Automatic flanging mechanism

An automatic flipping and clamping technology, which is applied to household components, household appliances, and other household appliances, etc., can solve the problems that cannot meet the production needs, the effect is not very ideal, and the structure is complicated, so as to achieve good flanging processing effect and ingenious design , Reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

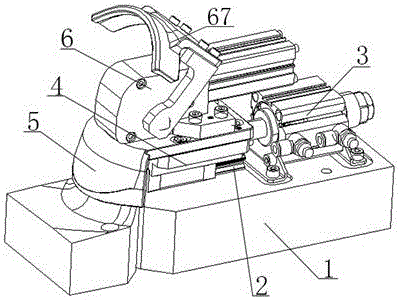

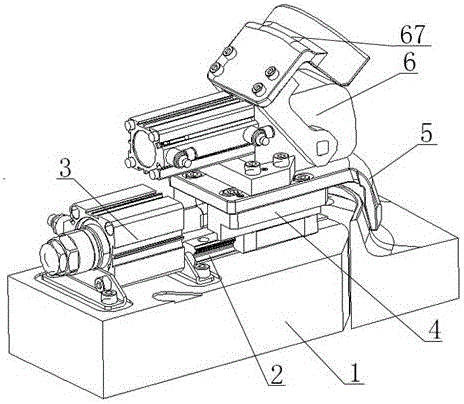

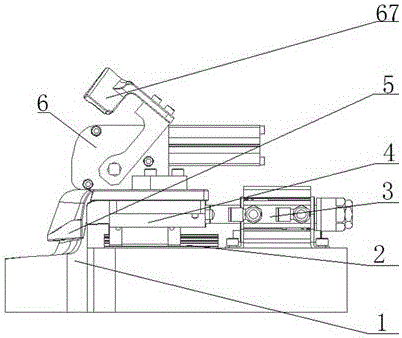

[0018] Refer to attached Figure 1-3 , an automatic flanging mechanism, which includes a fixed bottom mold 1, a linear guide rail 2, a push block cylinder 3, a slide seat 4, a flanging push block 5, and a fabric clamping mechanism 6, and the fixed bottom mold 1 is equipped with a linear guide rail 2 , Slider 4 is equipped with on the linear guide rail 2, slide block 4 rear end push block cylinder 3, slide block 4 front end is equipped with flanging push block 5, slide block 4 is equipped with fabric clamping block mechanism 6 above. Described flanging push block 5 is positioned at slide seat 4 front ends, and flanging push block 5 upper end is connected with connecting plate, and connecting plate is contained on slide seat 4, and flanging push block is arc shape.

[0019] Figure 4-5 , the fabric clamping mechanism 6 includes a swing arm 61, a rotating shaft 62, a housing 63, a crank 64, a connecting rod 65, a cylinder 66 and a clamping block 67, and the housing 63 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com