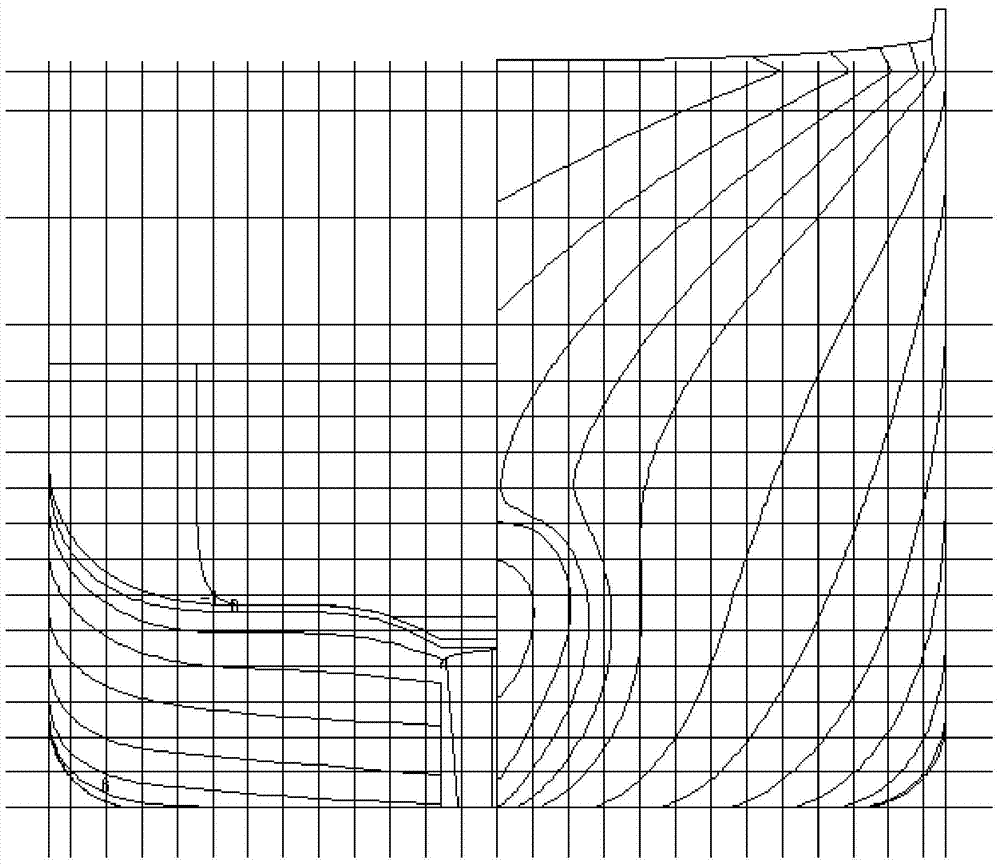

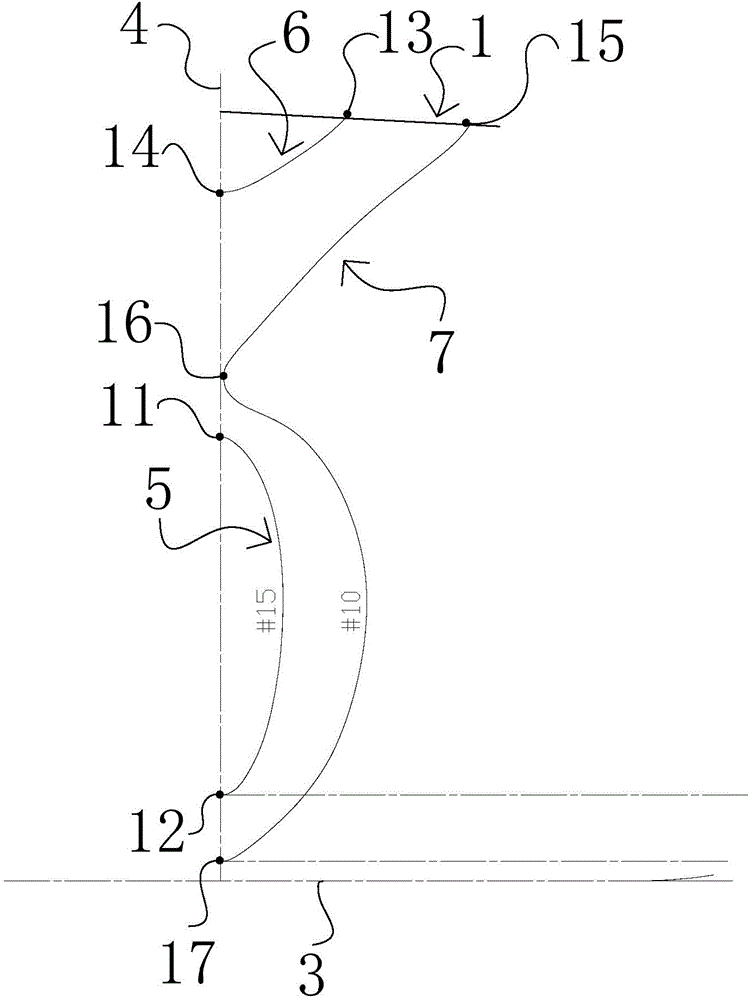

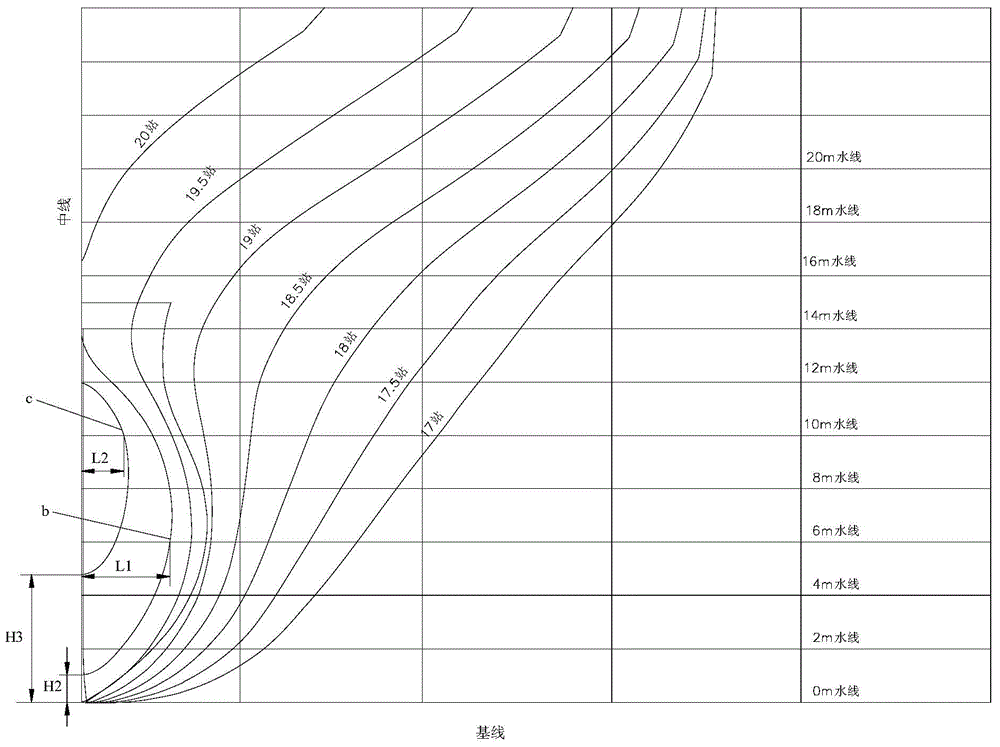

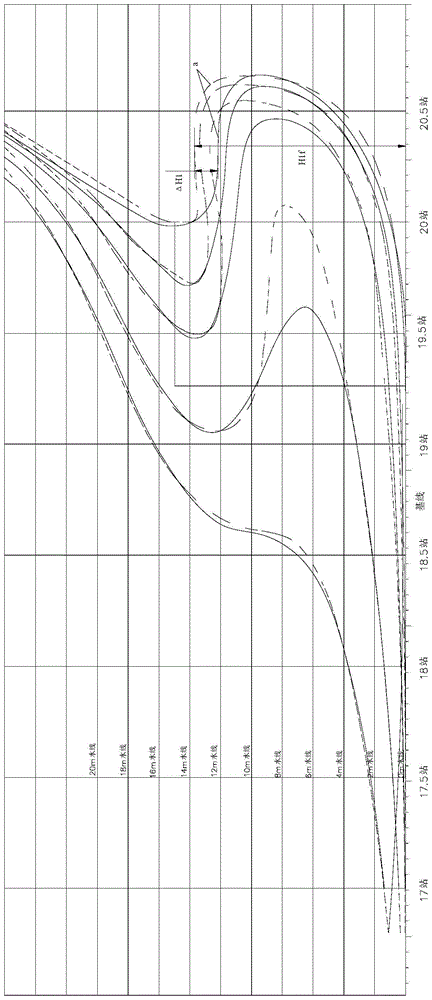

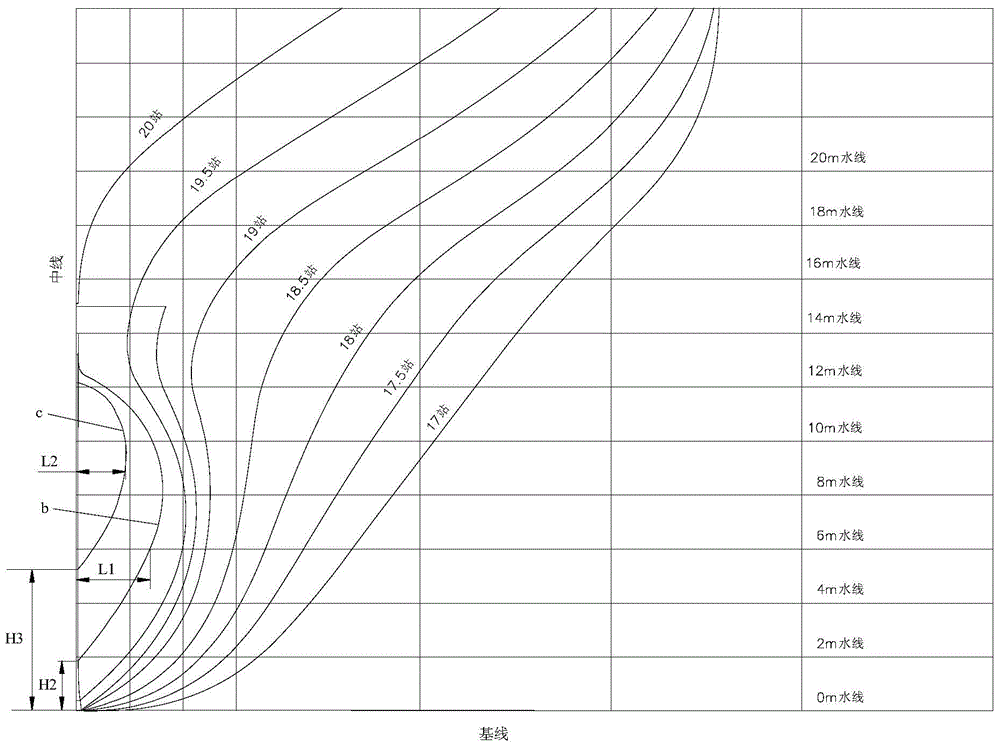

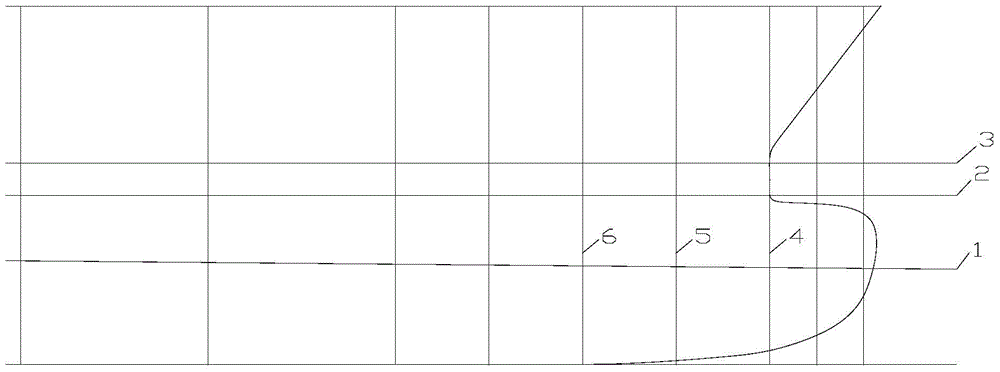

Expansion method for contour line of bulbous bow

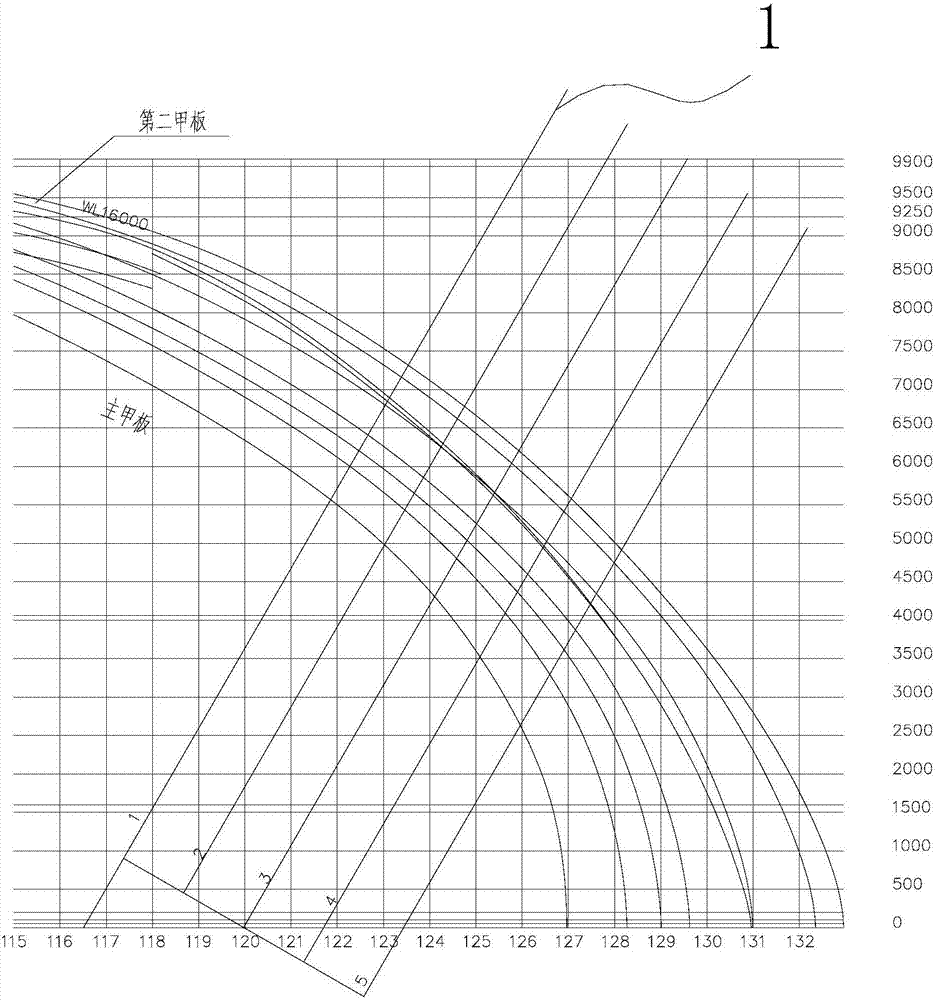

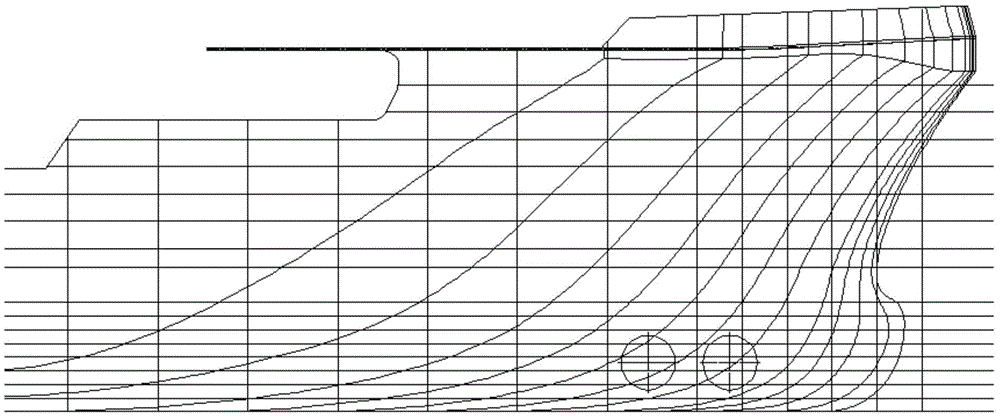

The invention provides an expansion method for a contour line of a bulbous bow. The expansion method specifically comprises the following steps: S1, sequentially drawing distances from various points to a baseline on a middle longitudinal section plan of the bulbous bow onto a shell expansion plan, expanding transverse curvature and not expanding longitudinal curvature of a bulb in a shell expansion way, and smoothly connecting the various points on the shell expansion plan to form an expanded outer contour line of the bulb; S2, determining an inflection point between the bulb and a shell which is adjacent to the bulb, wherein the inflection point is one point at the top of the bulb; S3, for the shell bow contour line above the inflection point on the shell expansion plan, by taking the contour line above the inflection point of the bow contour line in the middle longitudinal section plan as reference, further expanding other shell parts according to the principle of only expanding the transverse curvature and not expanding the longitudinal curvature. By adopting the expansion method provided by the invention, the bulb and the adjacent shell structure can be correctly expanded, and the shape and the size of the shell can be truly reflected, thereby being conductive to determining the specification of the shell; meanwhile, typesetting, lofting, nesting and processing of the shell in the late stage are guided.

Owner:SHANGHAI WAIGAOQIAO SHIPBUILDING & OFFSHORE ENG +1

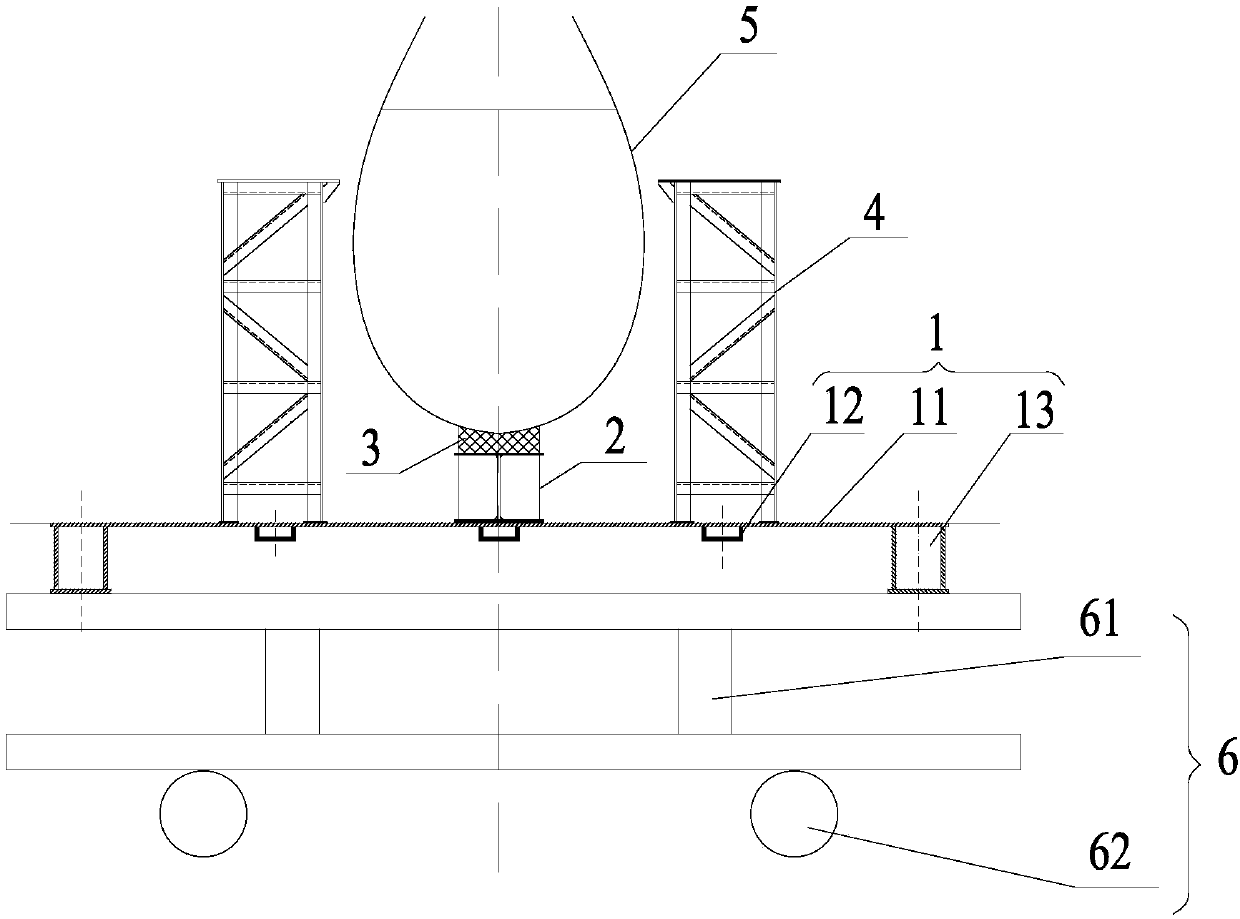

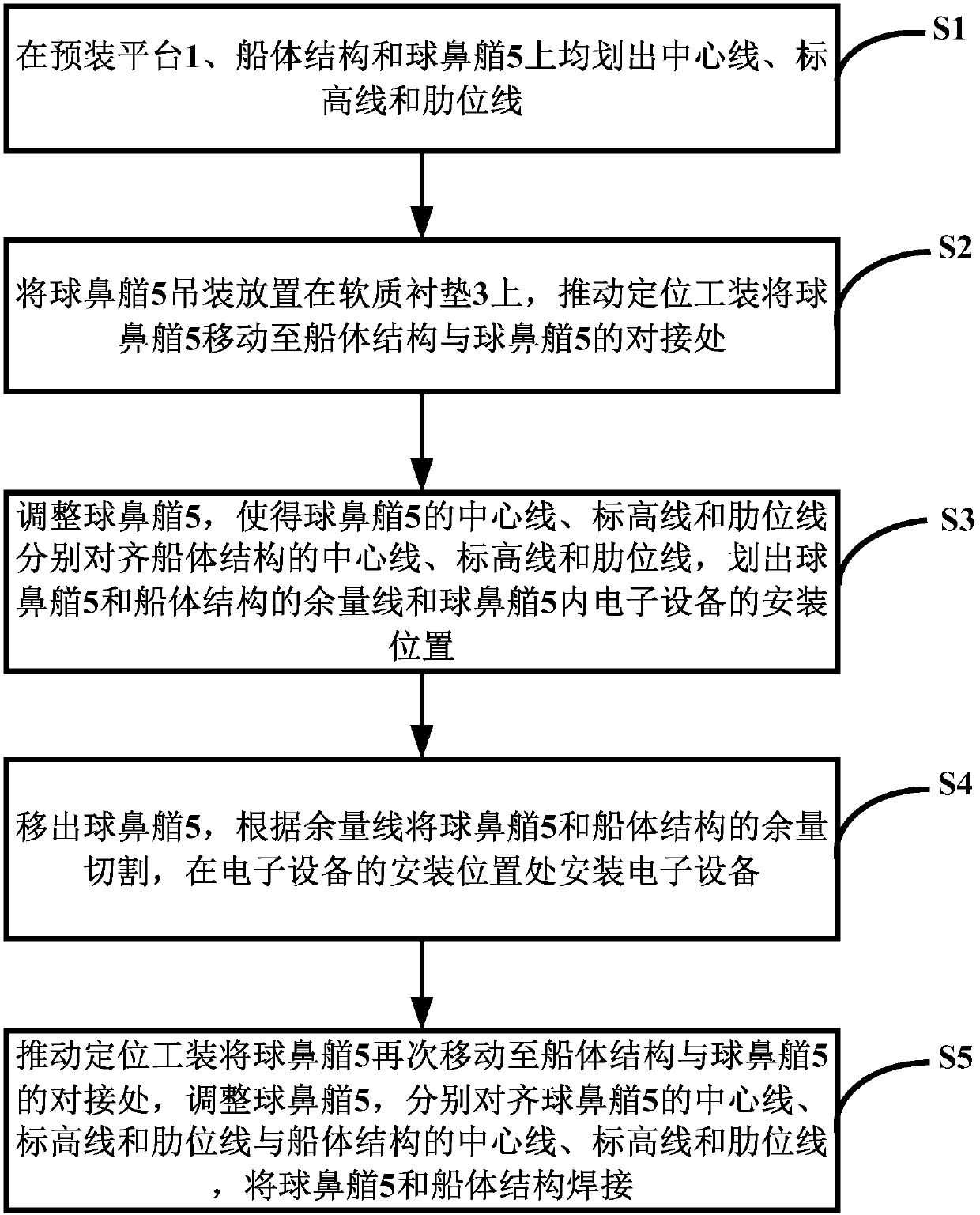

Bulbous bow positioning tool and positioning and installing method of bulbous bow

The invention discloses a bulbous bow positioning tool and a positioning and installing method of a bulbous bow, and relates to the field of ships. The positioning tool comprises a prefabricated platform, a base and a soft lining. The bulbous bow is placed on the upper side of the soft lining. The shape of the soft lining is matched with that of the bulbous bow. A movable device is arranged at thebottom of the prefabricated platform. The method includes the steps of S1, drawing a central line, an elevation line and a frame space line on each of the prefabricated platform, a ship body structure and the bulbous bow; S2, hoisting the bulbous bow on the soft limiting, and moving the bulbous bow to the butt joint position of the ship body structure and the bulbous bow; S3, drawing an installation position of an electronic device in the bulbous bow; S4, moving out the bulbous bow, and installing the electronic device at the installation position of the electronic device; S5, welding the bulbous bow and the ship body structure. The bulbous bow can be placed on the positioning tool, measurement is convenient, safety is high, the electronic device can be installed before the bulbous bow ismounted on a ship, and the advanced outfitting efficiency can be easily improved.

Owner:WUCHANG SHIPBUILDING IND

Corrosion-protection and soil-protection method for watercraft

InactiveCN101342934ASmall running resistanceImprove operating economicsVessel cleaningHullsEpoxyAdhesive

The invention relates to a watercraft anticorrosion and antifouling method. Firstly, the material of the watercraft is processed with buffing treatment so as to enable the material to be capable of combining with ceramic wafers; then the ceramic wafers are tightly combined with the material of the watercraft through epoxy resin, electric welding, plating or adhesive. The ceramic wafers are adhibited at the underside of the watercraft and the part of the watercraft underwater or above waterline, including the area of the bulbous bow, the area of the screw-shaft tube of the propeller, the area of the rudder, the area of the ballast tank and the double-deck underfloor. The ceramic wafers are interconnected through epoxy resin, electric welding, plating or adhesive, or are interconnected mechanically, forming a watercraft shell. The invention has the good effects that the ceramic wafers are arranged at the exterior of the watercraft to withstand corrosion from seawater and halobios to the watercraft and makes use of the intensity of the substrate material of the watercraft and the characteristics of corrosion resistance and fouling resistance. The invention causes no pollution to marine environment and is effective in a long time and can reduce the resistance to the watercraft during sailing and increase the economical efficiency of the operation of the watercraft.

Owner:DALIAN MARITIME UNIVERSITY

Anchor-pulling test method for simulating anchor recess of real ship

InactiveCN107292008AAvoid repeated revisionsSave human effortVessel designingDesign optimisation/simulationDesign softwareMaterial resources

The invention provides an anchor-pulling test method for simulating an anchor recess of a real ship. The method is characterized by comprising the following steps of 1, drawing an actual shape of the anchor recess according to a location dimension of a design drawing and a lines plan of a ship hull plate; 2, simulating multiple states of an anchor during dropping, judging whether the anchor is collided with a bulbous bow plate or not, and according to the judgment, determining the position of an outlet point of a hawse pipe; 3, simulating a state of the anchor when an anchor rod just enters the hawse pipe in a lifting process, judging whether an anchor sticking phenomenon occurs or not, and according to the judgment, determining an included angle between a central line of the hawse pipe and a vertical direction; and 4, simulating a state of the anchor during lifting in the anchor recess, and according to the state, determining the length of the hawse pipe, an angle of an anchor recess backboard, and the height of an anchor mouth. According to the method, by statically simulating an anchor-pulling test process on design software of a computer, a few defects of anchor recess design can be discovered in advance and then corresponding modification is performed, so that repeated modification of the hawse pipe and an anchor rack in an anchor-pulling test is avoided and manpower and material resources are saved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

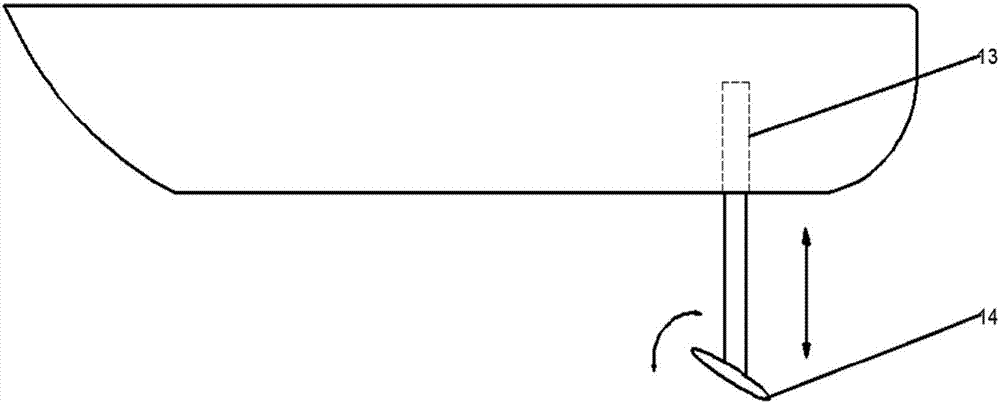

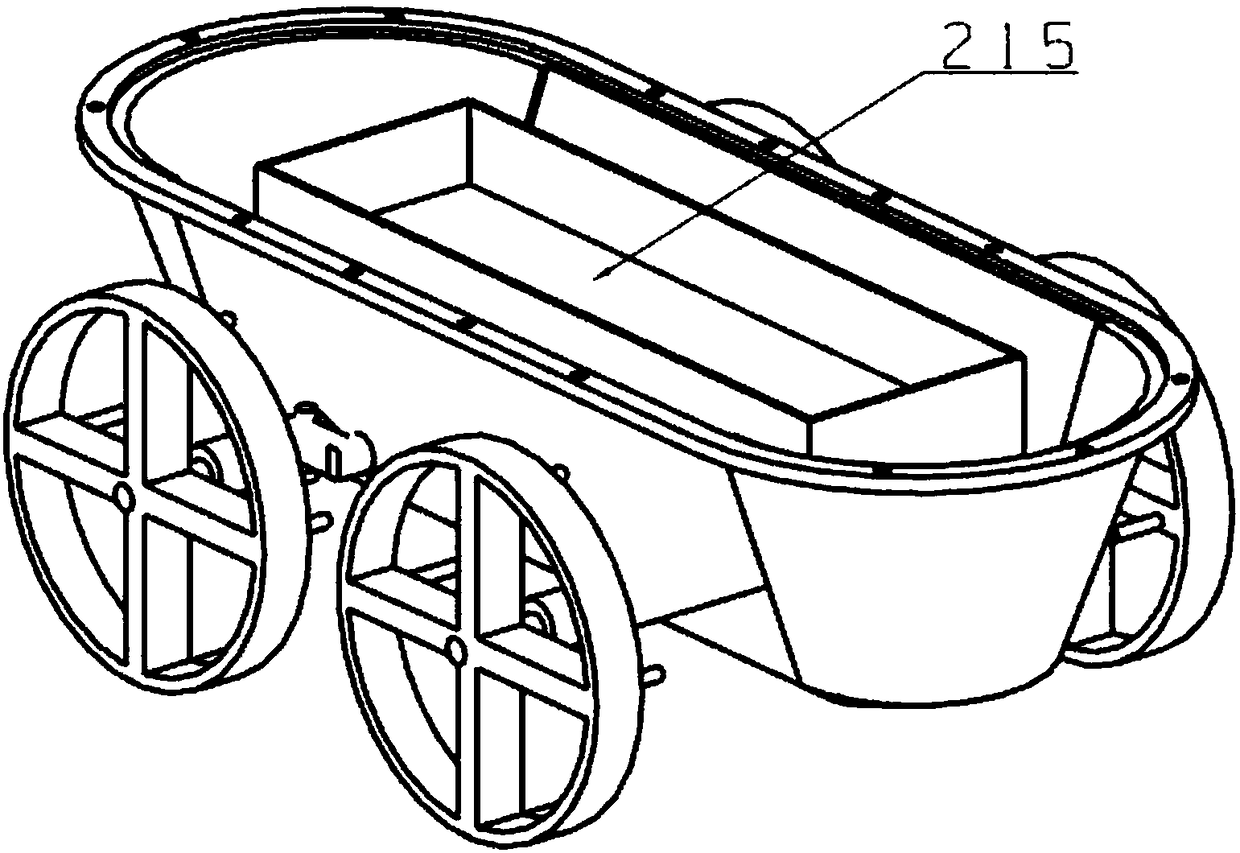

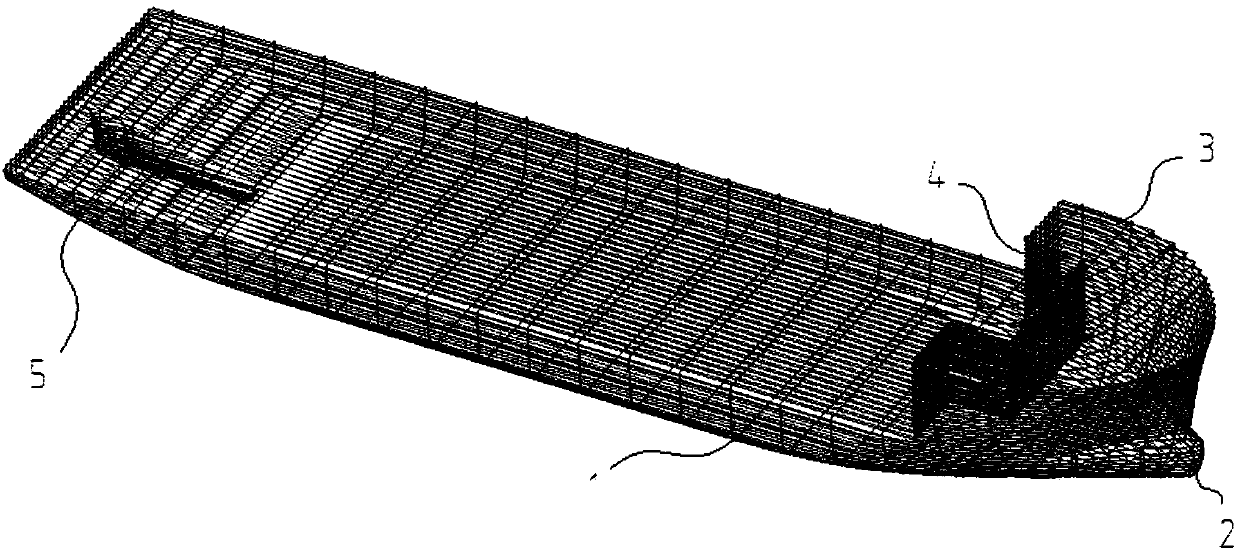

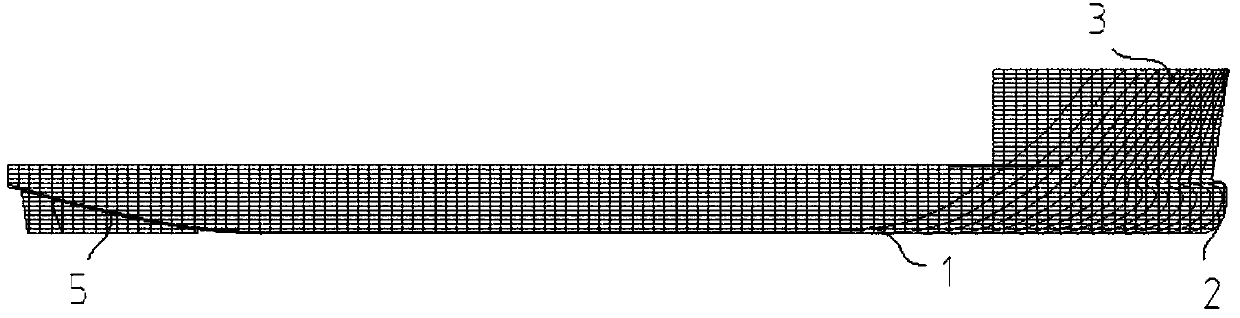

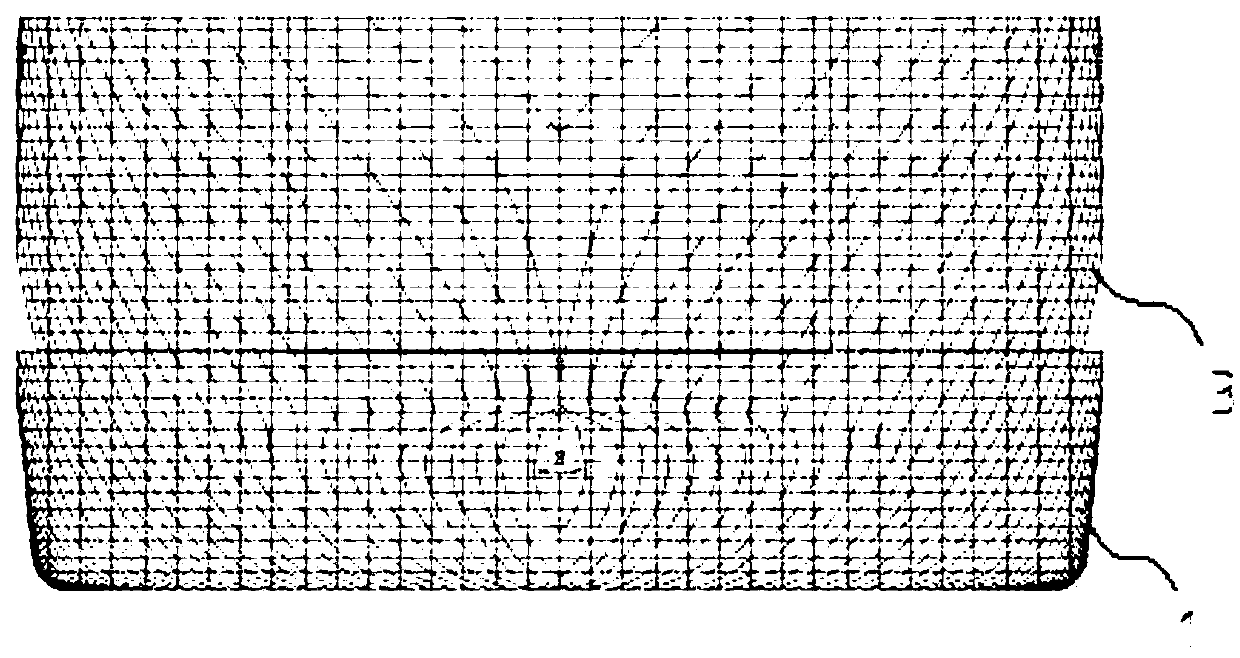

Bulbous bow assembly

InactiveCN103723240AReduce sailing resistanceReduce wave resistanceWatercraft hull designHull stemsShip wavesMarine engineering

The invention provides a bulbous bow assembly in the technical field of ship equipment. The bulbous bow assembly comprises a bulbous bow main body, a slideway and a driving slippage device, wherein the bulbous bow main body is arranged below a ship body along the length direction of a ship; the slideway is arranged between the ship body and the bulbous bow main body, and comprises slide rails which are distributed along the length direction of the ship and slide blocks matched with the slide rails in a sliding mode; the slide blocks slide front and back in the slide rails along the length direction of the ship; the slide rails are fixedly connected with the bottom of the ship body, and are fixedly connected with the top of the bulbous bow main body; the driving slippage device is fixedly arranged in the ship body, and comprises a main pulley and a driving belt; the main pulley is a fixed pulley; the driving belt surrounds the main pulley; two ends of the driving belt are respectively fixedly connected with the front end and the rear end of the bulbous bow main body. The ship body provided by the invention is separated away from the bulbous bow main body; the position of the bulbous bow main body can be adjusted in real time; according to a wave making cancellation principle, the bulbous bow main body can be fully utilized for reducing the ship wave making resistance under multiple navigation speeds and multiple sea conditions, furthest reducing the navigation resistance of the ship body, reducing energy source loss, and further reducing the operation cost.

Owner:SHANGHAI JIAO TONG UNIV

Ship

ActiveCN104890805AChange flow fieldChange pressureHydrodynamic/hydrostatic featuresEffective powerMarine engineering

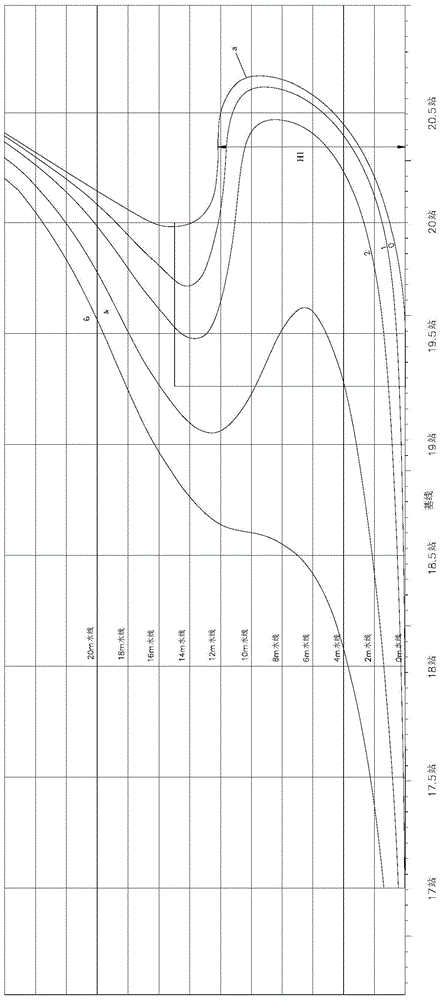

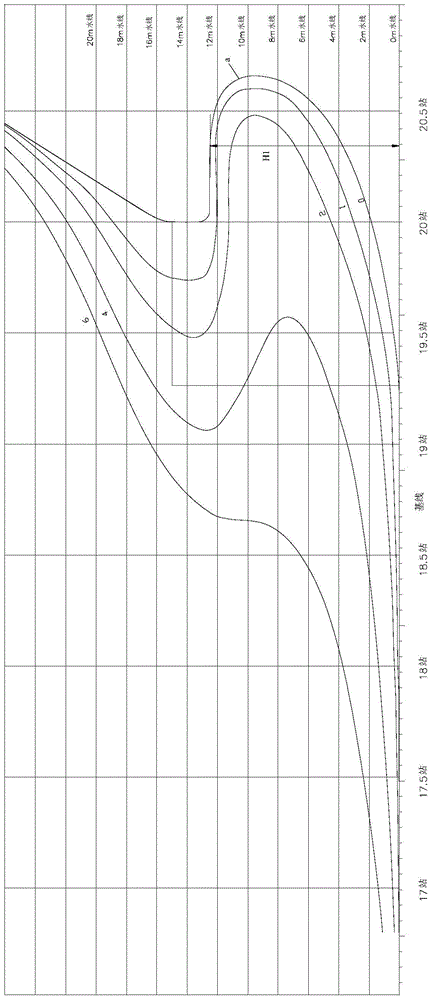

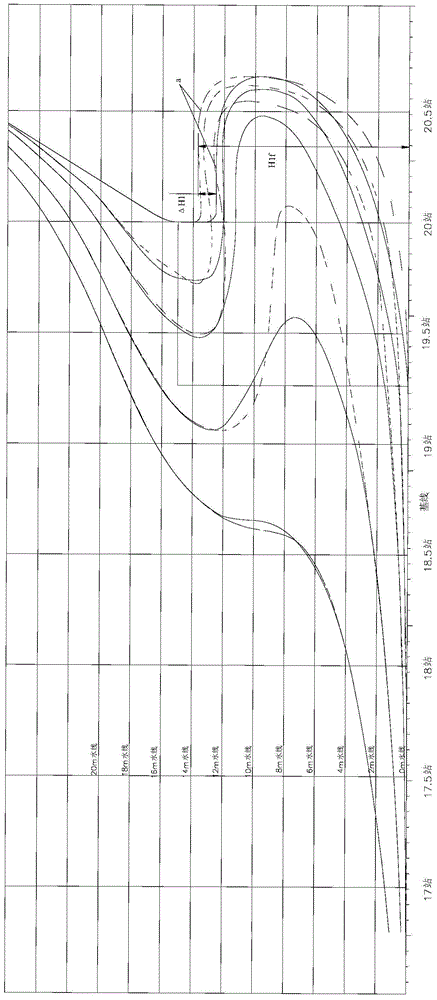

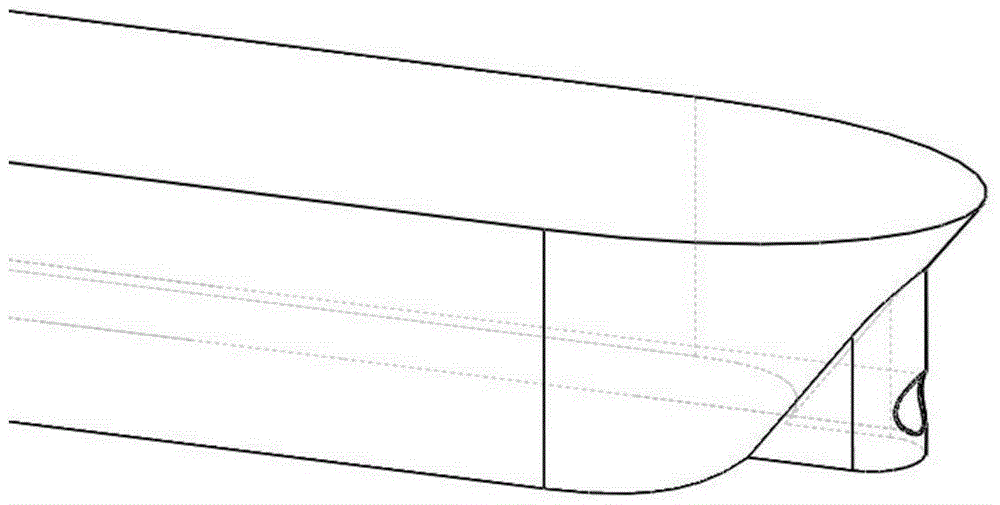

The invention discloses a ship. The ship comprises a ship body and a bulbous bow, wherein the bulbous bow is positioned under the bow part of the ship body, and the highest position of the upper part of the bulbous bow is 11.95-12.45m away from a baseline; at the 20th station of the ship body, the bottom of the bulbous bow is 750-1250mm away from the baseline; at the height of the 6m waterline at the 20th station of the ship body, the outer edge of the bulbous bow is 3100-3600mm away from a central line; at the 20.5th station of the ship body, the bottom of the bulbous bow is 4550-5050mm away from the baseline; at the height of the 10m waterline at the 20th station of the ship body, the outer edge of the bulbous bow is 1350-1850mm away from the central line. According to the ship, flow fields and pressure distribution, which is around the ship body, is changed by changing the bulbous bow, so that the ship can have lower effective power at any navigational speed, and the purpose of saving fuel oil is achieved.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

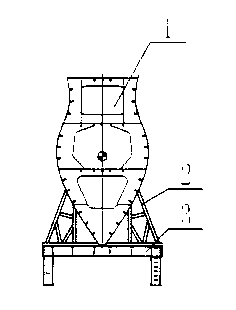

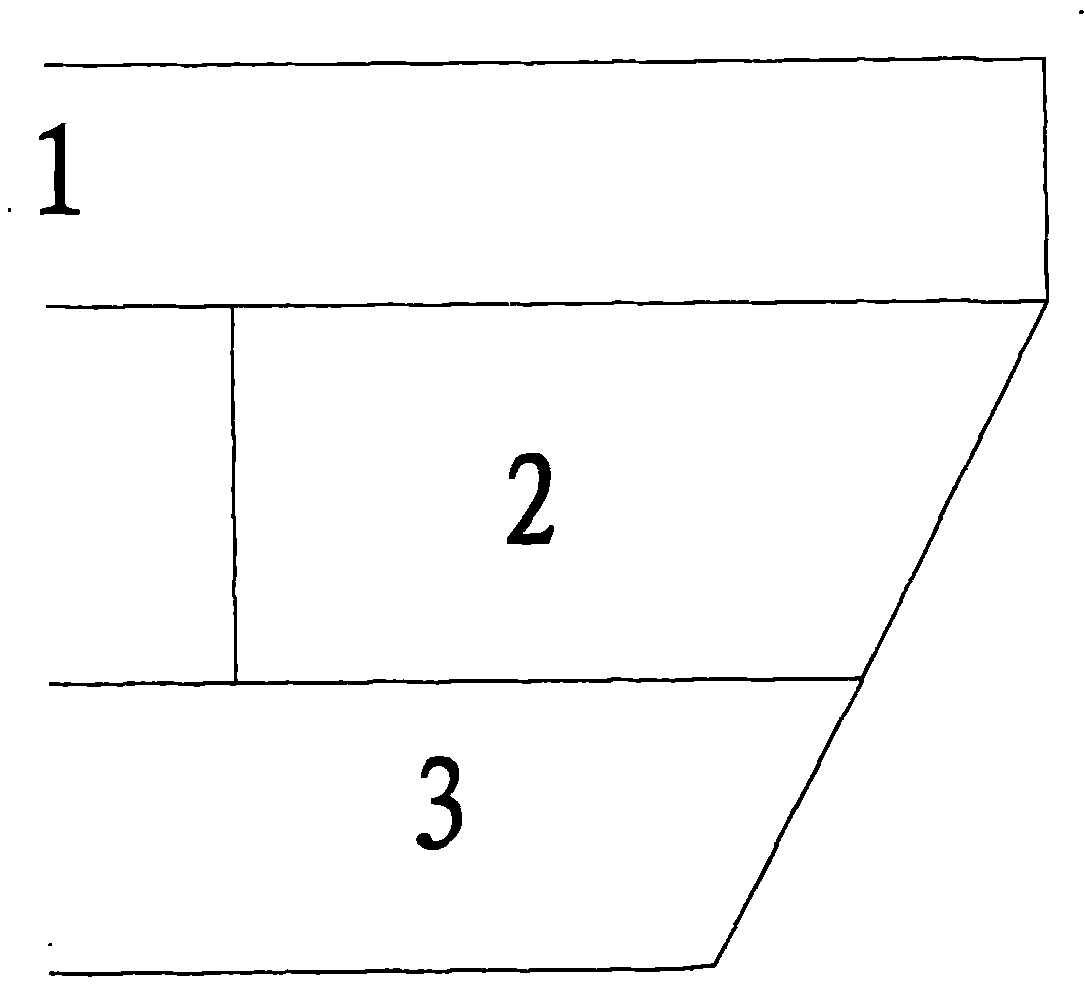

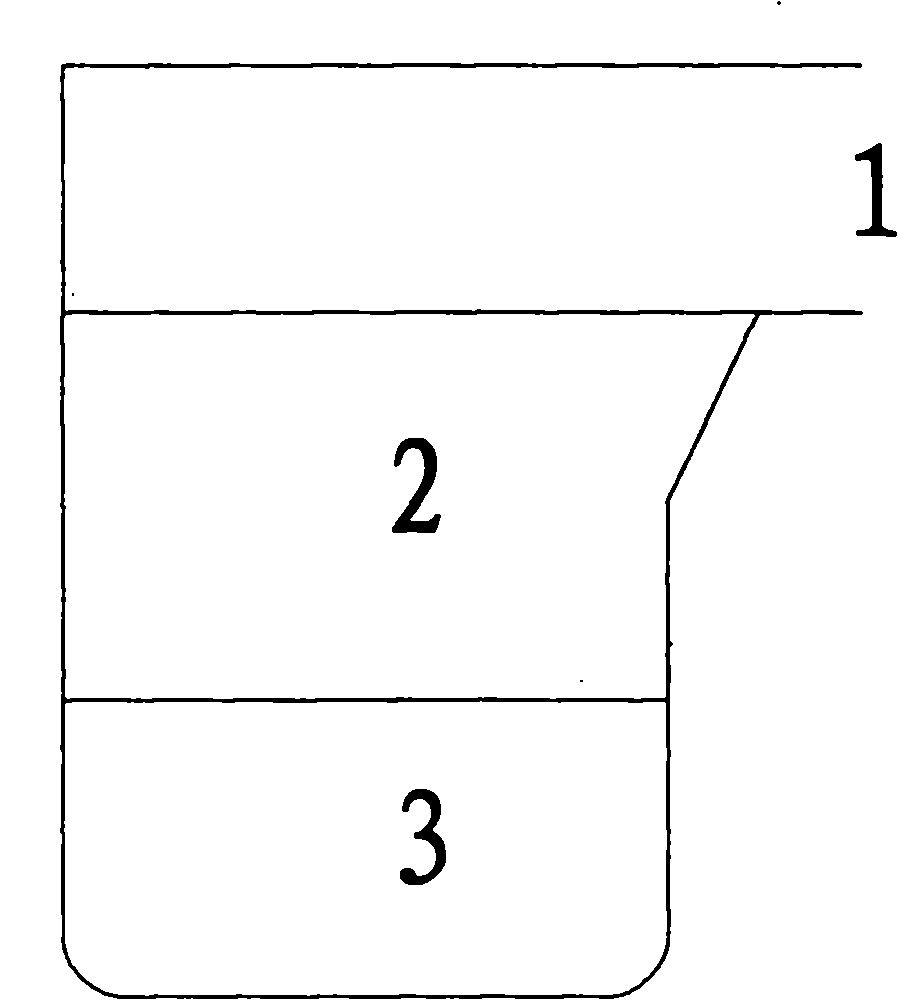

Ship type of semi-submersible crane pipe-laying vessel

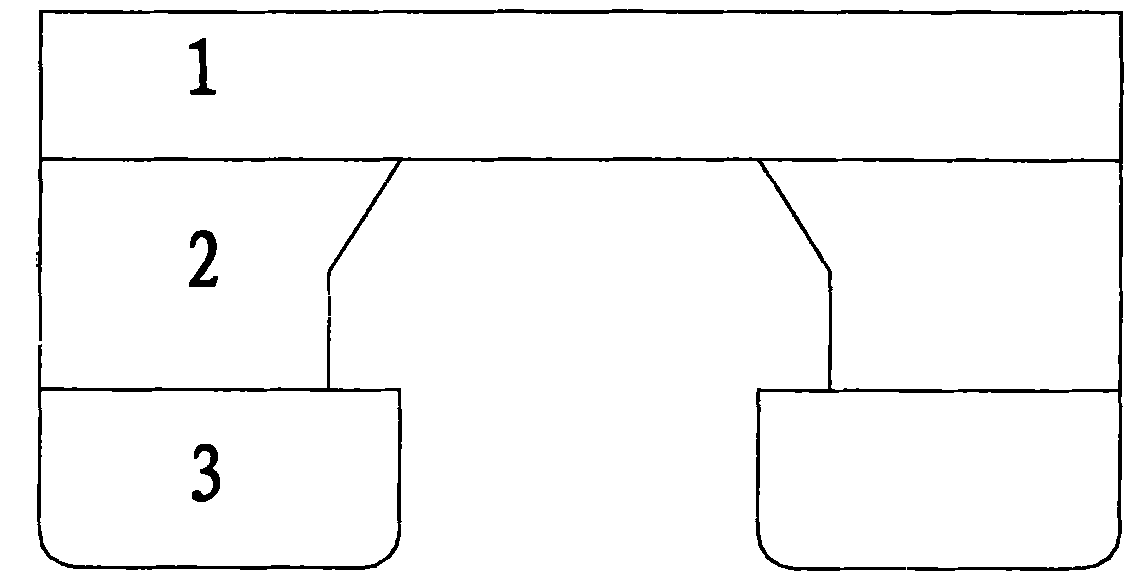

InactiveCN102267545AGuaranteed structural strengthGuaranteed buoyancyPipe-laying vesselsUltimate tensile strengthBuoyancy function

The invention relates to a ship form for a semi-submersible type hoisting pipe-laying ship. A ship body comprises an upper platform, a plurality of upright columns and two lower floaters, wherein the upright columns are fixed at the two sides under the upper platform and are arrayed in parallel; the lower floaters are fixed at two sides, are arrayed in parallel and are connected to the upright columns; and a crane is fixed on the tail part of the upper platform. The ship form is characterized in that a centrum structure expanding outwards from bottom to top is formed by the joints of the upper parts of the upright columns on the stem and the upper platform; the outer sides of the lower edges of the upright columns are matched with the deck molded lines of the lower floaters; the upper sides of the upper edges of the upright columns are aligned with the side boundaries of the upper platform; the joints between the bottoms of the upright columns and the lower floaters are in bulbous bow arch-shaped natural transition; and after being connected in such a manner, the ship form of the stem is of a streamline structure. The ship form for the semi-submersible type hoisting pipe-laying ship can be used for maximally reducing the water resistance and improving the routing speed of the pipe-laying ship under the condition of ensuring the structural strength and buoyancy of the ship body.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Bulbous bow refit technology

ActiveCN108773455AShorten docking periodReduce workloadWatercraft hull designVessel partsMarine engineeringProjection line

The invention provides a bulbous bow refit technology. The bulbous bow refit technology comprises the three main processes of manufacturing of a new bulbous bow, removing of an old bulbous bow, and hoisting of the new bulbous bow. During hoisting of the new bulbous bow, an original ship center line, a rib position line and a horizontal detecting line are drawn on an original ship outer plate, projection lines of the original ship center line and the rib position line are drawn on the dock floor, and by combining a floating crane, a large segmented positioning tool and a segmented positioning trolley and taking the center line, the rib position line, the horizontal detecting line and the projection lines of the center line and the rib position line as the standard, precise positioning of the new bulbous bow in transverse, longitudinal and height directions is achieved. The bulbous bow refit technology can fully utilize existing equipment to shorten the docking period, and operation is accurate and quick.

Owner:广州文冲船舶修造有限公司

Icebreaker

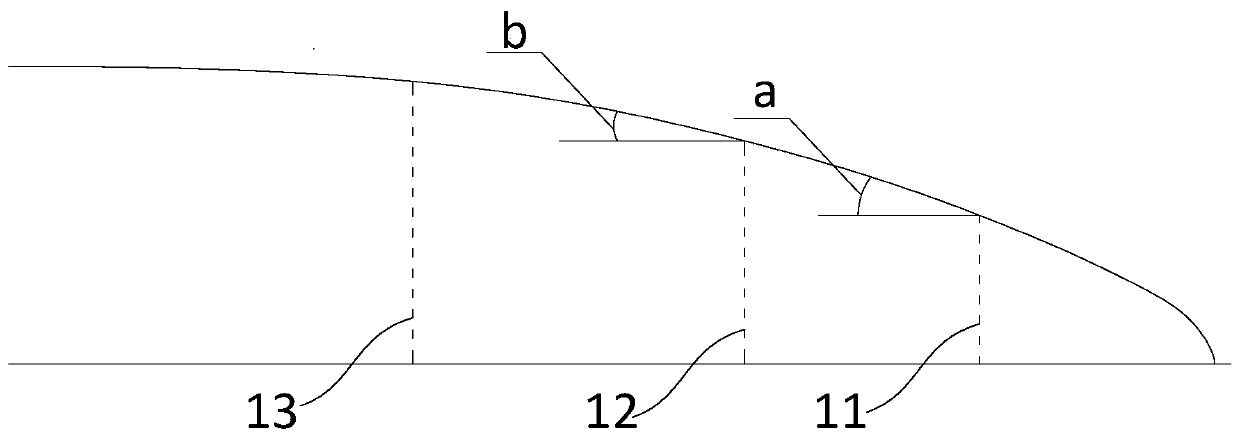

ActiveCN110466698AWith ice breaking abilityMeet the requirements of polar navigationIce breakersHydrodynamic/hydrostatic featuresEntrance angleStern

The invention discloses an icebreaker. One end of a ship prow is provided with three characteristic positions including the first position, the second position and the third position. The first position is located at the 45%-55% of the width of the icebreaker. The second position is located at the 70%-80% of the width of the icebreaker. The third position is located at the 90%-95% of the width ofthe icebreaker. A bulbous bow is arranged on the ship prow. The half entrance angle in the first position is smaller than 30 degrees. The half entrance angle in the second position is smaller than 20degrees. The horizontal distance between the third position and the ship prow is greater than 40 meters. According to the icebreaker provided by the invention, by arranging the bulbous bow on the shipprow and designing the corresponding ship prow specification facilitating icebreaking, the ship prow is made to have the icebreaking capability; and in addition, a series of icebreaking structures are designed on a ship stern portion as well, the ship stern portion is made to have the icebreaking capability as well on the premise that the ship prow of the icebreaker has the icebreaking capability, the icebreaker meets arctic navigation requirements conveniently and can adapt to different navigation demands, and the economical efficiency and the versatility of the icebreaker are improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Novel icebreaker bow structure and ice breaking method

PendingCN109501952AReduce wave resistanceOptimize layoutHull stemsIce breakersOpen waterMarine engineering

The invention discloses a novel icebreaker bow structure and an ice breaking method. The bow structure comprises a bow upper part, a bow middle part and a bow lower part, the bow upper part is a straight bow body and is perpendicular to a horizontal plane, and the inclination angle is 90 degrees; the bow middle part adopts an ice-breaking blade inclining downwards, and the inclination angle of theice-breaking blade is 15-40 degrees; the bow lower part adopts a bulbous bow, the lower edge line of the bulbous bow is provided with an ice-breaking blade, and the inclination angle of the ice-breaking blade is 35-50 degrees; the upper edge line of the bulbous bow is provided with an ice-breaking blade with the inclination angle of 15-30 degrees. The bow structure can have good ice breaking performance under ice conditions at different degrees in polar regions and have good resistance performance in open water areas at the same time.

Owner:NANTONG COSCO KHI SHIP ENG

Ship

InactiveCN104890807AChange flow fieldChange pressureHydrodynamic/hydrostatic featuresEffective powerMarine engineering

The invention relates to a ship, which comprises a ship body and a bulbous bow positioned under a bow part of the ship body, wherein the distance between the highest part of the upper part of the bulbous bow and a base line is between 12.25m and 12.75m; at the 20-th station of the ship body, the distance between the bottom of the bulbous bow and the base line is between 1600mm and 2100mm; at the height of a 6m water line of the 20-th station of the ship body, the distance between the outer edge of the bulbous bow and the center line is between 2550mm and 3050mm; at the 20.5-th station of the ship body, the distance between the bottom of the bulbous bow and the base line is between 5000mm and 5500mm; and at the height of a 10m water line of the 20.5-th station of the ship body, the distance between the outer edge of the bulbous bow and the center line is between 1600mm and 2100mm. The ship has the advantages that the flow field and pressure distribution around the ship body is changed through the change of the bulbous bow, so that the lower effective power can be realized at any navigational speed of the ship, and the goal of saving fuel is achieved.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

Vertical bow and front edge drainage combined damping structure used for low speed full formed ship

ActiveCN105197179AReduce dragReduce wave resistanceWatercraft hull designHydrodynamic/hydrostatic featuresLow speedRounded Rectangle

The invention discloses a vertical bow and front edge drainage combined damping structure used for a low speed full formed ship of which the ship speed is lower than 12 knots and a block coefficient (CB) is larger than 0.8. The structure comprises a ship body, a vertical bow is arranged at the head position of the ship body, the front end of the vertical bow is provided with a round hole, a rounded rectangle hole is formed in the tail of the ship body, the round hole and the rounded rectangle hole are communicated from front to back and are in smooth transition in the ship body to form a runner through which fluid passes. The invention innovatively puts forwards a concept of the vertical bow instead of a bulbous bow; further, a vertical bow technology and a front edge drainage technology are combined to effectively reduce wave-making resistance, and further reduce viscosity pressure resistance in a greater degree, and total resistance of the whole ship is reduced by more than 3%.

Owner:SHANGHAI JIAO TONG UNIV

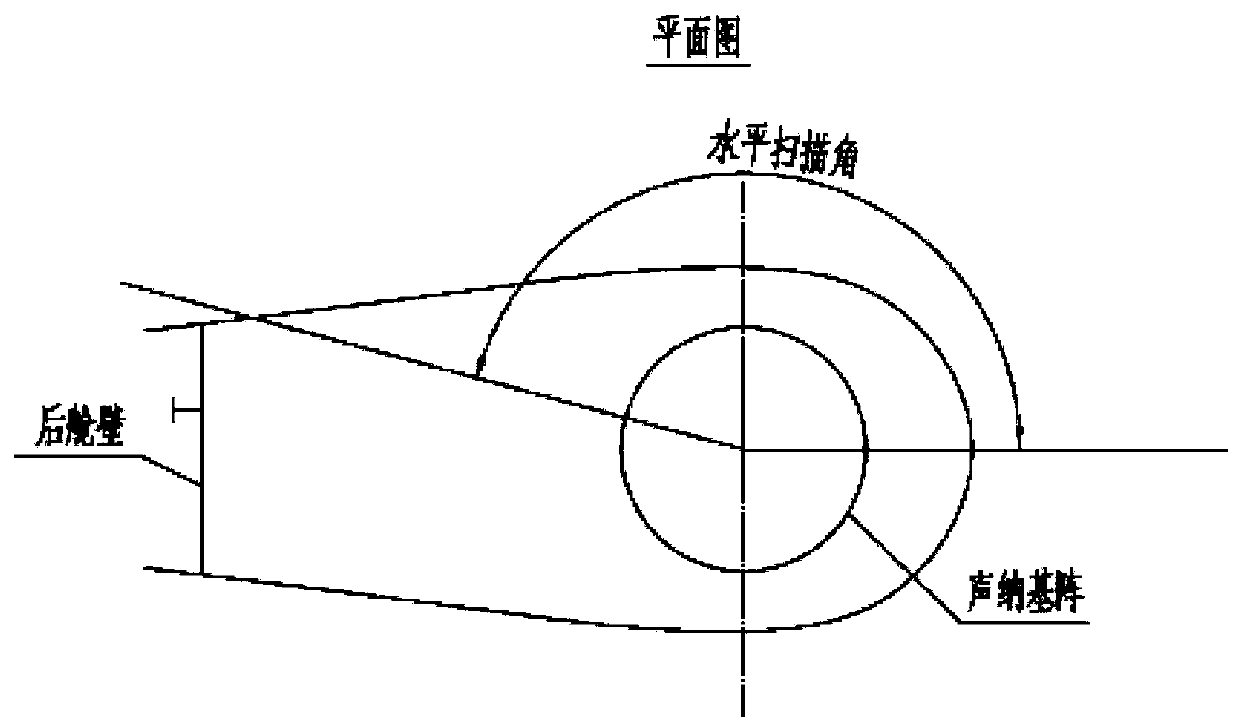

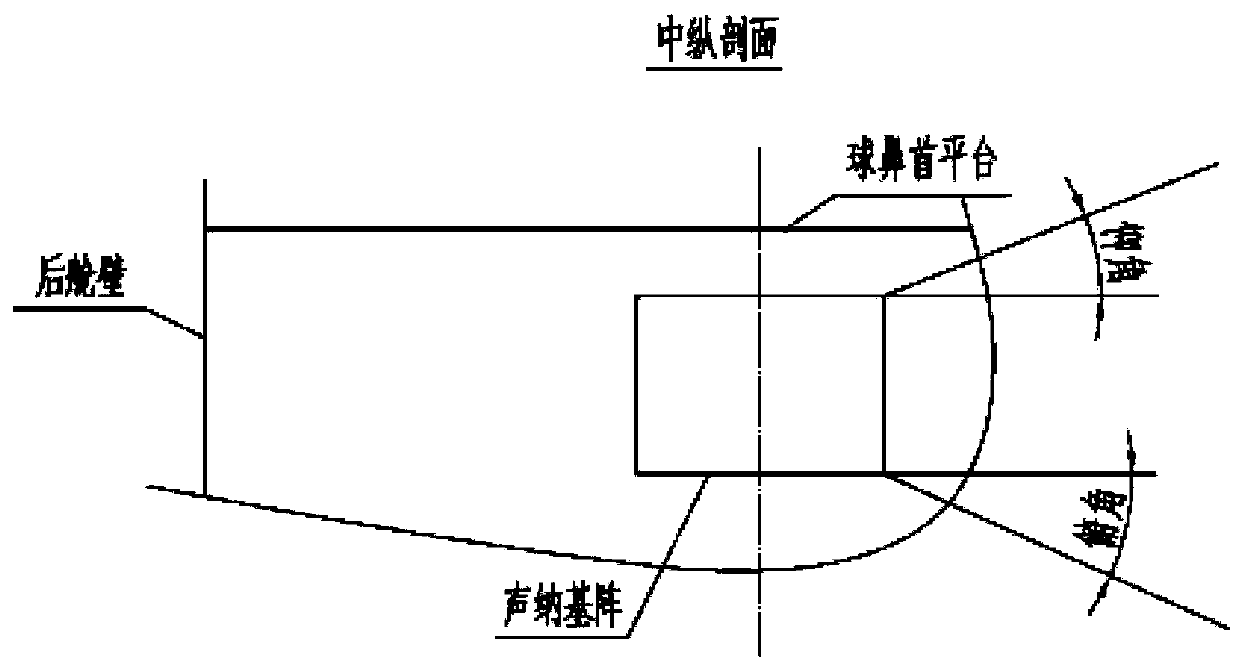

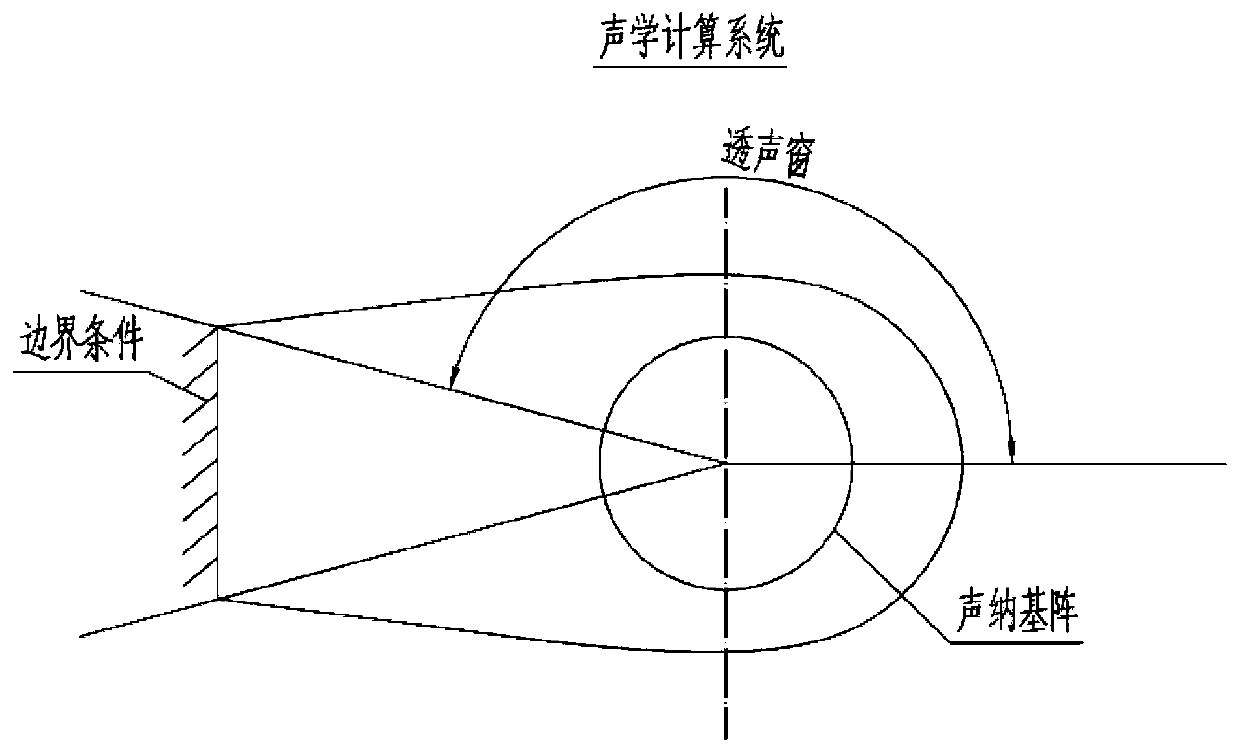

Double-layer shell titanium alloy deflector shroud acoustic three-dimensional control method

PendingCN109895943AGood design foundationGuaranteed structural strengthVessel partsHydrodynamic/hydrostatic featuresAcoustic transmissionSonar

The invention discloses a double-layer shell titanium alloy deflector shroud acoustic three-dimensional control method. The double-layer shell titanium alloy deflector shroud acoustic three-dimensional control method comprises the following steps of, firstly, determining the spatial range of an acoustic window according to agreed horizontal scanning angle and vertical angle of pitch and under thecondition that mold lines are determined; secondly, performing structure optimization on an acoustic cavity, specifically, arranging and computing the structure of non-acoustic transmission areas according to the determined range of the acoustic window; thirdly, performing acoustic modeling calculation according to the material and structure of the acoustic window; fourthly, performing vibration and noise reduction design inside the acoustic cavity, emphatically controlling the noise within the working frequency range of a sonar, applying sound absorbing materials and vibration and noise reducing materials onto the rear wall of the acoustic cavity, a sonar mounting platform and a bottom non-acoustic transmission area. The double-layer shell titanium alloy deflector shroud acoustic three-dimensional control method integrates multiple disciplines and combines engineering practical experience, thereby being high in systemic performance and operability and providing an effective engineering method for acoustic control of a bulbous bow deflector shroud.

Owner:CHINA SHIP DEV & DESIGN CENT

Head structure of container ship

InactiveCN103625601AImproved resistance propertiesIncrease speedWatercraft hull designHydrodynamic/hydrostatic featuresMarine engineeringEngineering

The invention relates to a head structure of a container ship. The head structure of the container comprises a bulbous bow below the front portion of a ship head. The top end of the bulbous bow is higher than a designed waterline of the container ship and lower than a structural waterline of the container ship. By changing the height of the bulbous bow, the top end of the bulbous bow is higher than the designed waterline and lower than the structural waterline. Thus, the resistance performance between the designed waterline and the structural waterline of the ship can be improved and rapidity between the structural waterline and the designed waterline of the ship is improved.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

Green energy-saving tail icebreaking type three-purpose tugboat

InactiveCN106628027AHas ice breaking abilityImprove ice breaking abilityWatercraft hull designIce breakersPropellerEngineering

The invention provides a green energy-saving tail icebreaking type three-purpose tugboat which comprises a tugboat body and a propeller arranged on the tugboat body, wherein an icebreaking part is arranged on a stern of the tugboat body; the icebreaking part is used for resisting against an ice layer and breaking the ice layer; the propeller can drive the tugboat body to advance towards the stern direction; the propeller is arranged on the stern of the tugboat body; the propeller is arranged as a full-rotating contra-rotating paddle propeller; a bulbous bow is arranged on a prow of the tugboat body. Under the condition of an icing water surface, the propeller can be utilized to drive the tugboat body to advance towards the stern direction and the icebreaking part is utilized to break the icing layer, so that the green energy-saving tail icebreaking type three-purpose tugboat can be used as an icebreaking boat. Under the condition of ice-free water surface, the propeller can be utilized to drive the tugboat body to advance towards the prow direction and the bulbous bow and the contra-rotating paddles all have obvious energy-saving effects and are capable of effectively reducing the energy consumption, so that the green energy-saving tail icebreaking type three-purpose tugboat can be used as a normal tugboat, the usage rate of the green energy-saving tail icebreaking type three-purpose tugboat can be greatly increased and the use cost can be reduced.

Owner:上海佳豪船海工程研究设计有限公司

Ship lift lifting type double-steel-beam anti-collision system and redundant blocking and preventing method thereof

PendingCN111893979AReduce section sizeReduce collision forceVertical ship-liftingMarine engineeringStructural engineering

The invention provides a ship lift lifting type double-steel-beam anti-collision system which comprises a double-blocking anti-steel-beam assembly, a supporting component assembly, a lifting driving device, a reversing device, a lifting connecting assembly and a supporting structure. The lifting driving device is arranged in the ship chamber main longitudinal beam structure on the side edge of theship reception chamber structure, the lifting driving device is connected with the double-blocking steel beam assembly through the reversing device and the lifting connecting assembly, and the double-blocking steel beam assembly can be driven by the lifting driving device to move up and down; the double-blocking steel beam assembly comprises an impact beam, a safety beam and a middle connecting device, the impact beam and the safety beam are fixedly connected through the middle connecting device, and the supporting structure is fixed to a ship chamber structure on the inner side of the safetybeam. Large safety redundancy is achieved, the collision force between the ship and the plastic beam is effectively reduced, and the adverse effect of the collision load of the ship colliding with the anti-collision beams on the ship compartment structure is reduced; a detachable connecting structure is adopted between the two stages of anti-collision beams so that the collision beam damaged by collision is convenient to replace; the ship lift lifting type double-steel-beam anti-collision system can meet blocking requirements of ships with bulbous bows.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

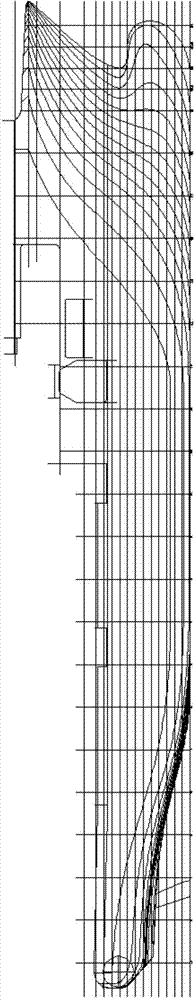

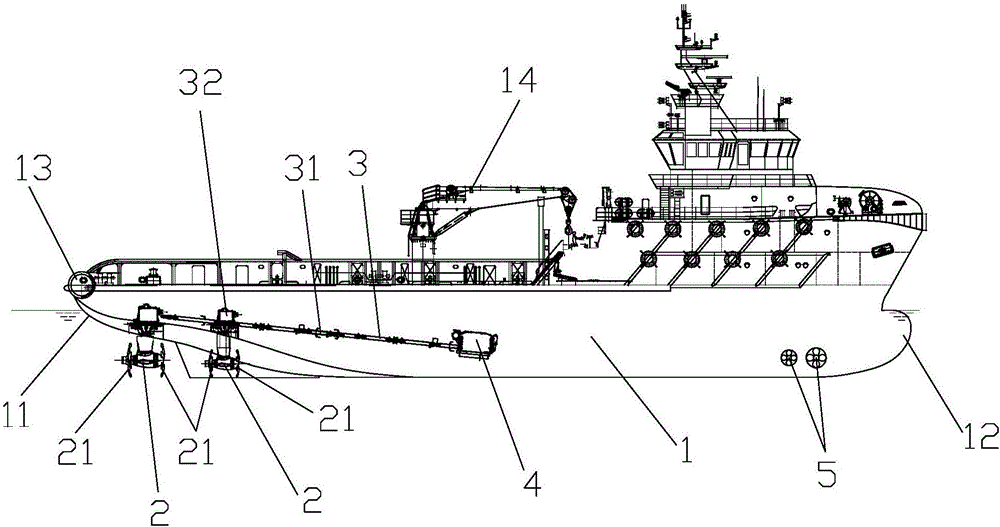

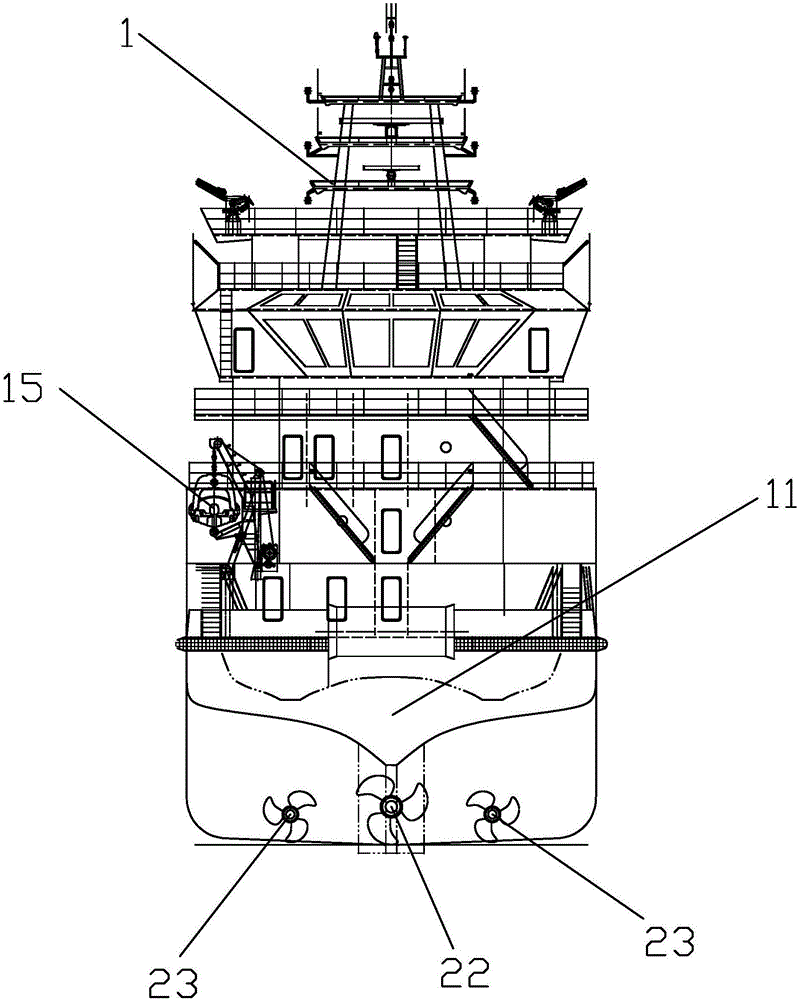

Hippocampus-shaped bulbous bow type bow structure of marine tug

The invention relates to a hippocampus-shaped bulbous bow type bow structure of a marine tug. The front part of a bulbous bow of the bow structure is positioned below a bow; the front end in the front of the bulbous bow is positioned at the rear part of the head end of a deck; the bulbous bow is hippocampus-shaped; one or more horizontal thrusters are mounted at the rear part of the bulbous bow of the bow structure; each horizontal thruster transversely penetrates through the rear part of the bulbous bow. The bow structure fully takes multiple factors such as ship resistance, sailing, arrangement, horizontal thruster mounting and using functions into consideration, so that compared with an oblique straight bow, the ship sailing economy is improved; the width of a part where a bow thruster is mounted is increased, so that the mounting of the large-diameter bow thruster can be facilitated, and the bow thruster can be conveniently arranged as far forward as possible to effectively improve applied moment of the horizontal thrusters; compared with the conventional bulbous bow type bow, after being close to an FPSO, a marine platform and other marine structures to perform pushing operation, the bulbous bow is free of collision with a pushed ship or a platform when the ship is in any longitudinal floating state, so that the head structure safety of the ship is ensured.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Method for noise reduction of working environment of underwater detection device

ActiveCN110689872AHigh stability of noise reduction effectImprove noise reductionSound producing devicesSource spectrumNoise

The invention discloses a method for noise reduction of a working environment of an underwater detection device. The method comprises the following steps of analyzing noise spectrums generated in a bulbous bow flow guide cover by using a noise source spectrum characteristic analysis device; determining noise influences of noises on the interior of the bulbous bow flow guide cover according to thedivided noise values; comparing the noise influences generated in the bulbous bow flow guide cover with the maximum noise influence value which can be borne by the underwater detection device; and selecting and reasonably arranging a sound insulation baffle and a sound absorption baffle according to a comparison result. According to the method, three-dimensional modeling and acoustic simulation analysis are carried out on the bulbous bow flow guide cover for mounting the underwater detection device, and different noise reduction processing is selected according to noise characteristics and values, so that the noise reduction effect can be improved; and the noise influences generated in the bulbous bow flow guide cover are compared with the maximum noise influence value which can be borne by the underwater detection device, and arrangement and noise reduction measures are reasonably selected for the bulbous bow flow guide cover according to the comparison result, so that the noise reduction effect is high in stability.

Owner:HARBIN ENG UNIV

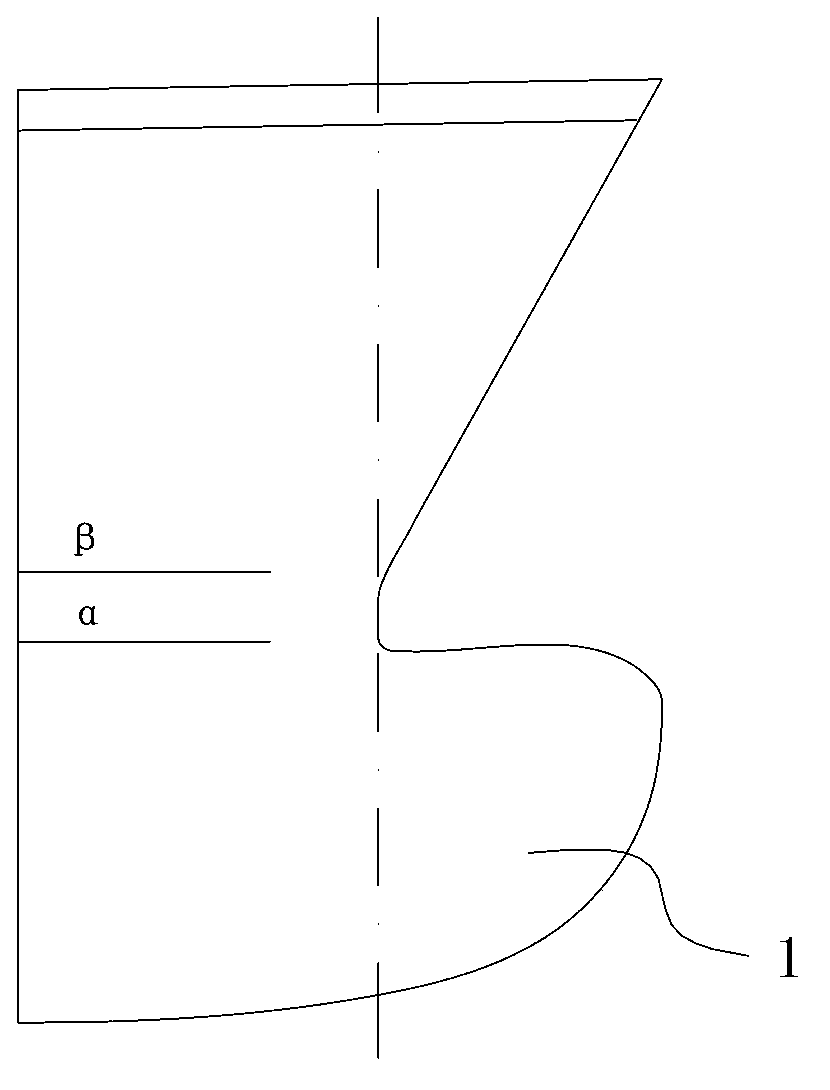

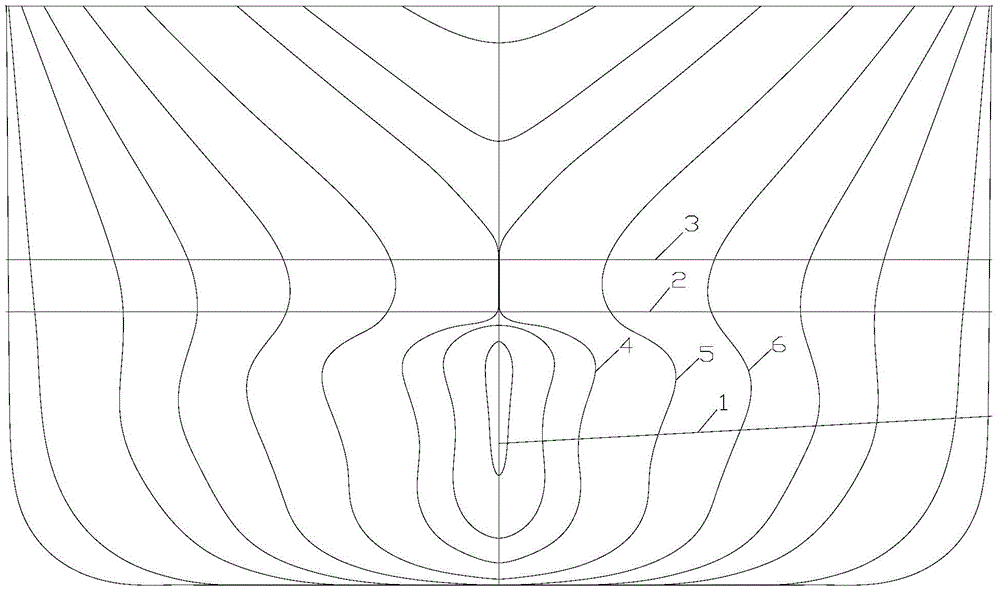

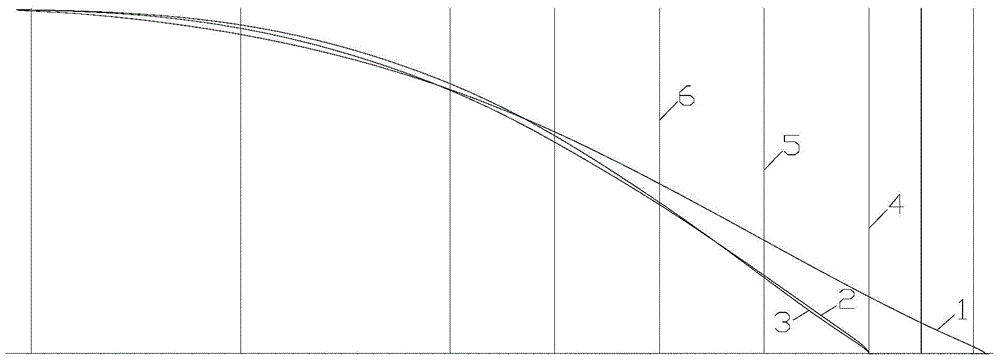

Novel bulbous bow with multi-draught resistance

ActiveCN104890809AReduce ballast draft resistanceResistance performance unchangedWatercraft hull designHull stemsMarine engineeringBallast

The invention discloses a novel bulbous bow with multi-draught resistance and belongs to the field of ship design. The novel bulbous bow is applicable to ships with various navigational draught conditions; each ship has a ballast draught state and a designed draught state. A transverse profile of the bow is concave around a ballast draught height; between the ballast draught height and the designed draught height and close to the designed draught height, the transverse profile is convex. The novel bulbous bow according to the technical scheme has the advantages that ballast draught state resistance is evidently improved, the designed draught and structural draught resistances are kept unchanged substantially, comprehensive oil cost of the multi-condition operating ship is lowered, economy is improved, and emission is reduced.

Owner:708TH RES INST OF CSSC

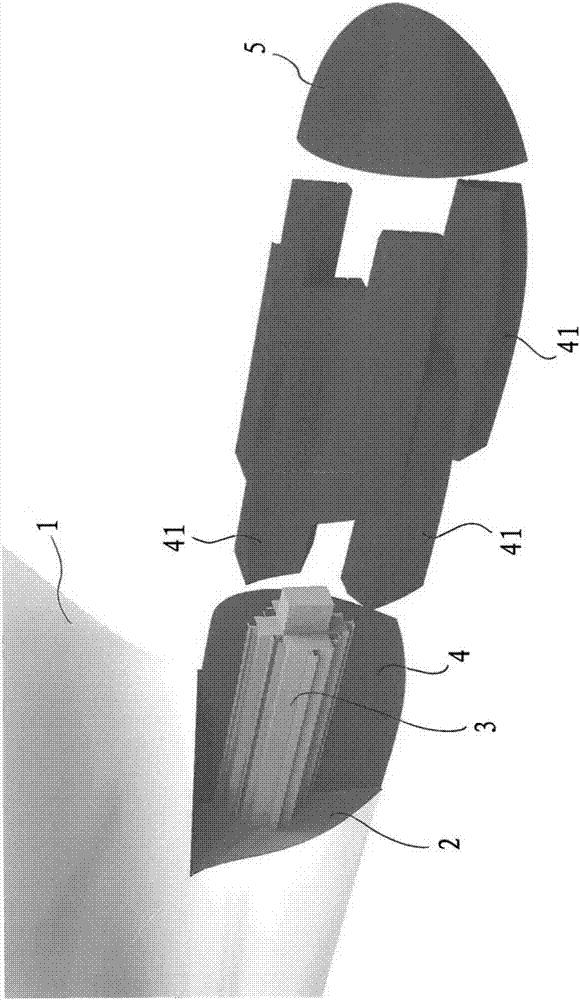

Bulbous bow, a sea-going vessel with such bow, and methods of its manufacture and installation

InactiveCN107021183AEfficient manufacturingCheap manufacturingVessel cleaningNon-magnetic metal hullsMarine engineeringLoad carrying

The present invention concerns a bulbous bow for a sea-going vessel, said bow comprising a load-carrying inner structure mounted at the stem of the vessel and an outer shell structure defining the hydrodynamic properties of the bulbous bow, wherein said outer shell structure is provided with a sub-structure for replaceably mounting on the inner structure. The invention further concerns a seagoing vessel comprising such bulbous bow as well as a method of producing a bulbous bow and a method of mounting or replacing a bulbous bow.

Owner:OPTIPOLBO ENTREPRENEURSHIP LTD

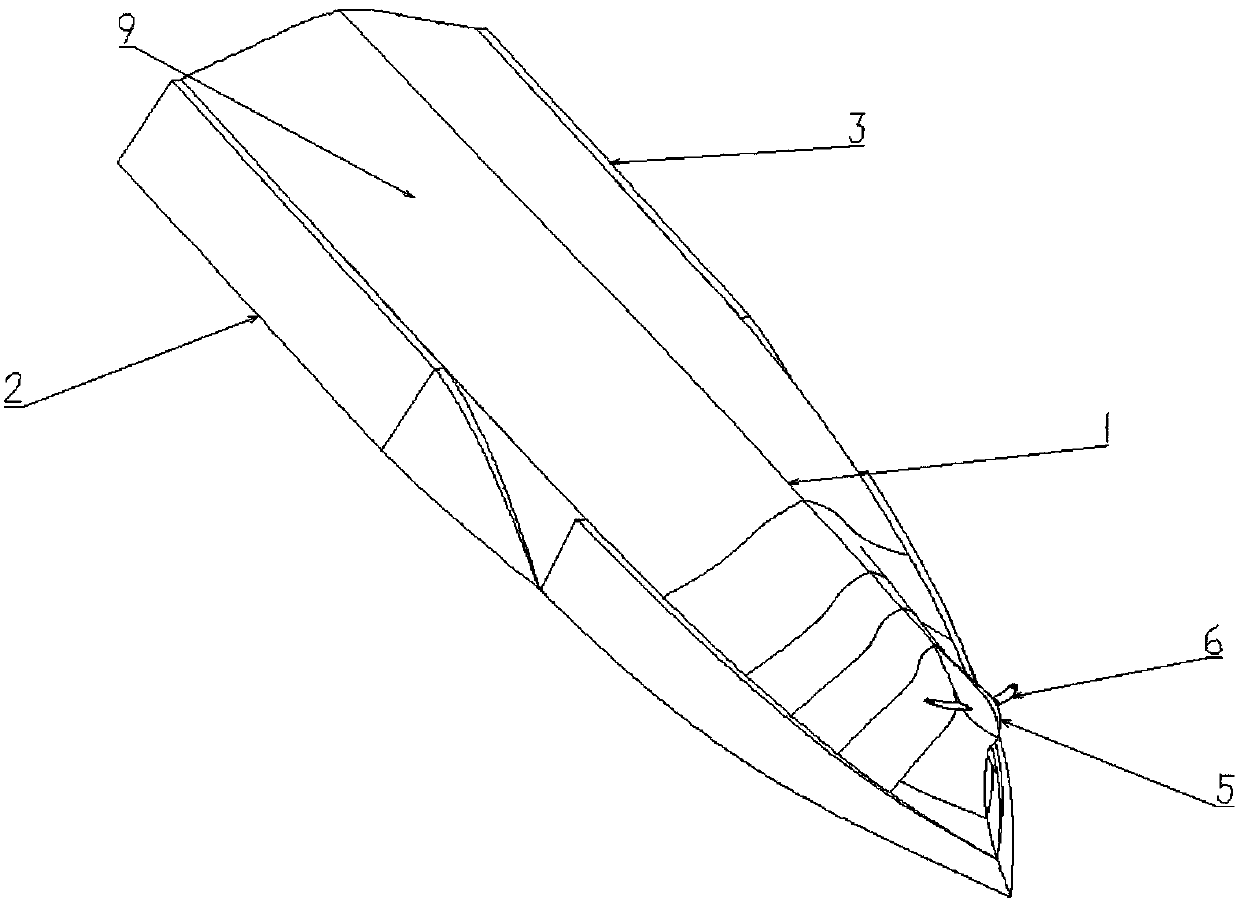

Straight obpyriform bulbous bow structure of ocean fishing vessel

InactiveCN103434608AReduce resistanceEffective additional wave systemHydrodynamic/hydrostatic featuresMarine engineeringEconomic benefits

The invention discloses a straight obpyriform bulbous bow structure of an ocean fishing vessel. The straight obpyriform bulbous bow structure comprises a vessel body and a bulbous bow, wherein the straight bulbous bow is arranged at the front part of the vessel body; the cross section of the bulbous bow is obpyriform; offset parameters of the bulbous bow are that the relative protruded length is 5.5 percent, the relative immersed depth is 17.5 percent and the area ratio of a bulb is 11.33 percent. The bulbous bow structure can generate a more effective additional wave system and realizes favorable interference with a wave system generated by a forward-inclined bulbous bow, thus reducing the resistance of the vessel body. The fuel amount of the ocean fishing vessel is reduced under the same work condition; economic benefits are increased by reducing cost; compared with the current ocean fishing vessel, the ocean fishing vessel disclosed by the invention has the characteristics that the same navigation speed can be realized at a lower host power, and thus the aim of saving fuel is achieved.

Owner:ZHEJIANG OCEAN UNIV

Bow island type semi-submersible ship form

InactiveCN107826208AReduce wave resistanceSolve operational needsWatercraft hull designHull stemsShip wavesBilge

The invention provides a bow island type semi-submersible ship form and belongs to the technical field of ship design. The bow island type semi-submersible ship form comprises an inclined side moldedline connected to the hull bottom through an arc bilge; a bow island is arranged at the upper part of a ship bow; the hull bottom comprises a short bulbous bow and a tail rising bottom, wherein the short bulbous bow is arranged on the ship bow and the tail rising bottom is on the stern; a port and a starboard of the short bulbous bow from the ship bow to the stern are in gradually widened smooth curve transition; and the bow island and the ship bow are in linear smooth transition and are gradually amplified to the breadth. According to the bow island type semi-submersible ship form, the favorable interference between the bulbous bow and a main hull is realized, the ship wave-making resistance is reduced, the operation requirement of multiple draft states of a semi-submersible ship is satisfied, the navigation performance of the semi-submersible ship within a larger draft range is also taken into consideration, the seakeeping performance during light draft is improved, the bow island satisfies the stability requirement in the submerging operation process, bow slamming resistance is improved, the cargo carrying area of a rear deck is increased because buoyancy tanks can also be placed, the weight of the structure is reduced, the loading capacity of tail ballast water is reduced, and the building and operation cost is reduced.

Owner:708TH RES INST OF CSSC

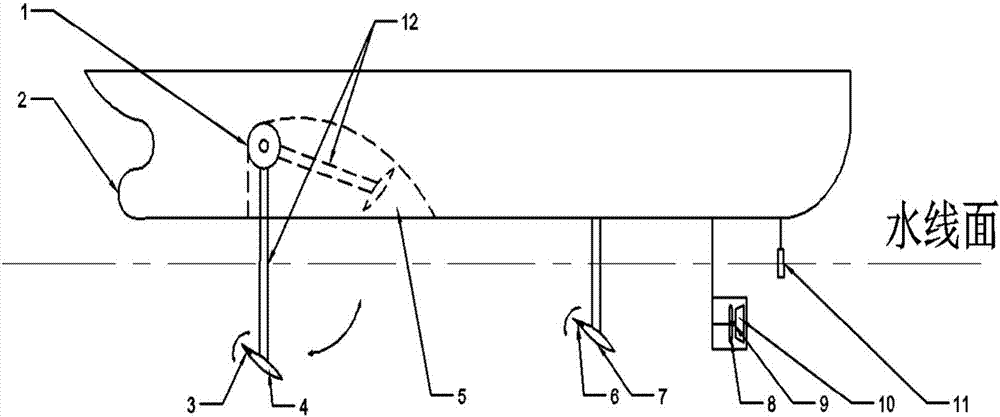

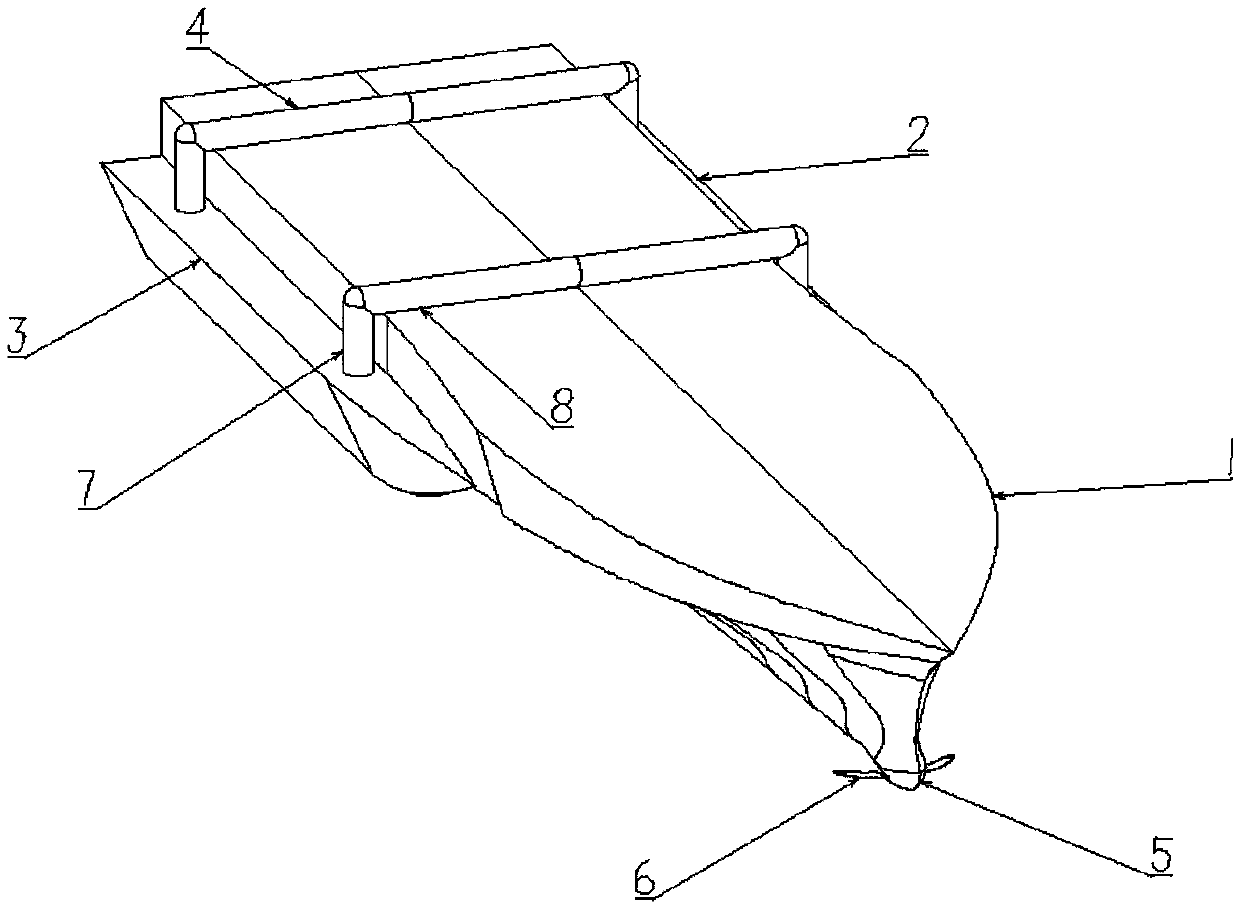

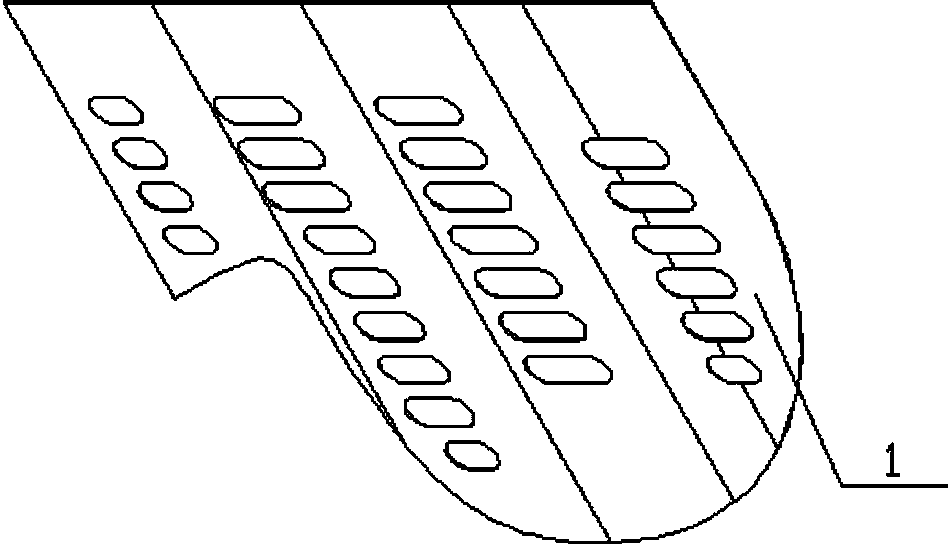

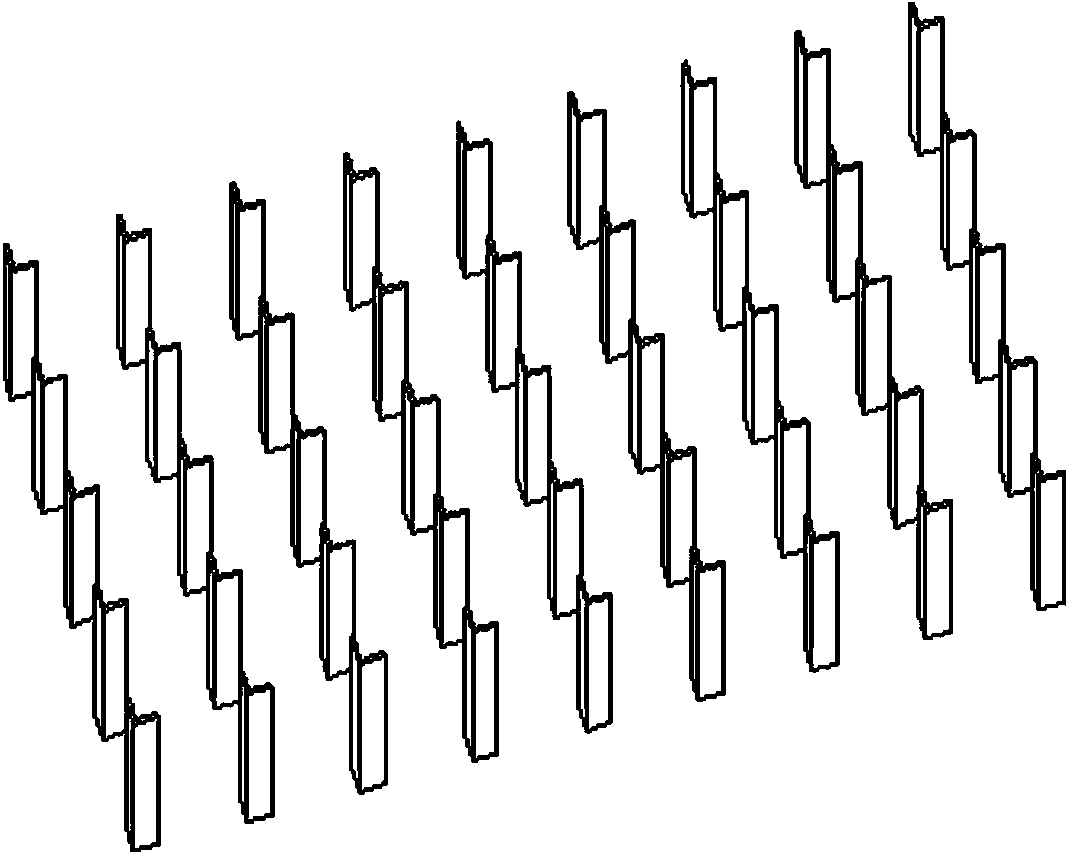

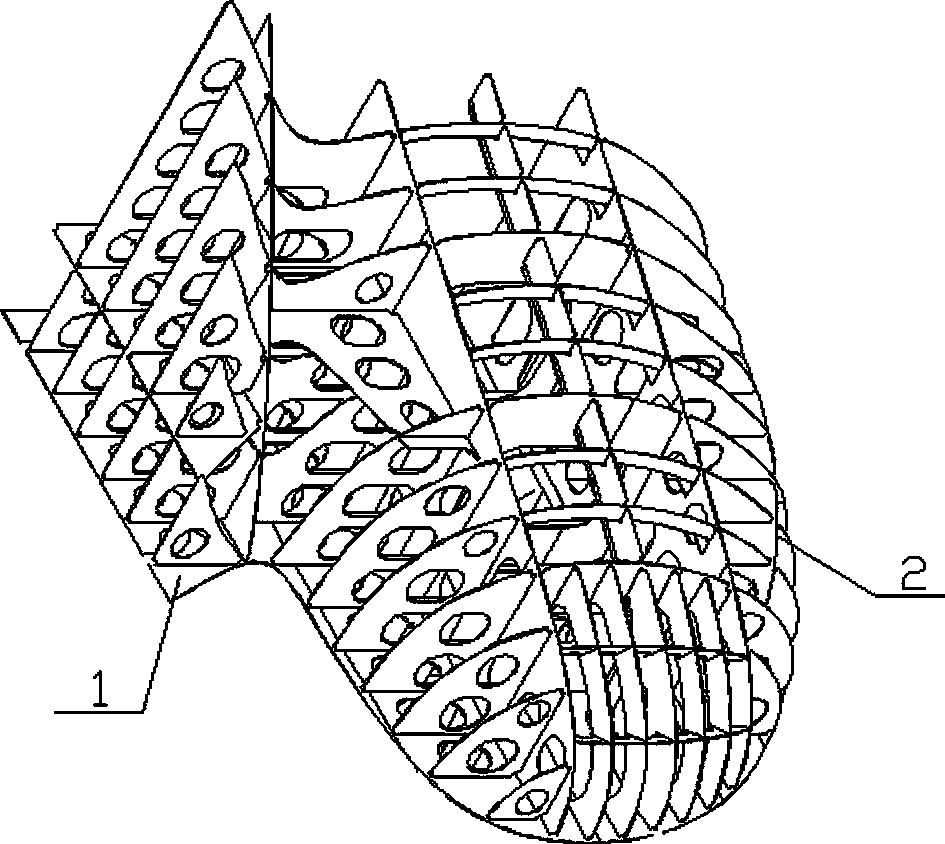

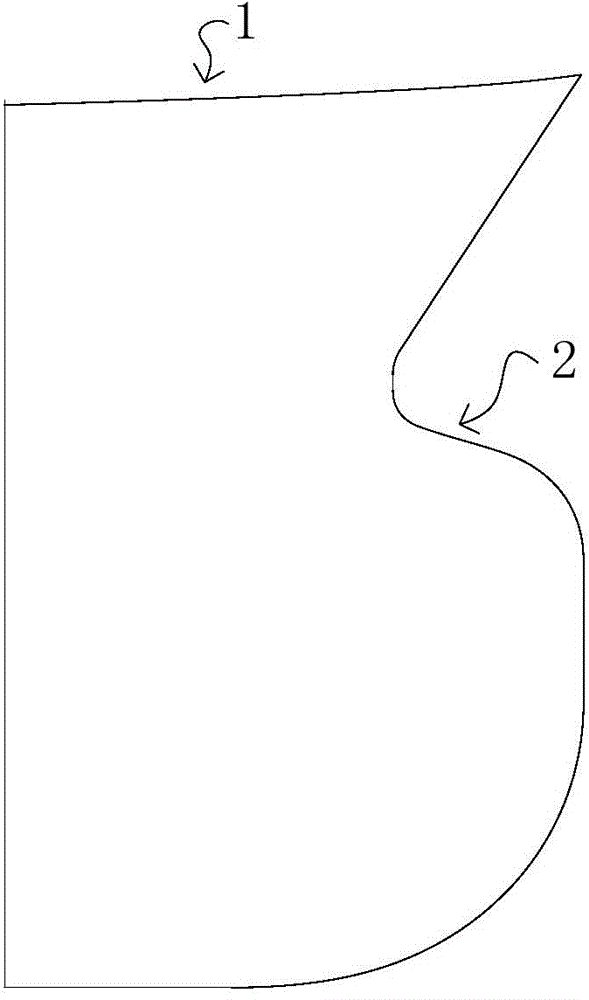

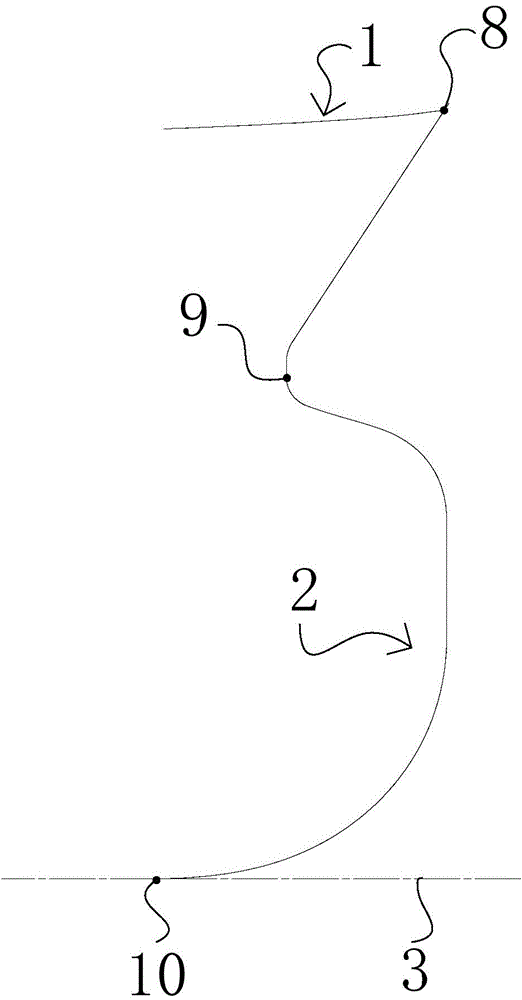

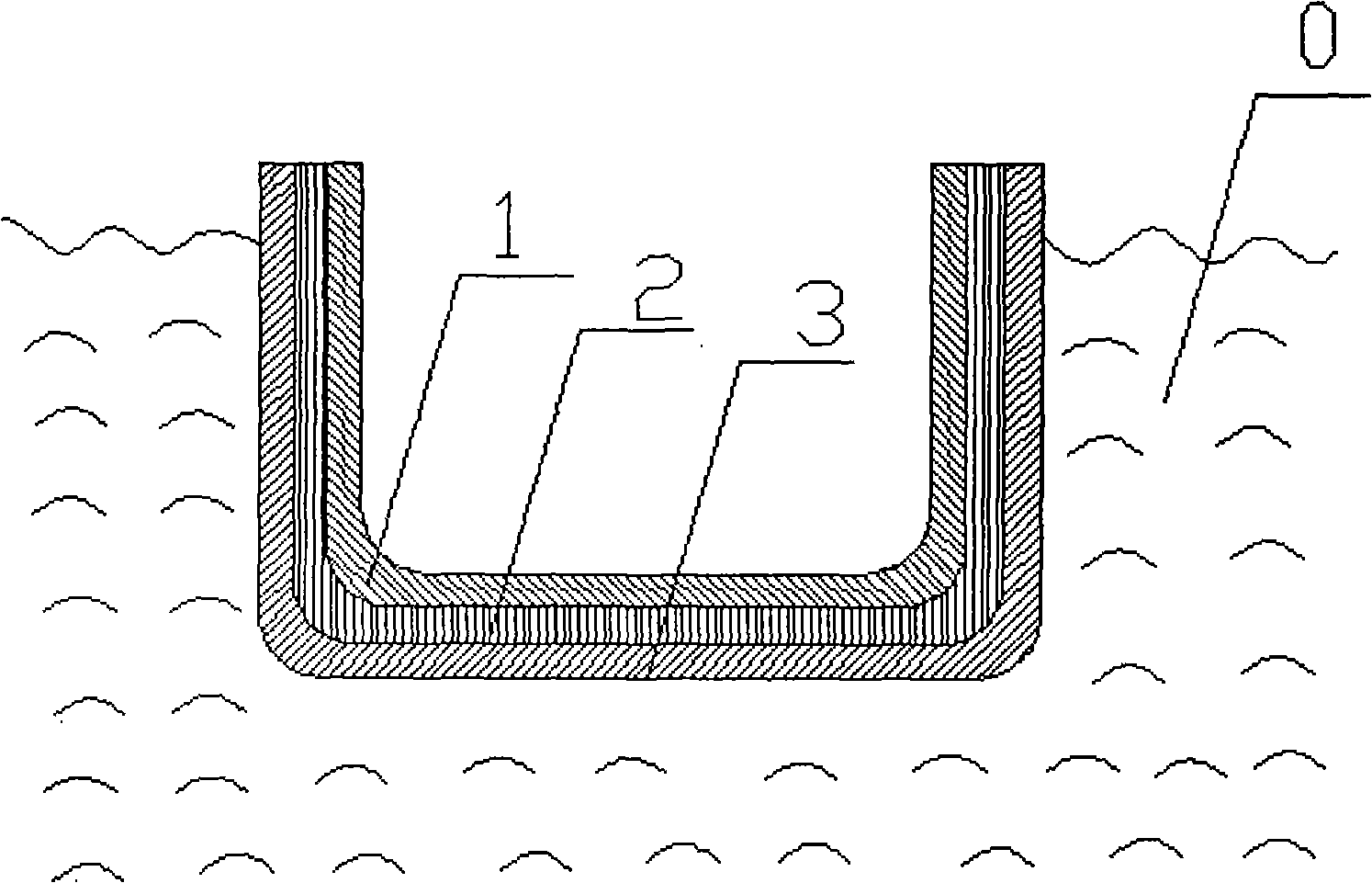

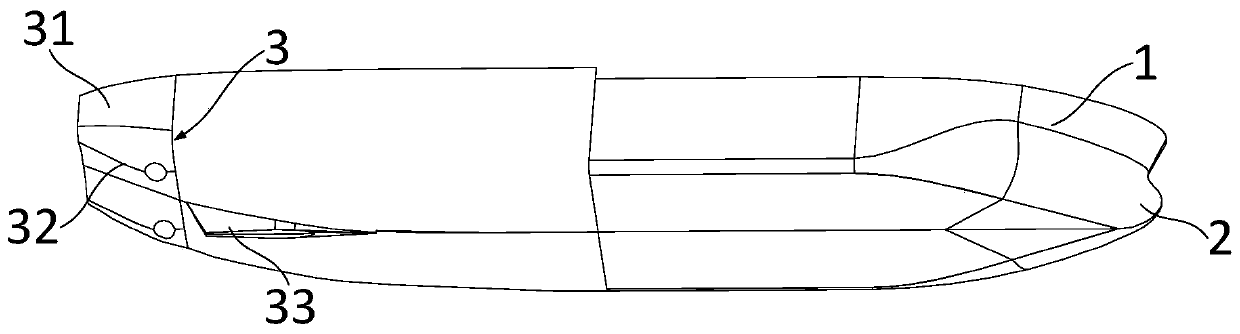

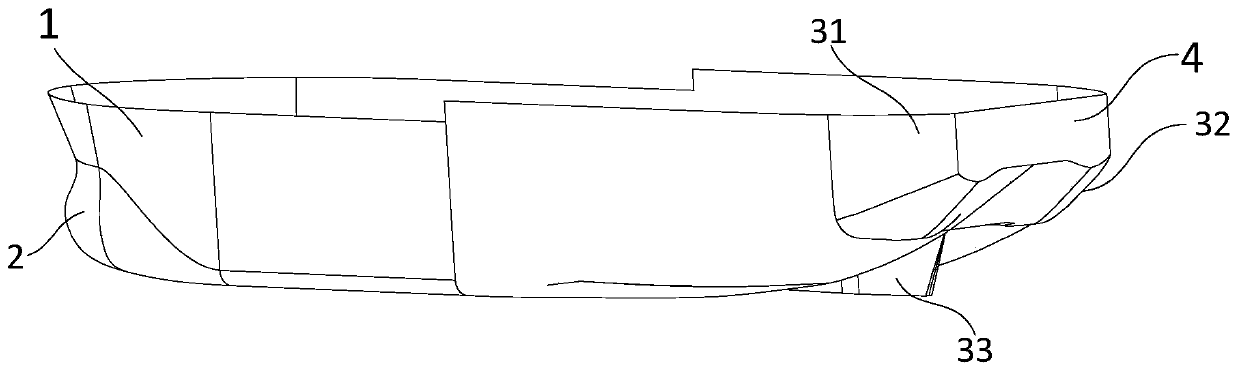

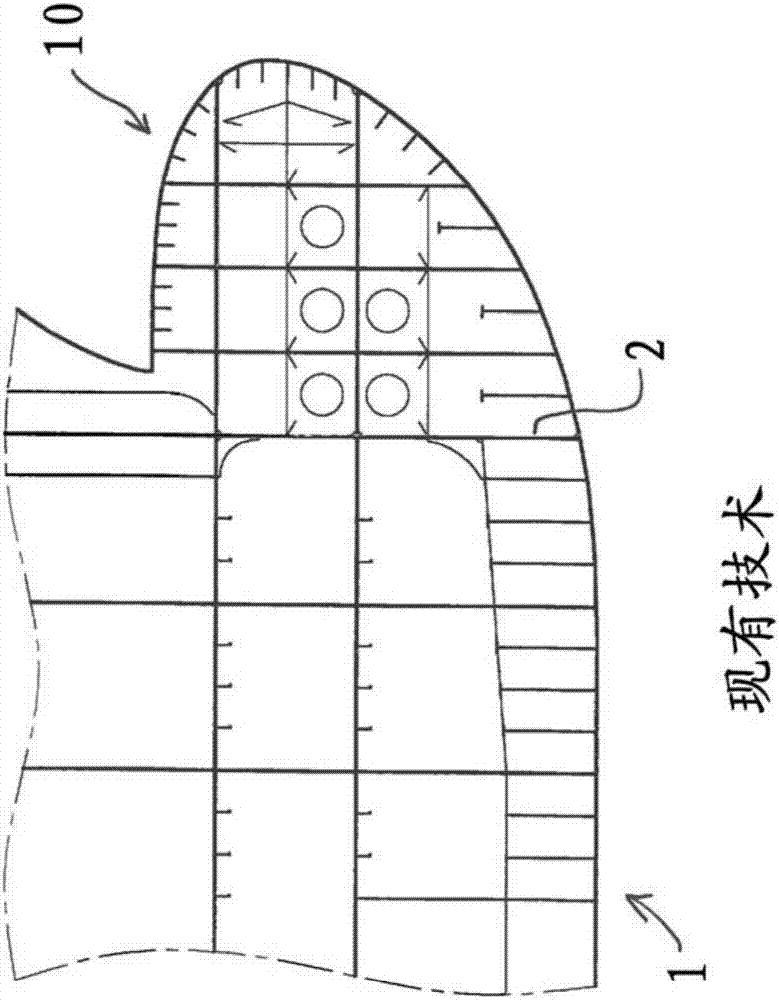

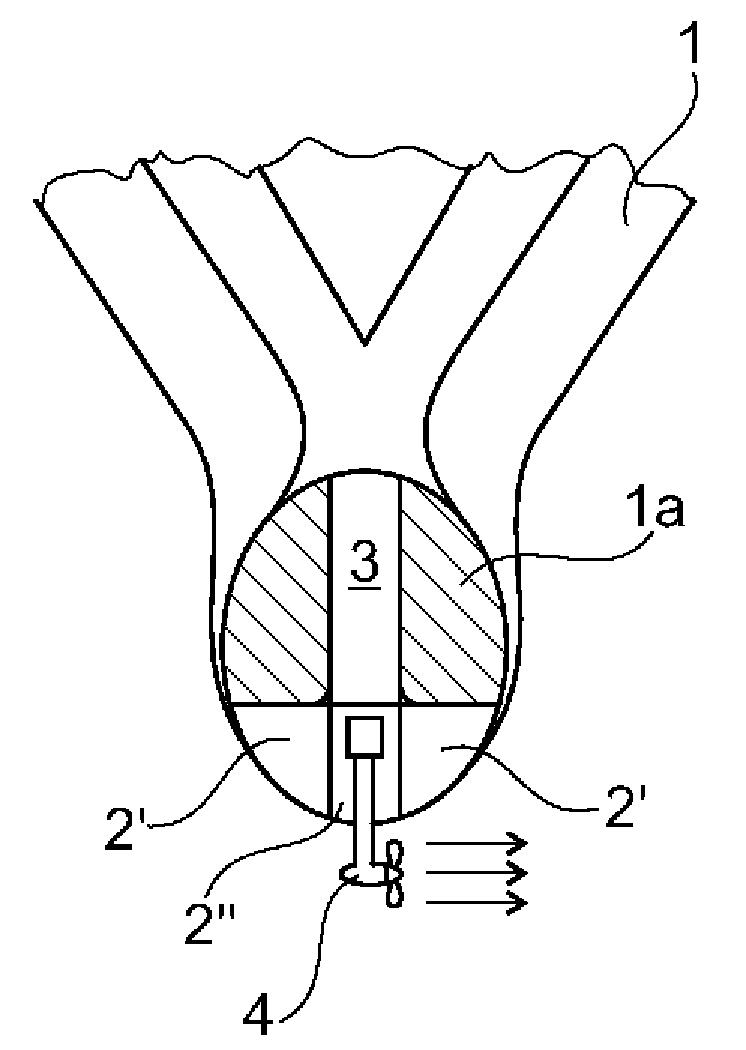

Marine vessel operating in ice-covered waters

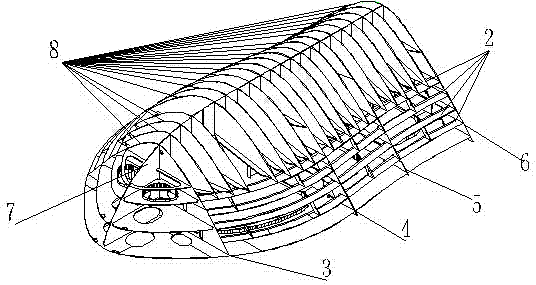

InactiveCN103842243AImprove skating performanceWatercraft hull designHydrodynamic/hydrostatic featuresWater flowPropeller

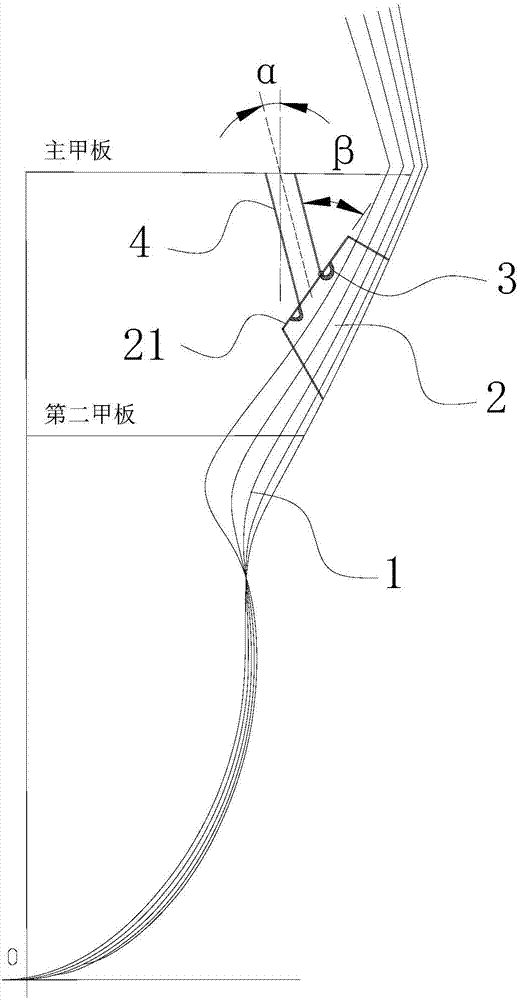

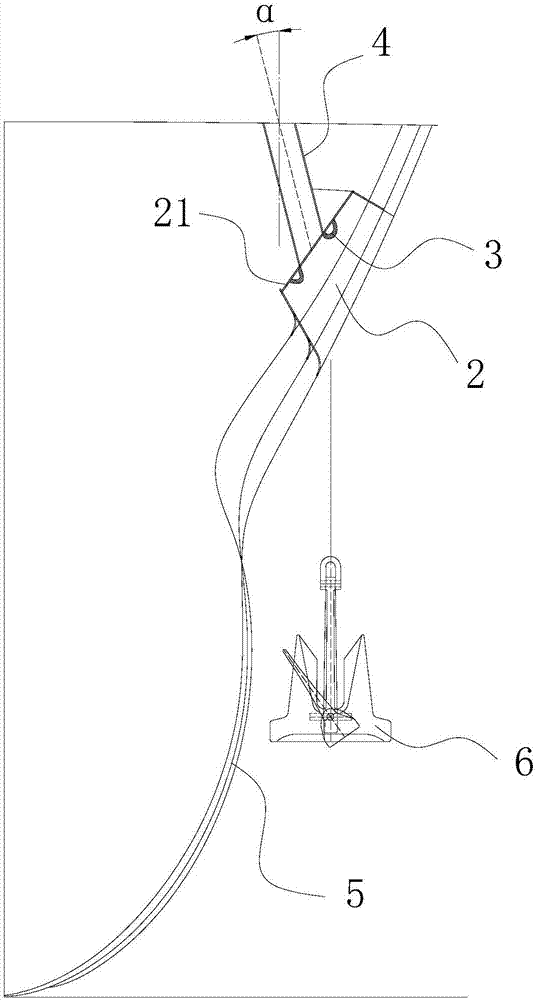

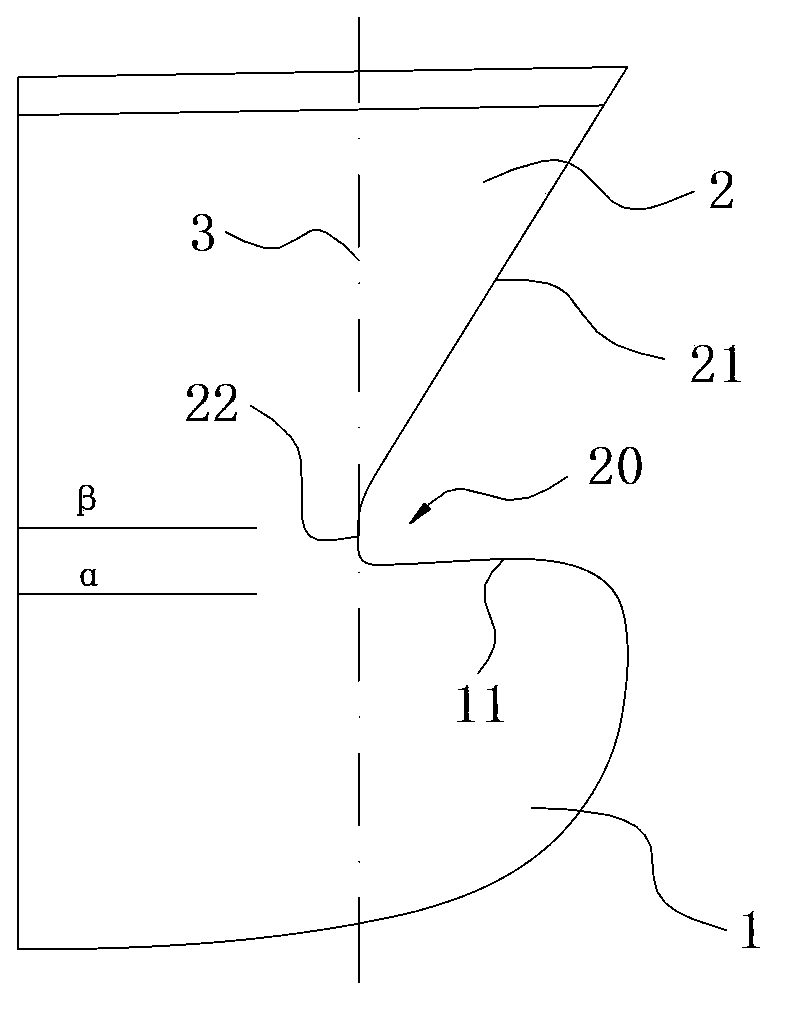

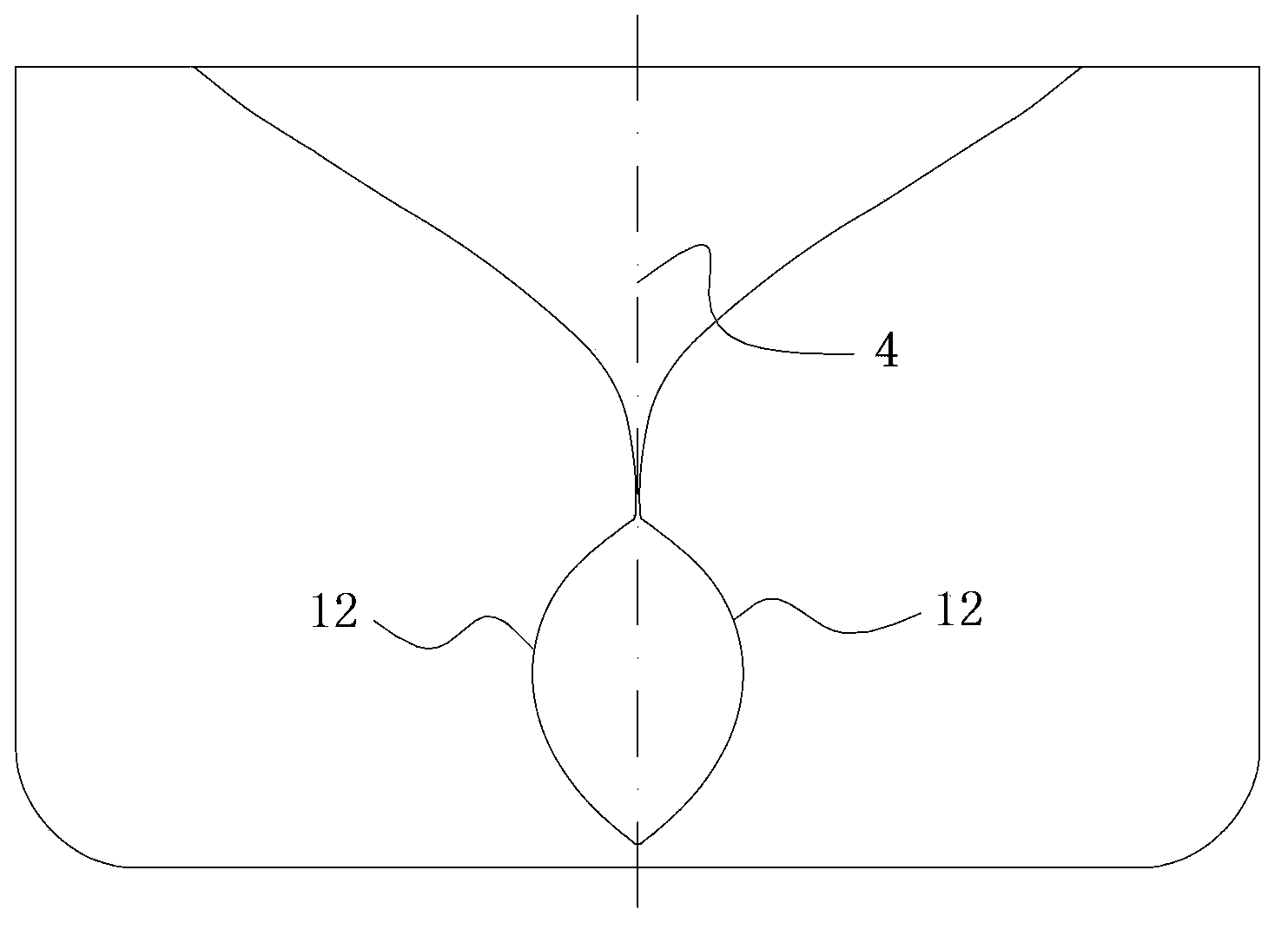

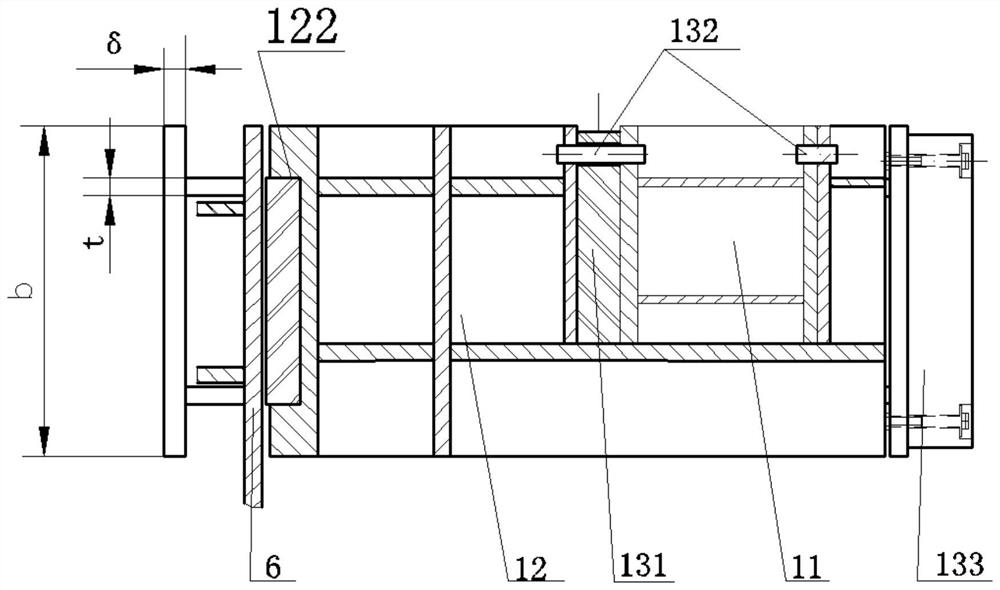

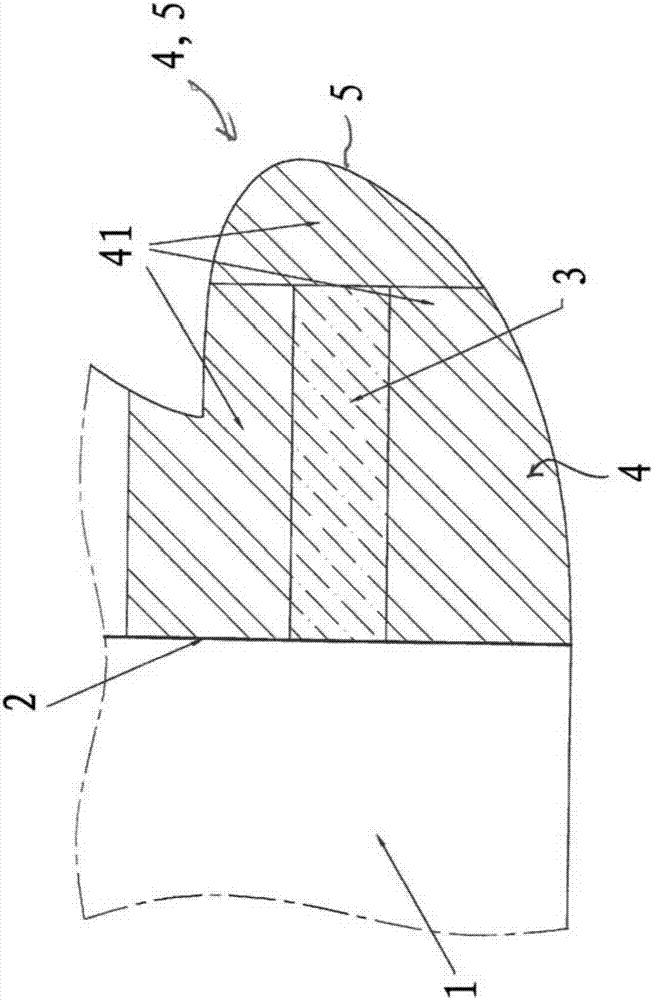

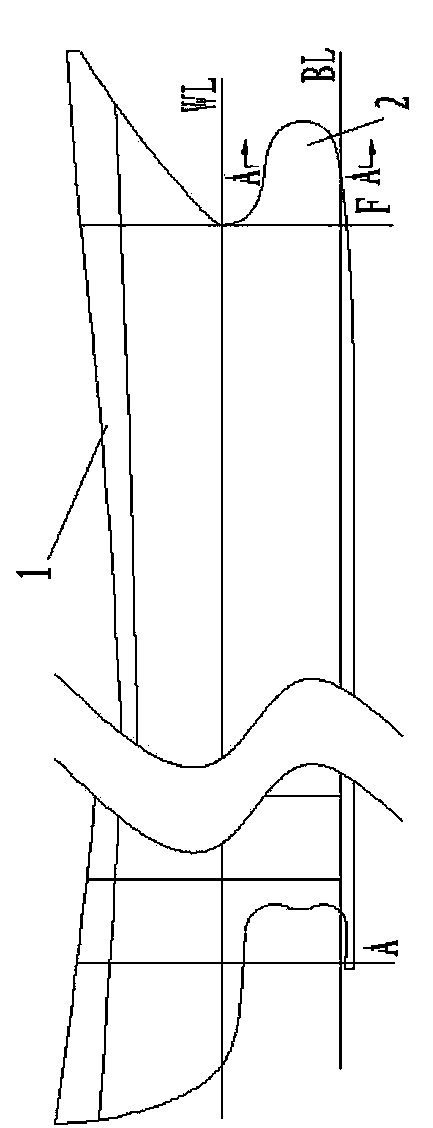

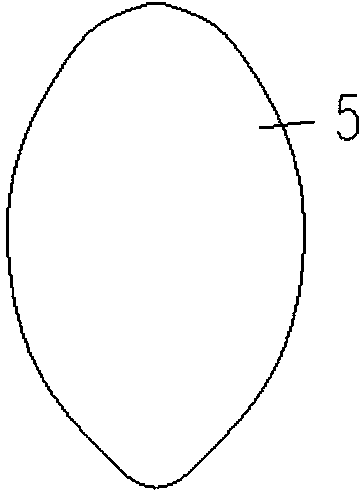

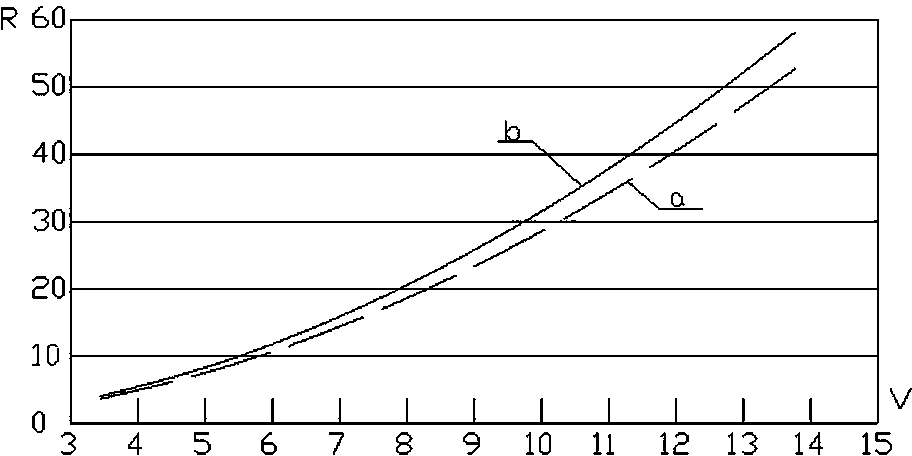

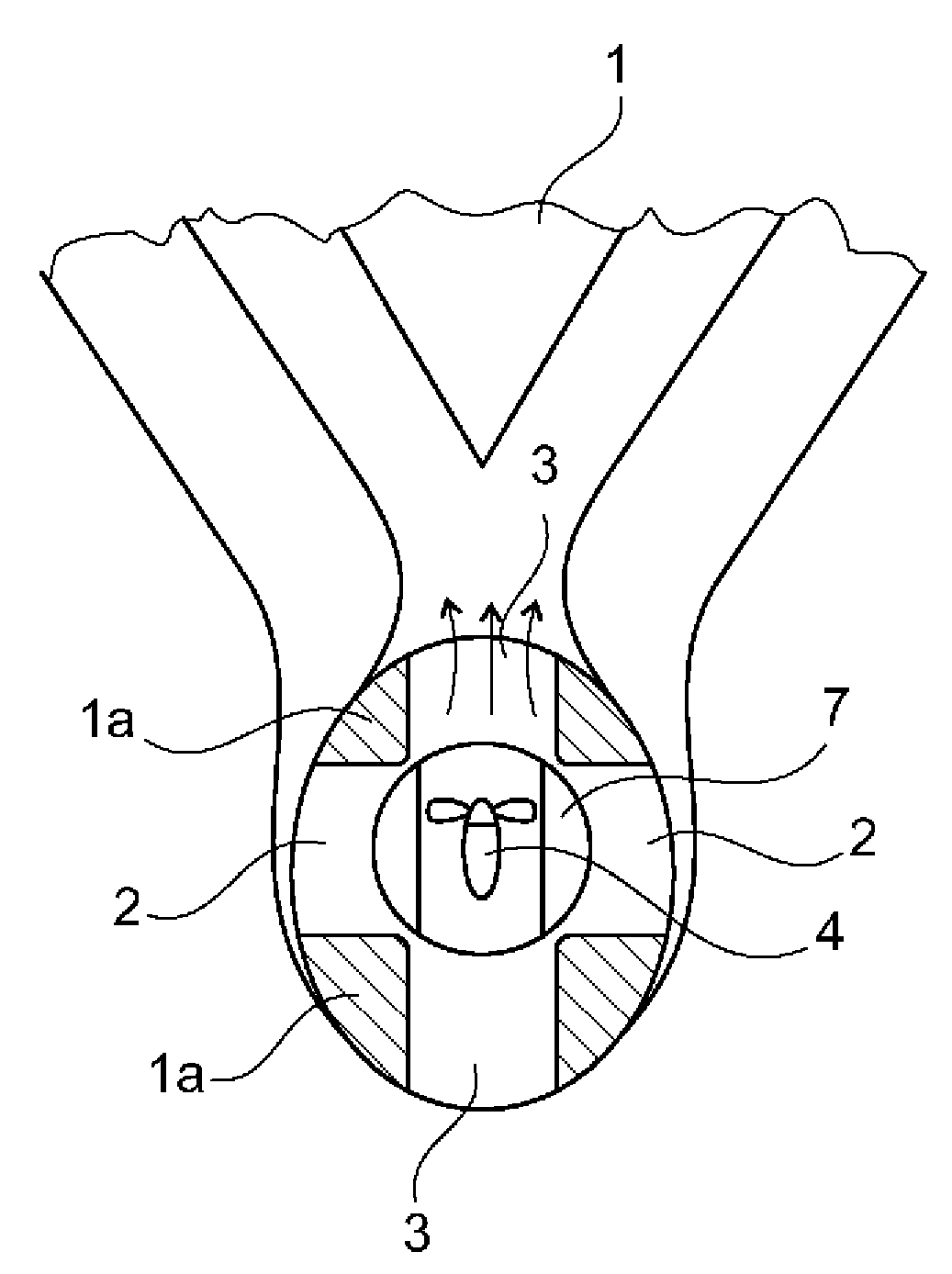

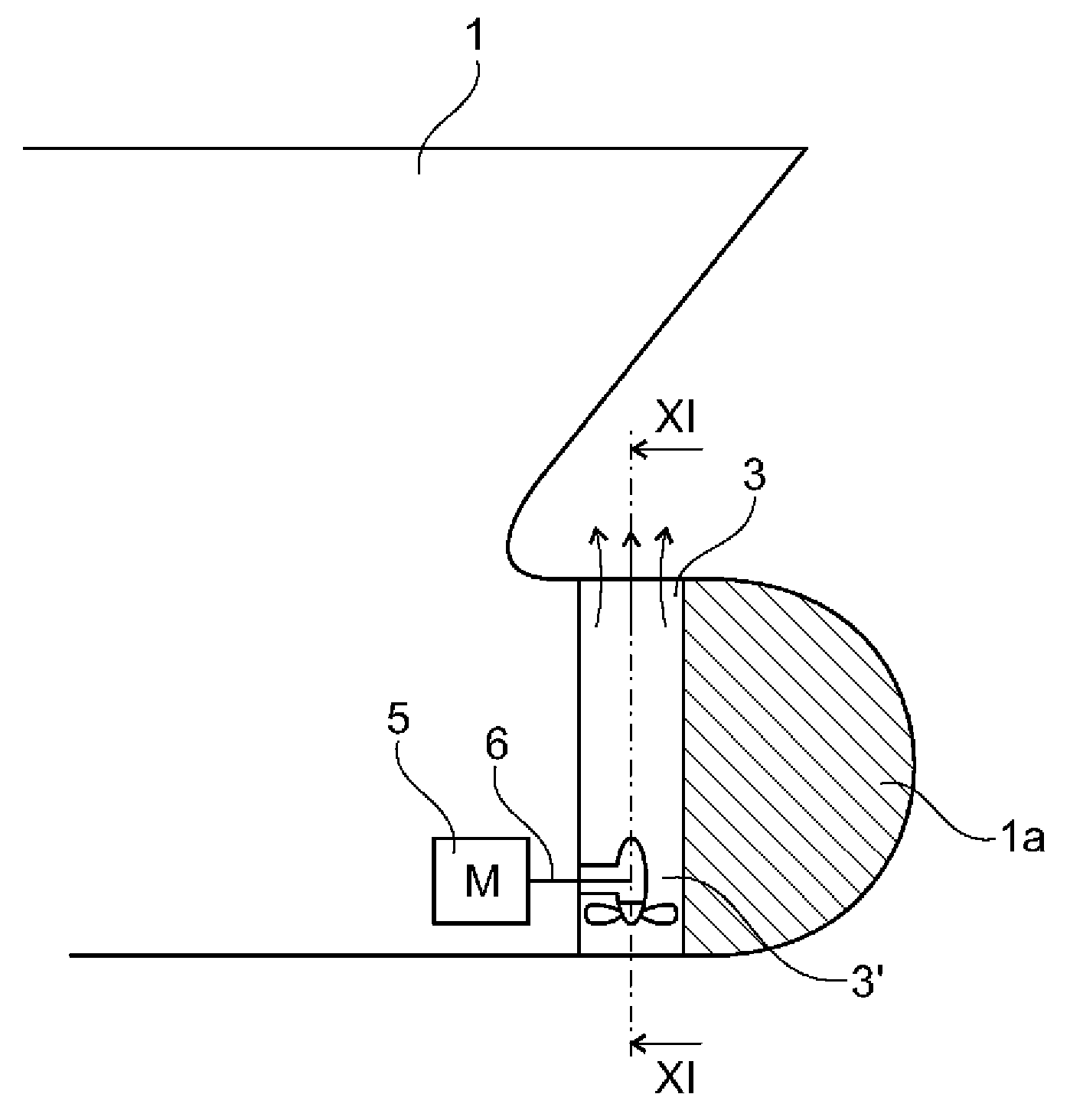

A marine vessel operating in ice-covered waters, having its hull (1) provided with a bulbous bow (1a) or a corresponding protruding part located at least for the most part below a load waterline (A). The bulbous bow (1a) or the corresponding protruding part is provided with a channel system, comprising a first channel part (2; 2a, 2b; 2') extending in a substantially horizontal direction through the bulbous bow (1a) or the corresponding protruding part transversely relative to a longitudinal axis of the vessel, and a second channel part (3; 3a,3b) extending through the bulbous bow (1a) or the corresponding protruding part at least substantially from below to above the bulbous bow (1a) or the corresponding protruding part. The bulbous bow (1a) or the corresponding protruding part is additionally provided with pump elements, a propeller (4), or the like, which are adapted to generate a powerful flow of water arranged to be directed by way of either one of said channel parts (2; 2a, 2b; 2'; 3, 3a, 3b) as required by each operation and need of the vessel.

Owner:AKER ARCTIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com