A process method capable of improving the refinement and modification effect of a356 aluminum alloy

A process method and aluminum alloy technology, which is applied in the field of aluminum alloy melting and casting, can solve the problems of large specific surface area, poor refinement and deterioration effect, and high surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

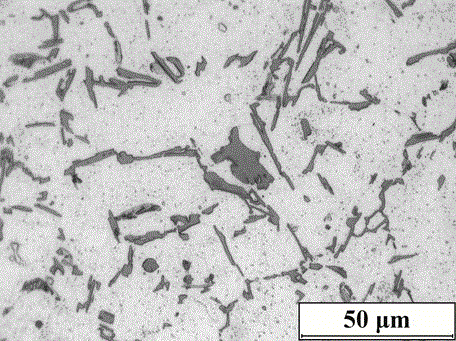

Embodiment 1

[0018]Al-10Sr master alloy is used as modifier: Sr 10.00%, Ti ≤ 0.02%, Si ≤ 0.12%, Fe ≤ 0.06%, the content of other impurity elements is not more than 0.05%, the balance is Al, and the modified object is A356 Aluminum alloy, of which Si7.00%, Mg 0.30%, Cu≤0.20%, Mn≤0.10%, Zn≤0.10%, Fe≤0.20%, Ti≤0.20%, and the content of other impurity elements is not more than 0.05% each, and the rest It is Al, the composition is calculated by mass percentage, and the amount of modifier used is 0.10% of the mass of A356 aluminum alloy.

[0019] The smelting process is as follows: first pretreatment, cutting the Al-10Sr master alloy ingot into moderately sized blocks, then grinding and polishing to remove the scale on the surface, cleaning, drying and weighing in an ultrasonic oscillator with acetone , the smelting auxiliary tools are painted with ZnO paint, the thickness of the coating is 1.0mm-1.5mm, and they are dried in a box-type resistance furnace at a temperature of 200°C-300°C for later...

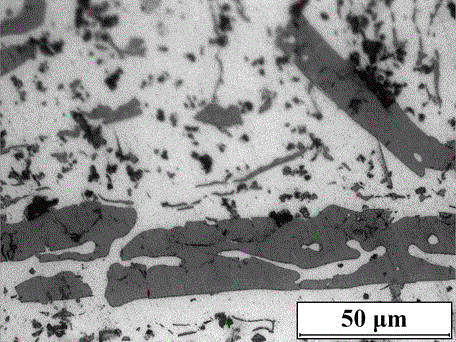

Embodiment 2

[0022] Al-10Sr master alloy is used as modifier: Sr 10.00%, Ti ≤ 0.02%, Si ≤ 0.12%, Fe ≤ 0.06%, the content of other impurity elements is not more than 0.05%, the balance is Al, and the modified object is A356 Aluminum alloy, of which Si7.00%, Mg 0.30%, Cu≤0.20%, Mn≤0.10%, Zn≤0.10%, Fe≤0.20%, Ti≤0.20%, and the content of other impurity elements is not more than 0.05% each, and the rest It is Al, the composition is calculated by mass percentage, and the amount of modifier used is 0.30% of the mass of A356 aluminum alloy.

[0023] The smelting process is as follows: first pretreatment, cutting the Al-10Sr master alloy ingot into moderately sized blocks, then grinding and polishing to remove the scale on the surface, cleaning, drying and weighing in an ultrasonic oscillator with acetone , the smelting auxiliary tools are painted with ZnO paint, the thickness of the coating is 1.0mm-1.5mm, and they are dried in a box-type resistance furnace at a temperature of 200°C-300°C for late...

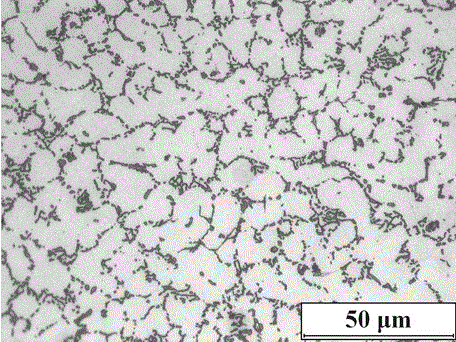

Embodiment 3

[0026] Al-10Sr master alloy is used as modifier: Sr 10.00%, Ti ≤ 0.02%, Si ≤ 0.12%, Fe ≤ 0.06%, the content of other impurity elements is not more than 0.05%, the balance is Al, and the modified object is A356 Aluminum alloy, of which Si7.00%, Mg 0.30%, Cu≤0.20%, Mn≤0.10%, Zn≤0.10%, Fe≤0.20%, Ti≤0.20%, and the content of other impurity elements is not more than 0.05% each, and the rest It is Al, the composition is calculated by mass percentage, and the amount of modifier used is 0.50% of the mass of A356 aluminum alloy.

[0027] The smelting process is as follows: first pretreatment, cutting the Al-10Sr master alloy ingot into moderately sized blocks, then grinding and polishing to remove the scale on the surface, cleaning, drying and weighing in an ultrasonic oscillator with acetone , the smelting auxiliary tools are painted with ZnO paint, the thickness of the coating is 1.0mm-1.5mm, and they are dried in a box-type resistance furnace at a temperature of 200°C-300°C for late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com