Intermediate annealing process of aluminum alloy and aluminum alloy for automobile covering part

An automobile cover and intermediate annealing technology, which is applied in the field of aluminum alloy casting, can solve the problems such as the inability to choose aluminum materials, and achieve the effects of improving the microstructure, improving the cooling speed, and improving the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the rapid annealing equipment, the 6-series aluminum alloy is heated to 450°C at a heating rate of 10°C / s, and the aluminum alloy is heated. After 1 minute, it is kept at 450°C for 3 minutes; then the aluminum alloy is cooled by air to 200°C / s The temperature is lowered at a rate of 1 min, and the temperature is lowered to room temperature to obtain an aluminum alloy after intermediate annealing.

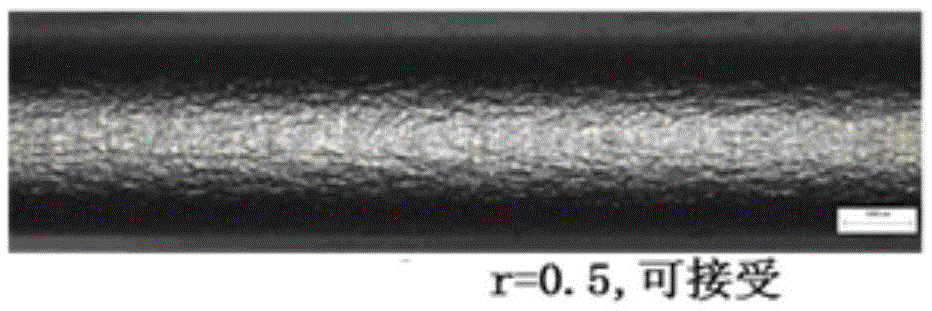

[0039] The present invention detects the flanging performance of the aluminum alloy after the intermediate annealing obtained in the present embodiment according to the national standard "Aluminum Alloy Sheet for Automobile" and the GMW15192 standard, and the results are as follows: figure 1 as shown, figure 1 It is the flanging performance diagram of the aluminum alloy used for automobile panels in Example 1 of the present invention. Depend on figure 1 It can be seen that the flanging factor r of the aluminum alloy after the intermediate annealing in this embodiment is ...

Embodiment 2

[0041] The 6-series aluminum alloy is heated to 550°C at a rate of 5°C / s in the rapid annealing equipment, and the aluminum alloy is heated. After 5 minutes, it is kept at 550°C for 2 minutes; then it is rapidly cooled with water. The temperature is 250°C / min, and the temperature is lowered to room temperature to obtain an aluminum alloy after intermediate annealing.

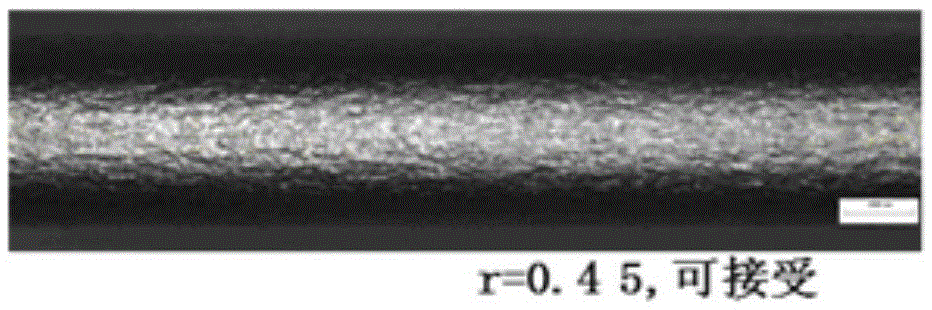

[0042] The present invention detects the flanging performance of the aluminum alloy after the intermediate annealing obtained in the present embodiment according to the national standard "Aluminum Alloy Sheet for Automobile" and the GMW15192 standard, and the results are as follows: figure 2 as shown, figure 2 It is the flanging performance diagram of the aluminum alloy for automobile panels in Example 2 of the present invention. Depend on figure 2 It can be seen that the flanging factor r of the aluminum alloy after the intermediate annealing in this embodiment is 0.45, there is no crack after flanging, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com