Detachable anti-scaling efficient evaporator for water source heat pump

A technology of water source heat pump and evaporator, which is applied in the direction of evaporator/condenser, heat exchanger shell, indirect heat exchanger, etc., which can solve the problem that the flow boundary layer and thermal boundary layer cannot be obtained, which affects the density of the anti-corrosion layer, and does not enhance the transmission. Heat and other problems, to avoid the impact of vibration and collision between tubes, improve economy and timeliness, and avoid metal fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

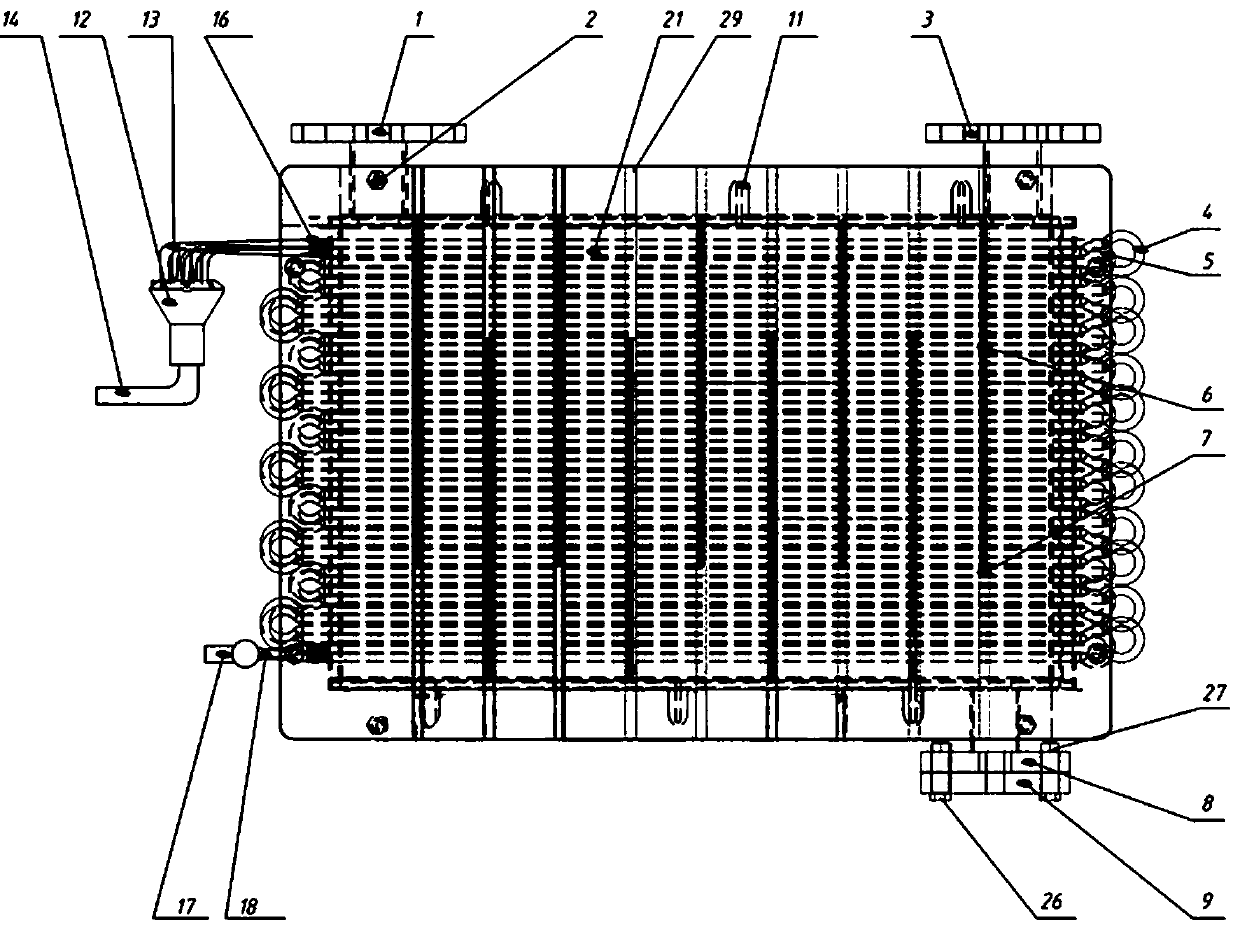

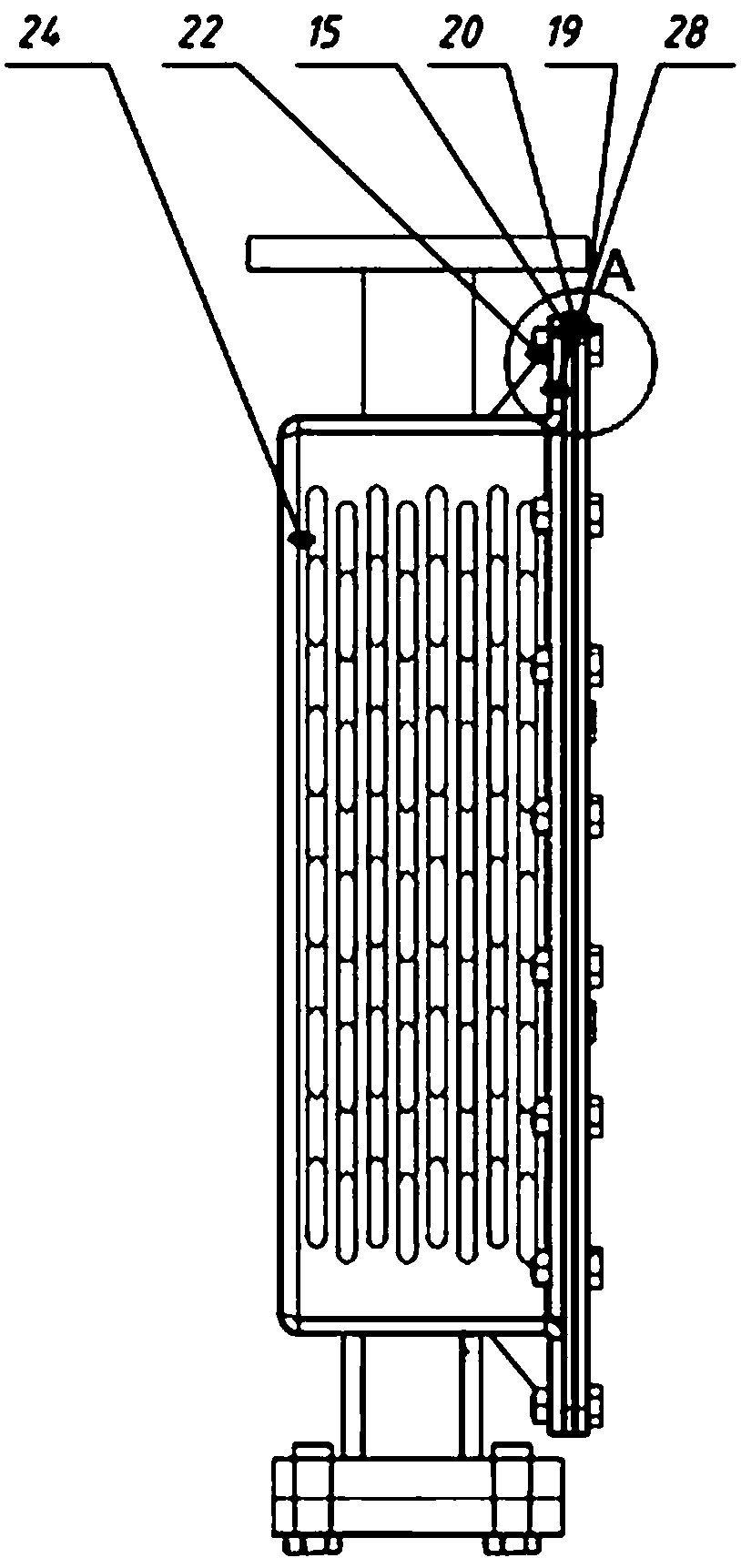

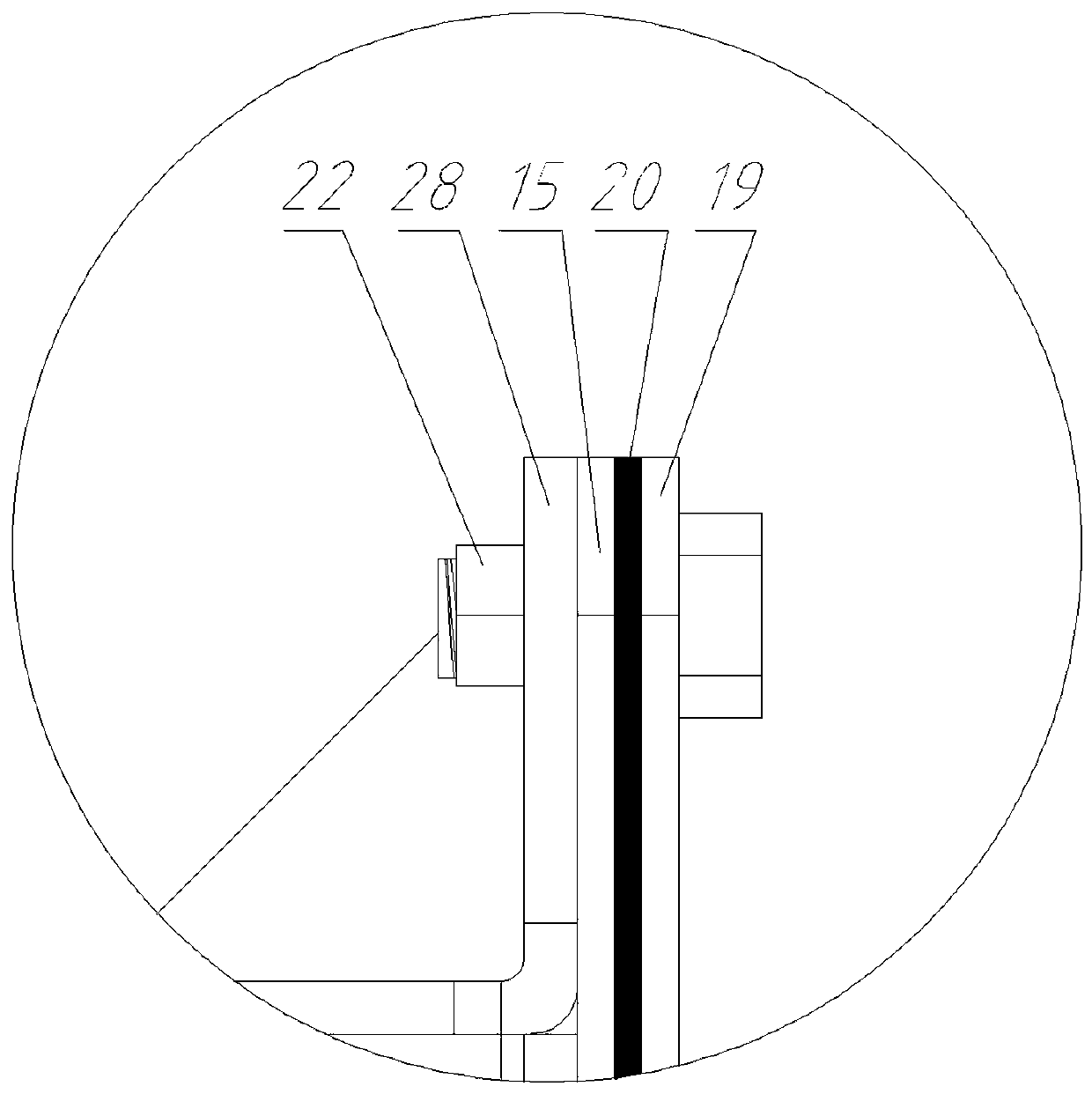

[0061]A detachable anti-scaling evaporator for water source heat pumps that enhances flow channel heat transfer. The water supply enters the cylinder body 24 of the heat exchanger through the water inlet flange 1. The cylinder body 24 has a cylinder flange flange 28 to ensure the sealing surface It is smooth, and a sealing and fitting reinforcing frame 15 is welded on the flange flange of the cylinder, and the sealing and fitting reinforcing frame 15 has a sealing rubber limit groove. A rubber sealing frame 20 is sandwiched between the cover plate 19 and the sealing and fitting reinforced frame, and the sealing rubber frame 20 is limited by the sealing rubber limiting groove. The cylinder body 24 and the cover plate 19 and the clamped parts are fixed by several cover plate bolts 2 and cover plate nuts 22 . In order to ensure the overall strength of the cylinder body, a sheet metal gusset 11 is installed on the flange flange 28 of the cylinder body. A plurality of deflectors 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com