Bulbous bow, a sea-going vessel with such bow, and methods of its manufacture and installation

一种船首、球鼻的技术,应用在海船领域,能够解决设计昂贵、昂贵工艺、困难等问题,达到容易更换、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

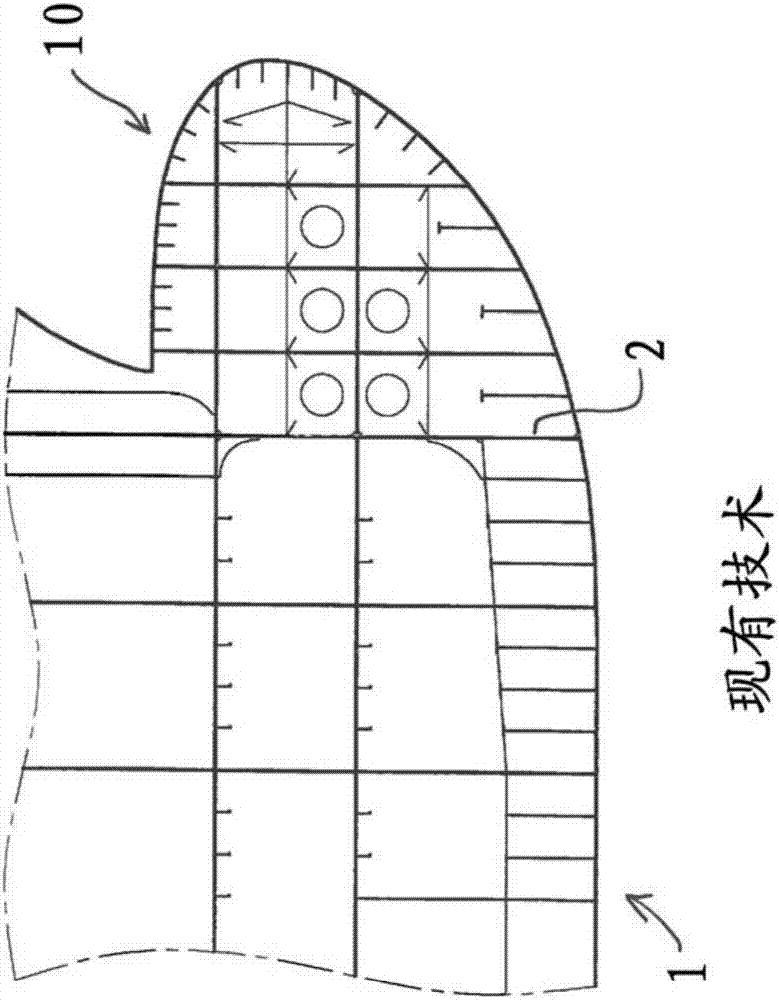

[0024] exist figure 1 The conventional structure of a marine vessel 1 with a bulbous bow 10 in its bow is shown. The bow 10 is constructed integrally with the structure of the vessel 1 .

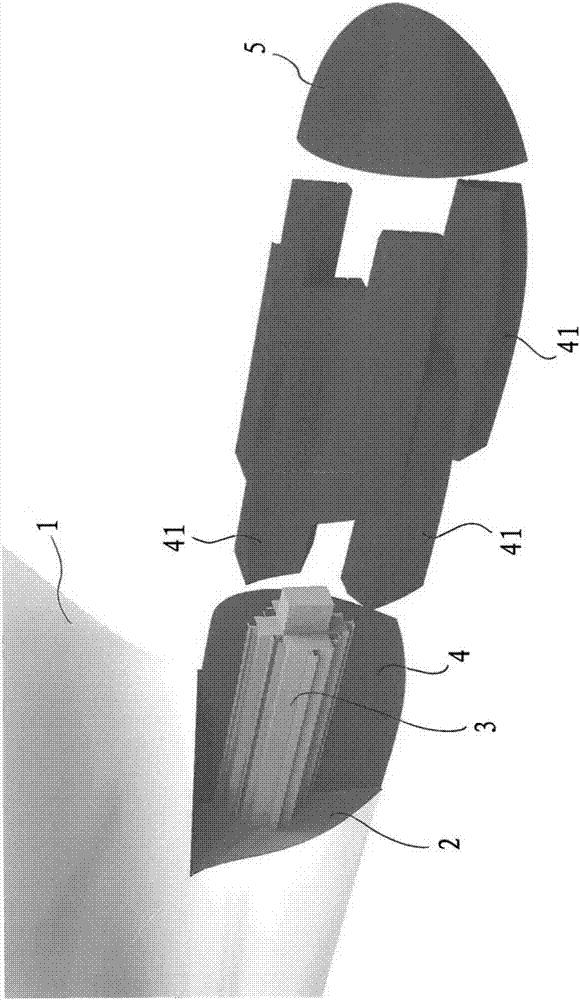

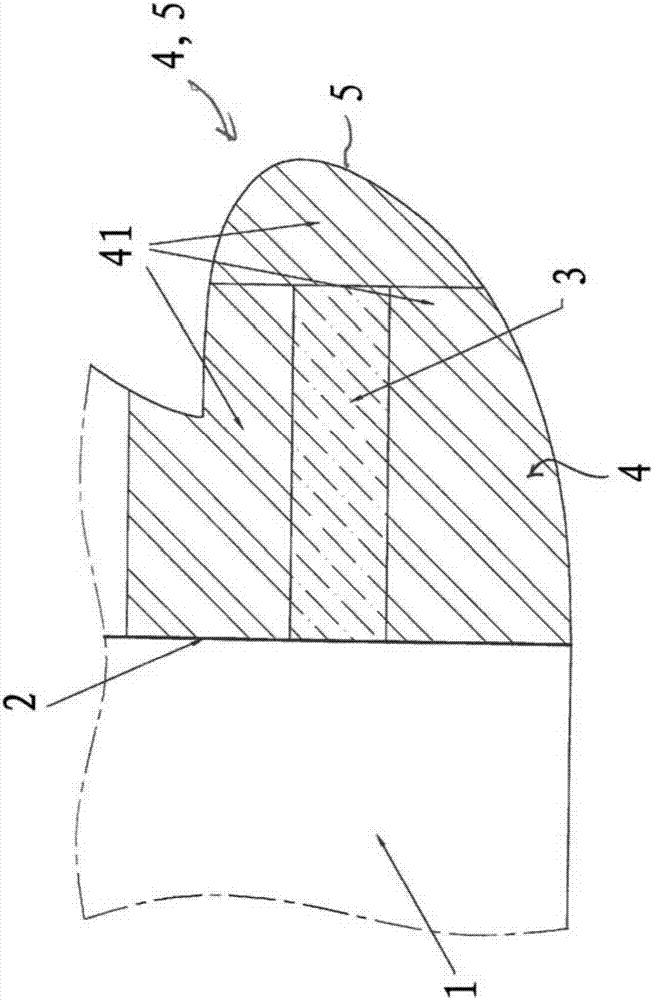

[0025] instead of figure 1 The marine vessel design with bulbous bow shown in , it is advantageous to find that the vessel can be figure 2 designed as shown in figure 2 A first embodiment of the present invention is shown. The vessel 1 is provided with a bulkhead 2 in which a mounting structure 3 is arranged. Mounting structure 3 can be as figure 2 The protruding members shown in are of suitable design and size to withstand the forces experienced by the bow during use. Shell structures 4 and 5 are arranged on this mounting structure 3 to form a bulbous bow. The shell structure defines the hydrodynamic shape of the bulbous bow, which when installed is flush with the surface of the hull. The hull structure 4 is constructed from modular parts, while the starboard side is shown disass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com