Flanging die

A flanging die and flanging technology, applied in the field of stamping dies, can solve the problems of rough flanging process parts, high maintenance and replacement costs of flanging concave die inserts, and achieve the effect of convenient disassembly and replacement, and good flanging forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

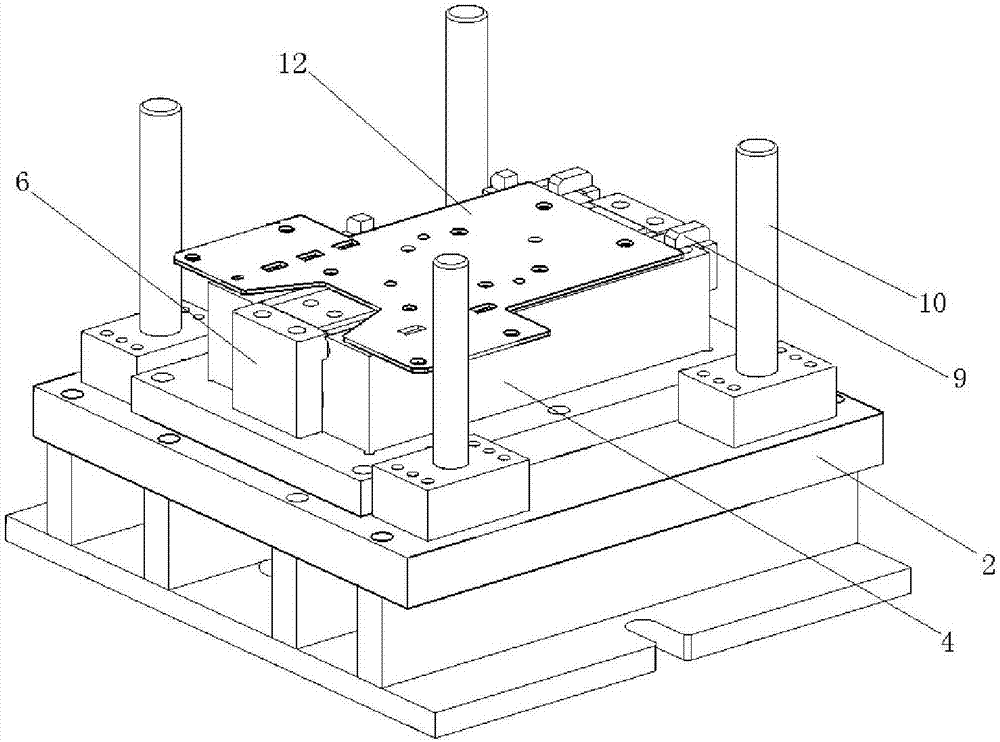

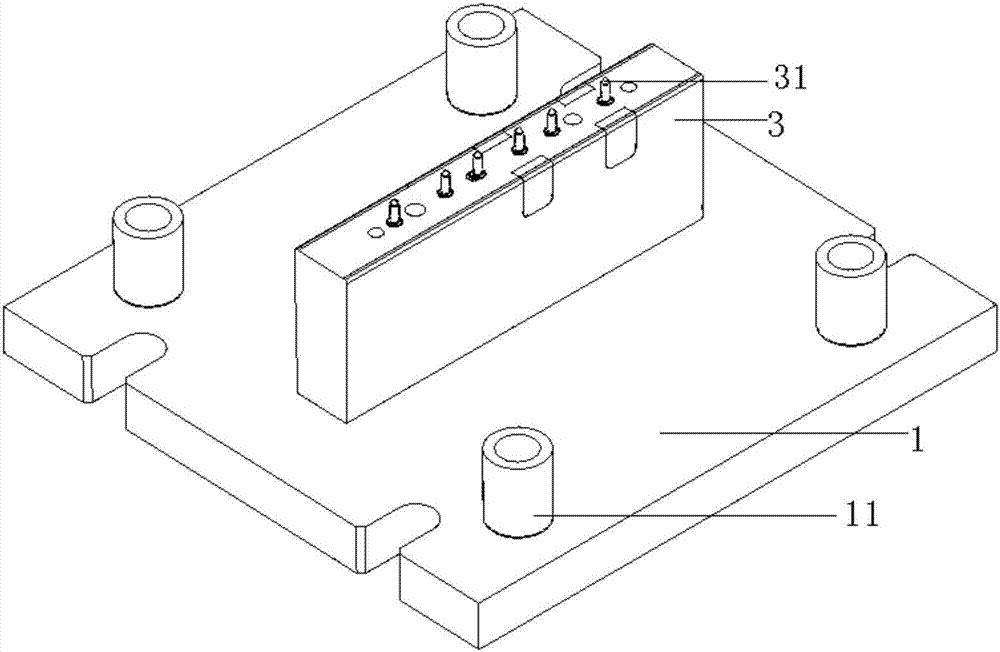

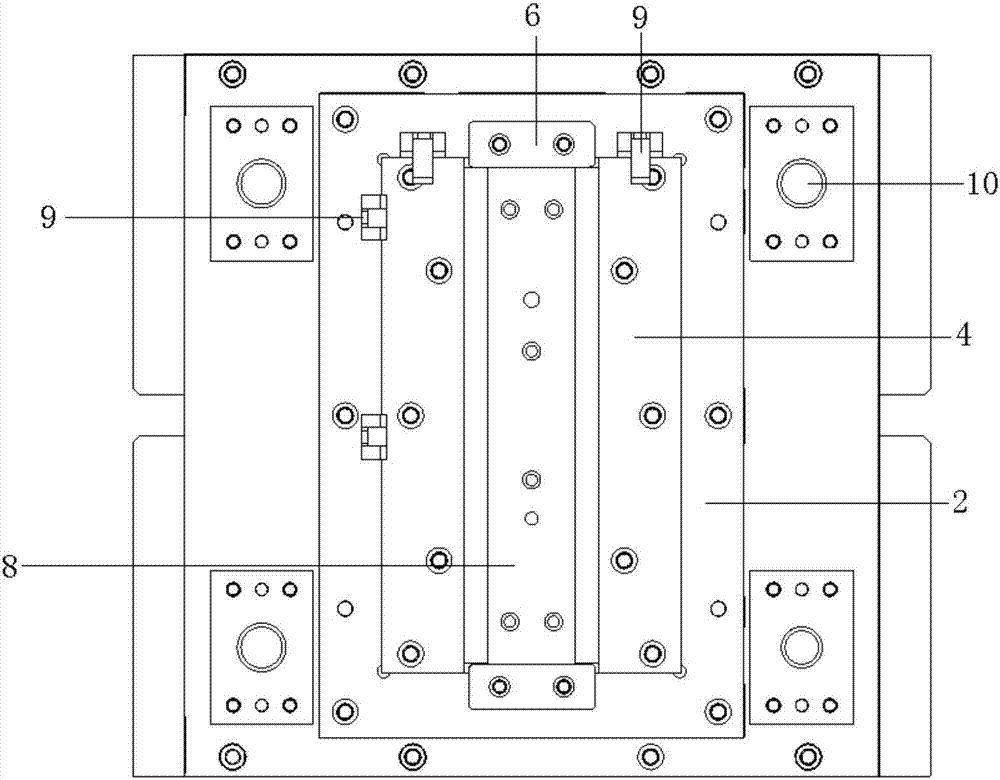

[0022] combine figure 1 , figure 2 and Figure 4 As shown, a kind of flanging mold provided for the embodiment of the present invention includes an upper mold base 1, a lower mold base 2, a flanging punch 3 installed on the bottom of the upper mold base 1 and a flange installed on the lower mold base 2 Die 4, the inner side of the flanging die 4 is its forming surface, and a group of forming rods 5 are installed on the top of the forming surface. The forming rods 5 are used to shape the flanging of the sheet material. The forming rods 5 are heat-treated to ensure their strength. The forming rods 5 are horizontally embedded on the top of the forming surface and can rotate on the forming surface. The opposite sides of the two forming rods 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com