Ship type of semi-submersible crane pipe-laying vessel

A pipe-laying vessel and semi-submersible technology, which is applied in the field of offshore oil engineering, can solve the problems of large water flow resistance, long column 2 length, and difficulty in ensuring the navigation speed of the pipe-laying vessel, so as to reduce the water flow resistance and improve the sailing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

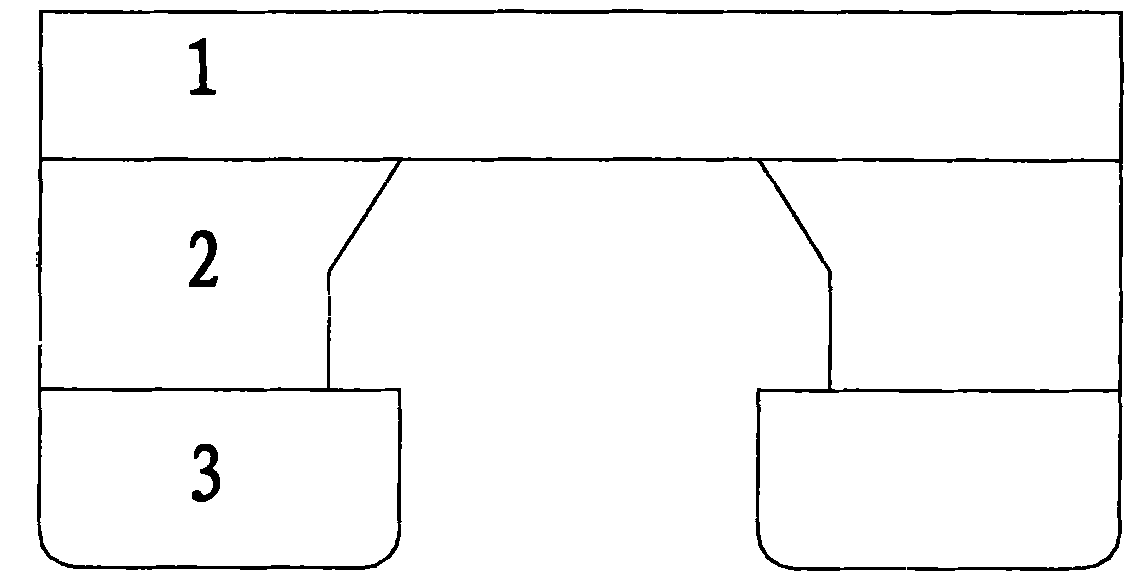

[0033] Embodiment: According to the requirements of the floating state and stability of the platform, the present invention adopts 5 rows of columns with different cross-sections and different spacings. The columns 2 are symmetrically arranged on the left and right sides of each row, and there are 10 columns 2 in total.

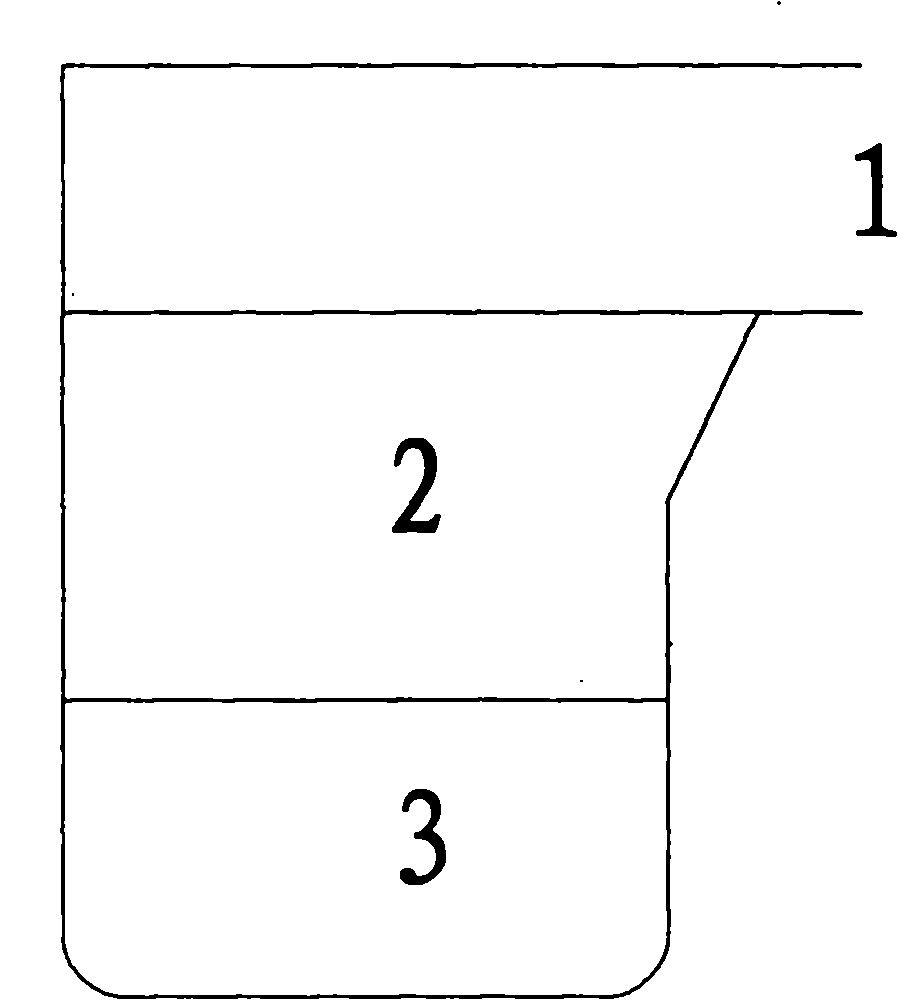

[0034] The uprights are arranged in different sections. The shape of several uprights arranged at the rear of the bow is: the connection between the upper half and the upper platform is a bottom-up inverted right-angled trapezoidal structure. Corner, the connection between the lower half and the lower floating body is a rectangular structure with four-cornered arcs.

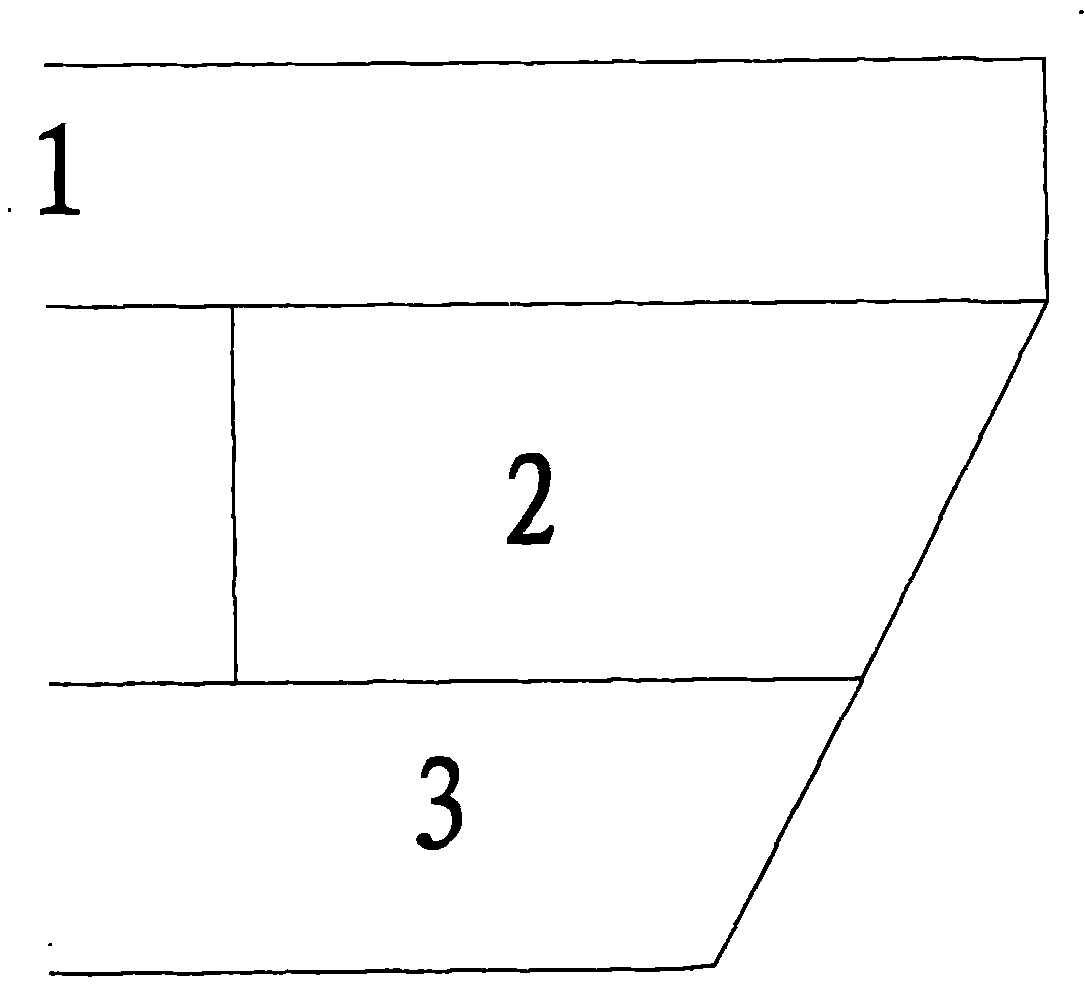

[0035] Starting from the bow, the side of the column 2 in the first row is irregularly trapezoidal according to the bow line. The upper bottom is 34.6m long, the lower bottom is about 26.4m long, 30m wide and 19.5m high.

[0036] The shape of the rear eight pillars 2 arranged at the rear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com