450HB-grade rare earth high-wear-resistance steel plate

A high wear resistance, rare earth technology, applied in the field of 450HB rare earth high wear resistance steel plate, can solve the problems of uncharacterized wear resistance, achieve high strength, refine the microstructure in the hot-rolled state, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] See Table 1 for the weight percentage of the chemical composition of the steel plate. The exit temperature of the slab heating furnace is 1210°C, two-stage rolling is adopted, and the rough rolling start temperature is 1160°C. The finish rolling temperature is 835°C, cooled to 680°C after rolling, and the thickness of the intermediate billet is 3 times the thickness of the finished product. Quenching process: 890 ℃, heat preservation 20min quenching; tempering process: 230 ℃, heat preservation 30min air cooling. Finally, the steel plate BTNM450-1 can be obtained.

Embodiment 2

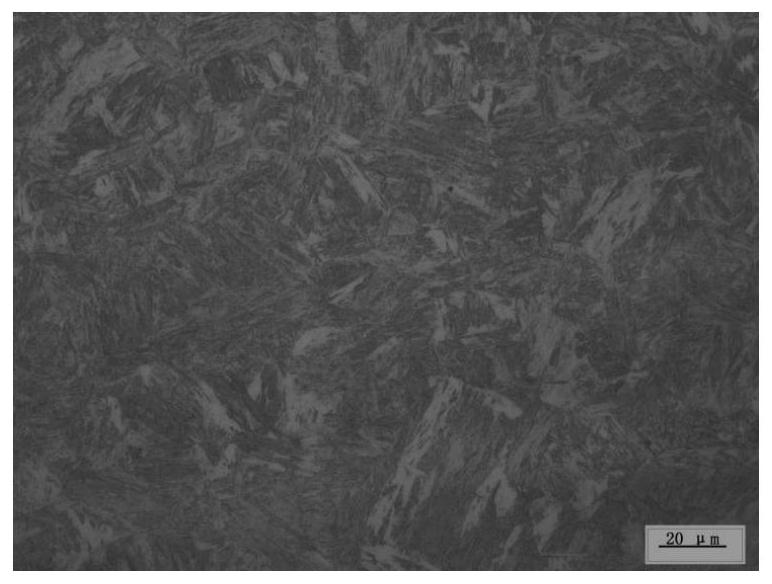

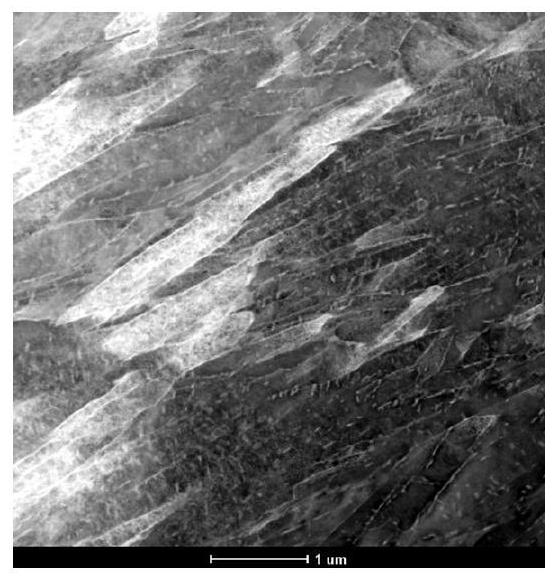

[0032] See Table 1 for the weight percentage of the chemical composition of the steel plate. The heating furnace temperature of the slab is 1205°C, and the slab is rolled in time after heating. Two-stage rolling is adopted, and the starting temperature of rough rolling is 1150°C. The finish rolling temperature is 830°C, cooled to 650°C after rolling, and the thickness of the intermediate billet is 3 times the thickness of the finished product. Quenching process: 905 ℃, heat preservation 25min quenching; tempering process: 220 ℃, heat preservation 50min air cooling. Finally, the steel plate BTNM450-2 can be obtained, and its metallographic structure transmission electron microscope photo is as follows figure 1 and figure 2 shown.

Embodiment 3

[0034] See Table 1 for the weight percentage of the chemical composition of the steel plate. The heating furnace temperature of the slab is 1200°C, and the slab is rolled in time after heating. Two-stage rolling is adopted, and the starting temperature of rough rolling is 1140°C. The finish rolling temperature is 840°C, cooled to 630°C after rolling, and the thickness of the intermediate billet is 3 times the thickness of the finished product. Quenching process: 920°C, heat preservation 30min quenching; tempering process: 220°C, heat preservation 70min air cooling. Finally, the steel plate BTNM450-3 can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Surface brinell hardness | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com