Hot-rolled pickled steel strip with high broaching performance and production method thereof

A hot-rolled pickling and production method technology, applied in the field of steelmaking, can solve the problems of low hole expansion performance and low elongation performance, and achieve the effects of high hole expansion rate, improved hole expansion rate, and excellent strip surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

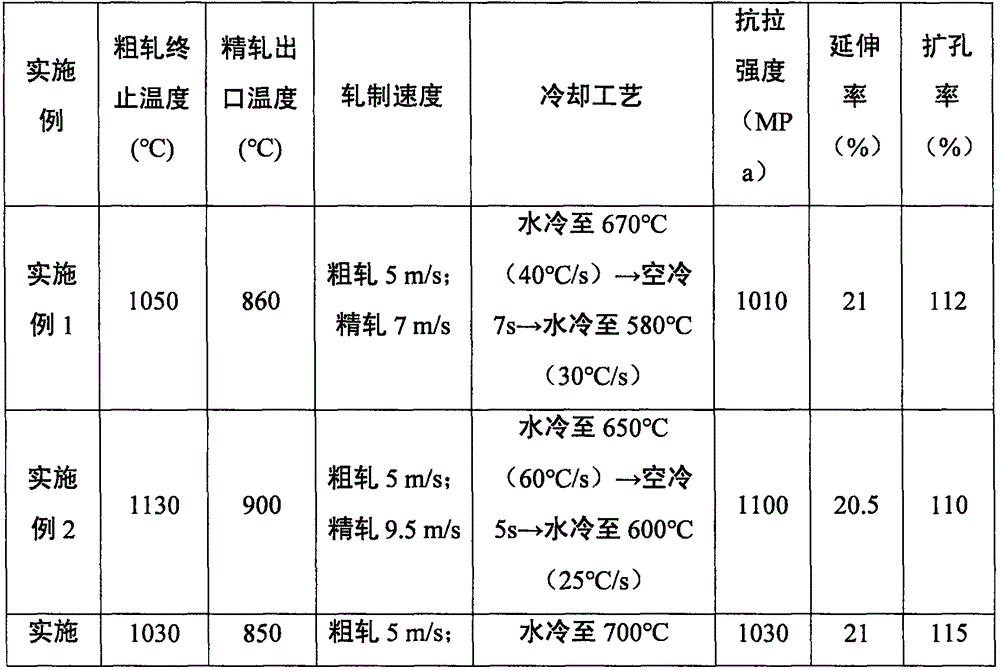

[0024] The embodiments of the present invention provide a hot-rolled pickled steel strip with high hole-expanding performance and its production method, which can ensure that the hot-rolled pickled steel with a tensile strength of 980 MPa has a high hole-expanding rate and elongation; the heat obtained The tensile strength of the rolled and pickled strip steel is ≥980MPa, the hole expansion ratio λ≥110%, and the elongation rate ≥20%, with excellent strip surface quality.

[0025] In order to achieve the above object, the present invention provides a hot-rolled pickled steel strip with high hole expansion performance, the mass percentage of its chemical composition is: C: 0.03% ~ 0.1%, Si: ≤ 0.1%, Mn: 0.5% ~ 1.5%, P≤0.02%, S≤0.006%, Nb≤0.05%, Ti≤0.1%, Mo≤0.15%, Re: 0.1%~0.4%, the rest is Fe and unavoidable impurities;

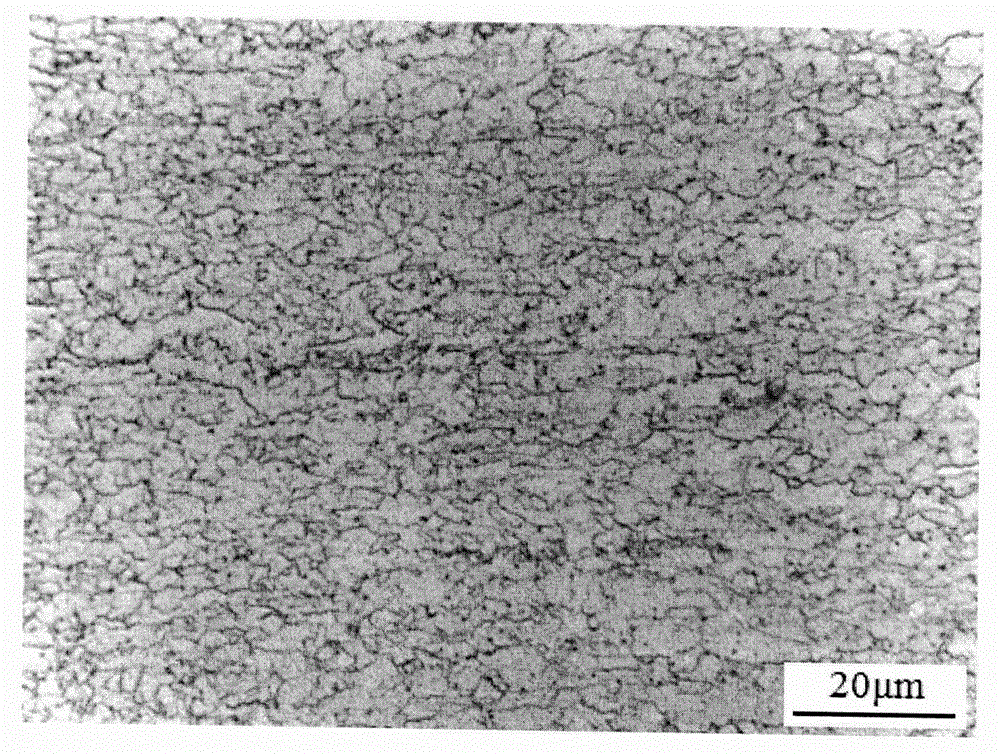

[0026] The internal microstructure of the hot-rolled pickled steel strip is ferrite.

[0027] The structure type of the steel strip obtained in the embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com