Sialon combined fireproof material containing aluminum silicon alloy

An aluminum-silicon alloy and refractory technology, applied in the field of sialon combined refractory materials, can solve the problems of inability to meet the use and construction, and achieve the effect of improving the resistance to high temperature thermal stress damage, improving the bonding strength, and increasing the fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

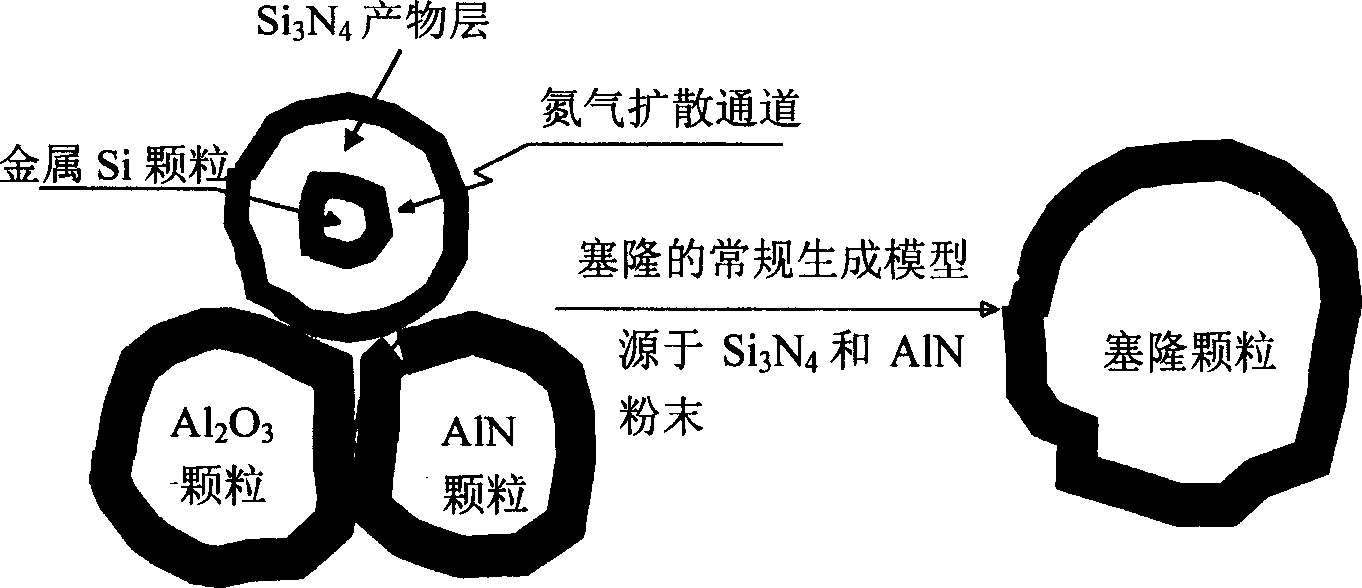

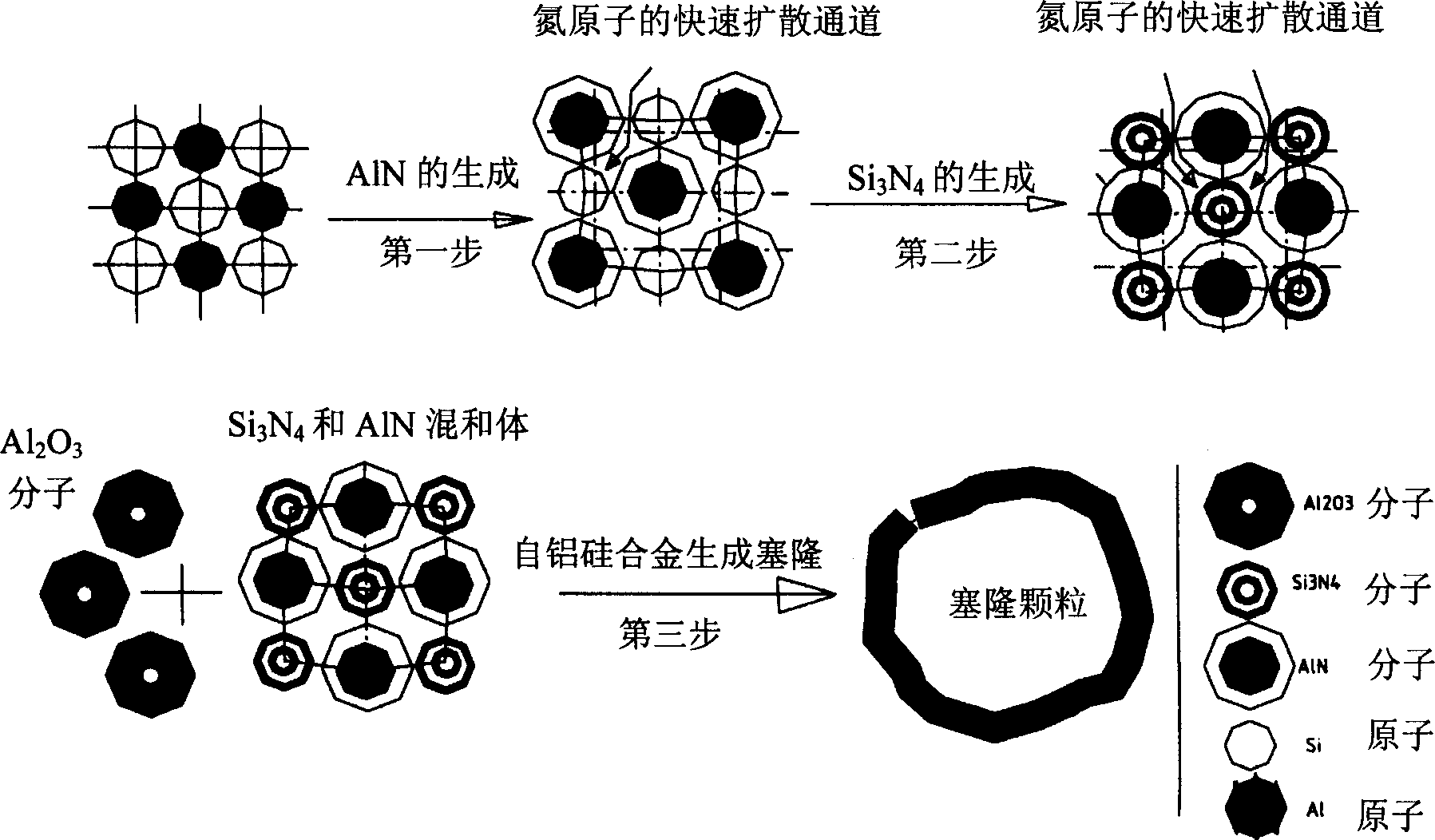

Method used

Image

Examples

Embodiment 1

[0045] The Sialon bonded corundum brick containing aluminum-silicon alloy of the present invention is composed of brown corundum aggregate, brown corundum fine powder, clay, alumina fine powder and aluminum-silicon alloy fine powder according to the following weight percentages:

[0046] Brown fused alumina aggregate: 70%

[0047] Brown corundum fine powder: 10.5%, 180-320 mesh

[0048] Al-Si alloy fine powder: 9.5%, 180-320 mesh

[0049] Guangxi clay: 2%, 180-320 mesh

[0050] Alumina fine powder: 8%, 180-320 mesh

[0051] The preparation method of aluminum-silicon alloy fine powder: when Z=1, Si: 93.98%, Al: 6.02%. The ratio of mixing to melting or sintering.

[0052] The preparation method of Sialon bonded corundum brick: according to the conventional method, after mixing the raw materials, molding, and then sintering to obtain the product of the present invention.

Embodiment 2

[0054] The Sialon bonded corundum brick prepared by the aluminum-silicon alloy method of the present invention is composed of brown corundum aggregate, brown corundum fine powder, clay, alumina fine powder and aluminum-silicon alloy fine powder according to the following weight percentages:

[0055] Brown fused alumina aggregate: 65%

[0056] Brown corundum fine powder: 17.25%, 180-320 mesh

[0057] Al-Si alloy fine powder: 9.25%, 180-320 mesh

[0058] Guangxi clay: 2%, 180-320 mesh

[0059] Alumina fine powder: 6.5%, 180-320 mesh

[0060] The preparation method of aluminum-silicon alloy fine powder: when Z=3, Si: 75.75%, Al: 24.25%. The ratio of mixing to melting or sintering.

[0061] The preparation method of Sialon bonded corundum brick: same as embodiment 1

Embodiment 3

[0063] The Sialon bonded corundum brick prepared by the aluminum-silicon alloy method of the present invention is composed of brown corundum aggregate, brown corundum fine powder, clay, alumina fine powder and aluminum-silicon alloy fine powder according to the following weight percentages:

[0064] Brown fused alumina aggregate: 68.5%

[0065] Brown corundum fine powder: 10%, 180-320 mesh

[0066] Al-Si alloy fine powder: 10.8%, 180-320 mesh

[0067] Guangxi clay: 2%, 180-320 mesh

[0068] Alumina fine powder: 8.7%, 180-320 mesh

[0069] The preparation method of aluminum-silicon alloy fine powder: when Z=4, Si: 60.95%, Al: 39.05%. Proportions for mixing to prepare for melting or sintering.

[0070] The preparation method of Sialon bonded corundum brick: same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com