Prestage vacuum oil-water separating device

A pre-stage, oil-water technology, applied in the direction of vacuum distillation, separation method, evaporation, etc., can solve the problems of short-circuit separation efficiency, etc., and achieve the effect of enlarged evaporation area, high separation efficiency and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

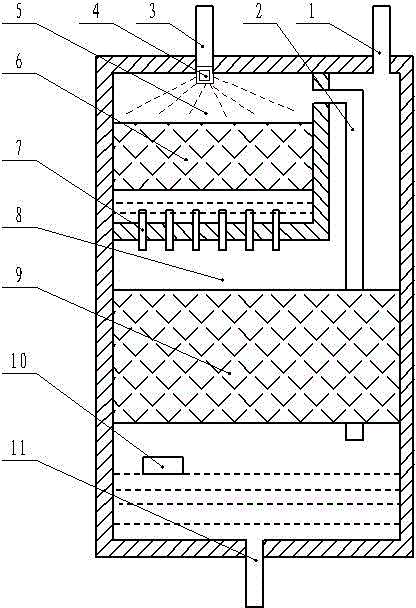

[0009] detailed description The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, after starting the vacuum pump, the pre-stage vacuum chamber 5 is discharged from the vacuum pumping port 1 through the gas conduit 2 and the gas in the main vacuum chamber 8, and the oil-water mixture enters the pre-stage from the oil inlet 3 under the vacuum pressure. The atomizing distributor 4 in the vacuum chamber 5, because the vacuum pressure in the pre-stage vacuum chamber 5 is realized through the gas conduit 2, the "short circuit" phenomenon caused by the oil-water mixture directly entering the vacuum suction port 1 is avoided; Spray at a certain speed onto the pre-stage separation tray installed in the middle of the pre-stage vacuum chamber 5, along the "tortuous" path of the pre-stage separation tray 6, so that part of the water can be evaporated, and the water vapor formed by ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com