Veneer timber drying equipment

A technology of veneer wood and drying equipment, which is applied in the direction of drying, drying machines, lighting and heating equipment, etc. It can solve the problems of uneven drying, high energy consumption, and low efficiency, so as to improve product quality and production Efficiency, solve the effect of uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described below with reference to the accompanying drawings and examples.

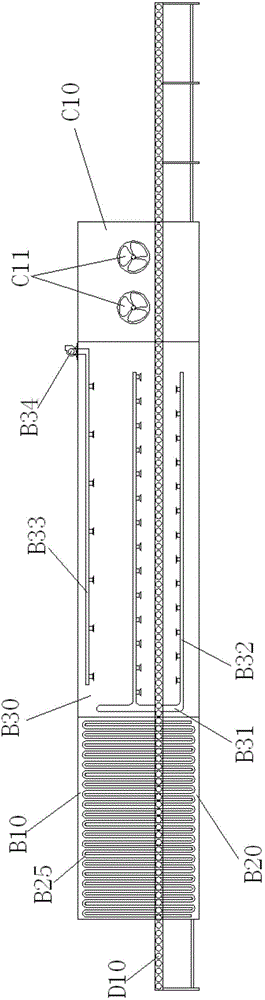

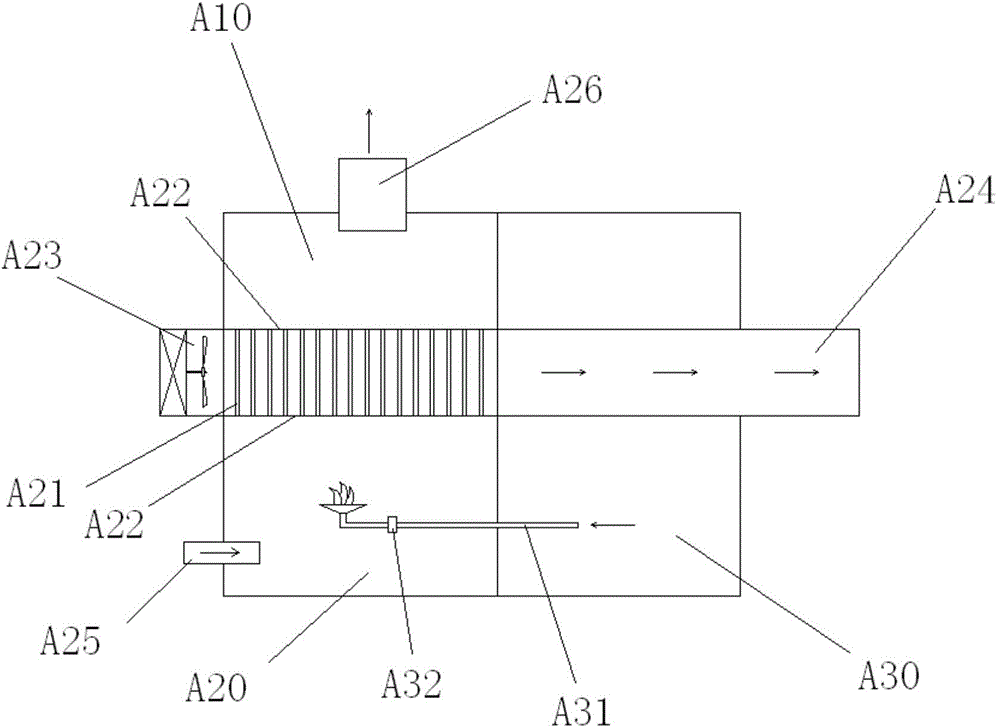

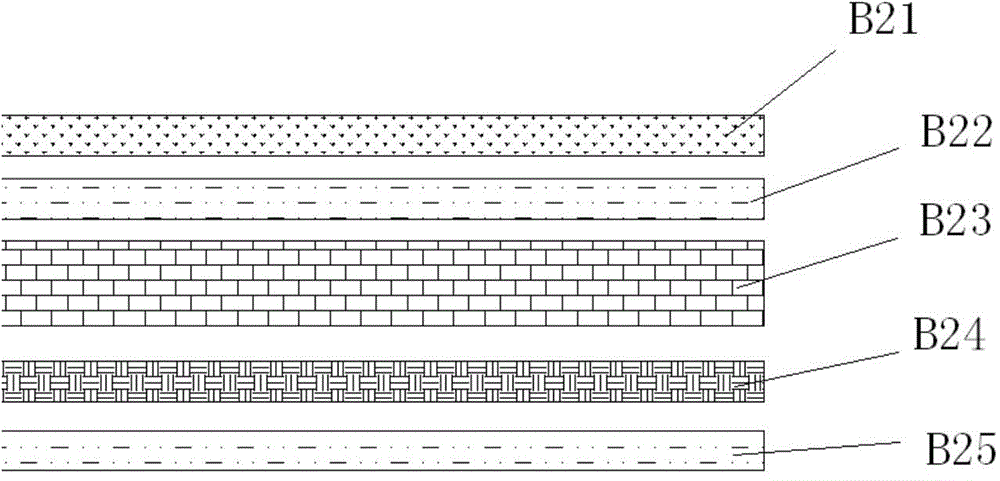

[0024] The invention discloses a veneer wood drying equipment, comprising: a heat supply device A10 providing a heat source for the drying device B10, a drying device B10 composed of a preheating zone B20 and a high temperature zone B30, using air cooling and water cooling to A cooling device C10 for dissipating heat from the dried veneer, an automatic folding device (not shown in the figure), and a conveying line D10 for transporting the veneer.

[0025] In this embodiment, preferably, the length of the preheating zone B20 is set to be ten meters, the length of the high temperature zone B30 is set to be twenty meters, and the length of the cooling device C10 is set to be five meters.

[0026] Each device is described further below by embodiment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com