Quick flanging method of casing

A flanging and sleeve technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of high scrap rate, and achieve the effect of improving work efficiency, ensuring product quality, and fast flanging forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

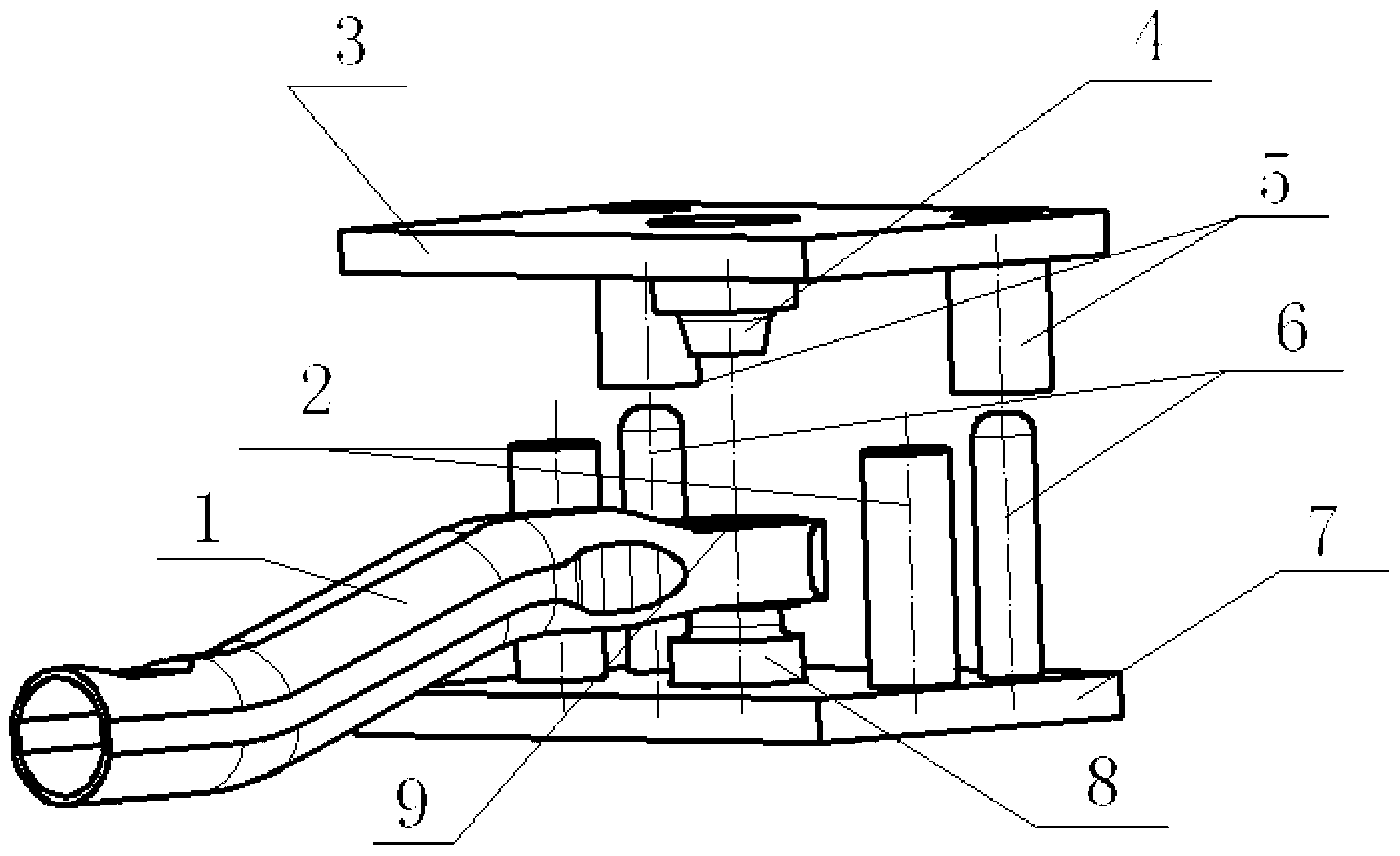

[0010] Referring to the accompanying drawings, a method for rapid flanging of a casing includes the following steps:

[0011] a, make the flanging mold, the flanging mold includes an upper template 3, a lower template 7, the upper template 3, the lower template 7 are respectively equipped with a corresponding upper flanging punch 4, a lower flanging punch 8, and an upper template 3, a guide sleeve 5 is fixedly installed on the lower template 7, and a guide post 6 that guides and cooperates with the guide sleeve 5 is fixedly installed on the lower template 7. Set, the upper flanging punch and the lower flanging punch have arc transition surfaces; the lower template 4 is fixed with a limit column 2;

[0012] b. First put 9 sets of sleeves to be assembled on the lower flanging punch 8, then place 1 set of tubular workpieces outside the sleeve 9 that needs to be flanged, start the press to drive the upper template and the upper flanging convex The mold moves downward, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com