Technique for brewing alcohol

A technology of alcohol and process, applied in the direction of biofuel, fermentation, etc., can solve the problems of unfavorable sustainable development, rational utilization of resources, high cost, low yield of alcohol, etc., to solve the problem of non-biomass energy, solve the shortage of raw materials, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

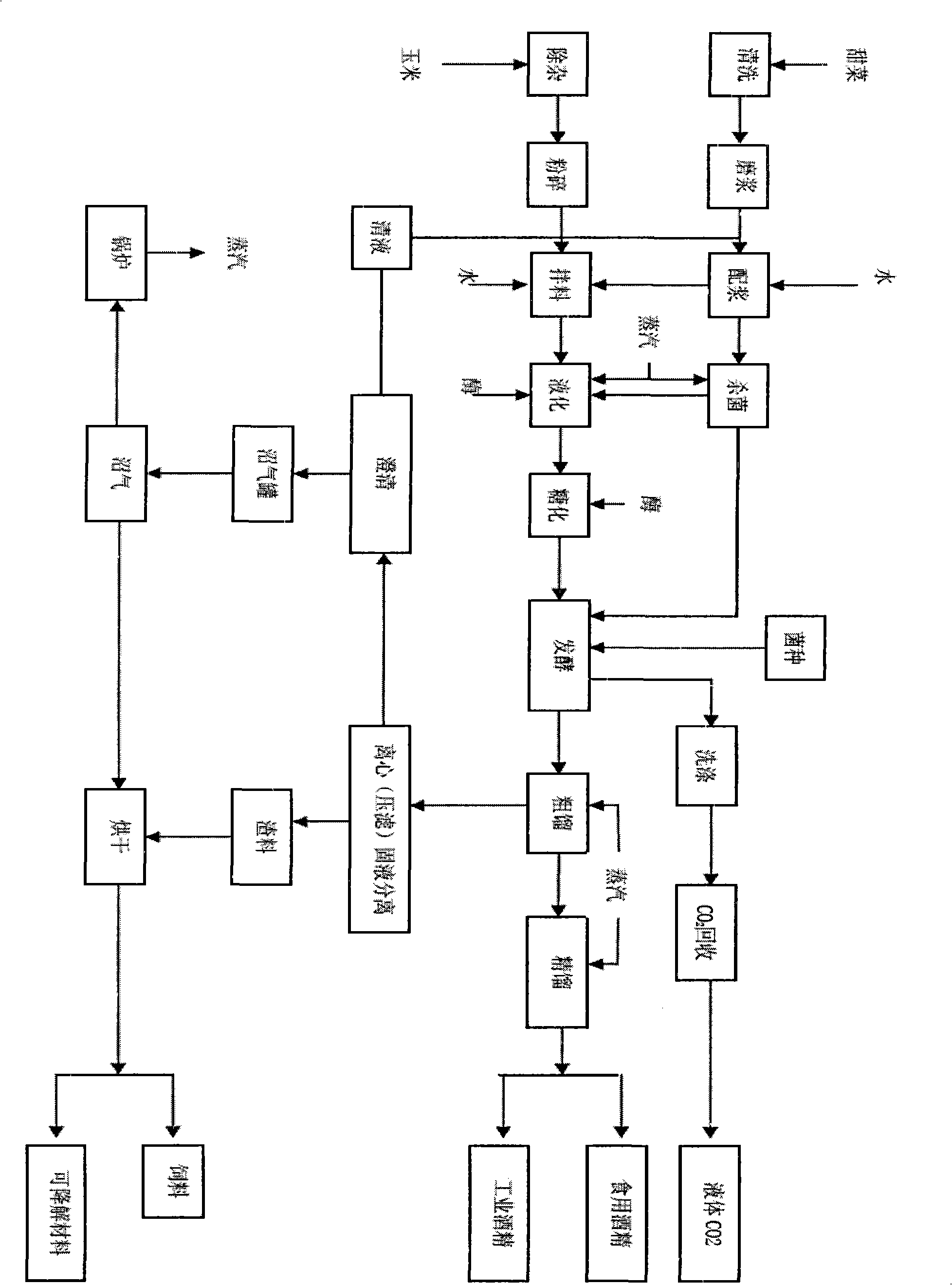

[0035] Such as figure 1 As shown, sugar beet and corn are used as raw materials for illustration.

[0036] Sugar beets are mixed with water for refining to obtain a mash mixed with beet pulp. The beets can be sliced and dried dry beets, washed and crushed fresh beets, or mixed raw materials of dry and fresh beets.

[0037] The corn is cleaned and crushed and transformed into sugary mash through liquefaction and saccharification.

[0038] In the mash containing sugar beet pulp as raw material and converted into sugar by corn through liquefaction and saccharification, adjust the pH value, concentration and temperature of the mash containing beet pulp, and use the remixed mash, water, and additives to adjust the beet pulp in proportion The pH value of the mash is 4 to 6, the concentration is adjusted by adjusting the weight ratio of sugar beets and water to 1:0.8-5, adjusting the temperature of the mash containing beet pomace between 28 degrees Celsius and 35 degrees Celsius,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com