Carbon fiber composite McPherson suspension control arm and preparation method thereof

A composite material and control arm technology, used in suspension, cantilever mounted on a pivot, transportation and packaging, etc., can solve the problems of limited space for lightweight and weight reduction, uneven local force, and low product qualification rate. , to reduce the cost of materials, improve the qualification rate, and simplify the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Attached below figure 1 To attach Figure 7 The present invention is further elaborated:

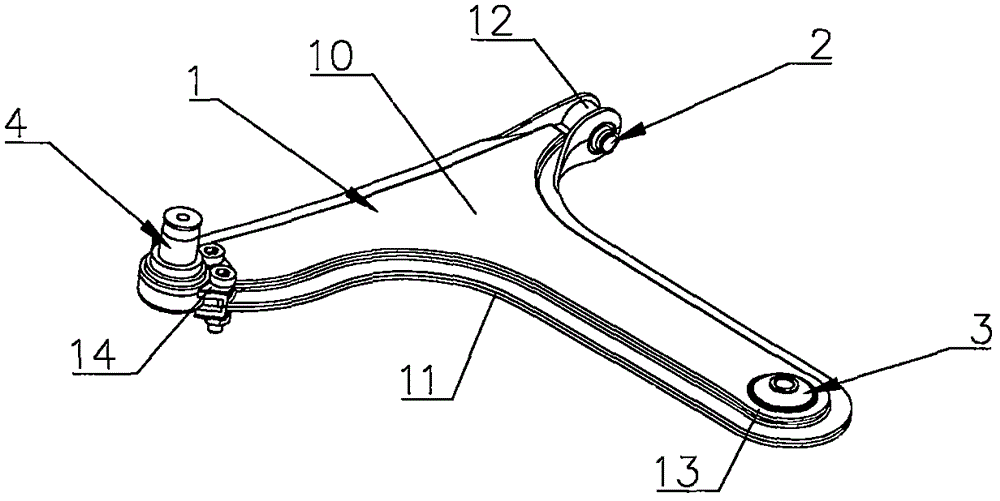

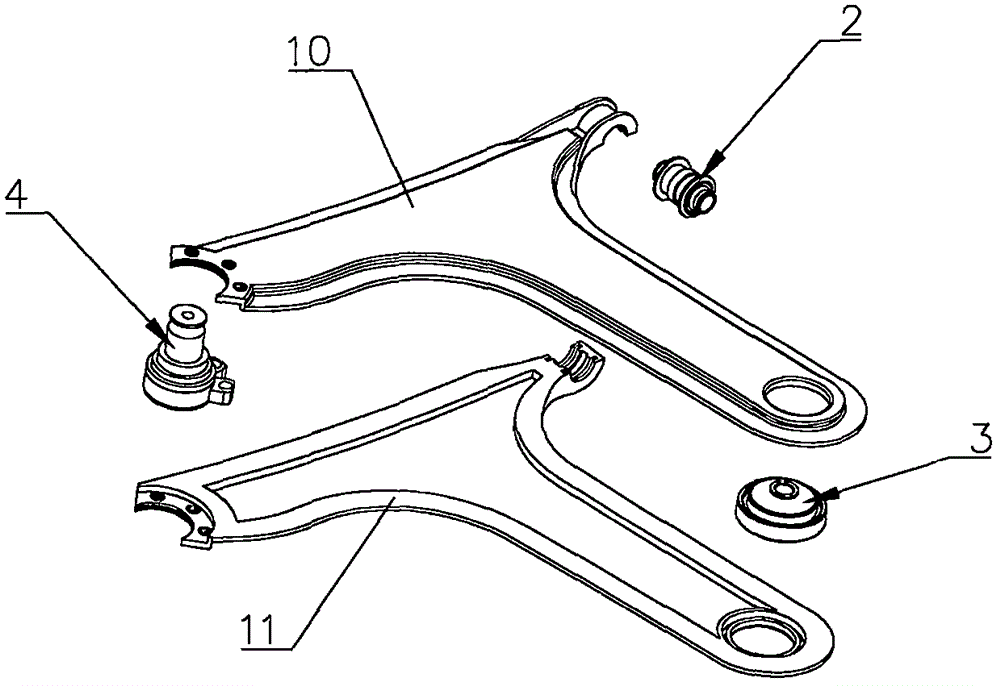

[0032] like Figure 1 to Figure 3 The shown carbon fiber composite MacPherson suspension control arm includes a control arm body 1, a first bush 2, a second bush 3 and a ball pin 4, the control arm body 1 is made of carbon fiber, and the first bush The sleeve 2 is used to connect the body, and the second bush 3 is used to connect the steering knuckle. like Figure 5 As shown, the control arm body is integrally formed by laminating the upper single piece 10 and the lower single piece 11 to form a hollow hat-shaped cavity structure, wherein the upper single piece 10 and the lower single piece 11 are mirror-symmetrically distributed along the parting surface , the control arm body 1 is respectively provided with a first bushing end 12 for installing the first bushing 2, a second bushing end 13 for installing the second bushing 3, and a ball pin end 14 for connecting the ball pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com