Continuous drying system for slurry or powder and its working method

A drying system and drying technology, which is applied to the dryer of static materials, the separation method, and the drying of solid materials, etc., can solve the problems of high water content of materials, low production efficiency, and low heat transfer efficiency, and achieve high evaporation efficiency and production efficiency. The effect of high efficiency and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

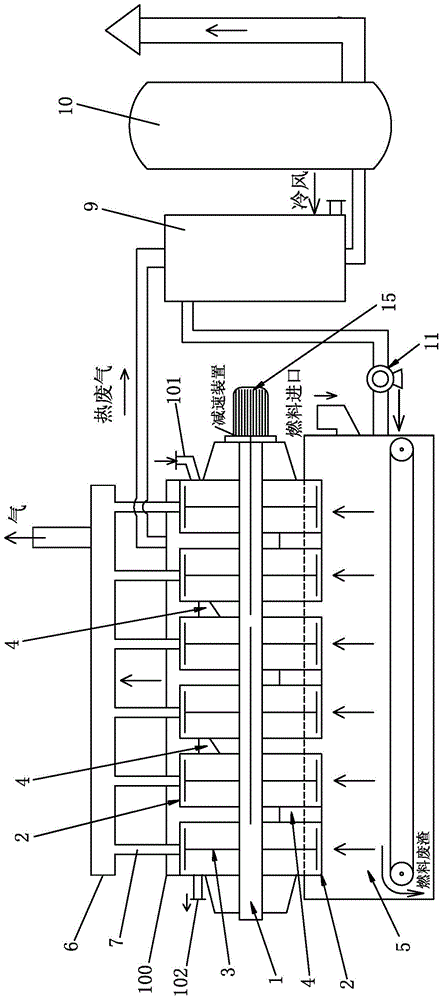

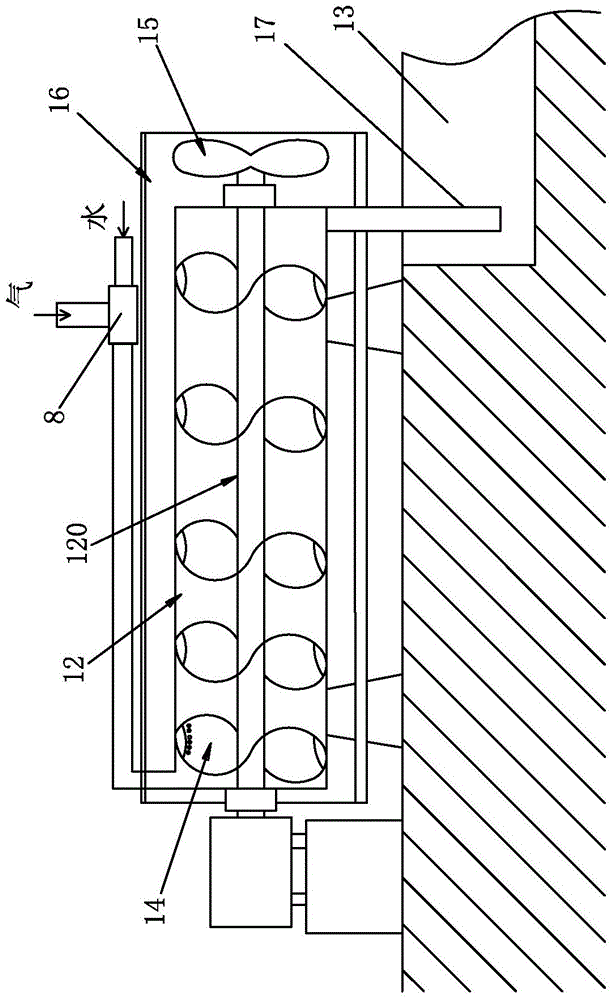

[0035] See figure 1 The continuous drying system for slurry or powder in this embodiment includes: a drying host 100 and a collection system for collecting volatiles discharged from the drying host 100 .

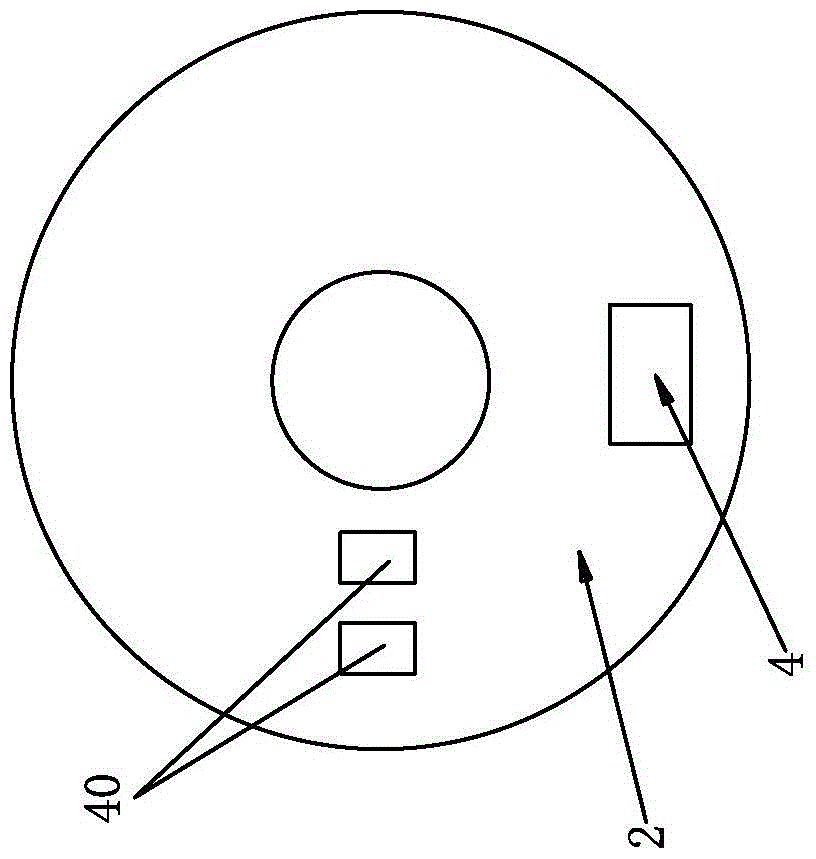

[0036] The drying host 100 includes: a central main shaft 1, 5 to 10 annular cavities 2 arranged in parallel vertically, and a heating device for heating each annular cavity 2 . The annular cavities 2 are arranged alternately front and back and are fitted in a sliding seal on the central main shaft 1, and the scrapers 3 in each annular cavity are fixed on the central main shaft 1 for driving each scraper to rotate. The scraper 3 is in the shape of a rice pad or wind blades, and is attached to the rear side wall of the corresponding annular cavity. The scraper 3 is adapted to rotate against the rear side wall of the annular cavity 2, so as to prevent the formation of a scale layer on the bottom plate, which affects the thermal conductivity of the bottom plate, and at the sam...

Embodiment 2

[0049] The working method of the continuous drying system of the slurry or powder described in the above-mentioned embodiment 1, comprising:

[0050] A. To heat each annular cavity 2; so that the temperature of the annular cavity 2 is suitable to reach 50-700°C (the specific temperature needs to be selected according to different materials).

[0051] B. Input the slurry through the pump or the powder through the screw conveyor from the feed port of the annular cavity at the front end, and at the same time turn on the main motor 15 to drive the central main shaft 1 to rotate, and at the same time, each scraper 3 rotates ;

[0052] C. Under the rotation of each scraper plate 3, the slurry or powder enters each annular cavity 2 for heat exchange and drying, and finally is discharged from the outlet of the rear annular cavity 2; during this period, the volatile matter is discharged from the The exhaust channel 6 is output, and the volatile matter is collected through a collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com