Bulbous bow positioning tool and positioning and installing method of bulbous bow

A positioning tooling, positioning and installation technology, used in transportation and packaging, ship components, ships, etc., can solve problems such as easy deformation and damage, low efficiency, and small installation space, and achieve positioning efficiency and accuracy. Outfitting rate and the effect of reducing enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

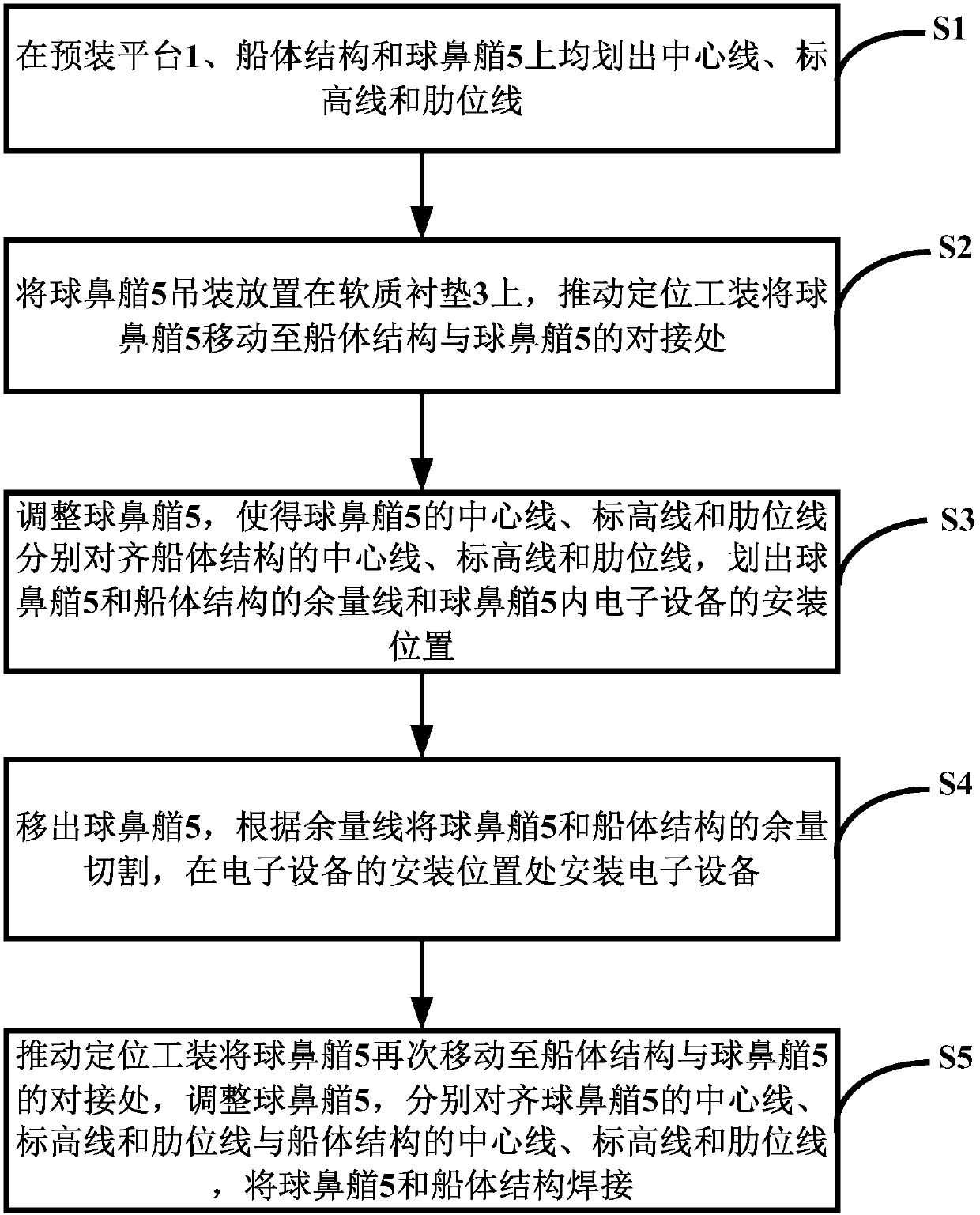

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

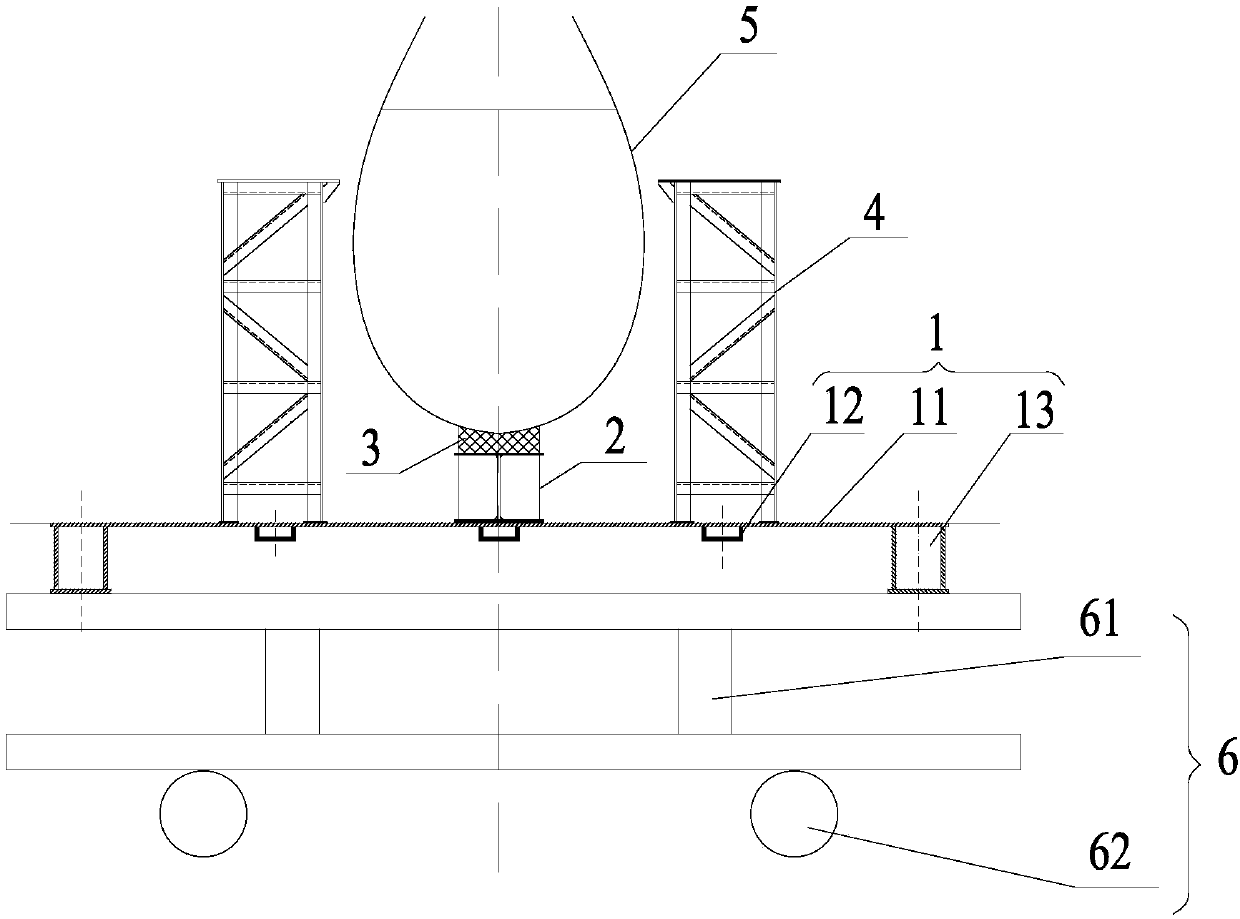

[0028] see figure 1 As shown, the embodiment of the present invention provides a bulbous bow positioning tool for installing the bulbous bow 5. The positioning tool includes a pre-installation platform 1, a base 2 fixed on the top of the pre-installation platform 1, and a base 2 fixed on the top of the base 2. The soft liner 3, the bulbous bow 5 is placed on the top of the soft liner 3, the shape of the soft liner 3 matches the shape of the bulbous bow 5, and the bottom of the pre-installed platform 1 is provided with a moving device 6 to move it . Wherein, the base 2 is a pier wood seat, and the soft pad 3 is made of pier wood. The base 2 and the soft pad 3 can be strip-shaped, or there can be multiple ones, and the multiple bases 2 and the soft pad 3 are arranged at a certain distance.

[0029] In this embodiment, the pre-install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com