Crop drying device with rapid drying function

A technology of rapid drying and drying equipment, which is applied in the direction of drying, drying machines, drying solid materials, etc., and can solve the problems of reducing the drying efficiency of crops, rotten crops, and poor drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

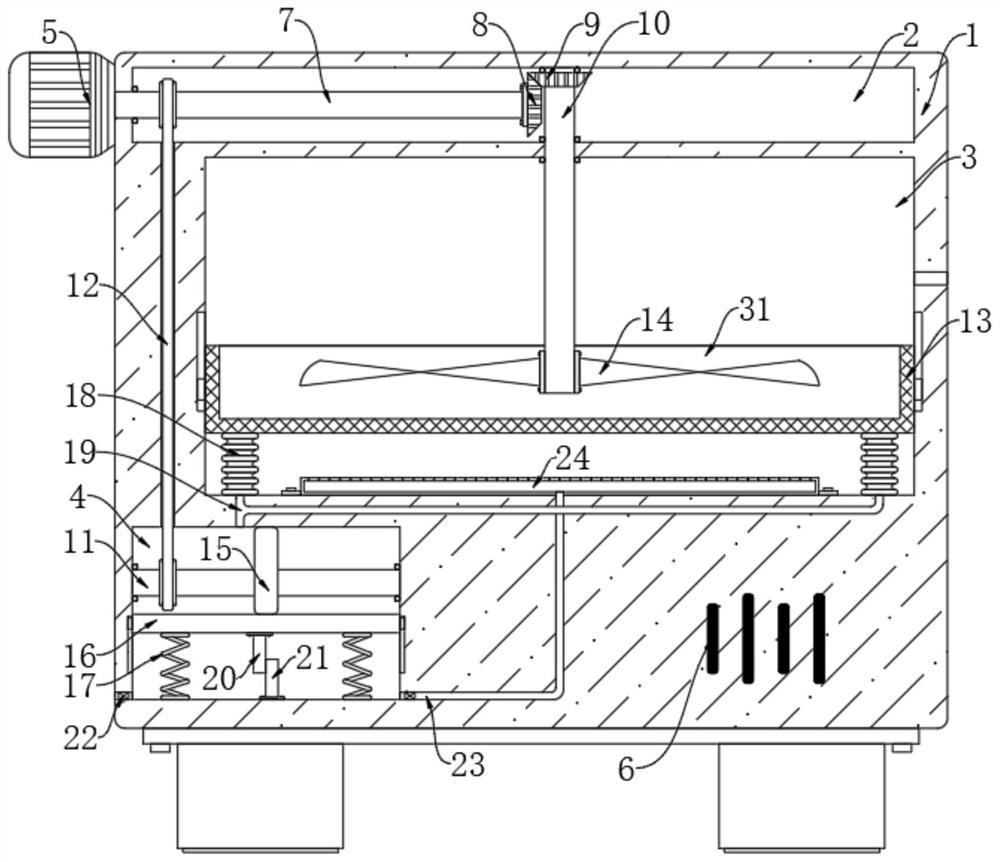

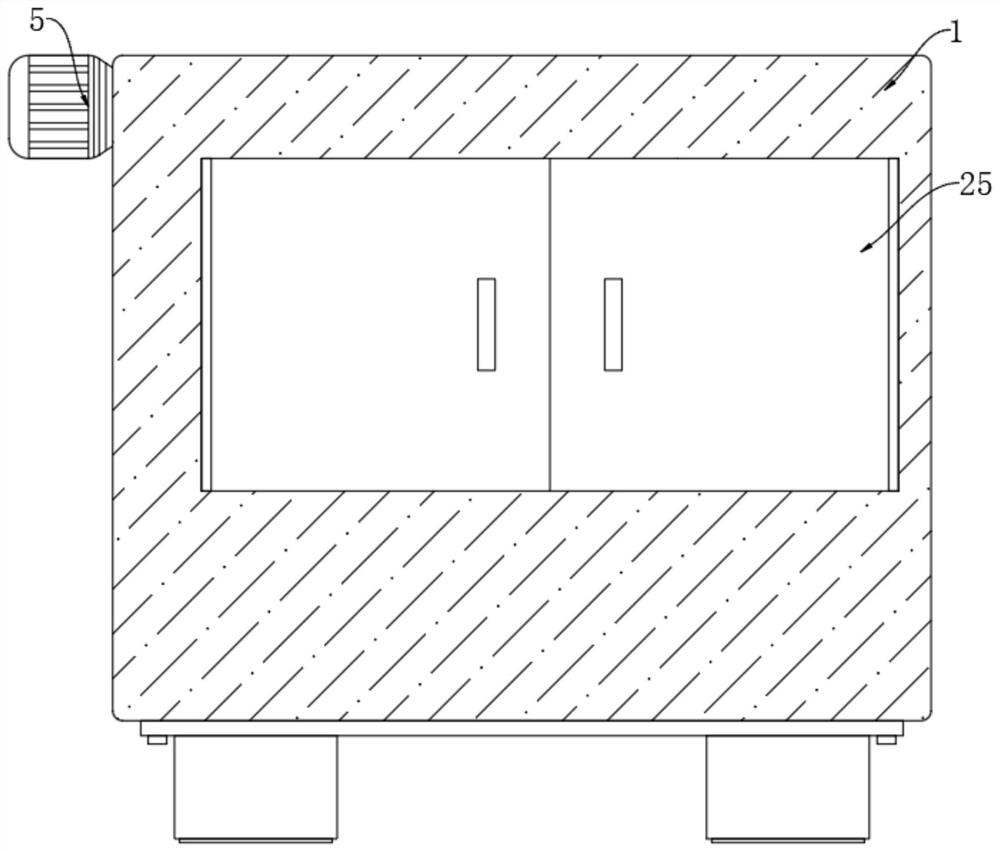

[0022] refer to Figure 1-2 , a crop drying device with fast drying function, comprising a box body 1, the box body 1 is sequentially provided with a rotating chamber 2, a working chamber 3 and a moving chamber 4 from top to bottom, and the front inner wall of the working chamber 3 is provided with An opening communicating with the outside world, on which a sliding door 25 is installed;

[0023] Trigger mechanism, the trigger mechanism includes a first rotating rod 7 horizontally arranged in the rotating chamber 2, a motor 5 is installed on the left side wall of the box body 1, the output shaft end of the motor 5 extends into the rotating chamber 2, and is connected with the first rotating rod. The left end of rod 7 is fixedly connected, and the right end of first rotating rod 7 is fixedly connected with first bevel gear 8, and vertically is provided with second rotating rod 10 in rotating chamber 2, and the upper end of second rotating rod 10 is connected with the interior of...

Embodiment 2

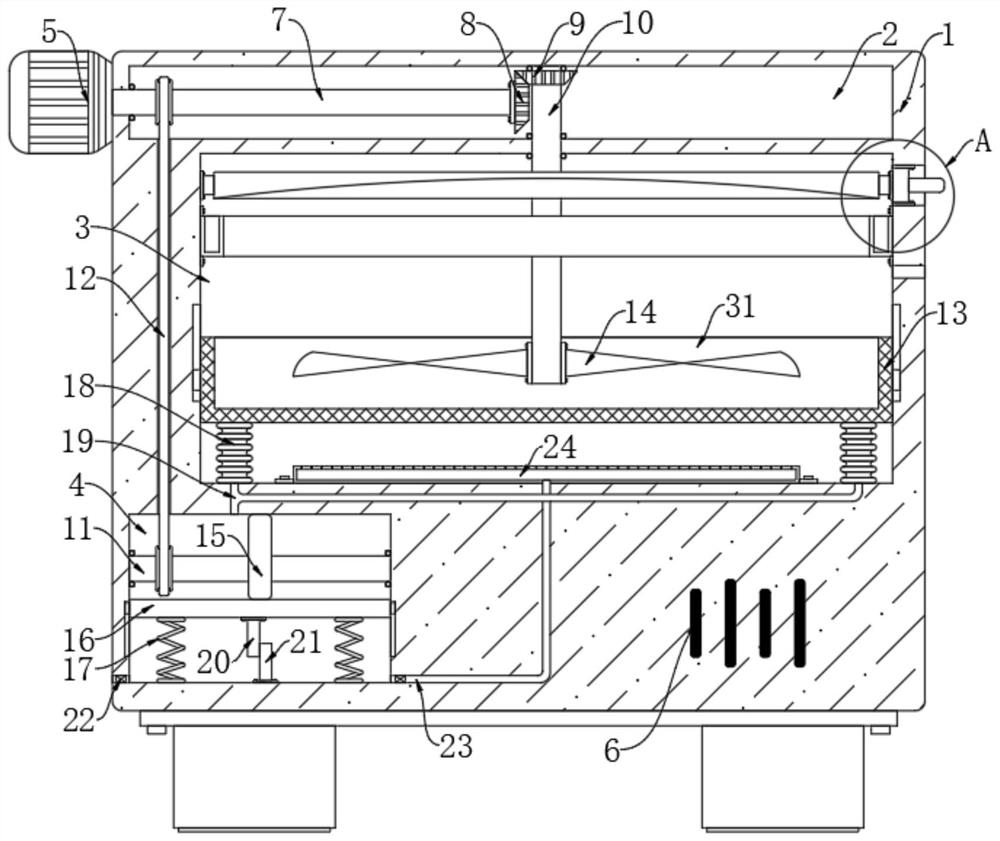

[0032] refer to Figure 3-4 The difference between this embodiment and Embodiment 1 is that the right inner wall of the working chamber 3 is provided with a port 26 communicating with the outside world, and a cooling plate 27 is installed in the port 26, the cooling plate 27, the motor 5 and the power supply 6 Electrically connected in turn, the second rotating rod 10 is fixedly connected with a circular plate 28, the lower end of the circular plate 28 is provided with a groove 29, the inner wall of the working chamber 3 is fixedly connected with a ring-shaped heat-conducting block 30, the right end of the ring-shaped heat-conducting block 30 Contact with the cooling sheet 27, so that the heat in the annular heat conducting block 30 can be introduced into the cooling sheet 27, the inner side wall of the annular heat conducting block 30 is in contact with the circular plate 28, the circular plate 28 is a heat conducting material, and the heat in the circular plate 28 The heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com