Image collecting circuit of high-speed absolute grating ruler

An absolute grating ruler and image acquisition technology, which is applied in the direction of using optical devices, converting sensor output, and measuring devices, to achieve the effects of increasing the average measurement speed, improving the bottleneck of process difficulty, and improving the measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

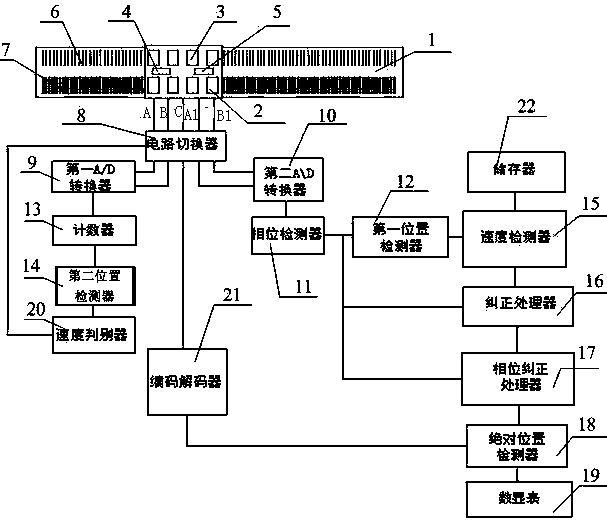

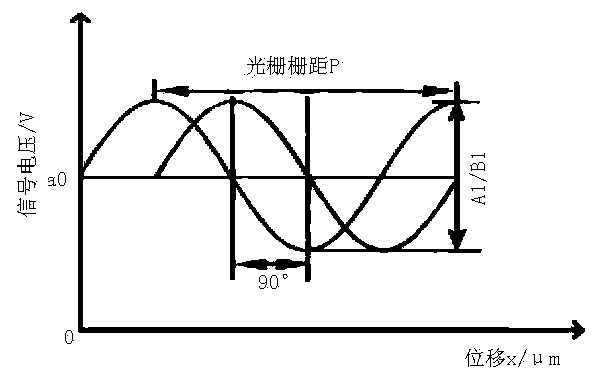

[0025] The image acquisition circuit of the high-speed absolute grating ruler of the present invention, such as figure 1 As shown, the grating ruler bar 1 of the present invention is engraved with equidistant incremental code channels 6 and equidistant absolute code channels, the incremental code channel is a rough measurement code channel, and the absolute code channel 7 has a very dense fine line. Code track. The grating ruler 1 is also equipped with a photoelectric converter 5 for reading images and two LED light sources 4, wherein a number of reading data windows 2 and 3 are opened on the photoelectric converter 5, and the image acquisition circuit includes a circuit switcher 8. First A\D converter 9, second A\D converter 10, phase detector 11, first position detector 12, counter 13, second position detector 14, speed detector 15, correction processor 16. Phase correction processor 17, absolute position detector 18, speed discriminator 20, codec 21, storage 22, circuit s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com