Two-arm four-probe measurement device and method for measuring inner and outer diameters of end of steel tube

A measuring device and a technology of inner and outer diameters, which are applied in the field of geometric measurement, can solve the problems that the accuracy of the measuring tool and the subjective factors of the operator are greatly affected, and the measurement speed and the number of measured data points cannot reach a high level, so as to eliminate the misalignment Deviation, improved measurement speed, and enhanced usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

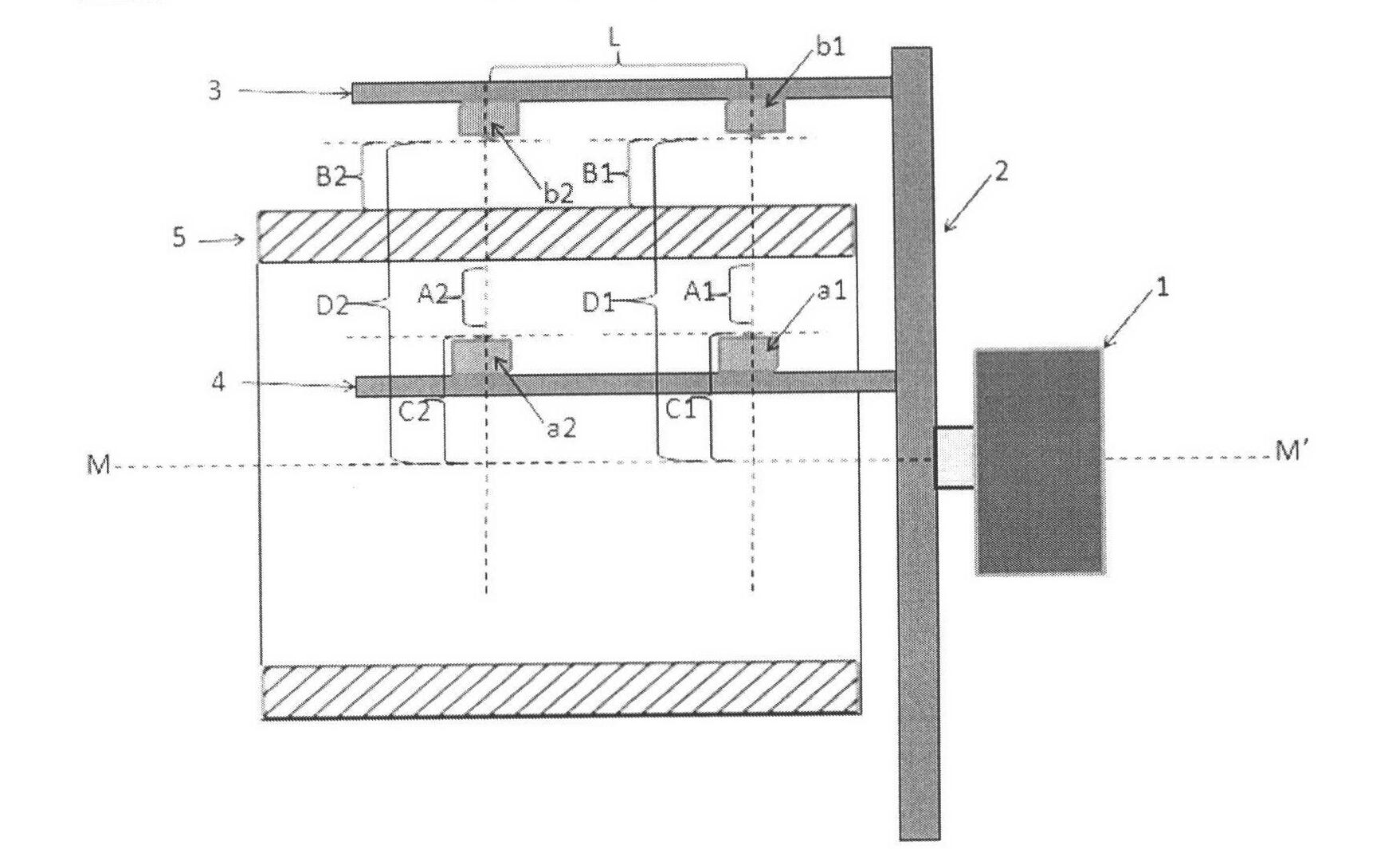

[0019] Such as figure 1 As shown, the double-arm four-probe measuring device for the inner and outer diameters of steel pipe ends of the present invention comprises: a rotating table (1), a rotating table fixed plane (2), 2 fixed arms (3 and 4), 4 laser ranging probes (a1 , b1, a2, b2). It is characterized in that: the rotating table drives the rotating fixed plane to rotate around the central axis M-M' of the rotating table, the fixed arm is vertically fixed on the rotating fixed plane, and two laser ranging probes are installed on each fixed wall. Probe a1, b1 is a group, fixed on a plane perpendicular to the central axis M-M'; probe a2, b2 is a group, fixed on another plane perpendicular to the central axis M-M', the two planes The distance between them is L. The probes a1 and a2 point to the direction of the central axis M-M', and the probes b1 and b2 face away from the direction of the central axis M-M'. 5 among the figure is the steel pipe to be tested.

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com