Process for producing glass reinforced plastic through strong core mat vacuum infusion

A technology of vacuum infusion and strong core felt, applied in the field of wind turbine equipment, can solve the problems of product quality defect, vacuum equipment damage, fast flow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

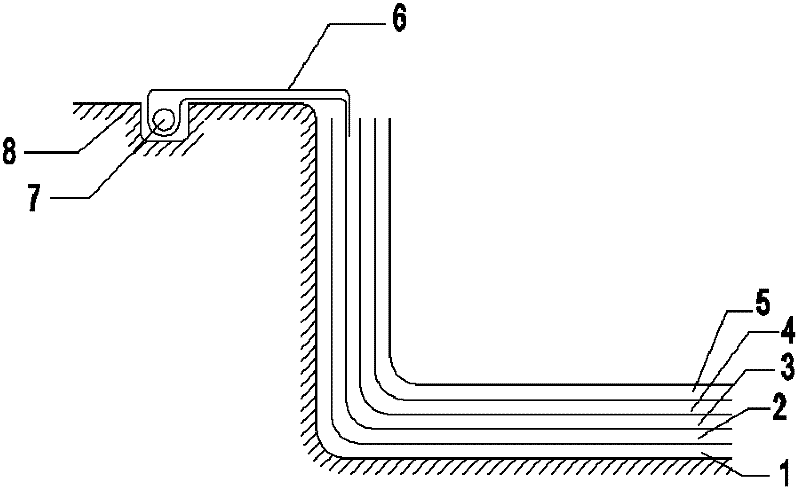

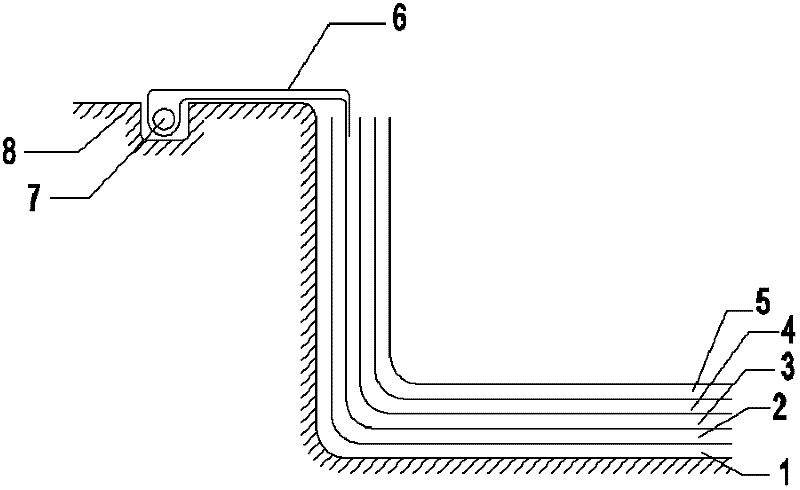

[0017] like figure 1 Shown, a kind of technique of the present invention uses strong core felt vacuum infusion to manufacture FRP, comprises the following steps:

[0018] 1) Fully clean the mold 8 and apply a release agent;

[0019] 2) Place the spiral exhaust pipe 7 in the groove provided at the upper end of the mold 8;

[0020] 3) Lay the first composite felt 1, the second composite felt 2, the third filament felt 3, the fourth composite felt 4 and the fifth composite felt 5 into the mold 8 from bottom to top, and the second composite felt 2 Between the third filament felt 3, a piece of strong core felt 6 with a width of 10 cm and a thickness of 2 mm is placed at a distance of 60 cm along the edge of the mold 8, and one end of each strong core felt 6 is placed in the glass fiber, and one end is wound around Place it under it through the spiral exhaust pipe, and wrap it back into the glass fiber laminate;

[0021] 4) cover the polyester film on the surface of the fifth com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com