Dewater device of water-jet loom

A dehydration device, water spray technology, applied in the direction of looms, weaving auxiliary equipment, textiles, etc., can solve the problem of not being able to obtain the suction force of the suction device, and achieve the effect of uniform moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings,

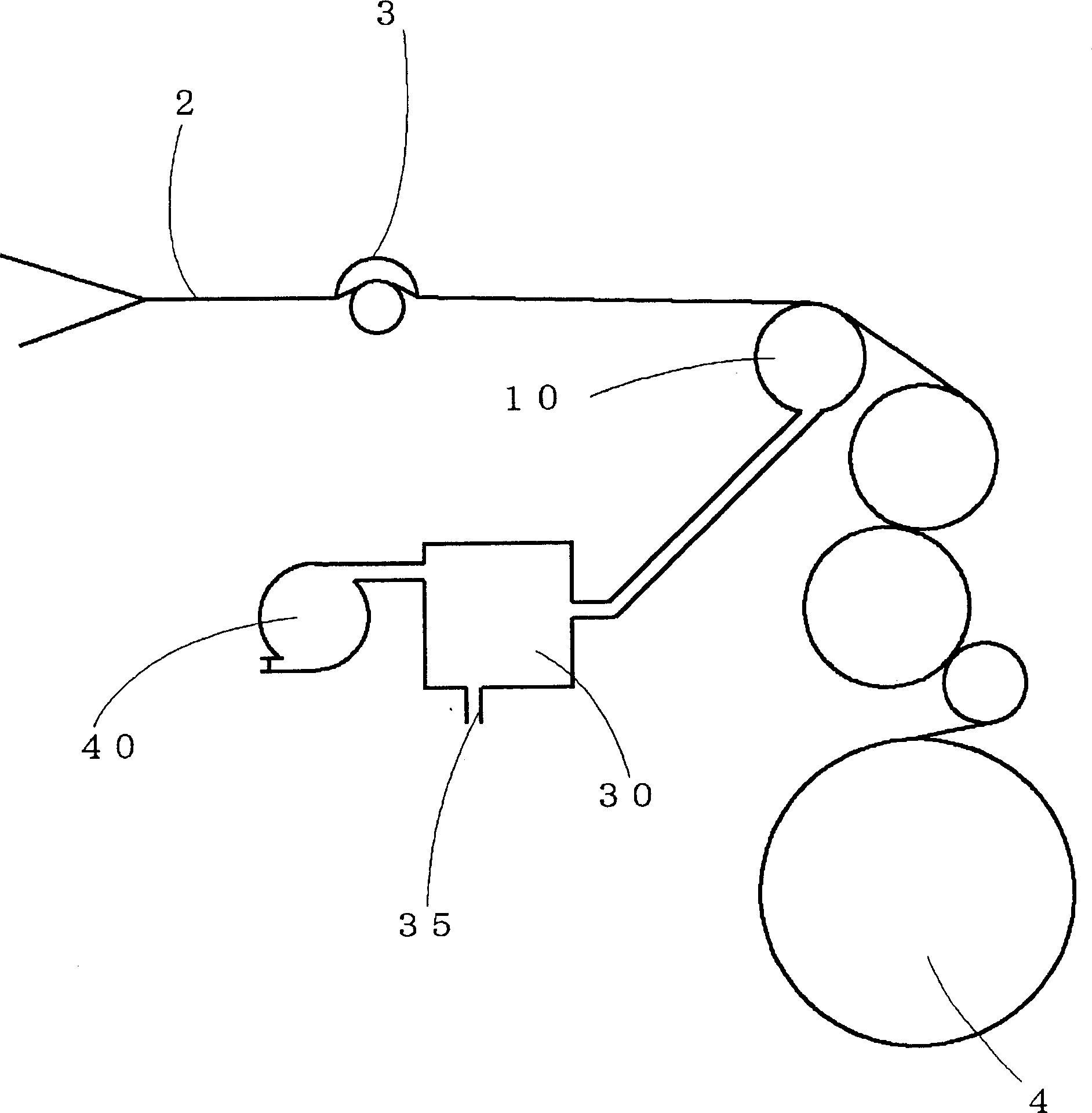

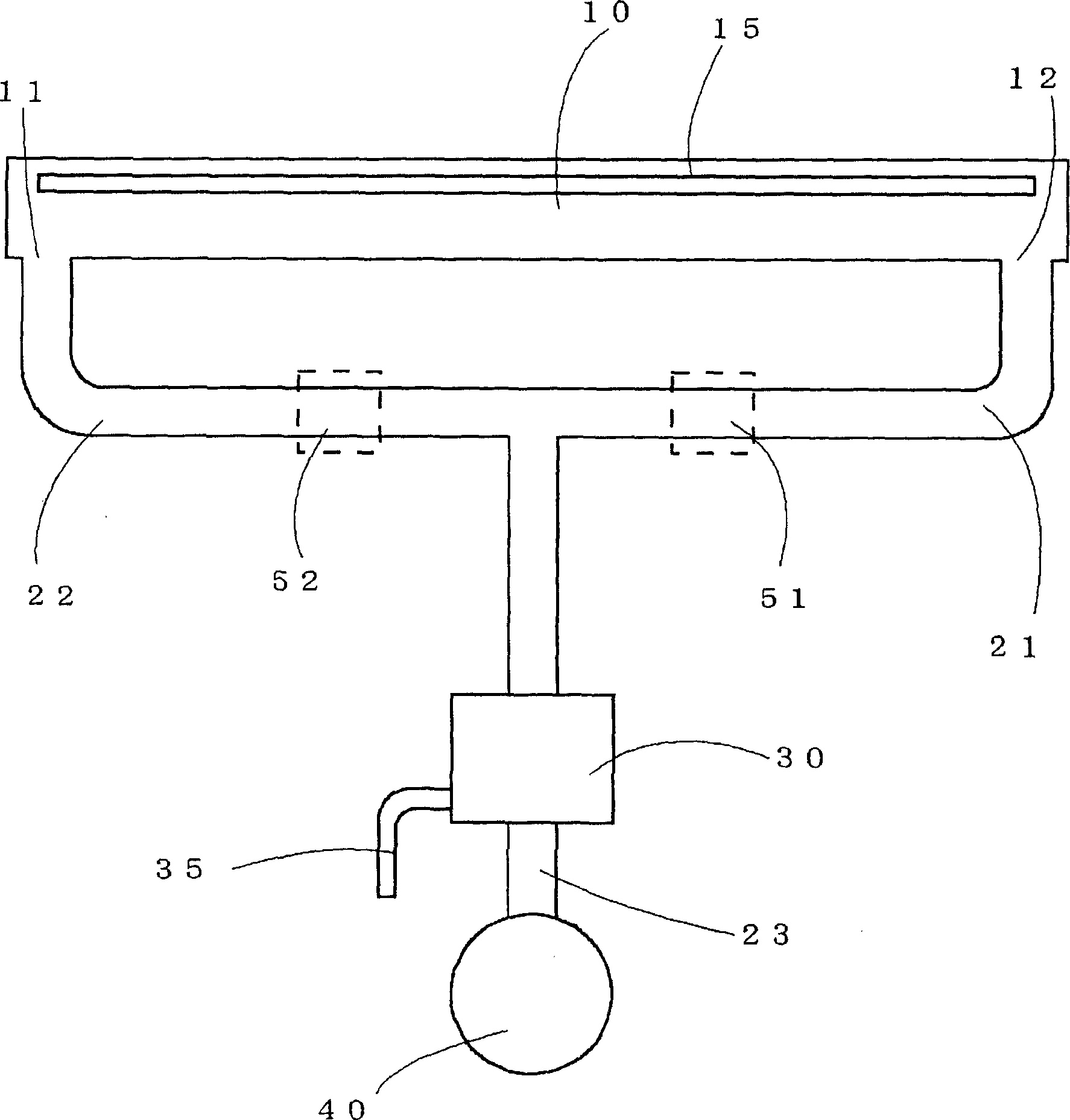

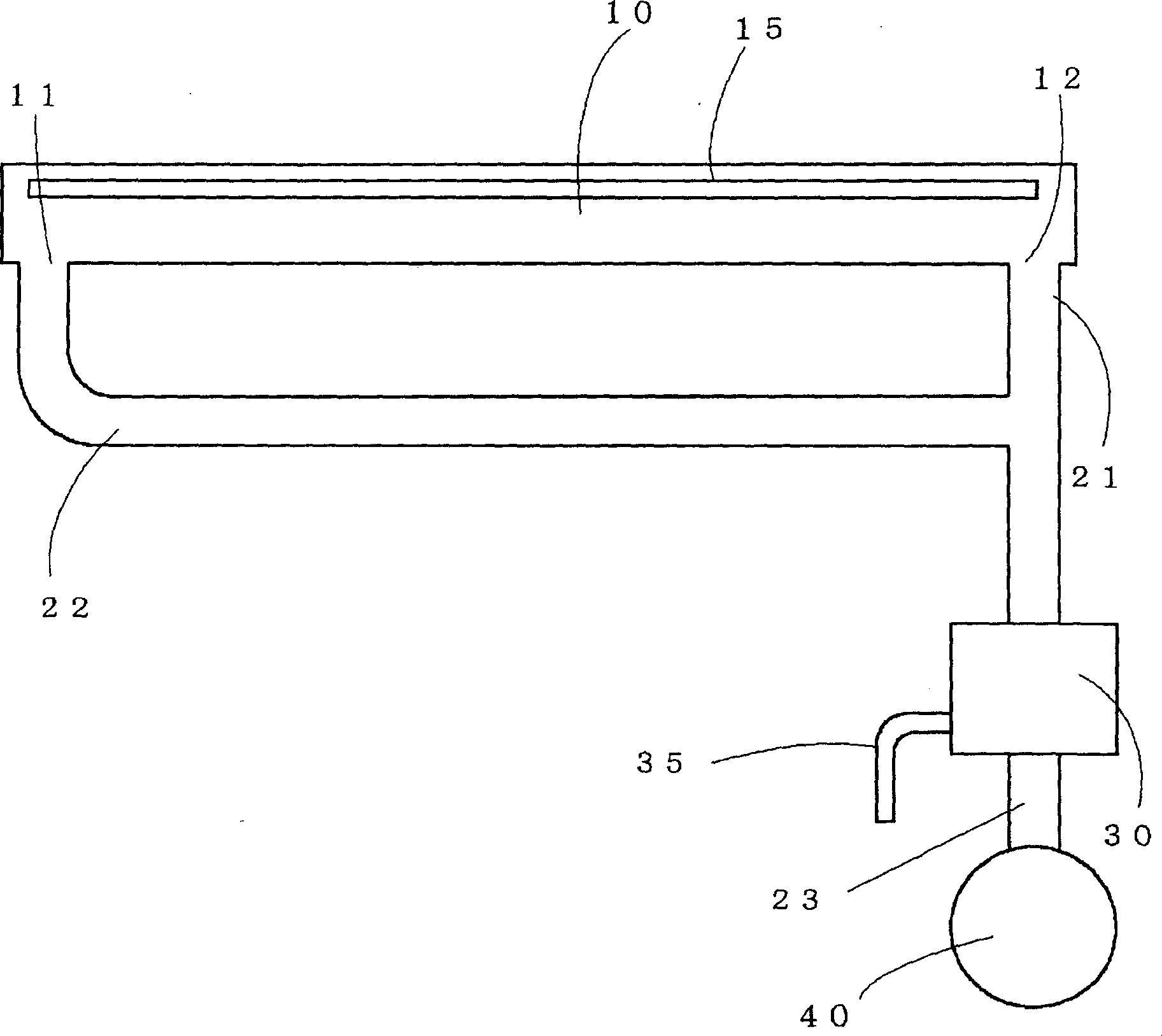

[0018] The first example is figure 1 and figure 2 shown. The fabric 2 passes through a tenter 3 and through a suction duct 10 , travels between rollers and is wound on a winding shaft 4 . On the fabric contact surface of the suction pipe 10, a suction port 15 is provided along the width direction of the fabric 2, and moisture contained in the fabric is sucked from the suction port 15. The suction port 15 may be a slit or a member provided with a plurality of holes. The gas-water separator 30 and the suction device 40 are connected to the suction pipe 10 through piping.

[0019] The suction pipe 10 is provided across the entire area in the web direction. On the suction port 12 of the anti-weft insertion side of the suction pipe 10, a first connection pipe 21 is provided, and a second connection pipe 22 is provided on the suction port 11 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com