Venturi mixer with diffuser containing shrinkage cavities

A technology of Venturi mixer and diffusion section, applied in the directions of fluid mixer, mixer, mixing method, etc., to achieve the effect of enhanced turbulent strength, convenient processing and installation, and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

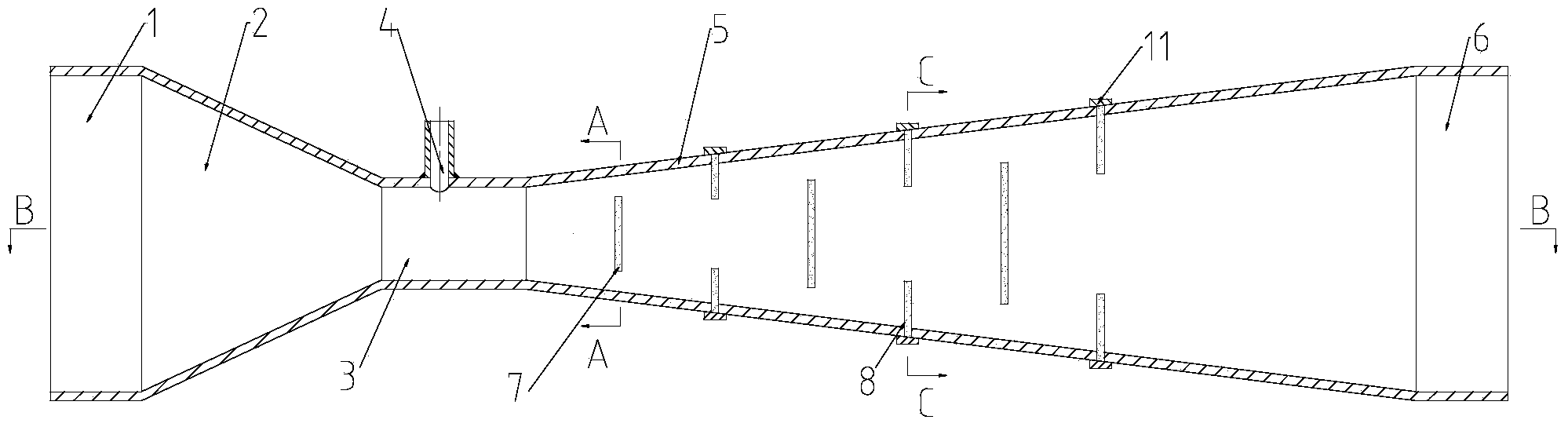

[0032] Such as figure 1 and figure 2 As shown, a Venturi mixer with shrinkage cavity in the diffuser section of the present invention includes a main flow Venturi tube through which the mainstream fluid flows, and the main flow Venturi tube includes an inflow pipeline 1, a tapered section 2, and a throat that are connected in sequence. part 3, diffuser section 5, and outflow pipe 6. On the side of the throat part 3, there is an introduction pipe 4 for the inflow of fluid, and also includes multiple sets of shrinkage holes set in the diffuser section 5. Each set of shrinkage holes includes a fixed shrinkage cavity. hole 7 and an adjustable shrinkage hole 8, the radial direction of the fixed shrinkage hole 7 and the adjustable shrinkage hole 8 are perpendicular to the flow direction of the mainstream fluid, and the fixed shrinkage hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com