A kind of 6xxx series aluminum alloy plate with high flanging performance and preparation method thereof

An aluminum alloy sheet and flanging technology, which is applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of unalloyed internal microstructure evolution process control, incomplete intermediate annealing system, and high process cost, and achieves satisfactory results. Industrial production needs, excellent flanging performance, and the effect of improving flanging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

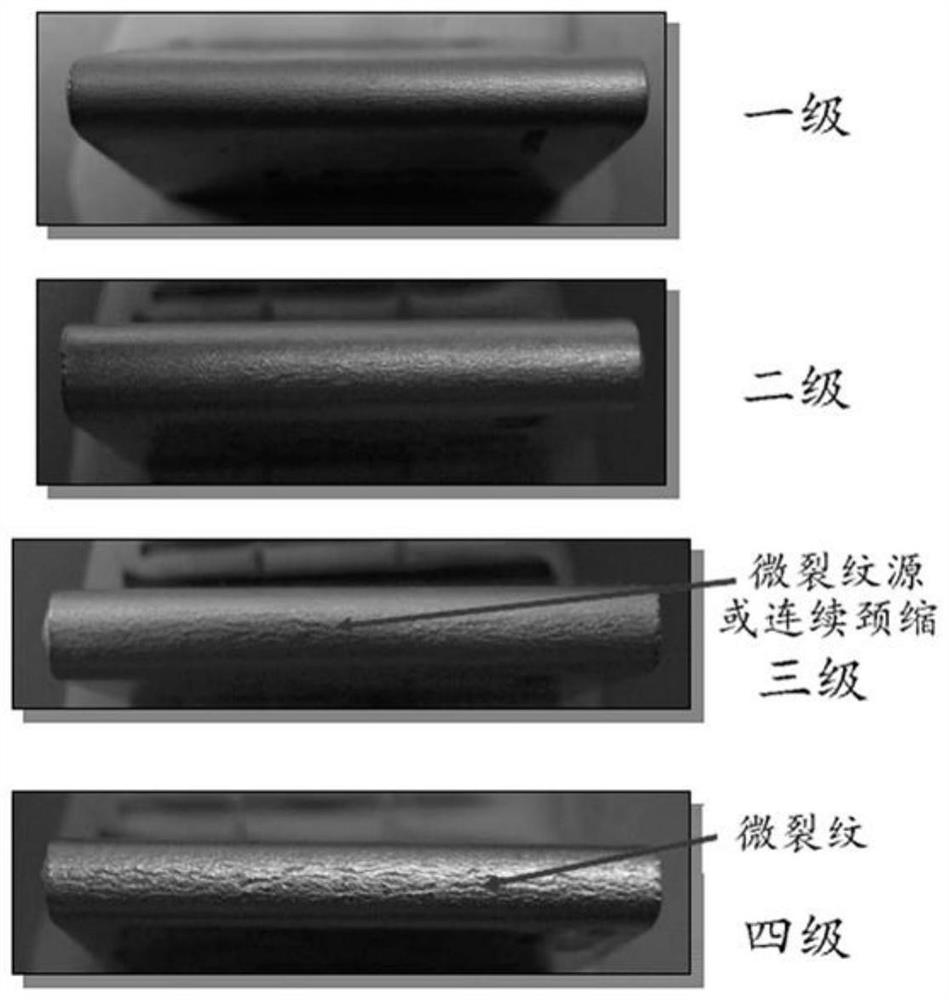

[0038] Embodiment 1~2, comparative example 1~2: according to 1 in table 1 # Table 2 shows the preparation process of the aluminum alloy composition preparation examples 1-2 and comparative examples 1-2, and the statistical results of the second phase distribution and grain size of the longitudinal section of the final finished plate are shown in table 3. The flanging performance of the finished board obtained in Examples 1-2 is qualified. The flanging performance of the finished boards obtained in Comparative Examples 1-2 was unqualified. In comparative example 1, the intermediate annealing temperature is too low, too many second phases are precipitated, there are too many fine phases, and the proportion of large-sized second phases is too low, resulting in too large grain size of the final finished plate; in comparative example 2, the intermediate annealing During the cooling process, the cooling rate is too low, so that a large amount of second phases precipitate during the...

Embodiment 5

[0040] Embodiment 5, comparative example 5: press 3 in table 1 # The preparation process of the aluminum alloy composition of Example 5 and Comparative Example 5 is shown in Table 2, and the statistical results of the second phase distribution and grain size of the longitudinal section of the final finished plate are shown in Table 3. The flanging performance of the finished board obtained in Example 5 is qualified. In comparative example 5, the solid solution temperature is too low, and the second phase is insufficiently remelted, so that the proportion of the large-sized second phase in the final finished board is too high, the number of crack sources increases during the flanging process, and the flanging performance is unqualified.

[0041] Table 1 Composition of aluminum alloy sheet

[0042]

[0043] Table 2 Intermediate annealing system of aluminum sheet

[0044]

[0045] Table 3 Second phase distribution and flanging properties on the surface of aluminum sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com