Condensing device for dish-washing machine and dish-washing machine provided with condensing device

A condensing device and dishwasher technology, which is applied to household cleaning devices, tableware washing machines/rinsing machines, tableware washing machines/rinsing and washing machine parts, etc. Drying and other problems, to achieve the effect of improving condensation efficiency, speeding up airflow and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

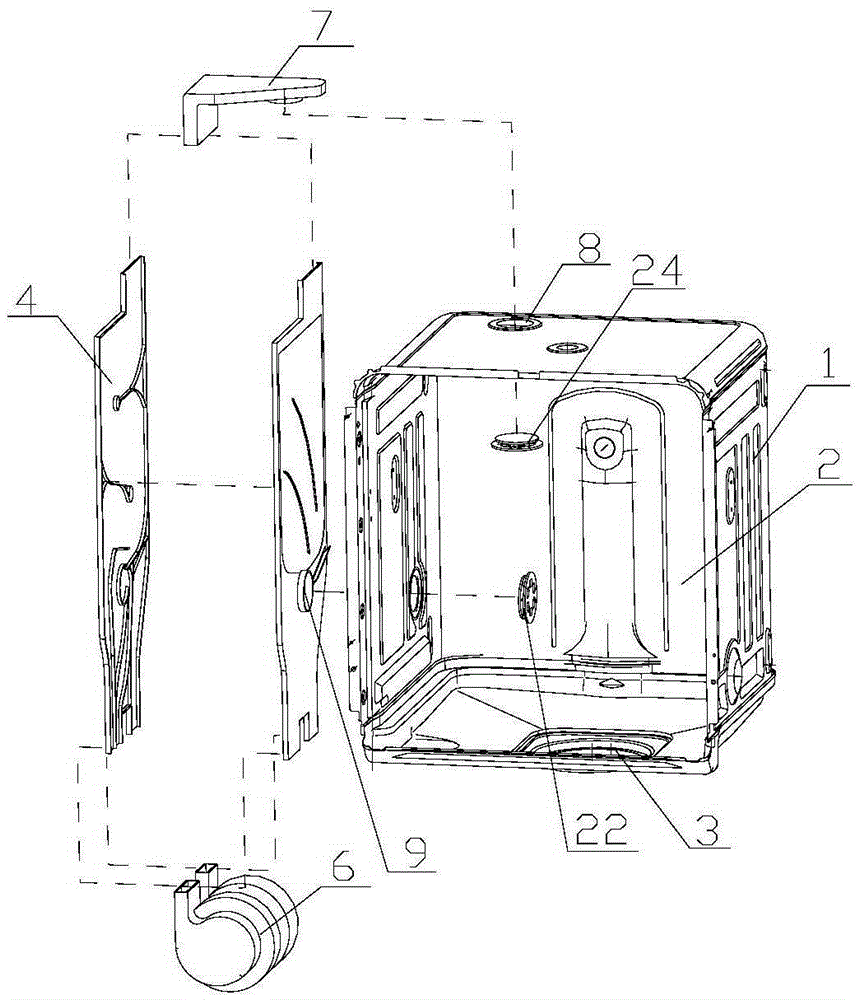

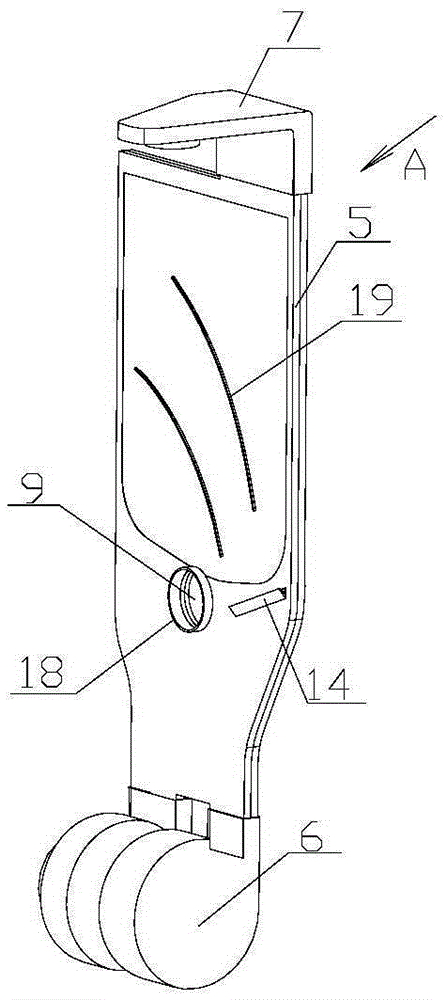

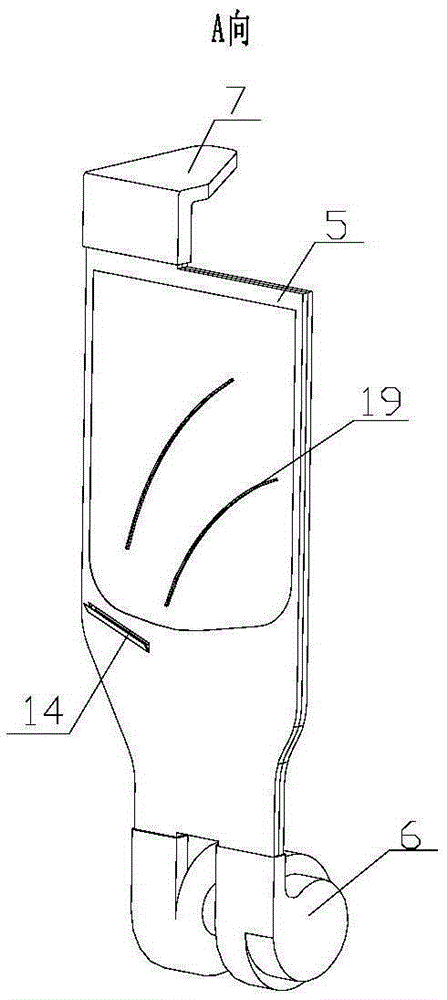

[0034] Such as figure 2 with image 3 As shown, in the present embodiment, the condensing device 4 includes a condenser 5, a blower fan 6 and an air intake passage 7, the top of the condenser 5 communicates with the air intake passage 7, and an air inlet 8 is provided on the top wall of the inner container 2, The air intake channel 7 is connected with the air intake port 8, and the water vapor in the liner 1 enters the air intake channel 7 through the air intake port 8, and finally enters the condenser 5, where the water vapor is condensed. The bottom of the condenser 5 is connected with the blower fan 6, and the blower fan 6 is installed between the bottom wall of the inner container 1 and the shell bottom wall of the dishwasher, so the inner container 1 and the shell of the dishwasher can be used to isolate noise to the greatest extent.

[0035] Such as Figure 2 to Figure 4 As shown, the condenser 5 is flat and formed by interlocking two side plates 5a and 5b, and the ch...

Embodiment 2

[0054] The difference from Embodiment 1 is that two fans 6 are used. The air outlet of one fan 6 is connected to the inlet of the air supply channel 12 in the condenser 5 to provide power for the internal air circulation, and the exhaust of the other fan 6 The outlet is connected to the inlet of the cooling air channel 11 in the condenser 5, which provides power for the external air circulation. There is also a return air port on the fan 6 which provides power for the internal air circulation, and is connected with the outlet of the condensation channel 13 in the condenser 5. A drain port 23 is provided at the bottom of the fan 6 for discharging a small amount of condensed water entering the fan 6 .

[0055] Both fans 6 are installed between the bottom wall of the liner 1 and the bottom wall of the shell.

Embodiment 3

[0057] The difference from Embodiment 1 and Embodiment 2 is that two fans 6 are used, and there are two airflow passages in the condenser 5, one of which is the air supply passage 12 for delivering airflow to the inner tank 1, and the air supply passage 12 The side plate 5b of the condenser 5 of 12 is provided with an air supply port 9, which communicates with the inner tank 1; the other is a condensation channel 13, and the water vapor in the inner tank 1 enters the air intake channel 7 from the air inlet 8 at the top of the inner tank 1 Finally, it enters the condensation channel 13 of the condenser 5 , and the water vapor is condensed in the condensation channel 13 . One of the fans 6 has an air exhaust port and an air return port, the air exhaust port is connected with the inlet of the air supply channel 12, and provides power for the internal air circulation, and the air return port is connected with the outlet of the condensing channel 13 of the condenser 5, in this fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com