A method for improving flanging performance of aluminum alloy sheet

A technology for aluminum alloy sheets and aluminum alloy ingots, which is applied in the manufacture of aluminum alloy sheets and improves the flanging performance of 6000 series aluminum alloy sheets, can solve the problems of unqualified flanging performance, and achieve the effect of improving flanging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

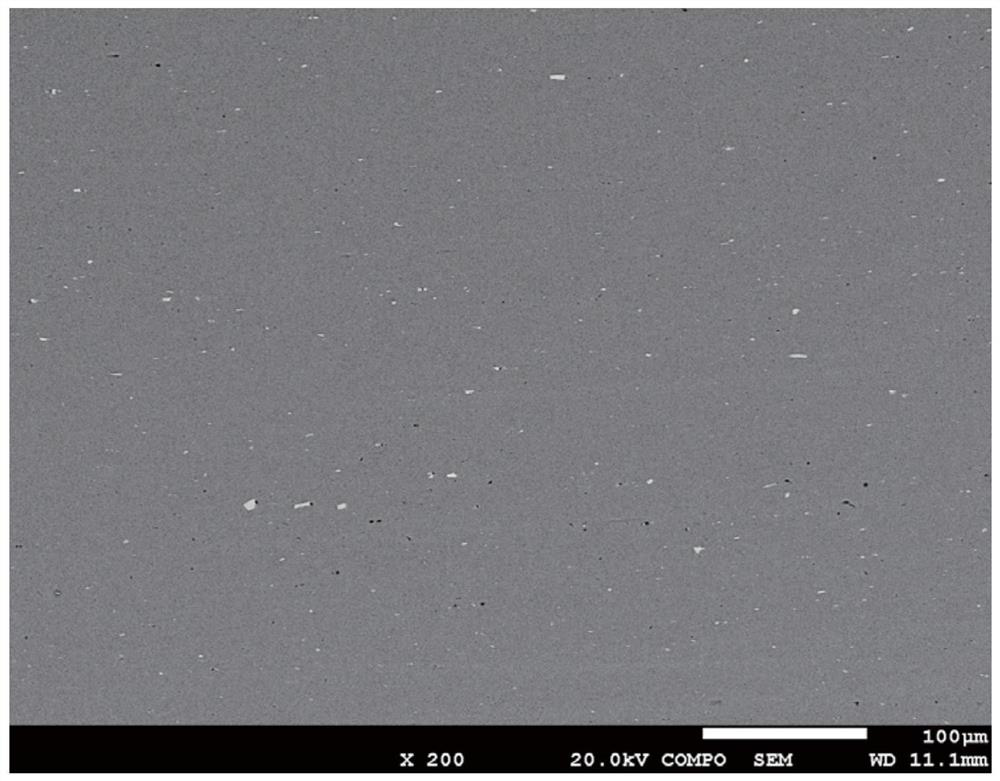

[0024] The present invention is applied to a 6000 series aluminum alloy, and its nominal composition range (mass fraction, %): Mg: 0.7-1.3, Si: 0.6-1.2, Cu: 0.02-0.20, Mn: 0.01-0.25, Fe≤0.40, Zn: 0.25~0.80, Cr≤0.10, Ti≤0.15, Zr: 0.01~0.20, the balance of Al and other unavoidable impurities; choose a typical alloy composition: Mg: 0.80, Si: 1.0, Zn: 0.55 , Cu: 0.18, Mn: 0.10, Fe: 0.15, Cr: 0.010, Zr: 0.080, Ti: 0.02, the balance Al and other unavoidable other impurities. The alloy was melted and casted to obtain an ingot with a width of 2200mm and a thickness of 620mm. After the ingot was homogenized at 550°C / 20h, it was cooled with the furnace in a heat treatment furnace at a cooling rate of 10°C / h. After the ingot was completely cooled, it was Transfer to the heating furnace for heating and heat treatment before hot rolling. The heating rate is 50°C / h, the holding temperature is 530°C, and the holding time is 4h. Then it is directly subjected to hot rolling, intermediate anne...

Embodiment 2

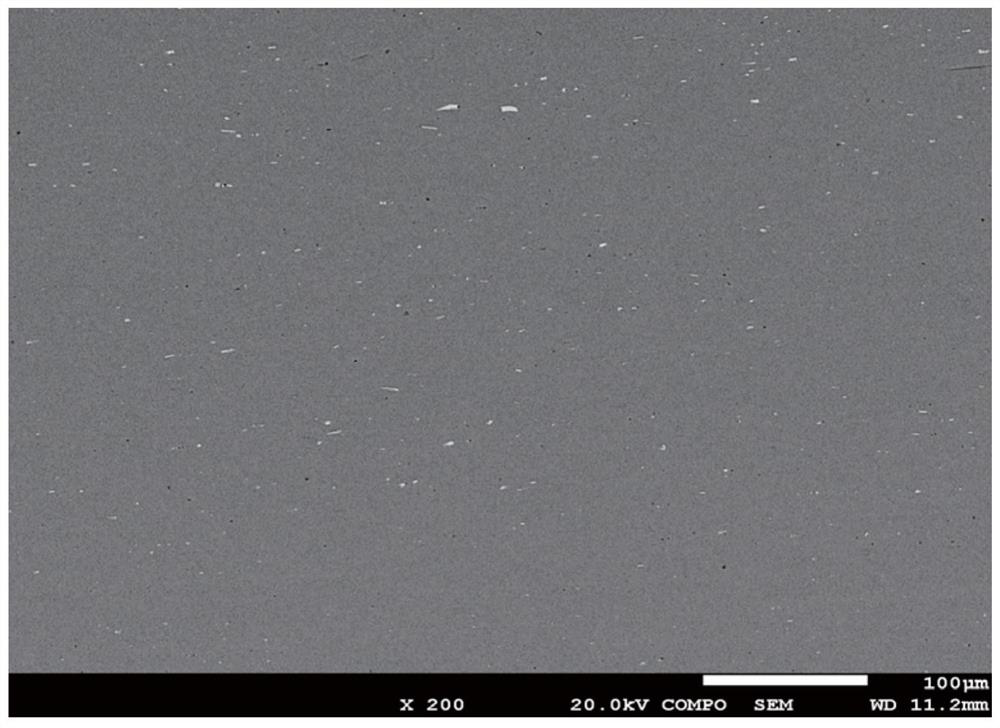

[0026] The 6000-series aluminum alloy with the same composition as in Example 1 was used. The alloy was melted and cast to obtain an ingot with a width of 1800 mm and a thickness of 420 mm. The ingot was homogenized at 550°C / 20h and then air-cooled. The cooling rate was 30°C / h. After the ingot is completely cooled, it is transferred to the heating furnace for heat treatment before hot rolling. The heating rate is 100°C / h, the holding temperature is 550°C, and the holding time is 2h. Then it is directly hot-rolled, intermediate annealed and Cold-rolled deformation to obtain cold-rolled plate and strip, and then the plate and strip are subjected to solution treatment at 555°C / 1min in the air cushion furnace, and pre-aging treatment is performed within 30min to obtain T4P state alloy plate and strip. The flanging performance of the T4P state alloy plate and strip is tested according to the standard of GB T 33227-2016 "Aluminum and Aluminum Alloy Plates and Strips for Automobiles",...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com