Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Reduce C content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrafine crystal bainite high-strength steel and manufacturing method thereof

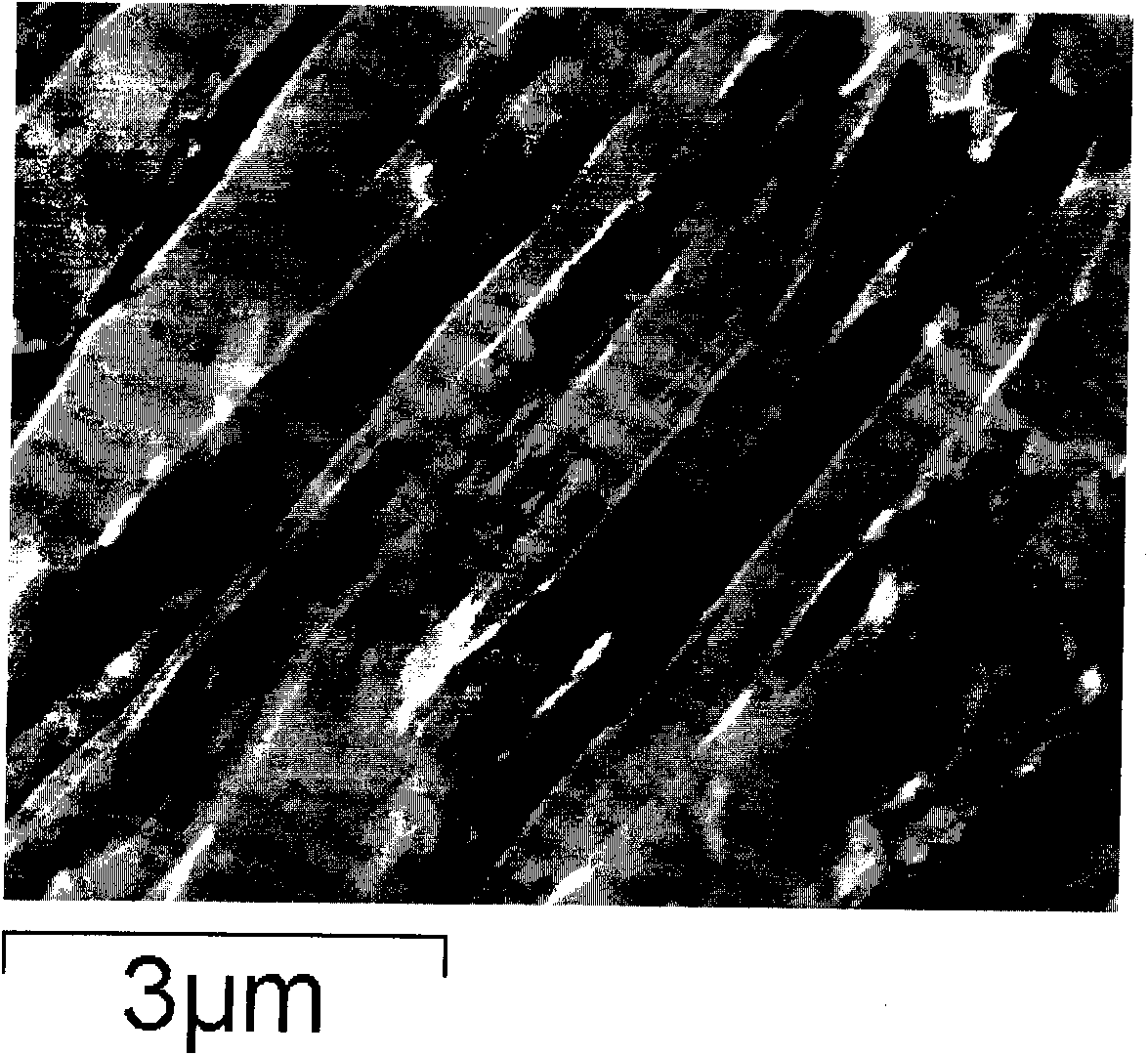

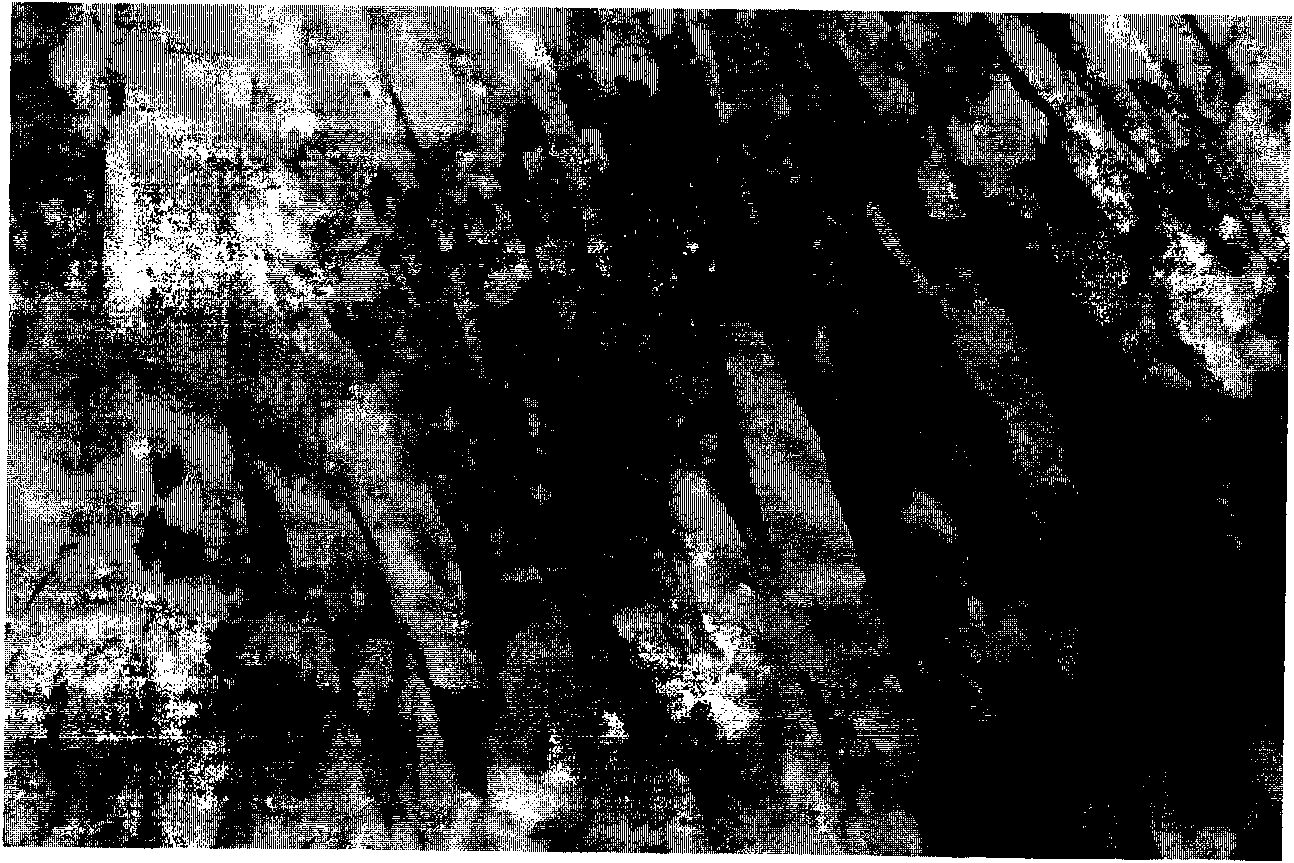

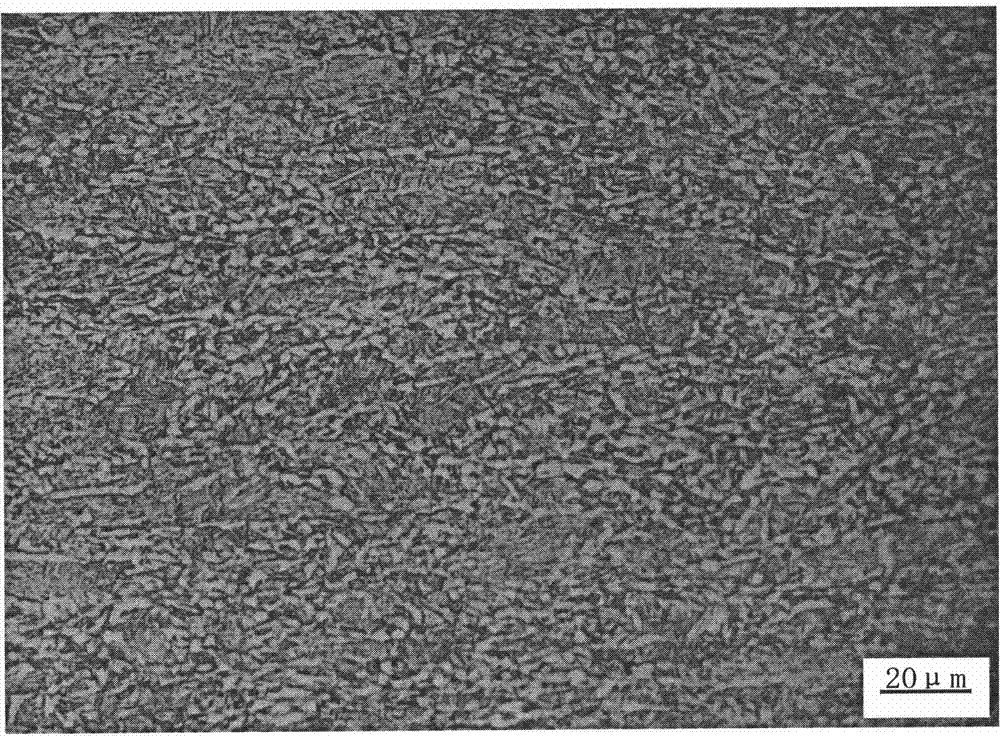

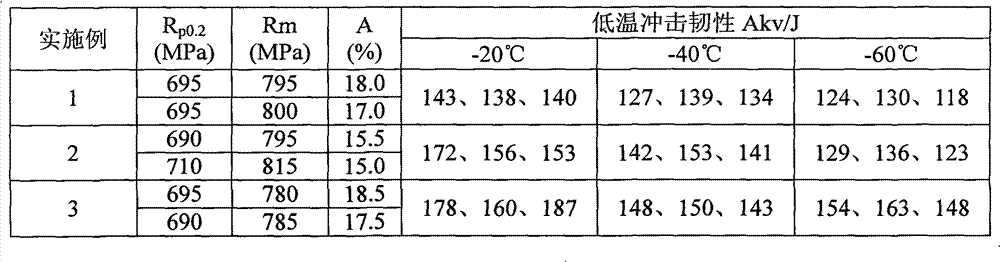

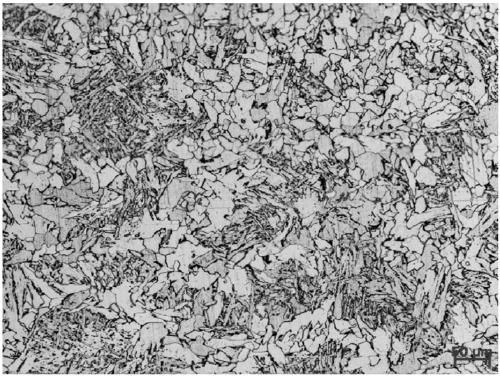

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Owner:BAOSHAN IRON & STEEL CO LTD

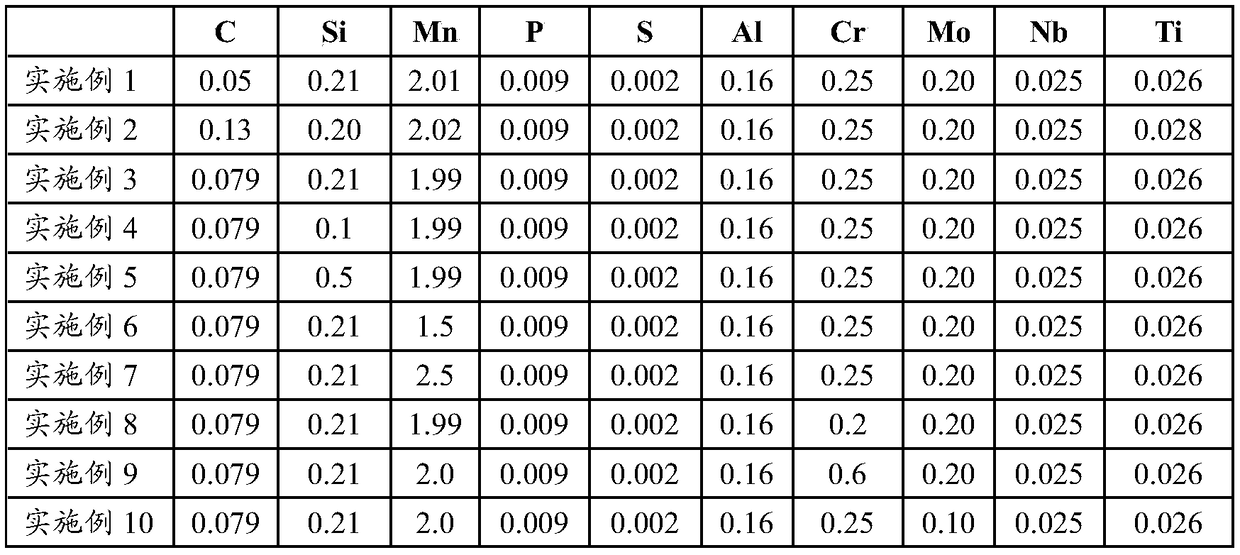

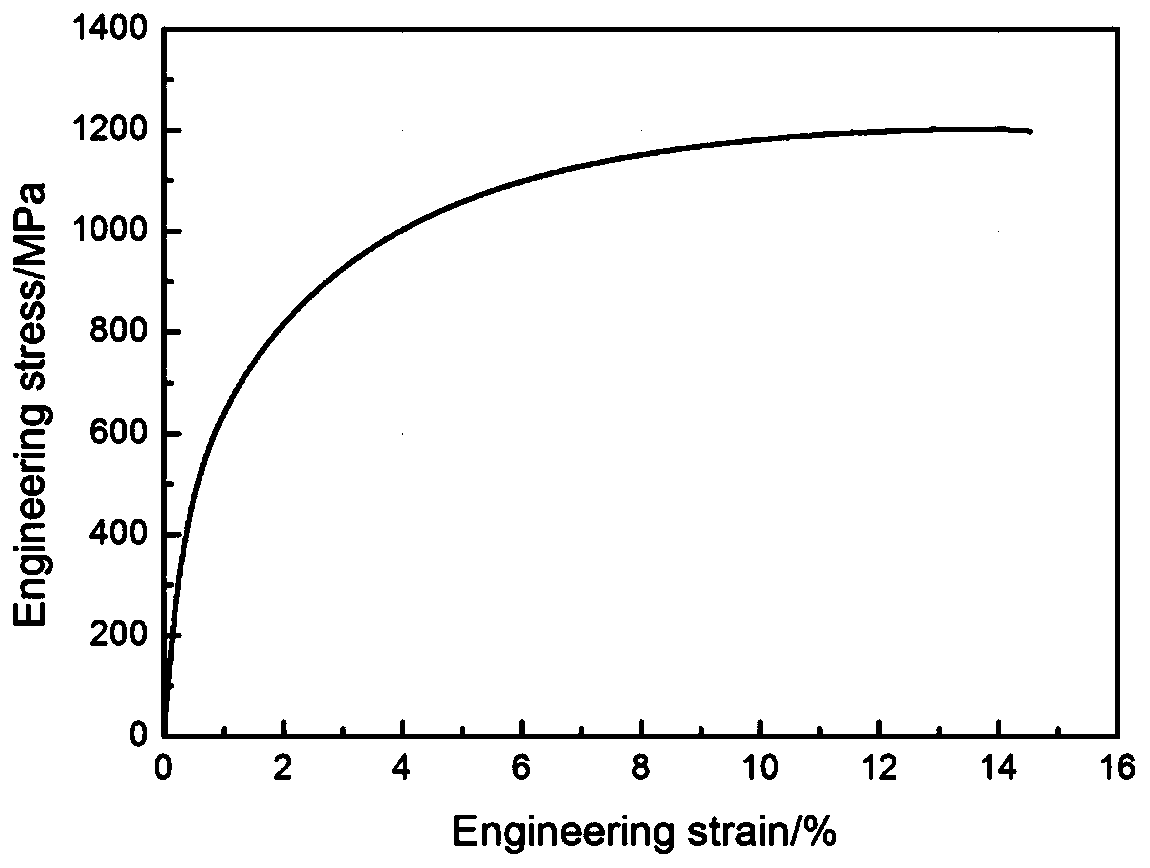

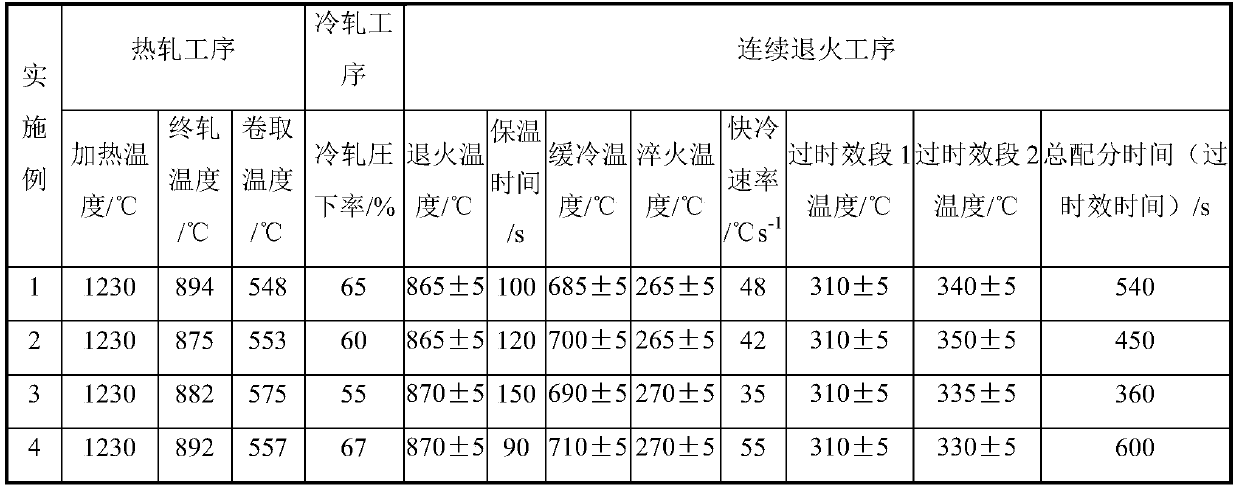

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

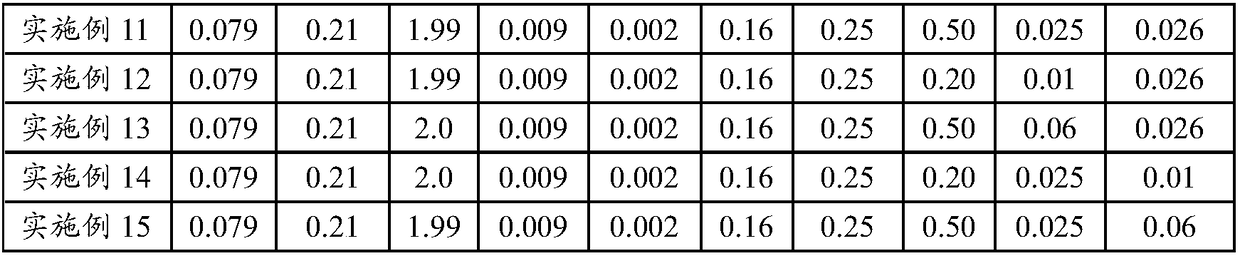

1180MPa-grade high-plasticity bainite complex phase steel plate for automobile and preparation method for 1180MPa-grade high-plasticity bainite complex phase steel plate

The invention belongs to the field of manufacturing of steel for automobiles and particularly relates to a 1180MPa-grade high-plasticity bainite complex phase steel plate for an automobile and a preparation method for the 1180MPa-grade high-plasticity bainite complex phase steel plate. The 1180MPa-grade high-plasticity bainite complex phase steel plate is prepared from the following components inpercentage by weight: 0.03-0.20 percent of C, 0.05-1.50 percent of Si, 0.5-2.5 percent of Mn, smaller than or equal to 0.05 percent of P, smaller than or equal to 0.05 percent of S, 0.01-0.04 percentof Nb, 0.01-0.04 percent of Ti, 0.01-0.15 percent of V, 0. 015-1.50 percent of Al, substitutable components, including 0-2.0 percent of Cr, 0-0.5 percent of Mo and 0.05-0.50 percent of Cu, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps of converter smelting, continuous casting of a medium-thin slab, hot continuous rolling, acid pickling cold rolling and continuous annealing. For the 1180MPa-grade high-plasticity bainite complex phase steel plate for the automobile and the preparation method disclosed by the invention, the chemical components of the steel take the C, the Si and the Mn as main elements, the content of the C is smaller than 0.25, and the alloy cost is lowered; by adopting the production process of converter smelting, continuous casting and continuous rolling of the medium-thin slab, acid pickling cold rolling and continuous annealing, the production process is simplified, the cost is low, new production equipment doesnot need to be added, and the production process is stable; and the obtained material has the force and energy characteristics of high yield, high tensile strength and high extension.

Owner:ANGANG STEEL CO LTD

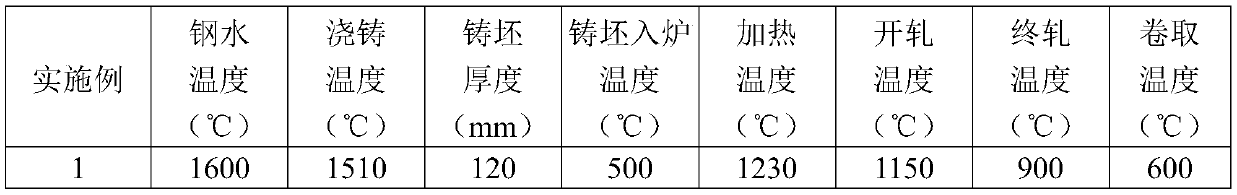

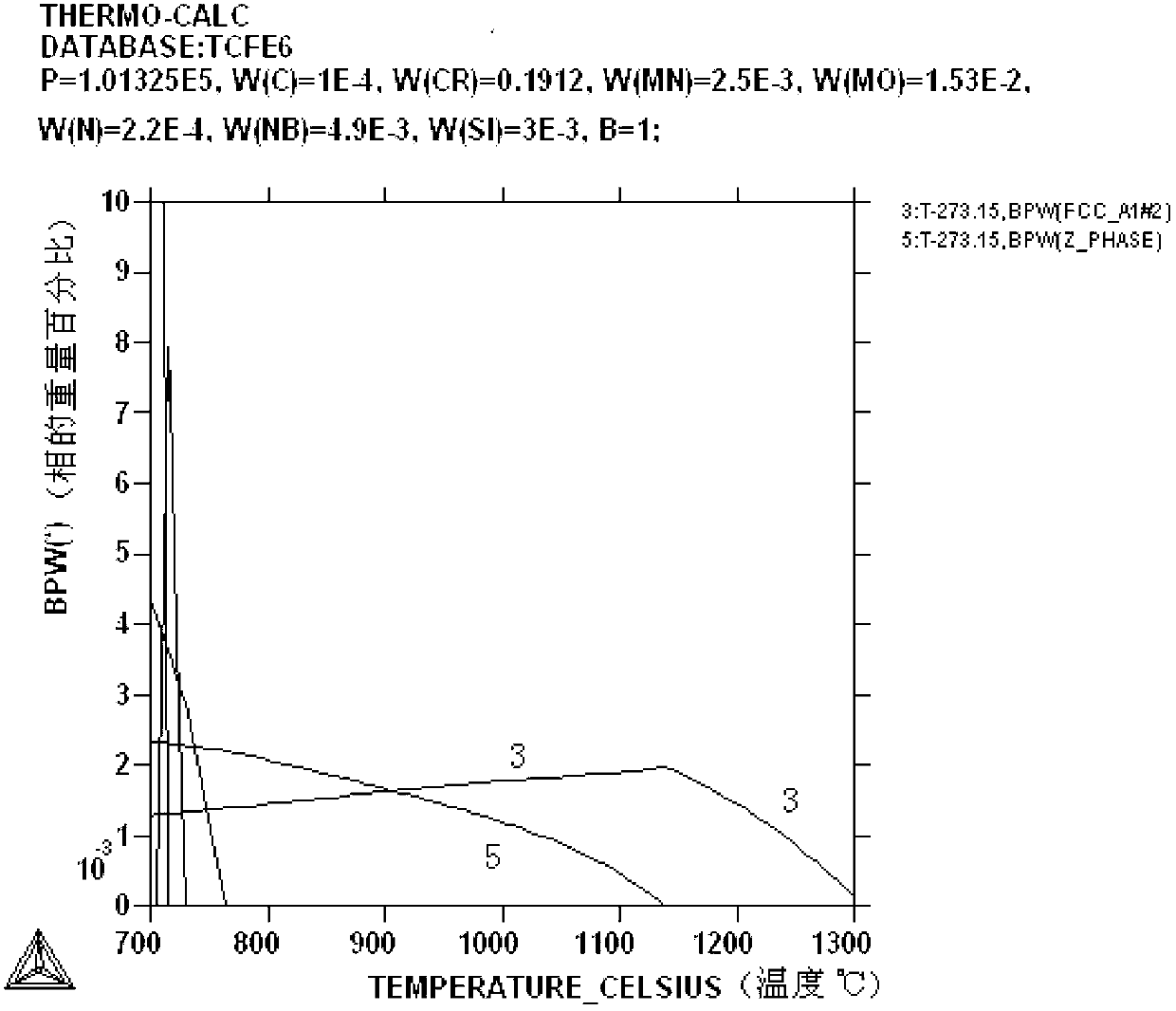

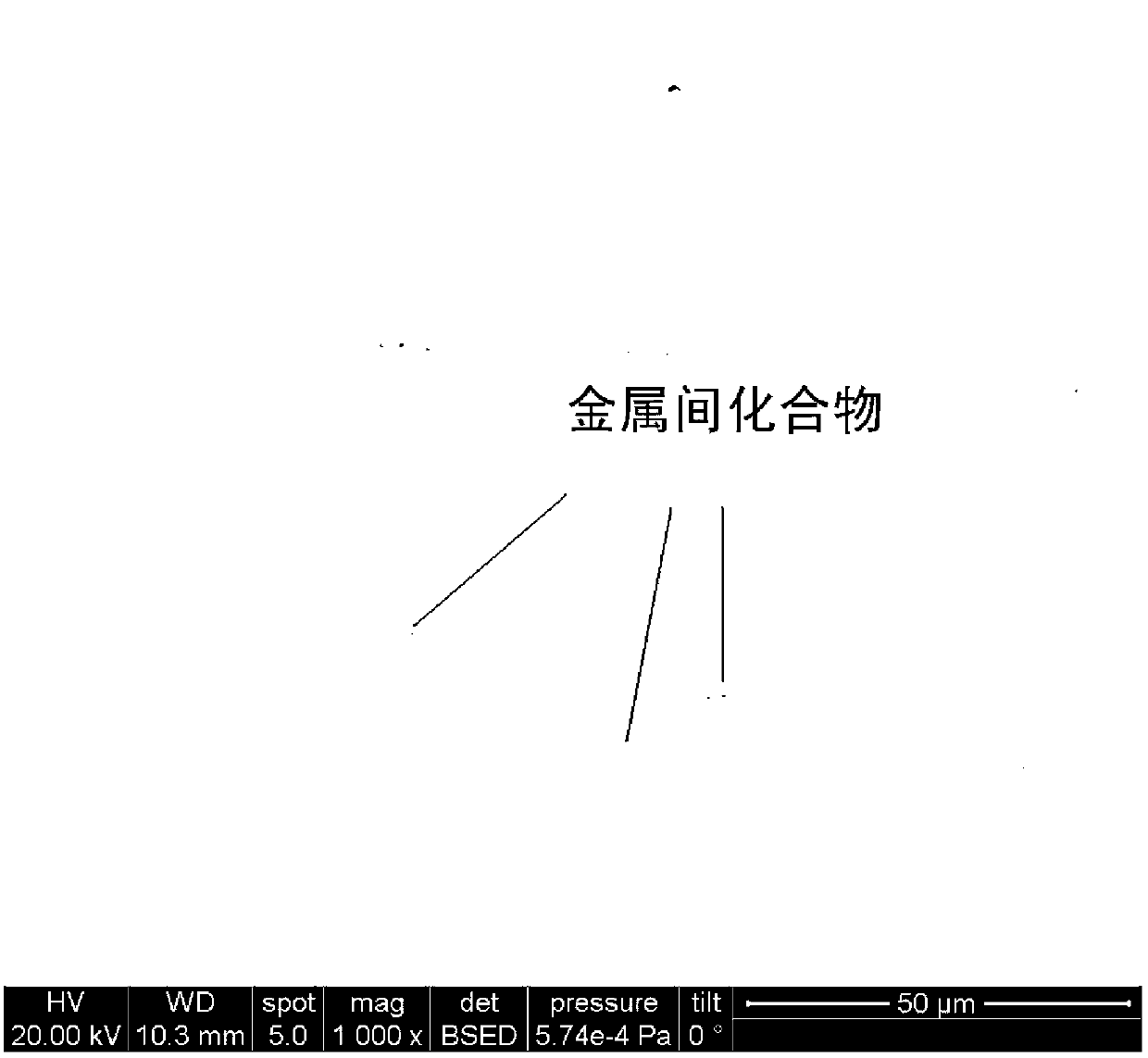

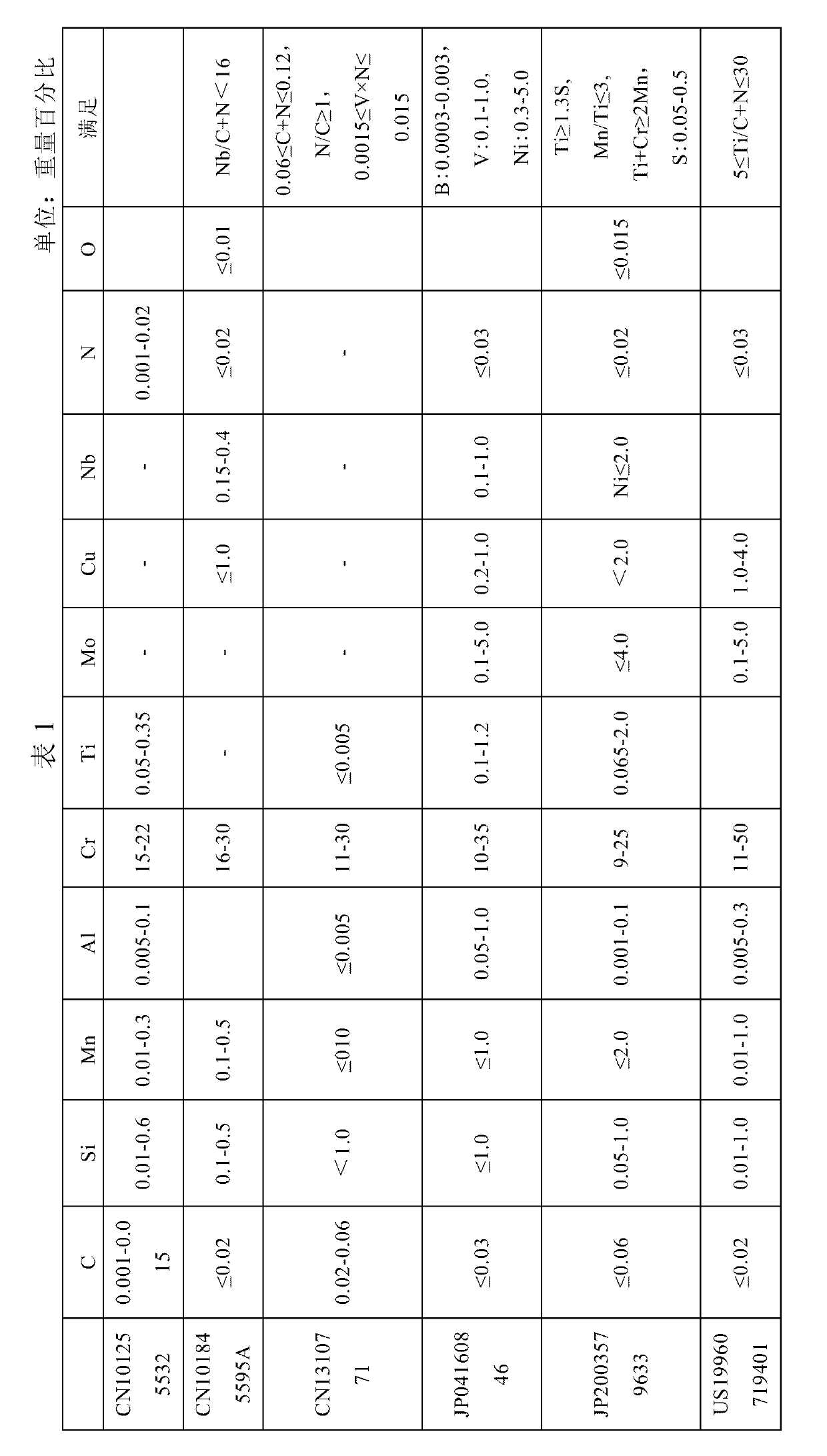

High-surface quality ferrite stainless steel plate and manufacturing method thereof

The invention discloses a high-surface quality ferrite stainless steel plate and a manufacturing method thereof. The high-surface quality ferrite stainless steel plate comprises, by weight, less than or equal to 0.03% of C, 0.20 to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.03% of P, less than or equal to 0.01% of S, 16 to 20% of Cr, 0.75 to 2.0% of Mo, 0.42 to 0.7% of Nb, less than or equal to 0.03% of N, less than or equal to 0.005% of Al, less than or equal to 0.005% of O and the balance Fe and unavoidable impurities, wherein based on Nb content, C content and N content respectively represented by Nb, C and N, Nb-20*C-7*N is greater than or equal to 0.15% and less than or equal to 0.7% and 1.2*C+N is less than or equal to 0.04%. Through smelting, hot rolling, two-rolling process cold rolling, bright annealing and flattening, the high-surface quality ferrite stainless steel plate which is a high-glossiness high-brightness low-roughness high-surface quality mirror material is obtained, has excellent corrosion resistance, cold deformation wrinkling resistance, high yield strength and high surface hardness and is suitable for automobile outer-decoration bright strips (pieces) and furniture decoration bright strips having high surface quality requirements.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

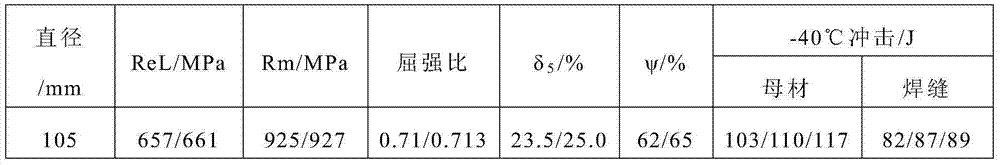

Steel plate with 890MPa-grade yield strength and low welding crack sensitivity and manufacturing method thereof

ActiveCN103898406AReduce C contentLow costFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

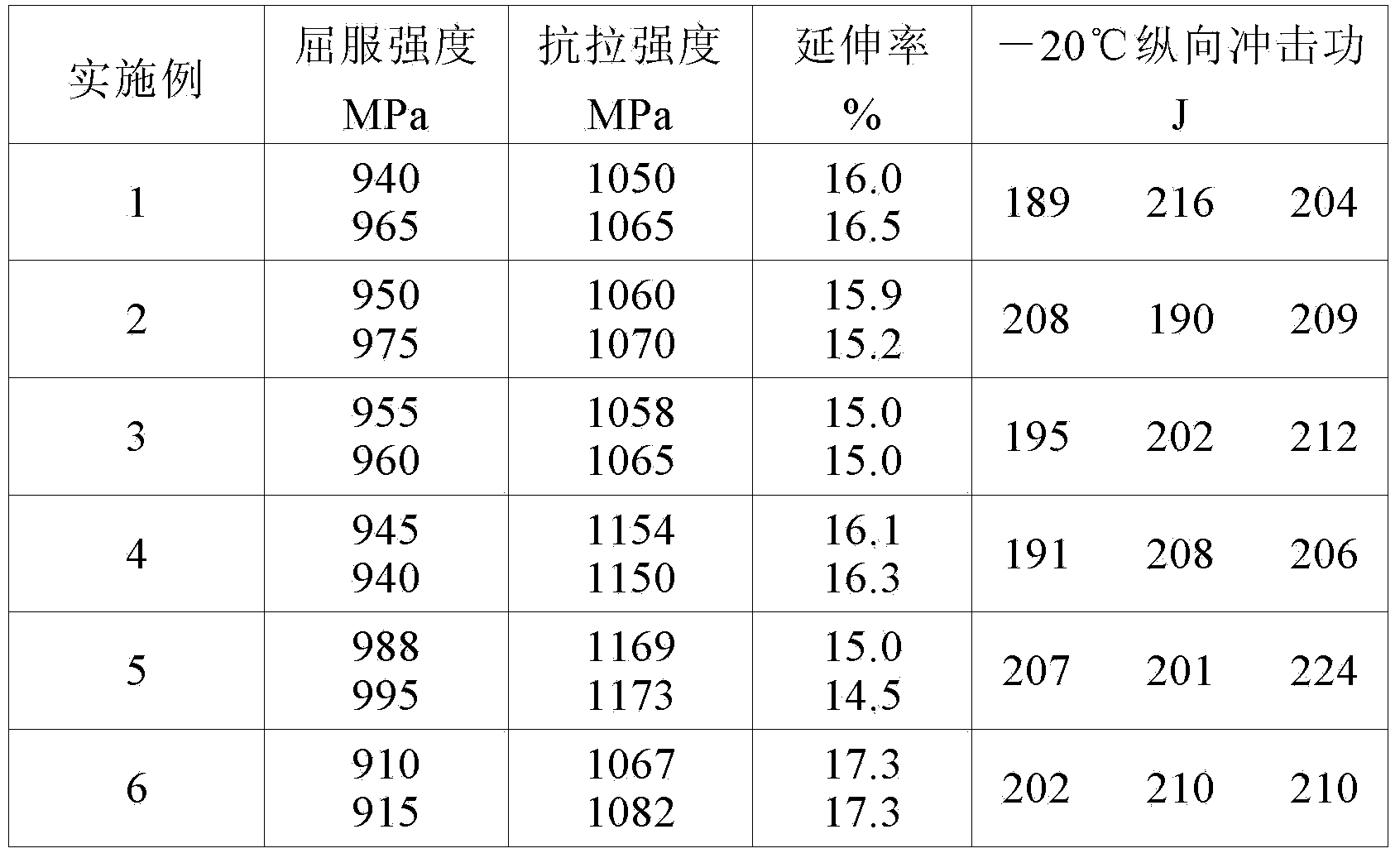

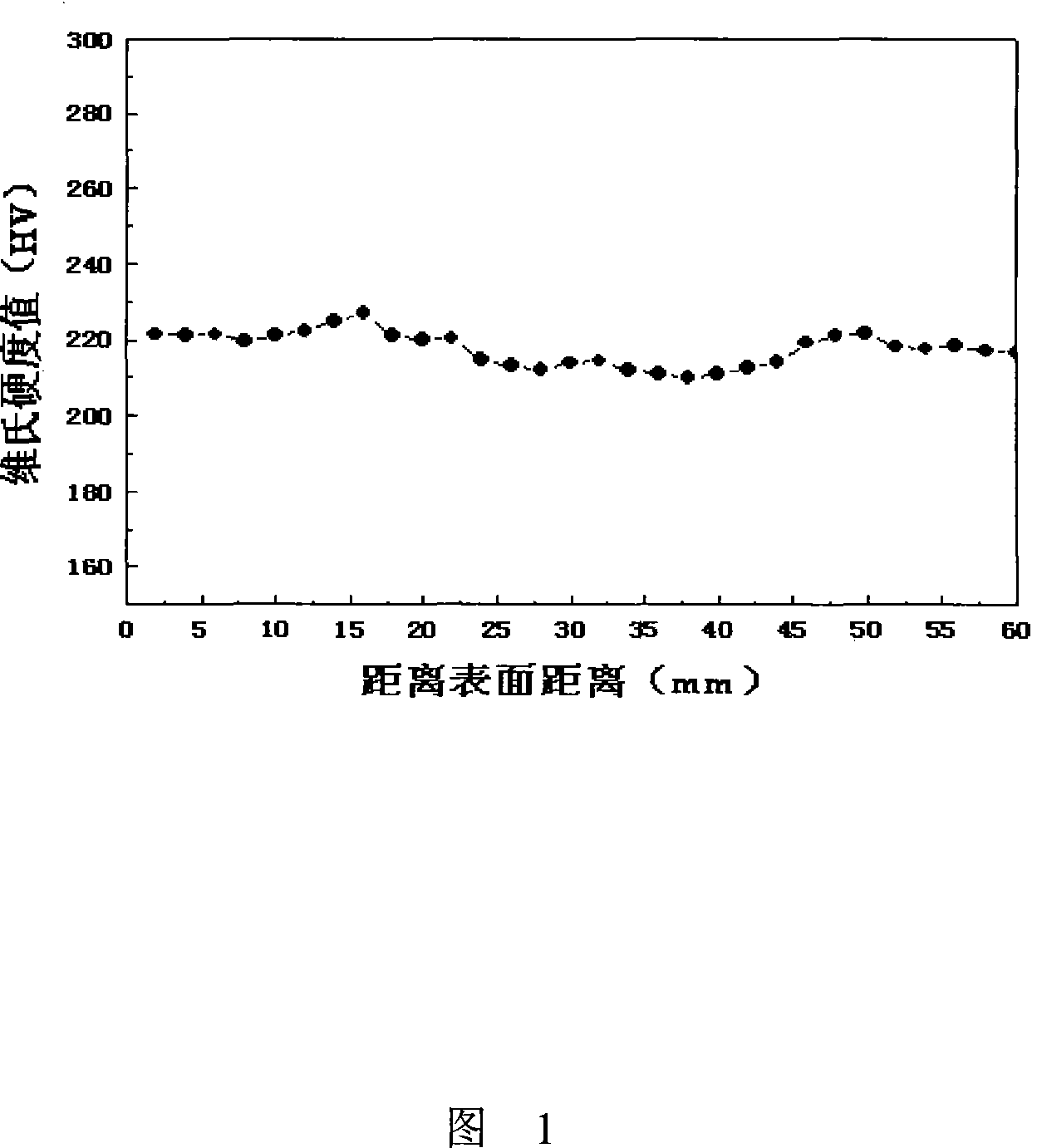

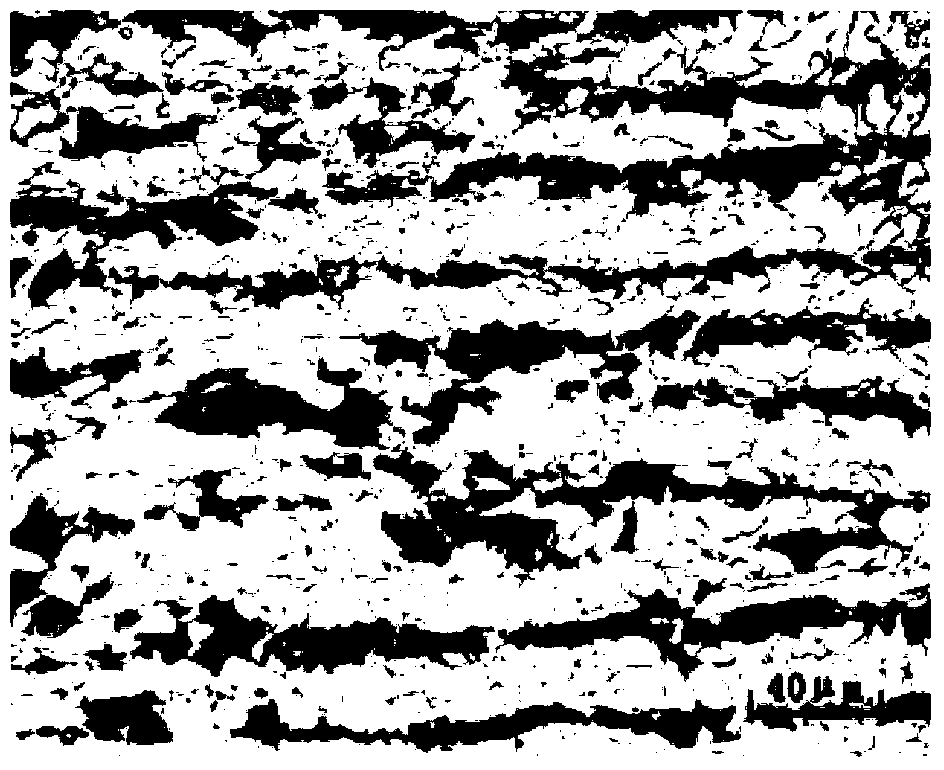

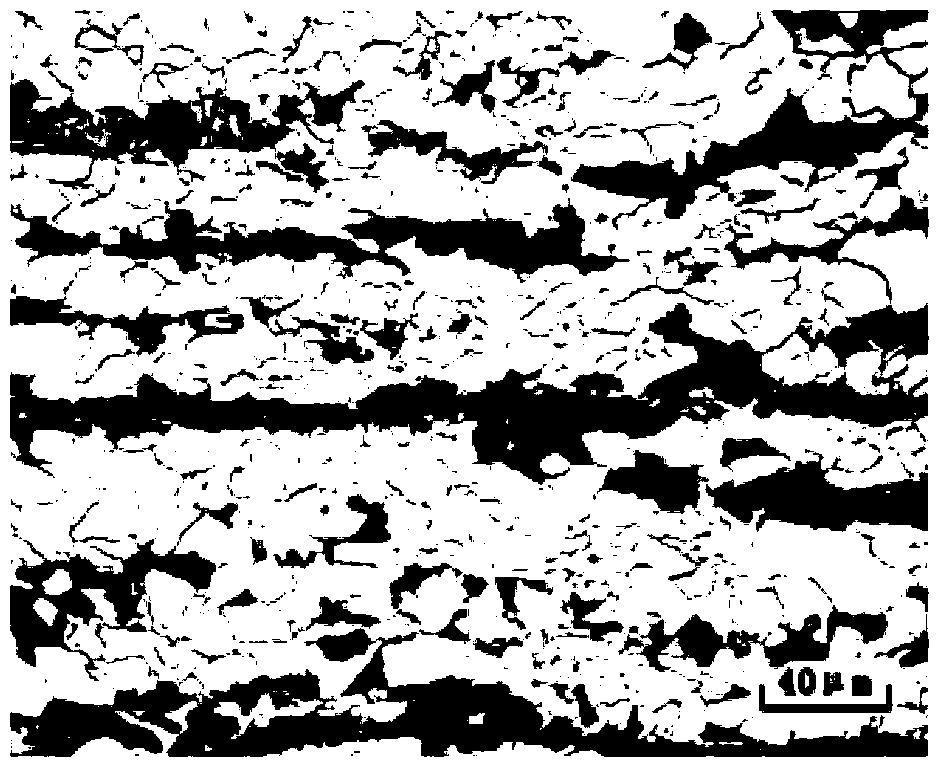

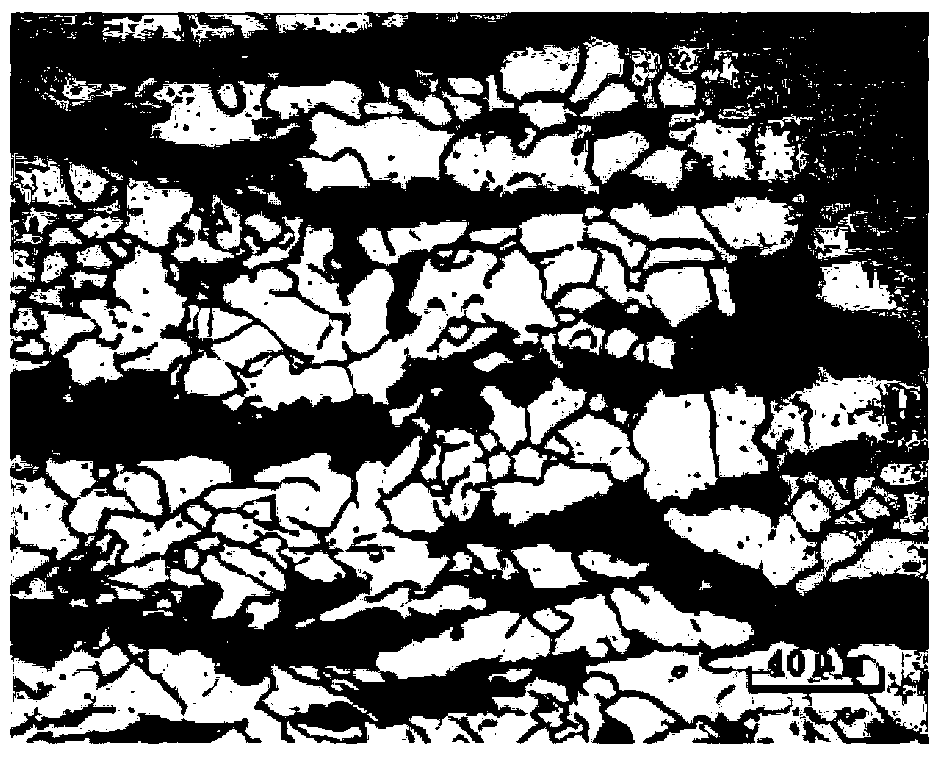

The invention discloses a steel plate with 890MPa-grade yield strength and low welding crack sensitivity and a manufacturing method thereof. The steel plate comprises the following components by weight percent: 0.06-0.13wt.% of C, 0.05-0.70wt.% of Si, 1.20-2.30wt.% of Mn, 0-0.25wt.% of Mo, 0.03-0.11wt.% of Nb, 0.002-0.050wt.% of Ti, 0.02-0.15wt.% of Al, 0-0.0020wt.% of B, no more than 8.5% of 2Si+3Mn+4Mo, and the balance being Fe and inevitable impurities. The tissue of taking a super-fine bainitic lath as a matrix is obtained by adopting a technology of controlling hot mechanical rolling and cooling, so as to improve the strength, the plasticity and the toughness of the steel plate. The yield strength of the steel plate with low welding crack sensitivity is greater than 800MPa, the tensile strength is greater than 900MPa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 150J, the welding crack sensitivity index Pcm is smaller than or equal to 0.20%, and the welding property is good.

Owner:BAOSHAN IRON & STEEL CO LTD

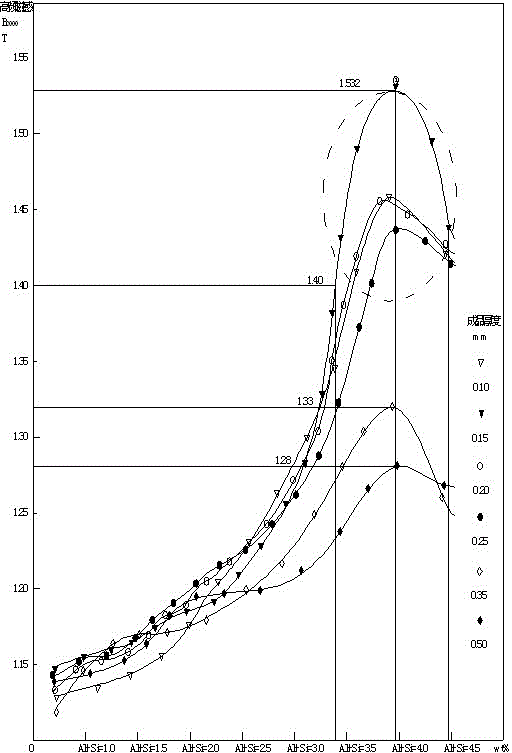

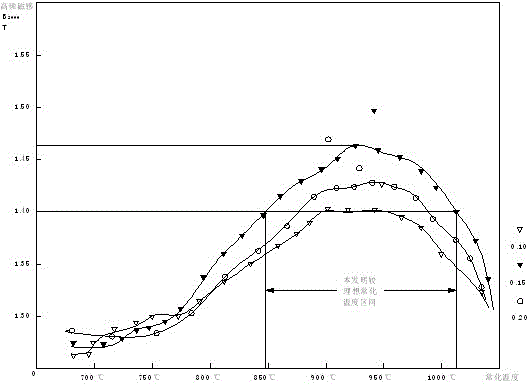

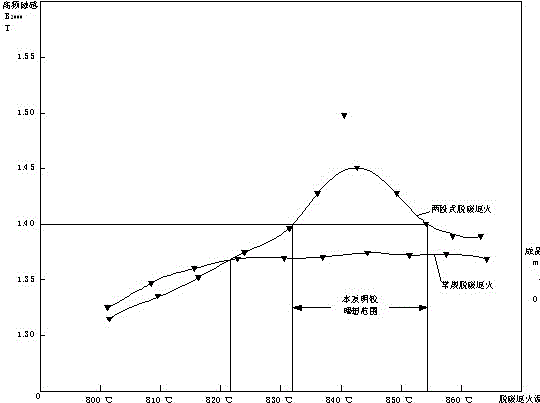

High-frequency low-iron-loss excellent-magnetic-property non-orientated silicon steel strip and production method thereof

The invention provides a high-frequency low-iron-loss excellent-magnetic-property 0.10-0.25mm non-orientated silicon steel strip which contains the following components in percentage by weight: 0.001-0.005% of C, 2.05-3.75% of Si, 0.150-0.850% of Als, at most 0.003% of N, at most 0.005% of S, at most 0.02% of P, 0.15-0.30% of Mn, 0.01-0.08% of Sn, 2.5-3.5% of Cr, 0.05-0.1% of Cu, at most 0.003% of Ti, and the balance of Fe and inevitable impurities. The content control range of acid-soluble aluminum and silicon is as follows: 2.2<Als(%)+Si(%)<4.6. The invention lowers the iron core loss under medium / high-frequency, and especially 1000Hz or above ultrahigh-frequency service conditions, stabilize the magnetic property in the operating state, lower the iron loss in the medium-high frequency or high-frequency state, enhance the mechanical strength of the strip product, and optimize the shape of strip, lamination factor and punching performance.

Owner:咸宁泉都带钢科技有限责任公司

Micro-alloying compound cored wire for high-strength steel

The invention relates to a micro-alloying compound cored wire for high-strength steel, comprising a carbon steel sheath and a powdery core, wherein the core is prepared from the following chemical components by weight percent: 23 to 28 wt% of Ca, 51 to 55 wt% of Si, 0.65 to 1.5 wt% of Mg, 1.3 to 2.5 wt% of Ba, 0.6 to 1.0 wt% of Re, 0.6 to 1.2 wt% of B, 1.6 to 3.5 wt% of Zr, 1.3 to 2.8 wt% of Ti, 0.6 to 1.2 wt% of Nb, and balance of ferrum and inevitable impurities. The invention reduces the content of C in high-strength steel through reasonably designing the chemical components and simultaneously and greatly enhances the grain sizes in continuous casting billets so that the grains are refined. The mechanical properties of the steel can be obviously improved, and the transverse impact properties of the steel are obviously enhanced to approximate to longitudinal impact value. Besides, the invention well solves the problems of center segregation and center porosity of the continuous casting billets, nonuniform impurity distribution, and the like.

Owner:HUBEI KMK WELDING MATERIALS

Corrosion-resistant welding rod and its preparing method

InactiveCN101148008AWill not cause short supplyAvoid corrosionLiquid surface applicatorsWelding/cutting media/materialsNiobiumBoron carbide

The present invention belongs to the field of welding material technology, and is especially one kind of anticorrosive welding rod. The welding rod includes one core wire and one welding rod coating comprising tungsten carbide 2-10 wt%, boron carbide or boron nitride 2-8 wt%, nickel powder 2-10 wt%, copper 0.30-0.85 wt%, RE elements 0.2-4.60 wt%, Mn-N alloy and / or V-N alloy in any ratio 0.20-2.80 wt%, ferromolybdenum 0.6-3.2 wt%, marble 25-38 wt%, titanium white powder 2-8 wt%, fluorite 1-6 wt%, low carbon ferromanganese 3-8 wt%, ferrovanadium 0.35-4 wt%, ferroniobium or ferrotitanium 0.35-4 wt%, and low carbon ferrochrome for the rest. The welding rod has high corrosion resistance, high wear resistance, good welding performance and other advantages.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

High-strength steel plate with yield strength at 690MPa level and manufacture method thereof

The invention provides a high-strength steel plate with yield strength at 690MPa level and a manufacture method of the high-strength steel plate, and belongs to the field of low-alloy high-strength steel. The steel plate comprises the following chemical components in percentage by weight: 0.04-0.09% of C, 0.25-0.50% of Si, 1.4-1.7% of Mn, not greater than 0.020% of P, not greater than 0.010% of S, not greater than 0.45% of Cr, not greater than 0.20% of Mo, 0.04-0.05% of Nb, 0.05-0.07% of V, 0.005-0.020% of Ti, 0.0005-0.0025% of B, and the balance of Fe and inevitable impurities. According to the high-strength steel plate with yield strength at 690MPa level and the manufacture method provided by the invention, the low-carbon microalloying design is adopted, the technology in combination of TMCP (Thermal Mechanical Control Processing) and tempering is carried out, so that a matrix structure with fine Bainite as the major is obtained, and as a result, the strength, the plasticity and the toughness are in good match. The high-strength steel plate with yield strength at 690MPa level and the manufacture method can be widely applied to the fields such as the engineering machinery field and the coal mine machinery field.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

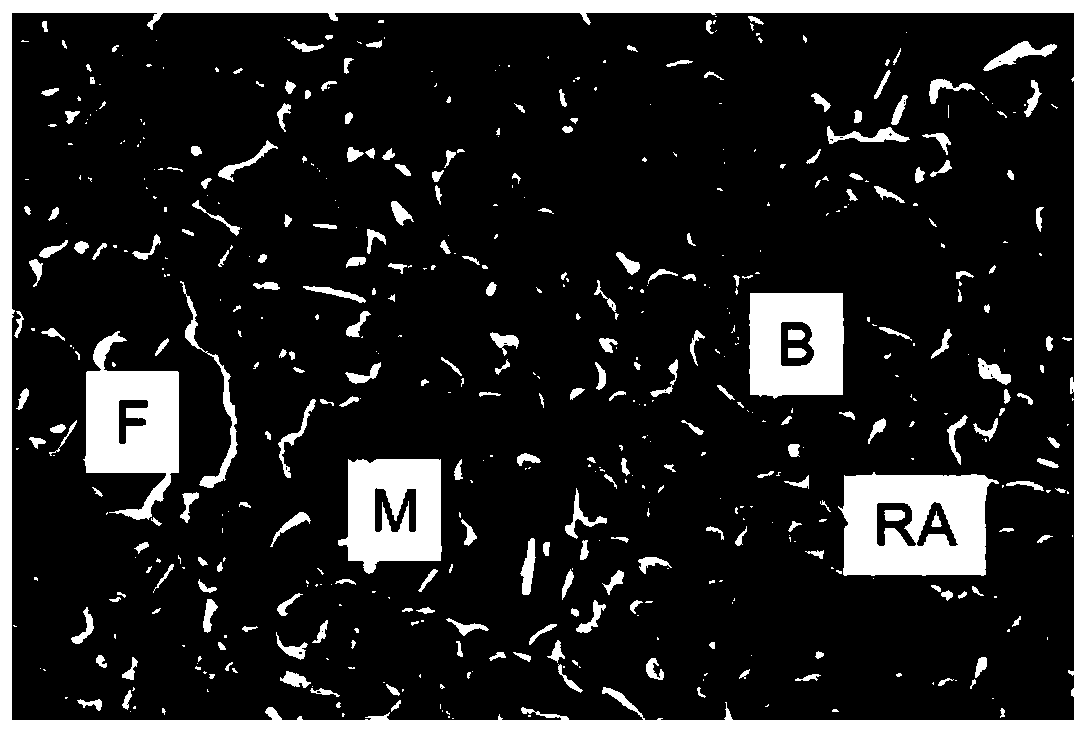

Q&P steel plate with high strength-elongation product and excellent welding performance and preparing method thereof

ActiveCN110093552AComposition and process design are easyStrong process operabilityFurnace typesProcess efficiency improvementSteel platesSheet steel

The invention discloses a Q&P steel plate with the high strength-elongation product and excellent welding performance and a preparing method thereof, and belongs to the technical field of cold-rolledsteel production of automobiles. The steel plate comprises the following chemical components of, in percentage by mass, 0.17%-0.21% of C, 1.80%-2.20% of Si, 2.10%-2.40% of Mn, 0.03%-0.05% of Nb, 0.008%-0.020% of Ti, 0.025%-0.045% of Als, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, and the balance Fe and inevitable residual impurities. The preparing method comprises the steps of steel-making, continuous casting, hot rolling, acid pickling, cold rolling and continuous annealing. The Q&P steel has the characteristic of excellent mechanical property, the yield strength greater than or equal to 600 MPa, the tensile strength greater than or equal to 1000 MPa, the elongation percentage greater than 20%, and the strength-elongation product greater than or equal to 22GPa%. According to the Q&P steel plate with the high strength-elongation product and excellent welding performance and the preparing method thereof, the Q&P steel with the high strength-elongation productcan be obtained at a relatively low partitioning temperature, and the requirement for process equipment is low, thus being suitable for the production of an existing continuous annealing production line.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Hot-rolled steel strip for CT90 level continuous pipe and production method of hot-rolled steel strip

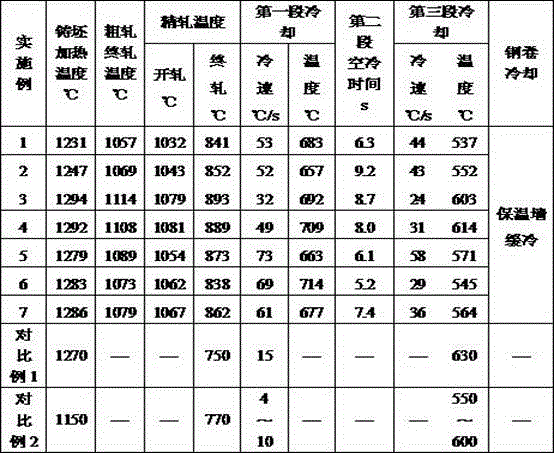

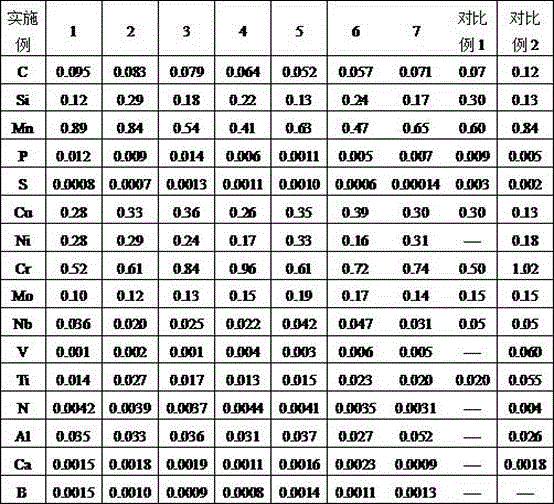

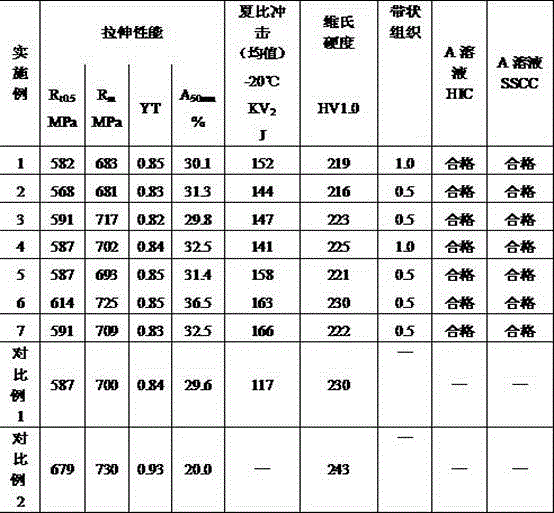

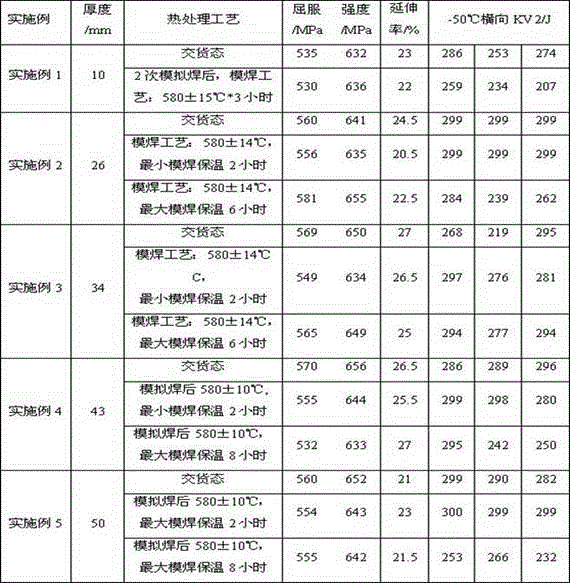

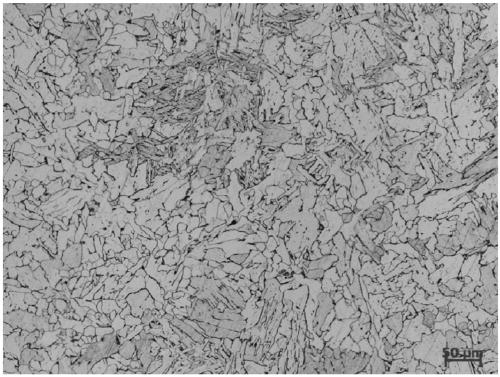

A hot-rolled steel strip for a CT90 level continuous pipe comprises chemical components including, by weight percent, 0.05%-0.10% of C, 0.10%-0.30% of Si, 0.40%-0.90% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.0020% of S, 0.25%-0.40% of Cu, 0.15%-0.35% of Ni, 0.50%-1.00% of Cr, 0.10%-0.20% of Mo, 0.020%-0.050% of Nb, smaller than or equal to 0.010% of V, 0.010%-0.030% of Ti, smaller than or equal to 0.0050% of N, 0.015%-0.060% of Al, 0.0008%-0.0025% of Ca and 0.0008%-0.0015% of B. A production method comprises the steps that a cast ingot is heated after smelting and ingot casting; rough rolling is conducted; finish rolling is conducted; cooling is conducted in three stages; and after a steel roll is rolled, the steel roll is placed in a thermal insulating wall to be subjected to slow cooling. Through adding of the B, the content of the C is reduced, structure segregation of the steel is improved, and it is ensured that the HIC resisting and SSCC resisting performance is qualified; through composite adding of the Cu and the Ni, the hot shortness of the Cu is improved; staging controlled cooling is conducted, regulation and control over a complex phase structure are achieved, and the yield ratio of the steel strip is reduced.

Owner:武汉钢铁有限公司

Tempering type high-strength steel plate for low-temperature container and production method for tempering type high-strength steel plate

The invention discloses a tempering type high-strength steel plate for a low-temperature container and a production method for the tempering type high-strength steel plate. The steel plate is smelted from the following components in percentage by mass: 0.05-0.09% of C, 0.20%-0.50% of Si, 1.50%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.020%-0.050% of Alt, 0.30%-0.60% of Ni, 0.15%-0.30% of Mo, 0.015%-0.025% of Nb, and the balance being Fe and inevitable impurities. According to tempering type high-strength steel plate for the low-temperature container and the production method for the tempering type high-strength steel plate disclosed by the invention, a uniform tempered sorbite+ferrite structure is obtained by adopting a production process with a reasonable component design, controlled rolling and controlled cooling as well as tempering thermal treatment, so that the good comprehensive mechanical property and the welding property of the steel plate are guaranteed, the production cost is low, the market competitiveness is strong, and the ever-growing market requirements are met.

Owner:WUYANG IRON & STEEL

Strip-casting 550-MPa-level weathering resistant steel and production method thereof

PendingCN109881084AReduce C contentGuaranteed bending performanceMetal rolling arrangementsSuperheatingImpurity

The invention discloses strip-casting 550-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.05-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted by a pair of coppercasting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lower than 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 450-600 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 550-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

Grain-oriented pure iron manufactured through adopting single cold rolling method and method

The invention relates to grain-oriented pure iron manufactured through adopting a single cold rolling method and a method. The method comprises the steps of converter smelting, liquid steel refining through a vacuum cycle degassing process, continuous casting, slab heating, hot rolling, normalizing, cold rolling and annealing, wherein after the continuous casting step, an obtained continuous cast slab comprises the following components by mass percent: 0.01 to 0.08% of C, 0.01 to 1.0% of Si, 0.05 to 0.5% of Mn, 0.01 to 0.1% of P, 0.003 to 0.01% of S, 0.005 to 0.05% of Als, 0.005 to 0.02% of N and 0.05 to 0.8% of Cu, and the balance being Fe; in the hot rolling process, the content of gamma phases obtained during finish rolling is controlled to be 10 to 30% by mass percent; in the normalizing step, the temperature of 650 to 800 DEG C is maintained for 30 to 600 s; and the annealing step comprises decarburizing annealing and high temperature annealing. According to the method, the grain-oriented pure iron which has high saturation magnetic induction intension and sharp {110}<001> preferred orientation can be obtained through utilizing conventional production devices of conventional iron and steel enterprises, through utilizing means such as component design, reasonable cooperation of inhibitor composition and appropriate setting of rolling and thermal treatment technologies, and through utilizing a traditional thick slab production technology.

Owner:CENT IRON & STEEL RES INST +1

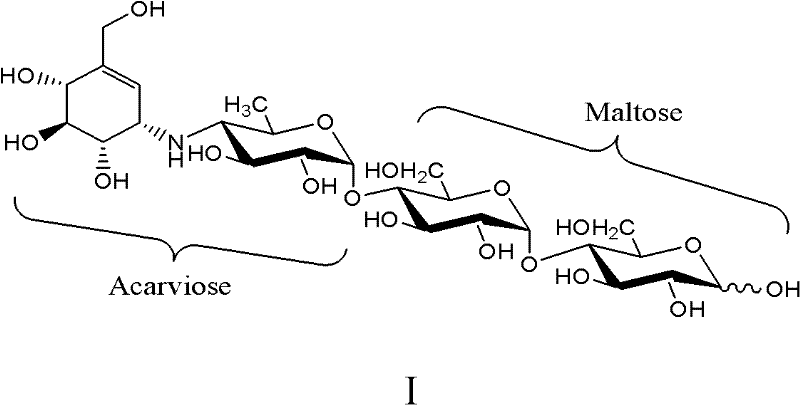

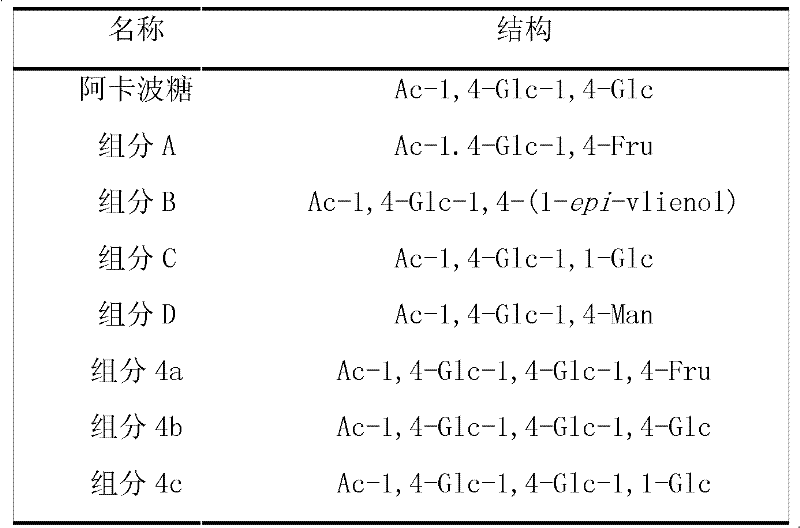

Method for synthesizing acarbose through microbial fermentation

ActiveCN102399837ARaise the level of fermentationImprove fermentation titerMicroorganism based processesFermentationBiotechnologyInorganic salts

The invention discloses a method for synthesizing acarbose through microbial fermentation, which comprises the following steps that acarbose producing strains CCTCC NO: M 209022 are inoculated to a fermentation culture medium containing carbon sources, nitrogen sources and inorganic salt applicable to all strains, the fermentation culture is carried out for 96 to 192hours at 20 to 32 DEG C, afterthe fermentation is completed, the obtained fermentation liquid is extracted and separated, and the acarbose is obtained. The method is characterized in that the fermentation culture is carried out for 0 to 60h, and water solution of ademetionine is added, so the ademetionine concentration in the fermentation culture medium is 1 to 300 mu mol / L. Through the supplementary addition of the ademetionine in the acarbose fermentation process, the fermentation level of the acarbose is improved.

Owner:ZHEJIANG UNIV OF TECH +2

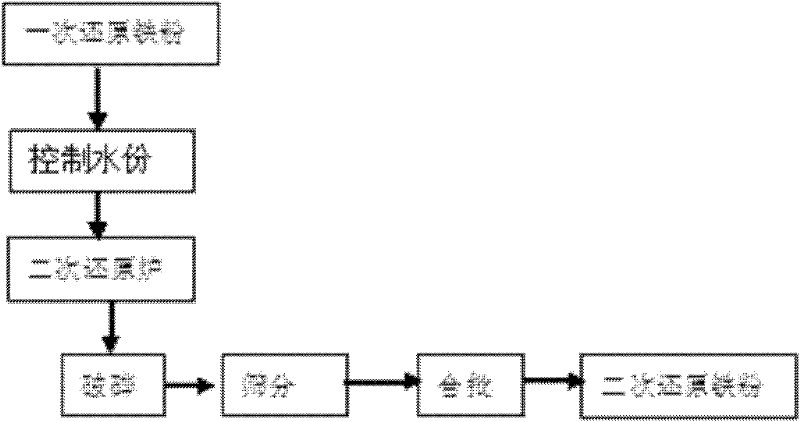

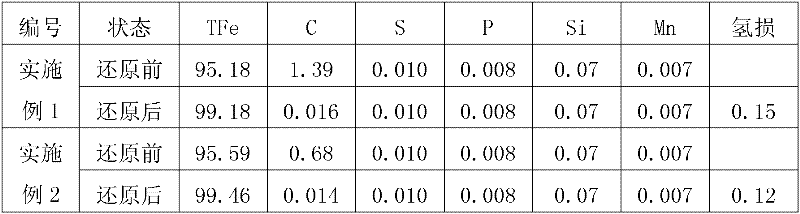

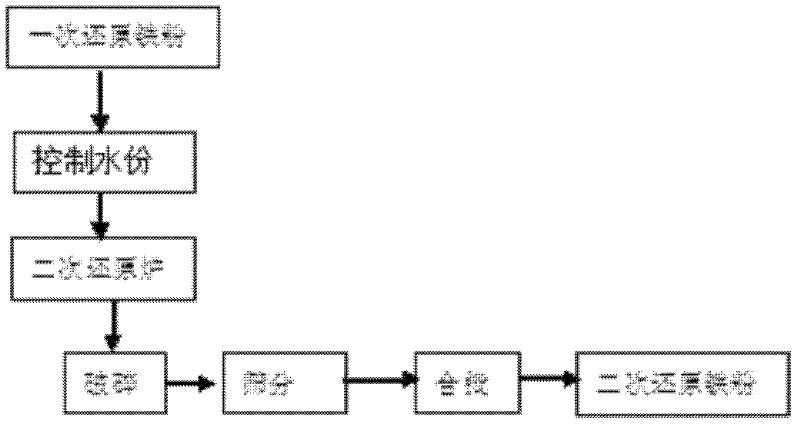

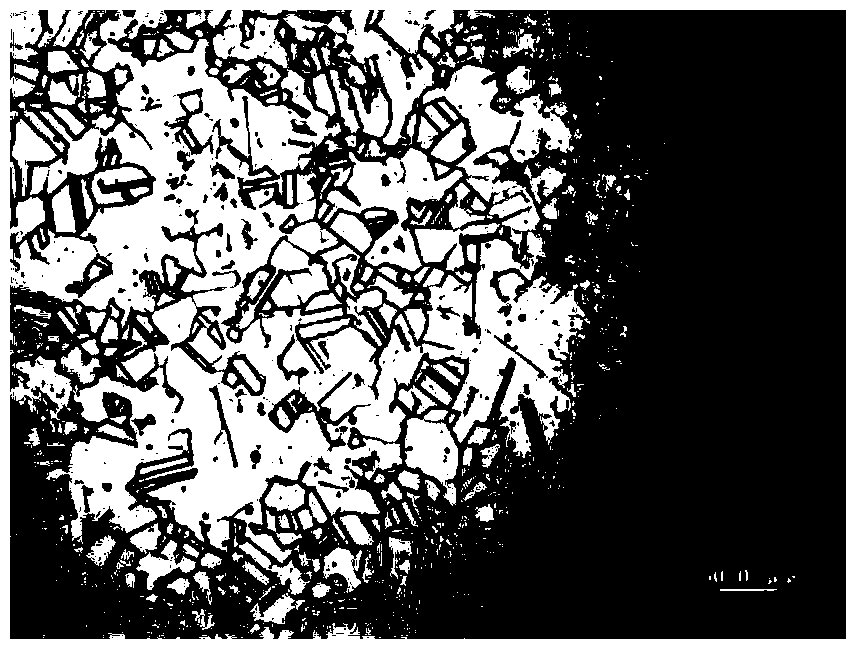

Method for second reduction and decarbonization of first reduced iron powder

The invention relates to a method for second reduction and decarbonization of first reduced iron powder, which belongs to the technical field of metallurgy and solves the technical problem. The lower energy consumption is realized in the method. The method for second reduction and decarbonization of first reduced iron powder comprises the following steps of: a, controlling water content of the first reduced iron powder to 3.5-10wt%; b, adding hydrogen gas or cracked ammonia gas, and fully reacting the first reduced iron powder with the hydrogen gas or the cracked ammonia gas at the temperature of 800-850 degrees centigrade; and c, cooling, breaking and sieving to obtain the second reduced iron powder.

Owner:攀枝花鑫润矿业有限公司 +1

Steel plate and preparation method thereof

The invention relates to a steel plate and a preparation method thereof. The steel plate is a 600MPa grade cold-rolled dual-phase steel plate with low yield ratio and comprises the following components by mass percent: 0.05-0.09% of C, 0.2-0.5% of Si, 1.4-1.8% of Mn, 0.020-0.060% of Als, not more than 0.4% of Cr, not more than 0.02% of P, not more than 0.01% of S and the balance of Fe and inevitable impurities. The method comprises the following steps: smelting; continuous casting; hot rolling; acid pickling and cold rolling; continuous annealing; finished product obtaining. The steel plate has the beneficial effects that on the basis of a C-Mn system, the contents of C and alloying elements are reduced to improve the weldability of the material; the content of Si in the design is lower and meanwhile high hydrogen annealing is adopted in the continuous annealing production process, so that the produced dual-phase steel has better surface quality; on the basis, the distribution state of martensite can be improved by adding proper amount of Cr, thus being beneficial for giving play to the plasticity; meanwhile, the continuous annealing production speed can be properly reduced and then the shape of the steel plate can be improved by reducing the yield ratio of the dual-phase steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

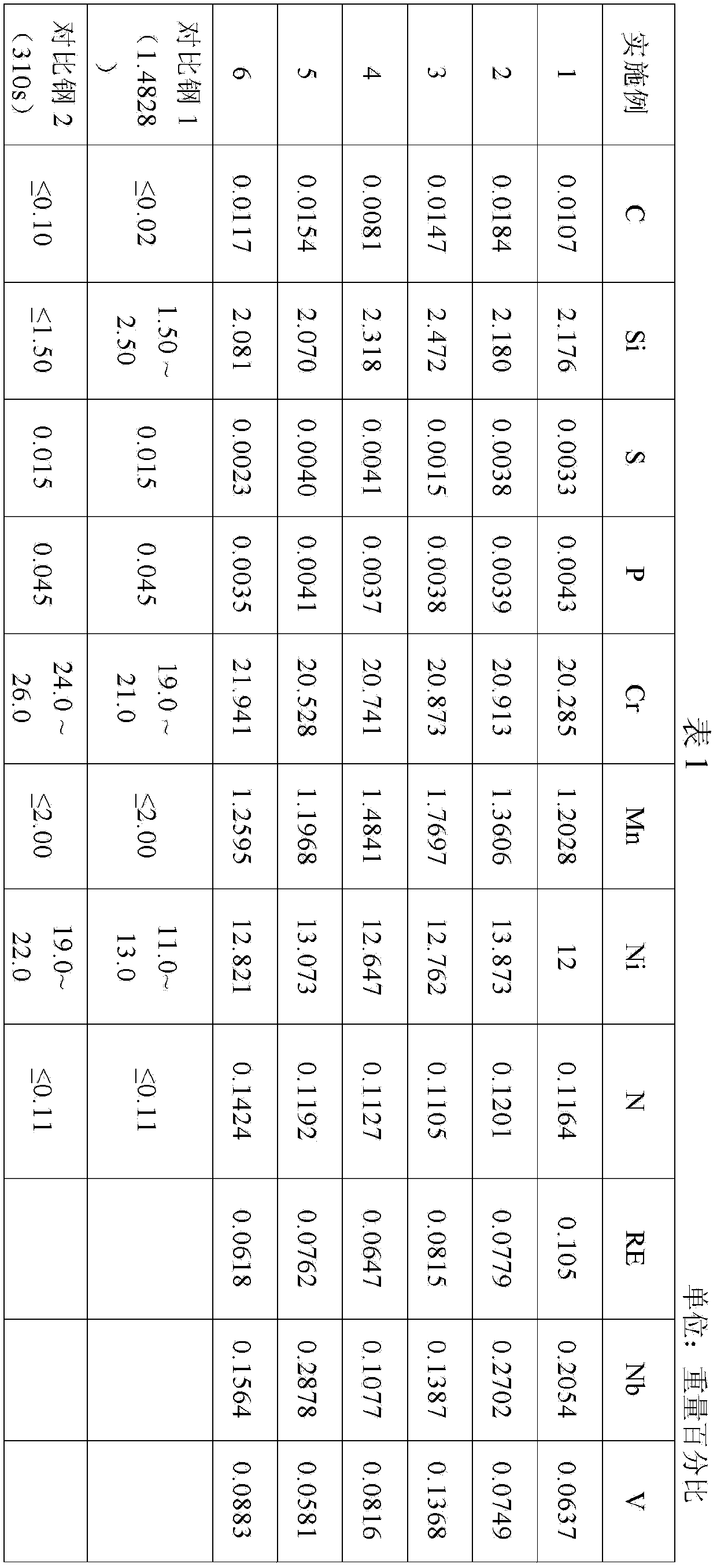

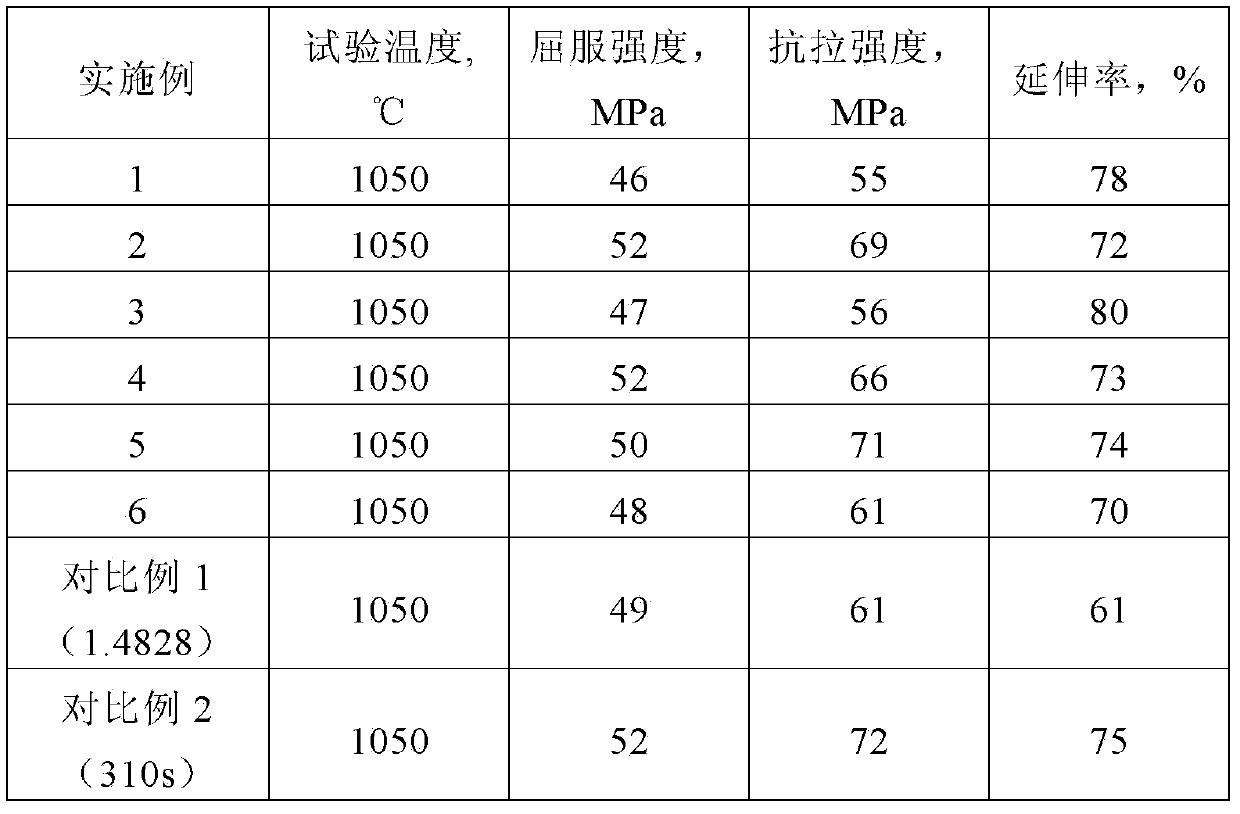

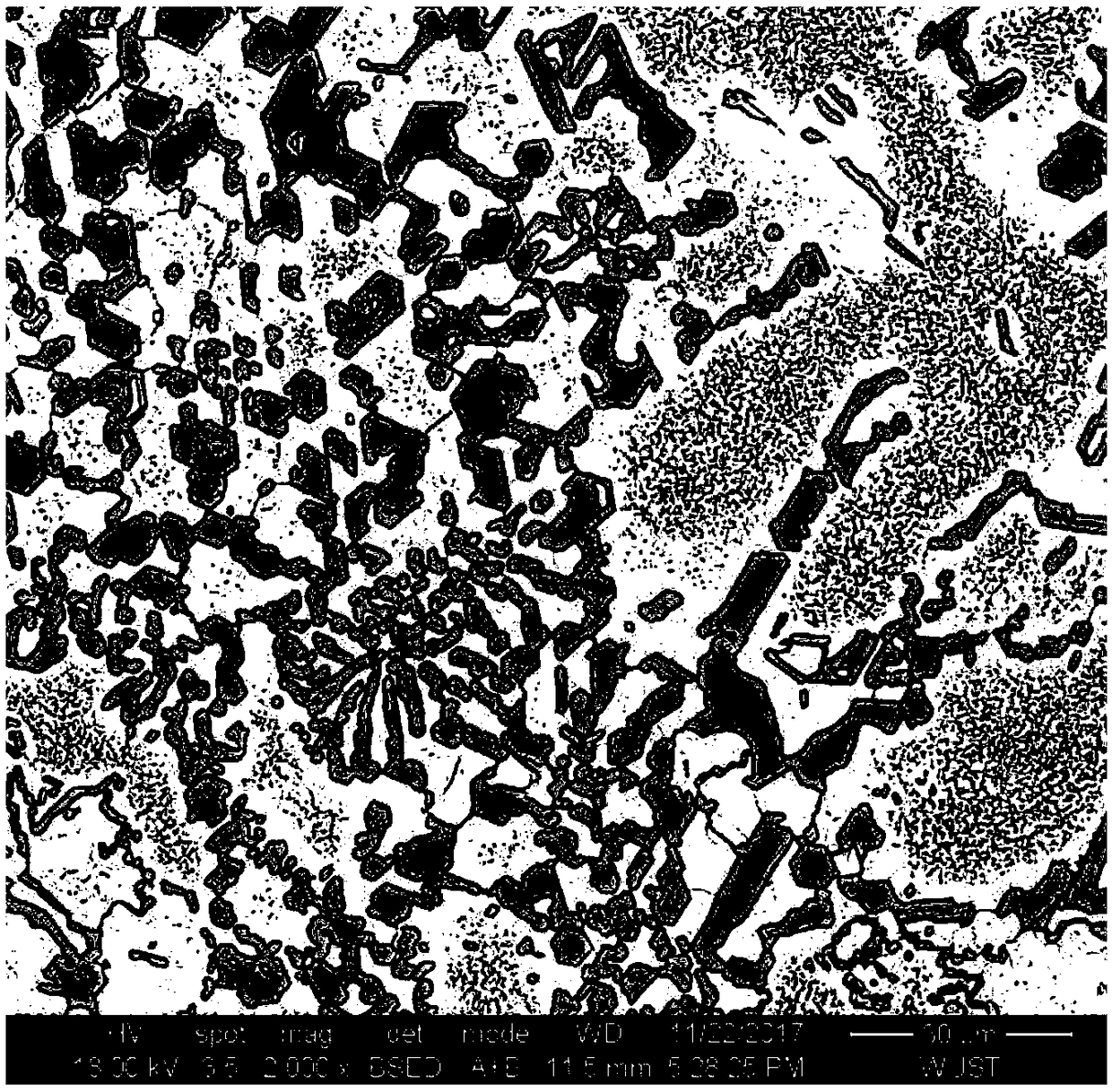

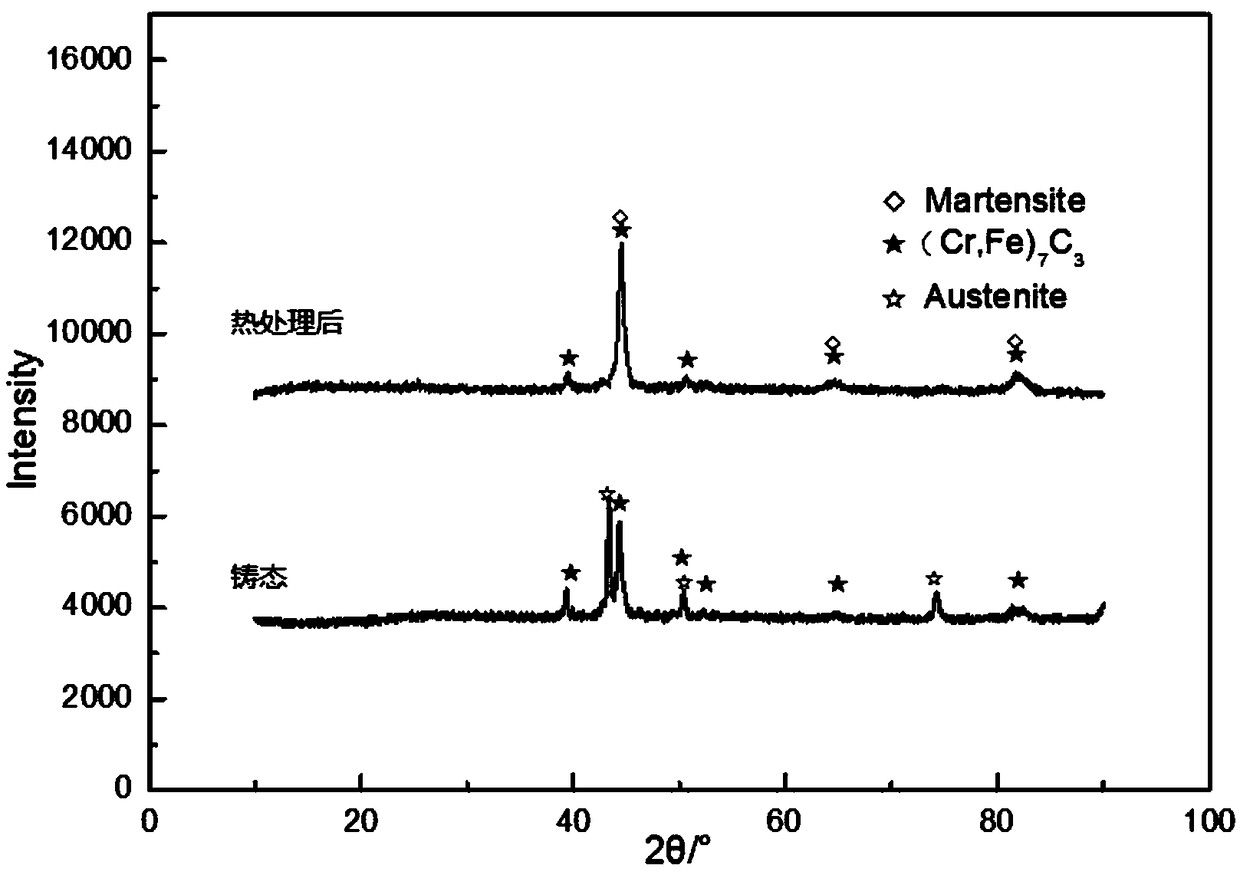

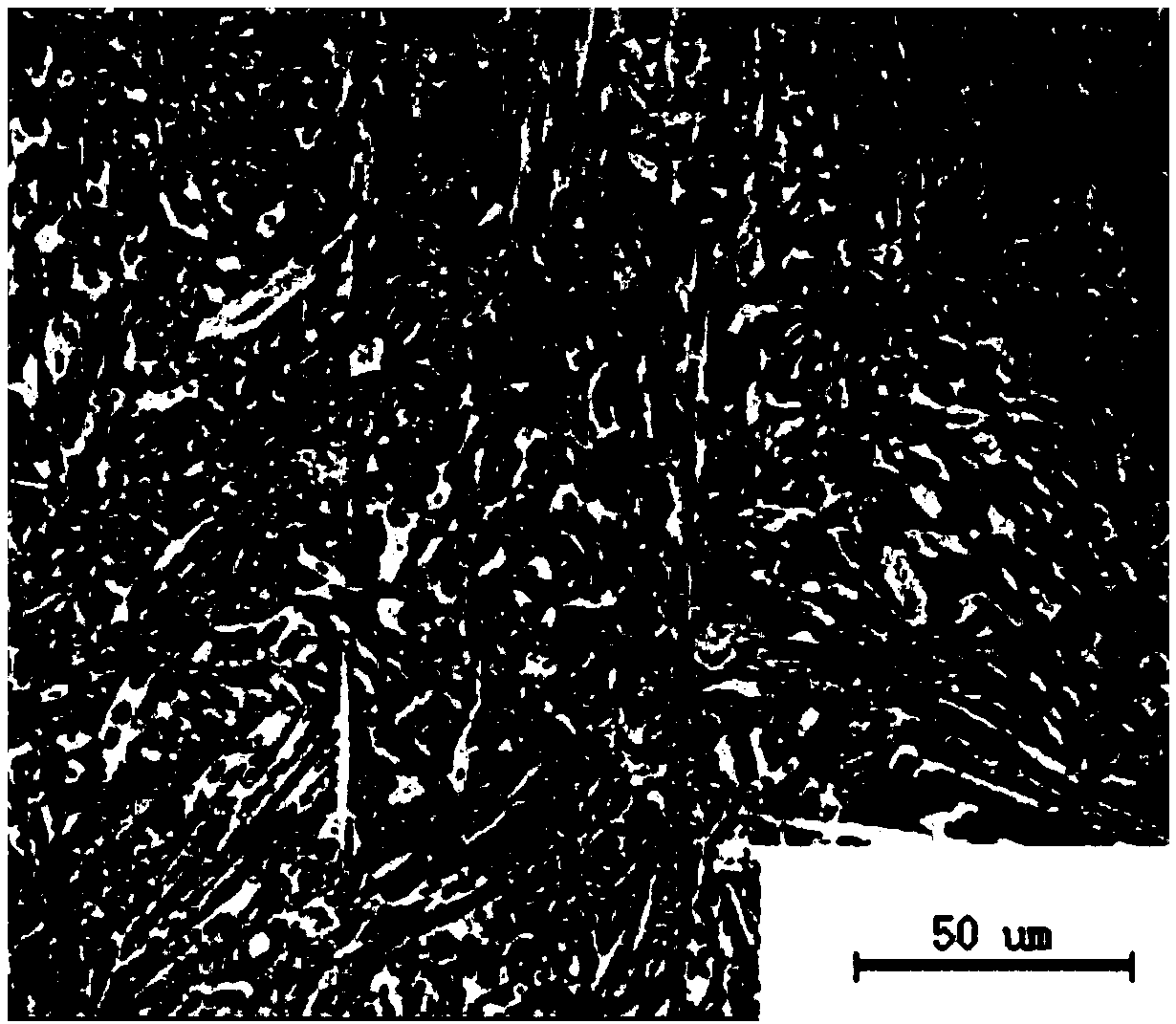

Austenite heat-resistance stainless steel resisting high temperature oxidation

ActiveCN103741065AImprove high temperature oxidation resistanceReduce C contentChemical compositionHeat resistance

The invention discloses an austenite heat-resistance stainless steel resisting high temperature oxidation. The austenite heat-resistance stainless steel comprises the chemical components in percentage by weight: below 0.02 percent of C, 2.0-2.5 percent of Si, 1-2 percent of Mn, 20-22 percent of Cr, 12-14 percent of Ni, 0.11-0.15 percent of N, less than 0.035 percent of P, less than 0.005 percent of S, 0.06-0.11 percent of Ce+La+Y, 0.05-0.15 percent of V, 0.1-0.3 percent of Nb and the balance of Fe and inevitable impurities, wherein (Cr+1.5Si+0.5Nb) / (Ni+0.5Mn+20N) is not less than 1.4 and not more than 1.6, and (Nb+V) is not less than 1.5(C+N) and is not more than 0.35 percent. The austenite heat-resistance stainless steel disclosed by the invention has good high temperature strength, oxidation resistance and formation property, and meets the requirements of continuous rise of use temperature of an automobile exhaust system and environment protection; the use temperature of the austenite heat-resistance stainless steel can reach 1050 DEG C; the requirements on the continuously raised use temperature of an automobile exhaust air system is continuously raised and environment protection are met.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Chemical high-chromium cast iron roller and preparation method thereof

ActiveCN108723091AReduce C contentGood uniformity of refinementFurnace typesRollsChemical compositionCentrifugation

The invention discloses a chemical high-chromium cast iron roller which comprises a high-chromium cast iron work layer and a nodular cast iron roller core. Chemical components of the high-chromium cast iron work layer comprise, by mass percent, 2.1%-2.9% of C, 0.4%-0.8% of Si, 0.5%-08% of Si, 0.5%-0.8% of Mn, 15%-20% of Cr, 0.5%-2% of Ni, 0.5%-2% of Mo, 0.2%-3.0% of V, 0.1%-0.4% of Ti, 0.2%-0.8% of Cu, 0.01%-0.03% of RE, smaller than 0.15% of P, smaller than 0.15% of S and the balance iron. During preparation, a composite centrifugation method is adopted for casting; during heat treatment, thetemperature of a forming roller is increased to range from 920 DEG C to 960 DEG C at the speed ranging from 9 DEG / h to 12 DEG / h, heat preservation is carried out, after quenching, the temperature isincreased to range from 200 DEG C to 250 DEG C for tempering, and heat preservation is carried out for 8 h to 10 h. Laser strengthening treatment is carried out, tempering is carried out at the temperature ranging from 200 DEG C to 250 DEG C, and after heat preservation is carried out for 2 h to 3 h, the chemical high-chromium cast iron roller is obtained. According to the chemical high-chromium cast iron roller, no chip off-falling phenomenon happens in the use process, the roller has good corrosion resistance and high hardness and wear resistance, and the service life of the roller is prolonged.

Owner:HUBEI GOLD STANDARD GENERAL ROLLER

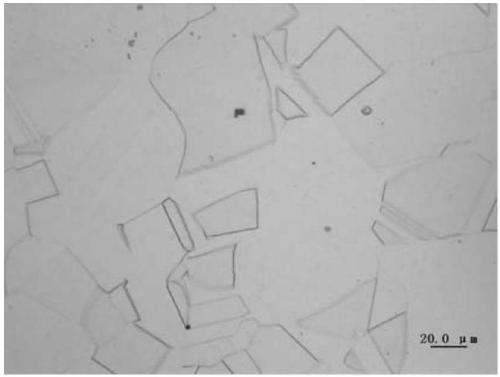

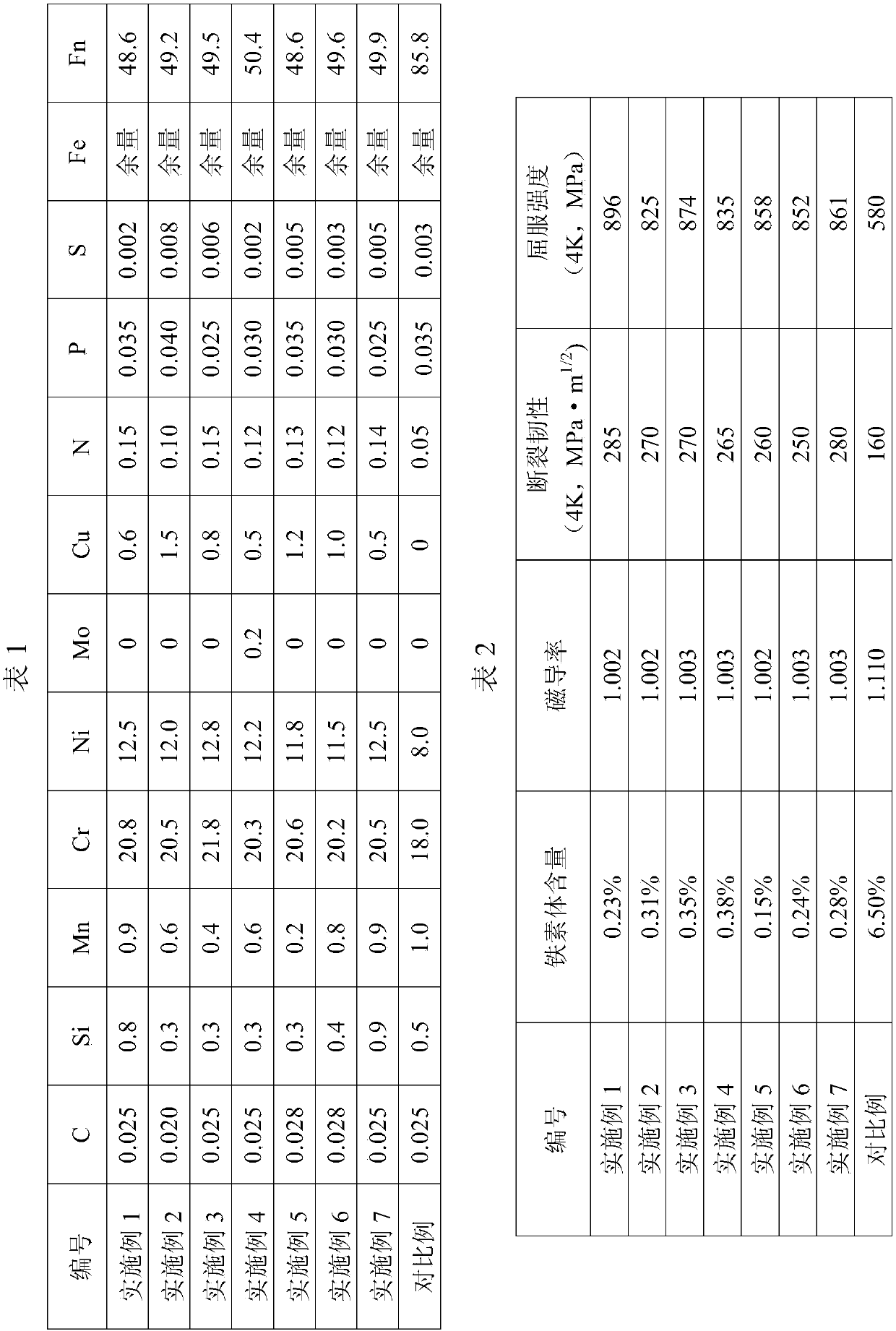

Austenitic stainless steel with excellent ultra-low temperature performance and manufacturing method thereof

ActiveCN109554608AReduced ferrite contentPrevent precipitationChemical compositionUltimate tensile strength

Provided are austenitic stainless steel with excellent ultra-low temperature performance and a manufacturing method thereof. Chemical composition weight percentage of the austenitic stainless steel isC <= 0.03%, Si 0.2 to 1.0%, and Mn 0.2 to 1. 0%, Cr 20.0 to 21.8%, Ni 11.5 to 12.8%, N 0.10 to 0.15%, Cu 0.5 to 1.5%, Mo <= 0.3%, P <= 0.04%, S <= 0.02%, the rest are Fe and inevitable impurities, Fn<51, and Fn=10Cr%+14Si+12Mo%-10Ni%-200N%-250C%-8Cu%-5Mn%. The ferrite content in the structure is < 0.5%. magnetic permeability of the austenitic stainless steel is < 1.01, fracture toughness propertyof 7K is > 200MPa.m1 / 2, and 7K yield strength is > 750MPa. The austenitic stainless steel can be used for nuclear power and superconducting and other industries which have special requirements on ultra-low temperature toughness and ultra-low temperature strength.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Cold roller for rolling stainless steel plates, and preparation method of cold roller

InactiveCN105063500AImprove matrix strengthReduce C contentIncreasing energy efficiencyFurnace typesSteel platesCryogenic treatment

The invention discloses a cold roller for rolling stainless steel plates, and a preparation method of the cold roller. The cold roller is prepared from the following components in percentage by weight: 0.50-0.90% of C, 0.20-0.80% of Si, 0.40-1.0% of Mn, 2.8-4.0% of Cr, 0.20-0.60% of Ni, 0.20-0.60% of Mo, S which is smaller than or equal to 0.015%, P which is smaller than or equal to 0.015%, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: manufacturing roller blank; performing rough processing and quenched-tempered heat treatment on the manufactured roller blank; performing semi fine processing on the heated roller blank; finely grinding a roller body and performing ultrasonic flaw examination; performing high-temperature induction quenching on the ground roller body under 920-950 DEG C; immediately performing cryogenic treatment on the quenched roller under minus 80-minus 100 DEG C; and performing tempering heat preservation on the cooled roller under 160-180 DEG C. According to the cold roller disclosed by the invention, the surface hardness is 85-90 HSD, and the cold roller has a good crack-expansion resisting performance and high basal-body strength.

Owner:YIXING YONGCHANG ROLL

Treatment process of aluminum ash for producing brown fused alumina

The invention relates to a treatment process of aluminum ash for producing brown fused alumina. The treatment process comprises the following steps of: adding aluminum ash into hot water, and then putting the mixture into a container, which is communicated with the outside, to react for a period of time; discharging the hot water in the plastic container, adding hot water which is equal in weight with the discharged water, and standing for a period of time; separating the aluminum ash out, and rinsing the aluminum ash with water; and filtering by using a vacuum filter, and drying the obtained aluminum ash to finish the treatment of the aluminum ash. After the aluminum ash is treated by using the treatment process, the impurities are removed, the content of aluminum oxide is improved, low-temperature smelting is realized, the content of aluminum oxide in a product is 96.5%, the hardness and abrasion resistance of a product are greatly improved, a carbon source is not introduced, the carbon content in the product is greatly reduced, and the high-temperature resistance of the product is improved.

Owner:洛阳智源再生资源有限公司

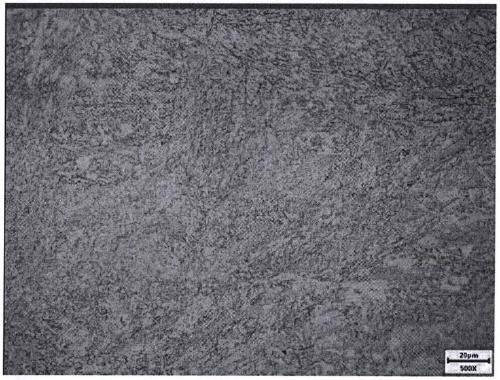

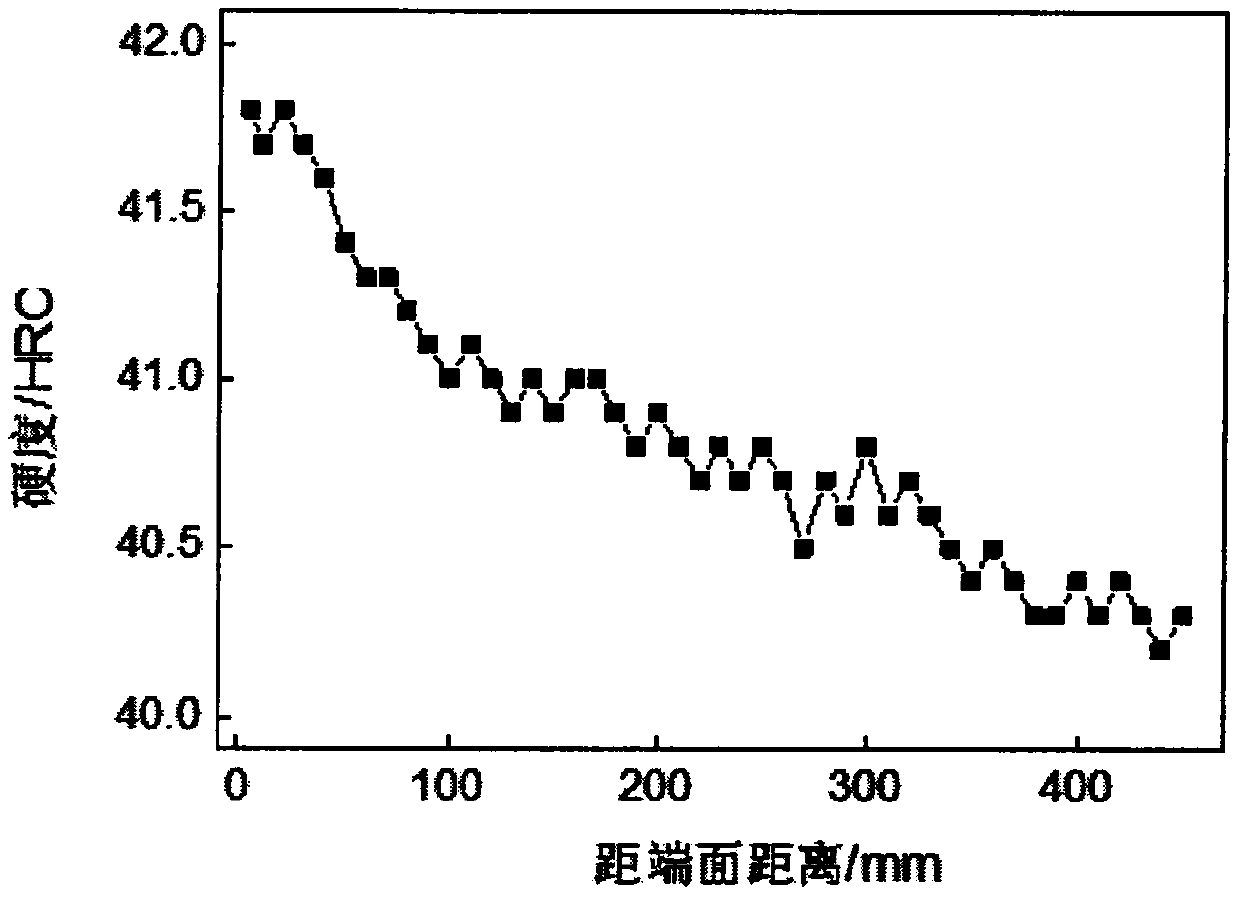

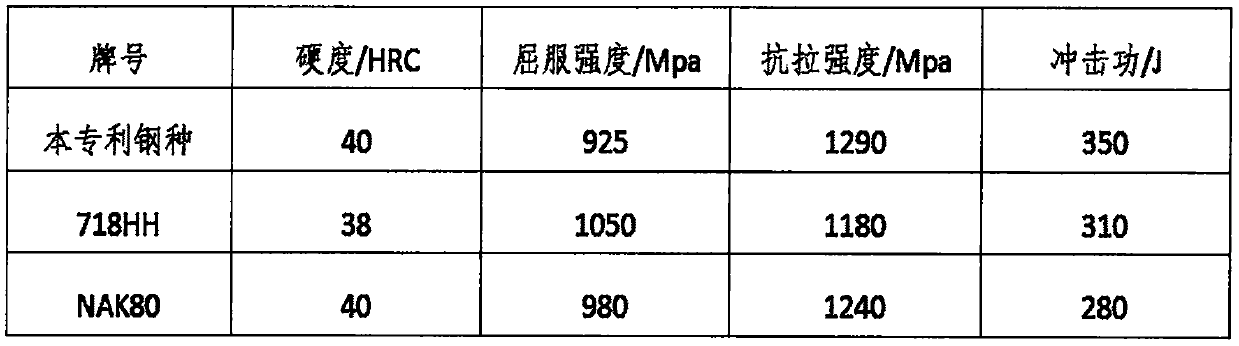

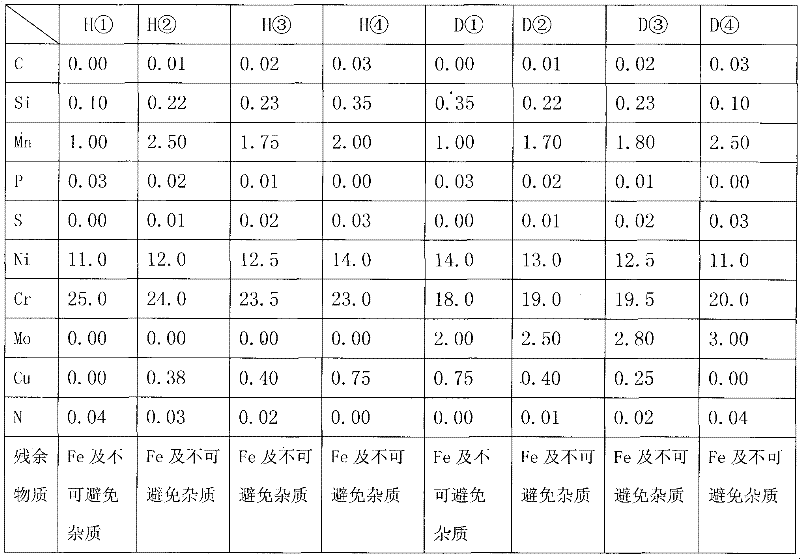

High-toughness high-mirror pre-hardened die steel and manufacturing process thereof

ActiveCN110295332AImprove toughnessImprove hardenabilityIncreasing energy efficiencyAdditive ingredientMartensite

The invention discloses high-toughness high-mirror pre-hardened die steel and a manufacturing process thereof, and relates to the technical field of die steel. The high-toughness high-mirror pre-hardened die steel comprises raw materials including, by weight, 0.08-0.18 part of C, 0.1-0.5 part of Si, 2.2-3.0 parts of Mn, 2.5-3.3 parts of Cr, 0.1-0.5 part of Mo, 0.7-1.5 parts of Ni, 0.1-0.25 part ofV, 0. 01-0.02 parts of P, 0.0005-0.002 part of S and the balance Fe. Preparation processes of the mold steel comprise ingredient smelting, ladle refining, vacuum degassing, pouring, electroslag remelting, forging, annealing and finally quenching and tempering heat treatment; and the tempered structure is mainly tempered martensite and retained austenite. By means of the high-toughness high-mirrorpre-hardened die steel and the manufacturing process of the high-toughness high-mirror pre-hardened die steel, the hardenability of the die steel is fully improved by using Mn-Cr-Ni-Mo composite alloying, the hardness and uniformity of the die steel are ensured, the ductility, toughness and strength of the die steel are improved, the pre-hardened die steel is uniform in hardness, the hardness is38-43HRC, the polishing performance is high, the impact toughness is excellent, the hardenability is excellent, and meanwhile, good weldability and corrosion resistance are achieved.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

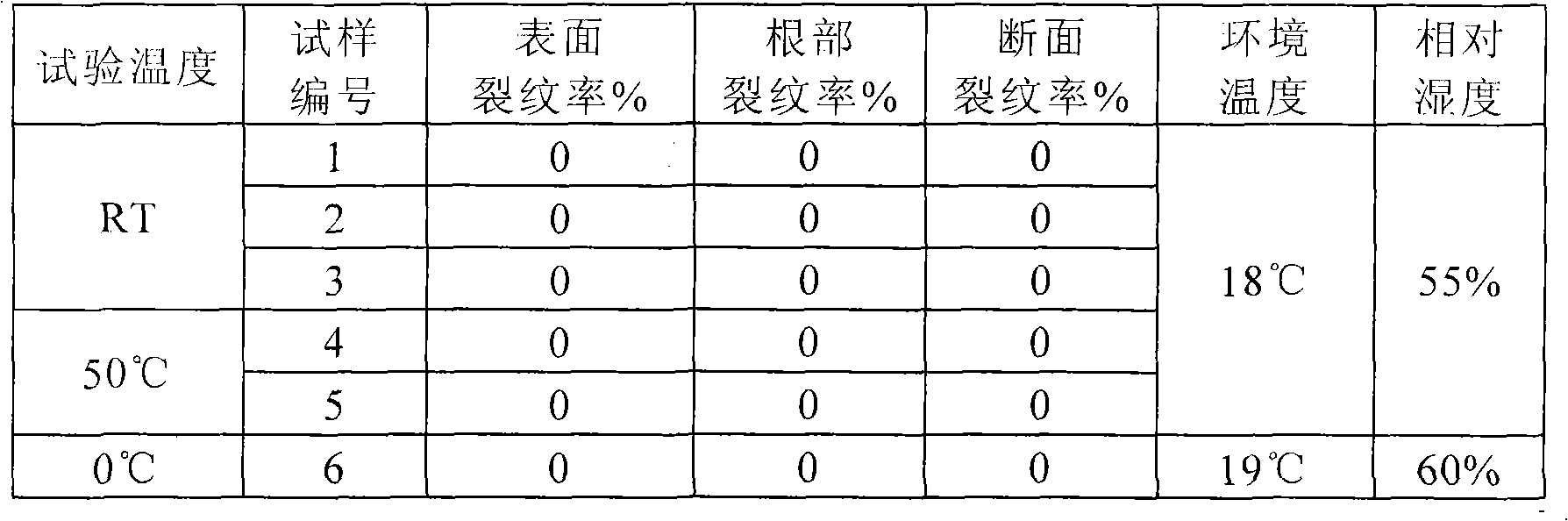

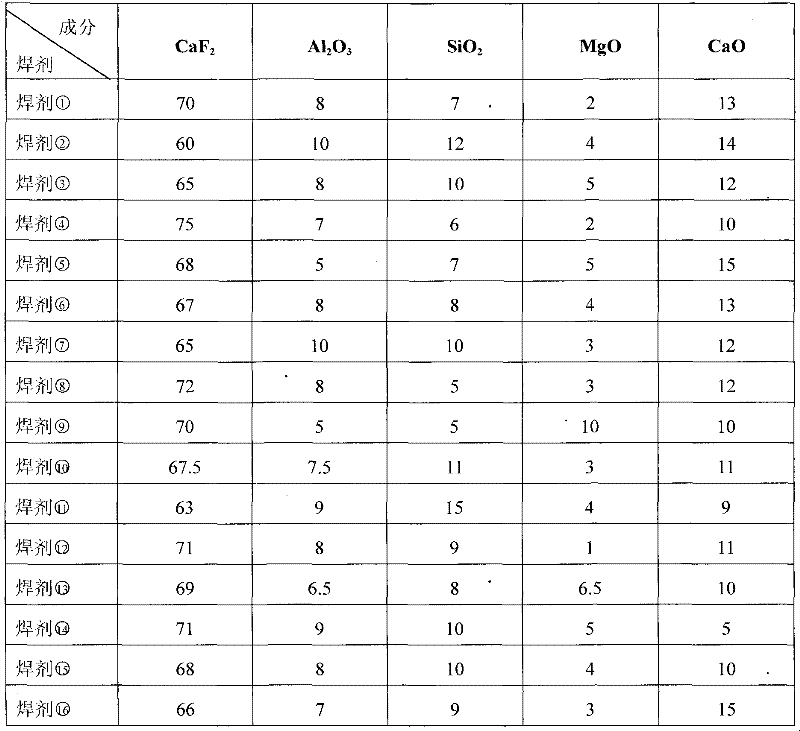

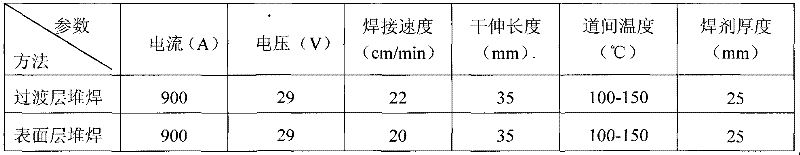

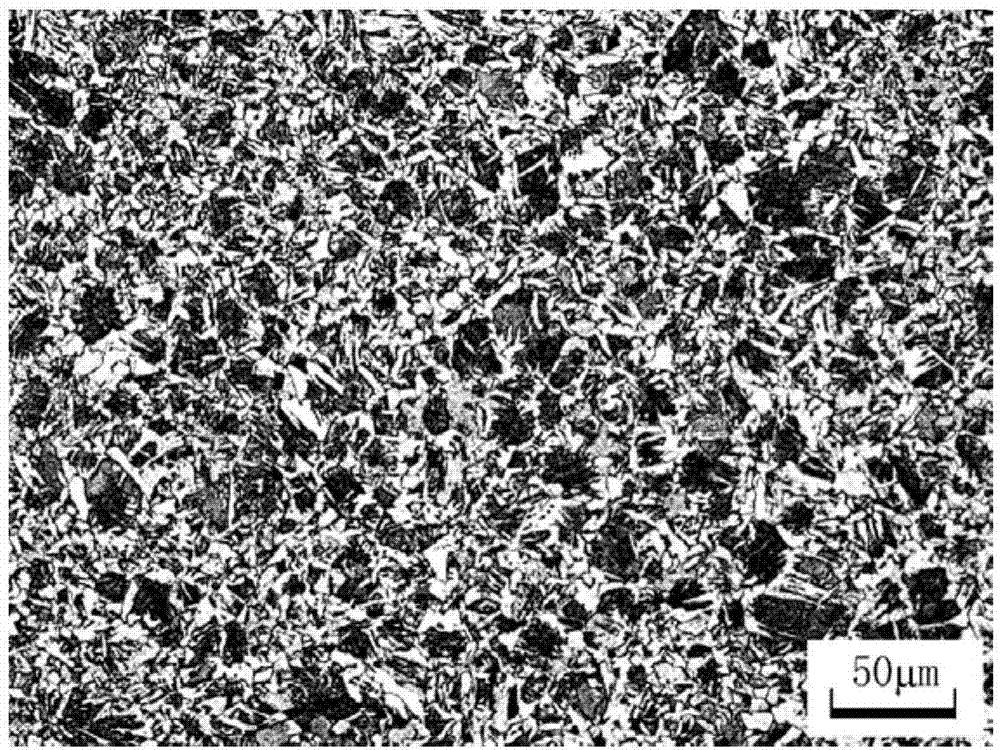

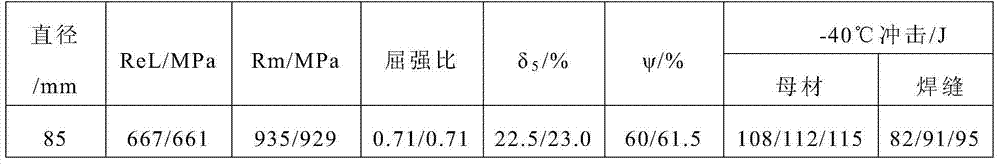

Stainless steel band electrode electroslag surfacing welding strip and welding flux

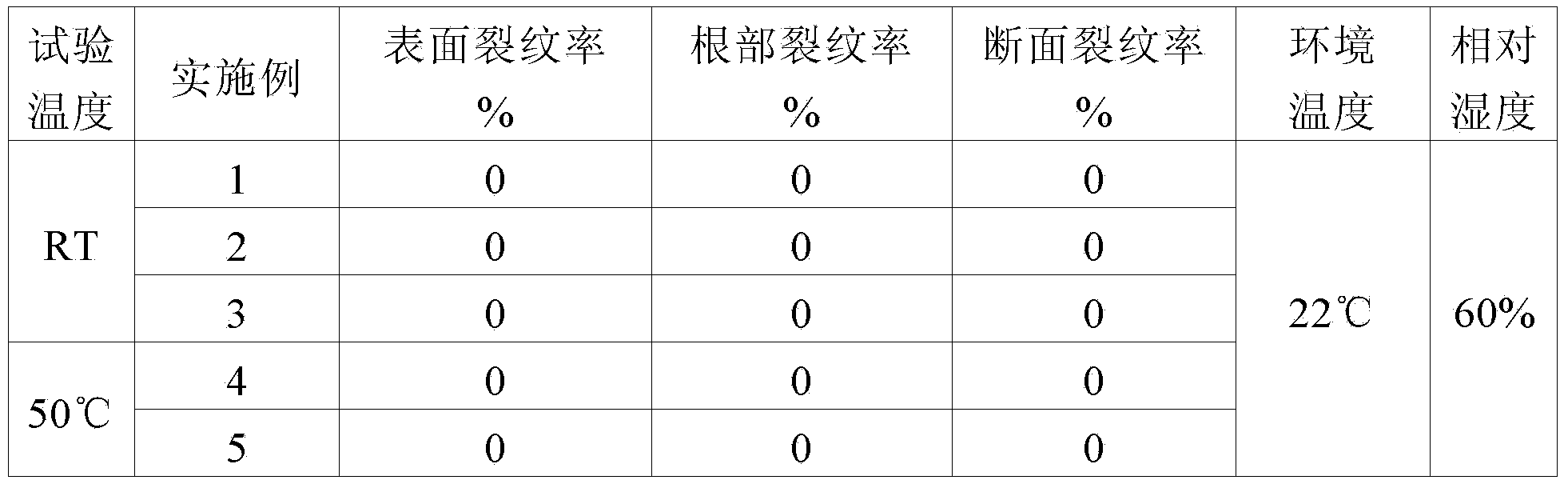

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

Steel for R4-grade mooring cables and preparation method thereof

InactiveCN103882346AReduce C contentAvoid organizational transformationTemperature control deviceChemical compositionHigh intensity

The invention discloses a steel for R4-grade mooring cables and a preparation method thereof. The steel comprises the following components in percentage by weight: 0.15-0.24% of C, 0.15-0.30% of Si, 1.2-1.60% of Mn, at most 0.025% of P, at most 0.025% of S, at most 0.02% of Cu, 0.8-1.3% of Cr, 0.70-1.30% of Ni, 0.2-0.50% of Mo, 0.02-0.05% of Al, at most 0.0050% of As, at most 0.0050% of Sb, at most 0.0050% of Sn, at most 0.0050% of N, at most 0.0020% of O, at most 0.0020% of H, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, LF (ladle furnace) refining, RH vacuum treatment, continuous casting, square billet heating, rolling, air cooling and nondestructive flaw detection. The steel for R4-grade mooring cables has the advantages of high strength, high toughness, low cost and corrosion resistance.

Owner:武汉钢铁有限公司

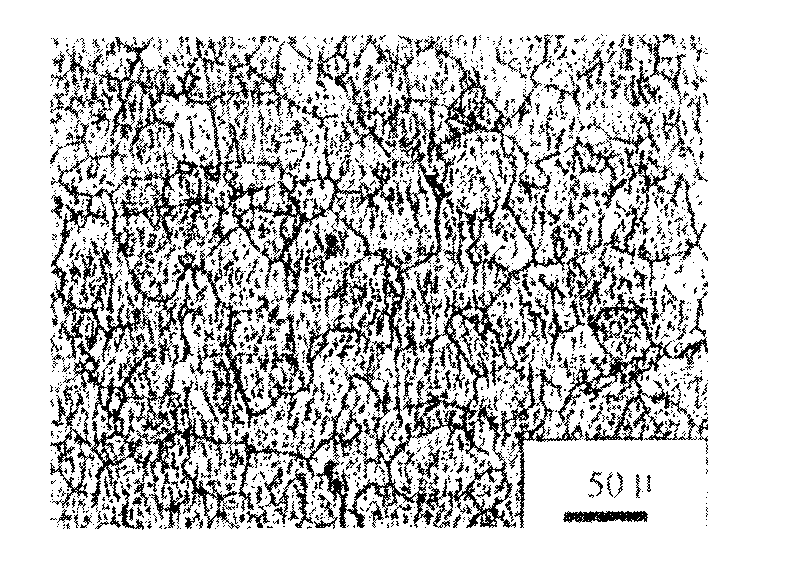

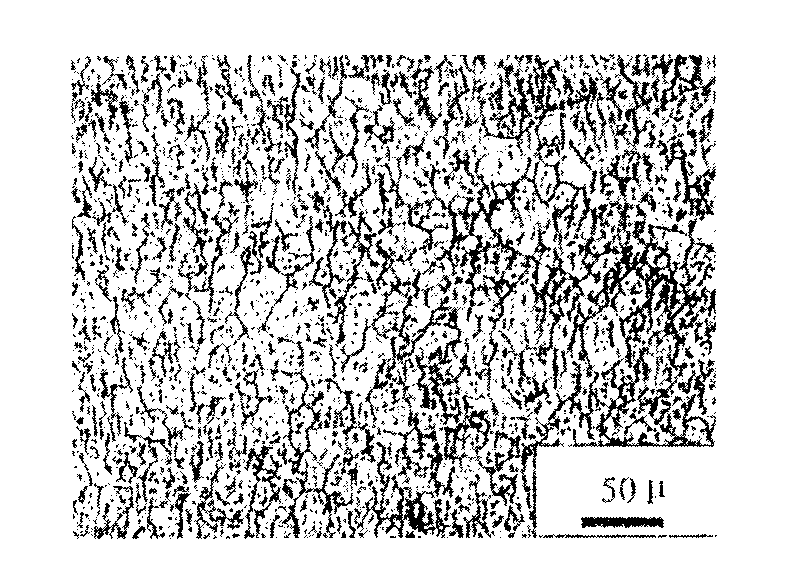

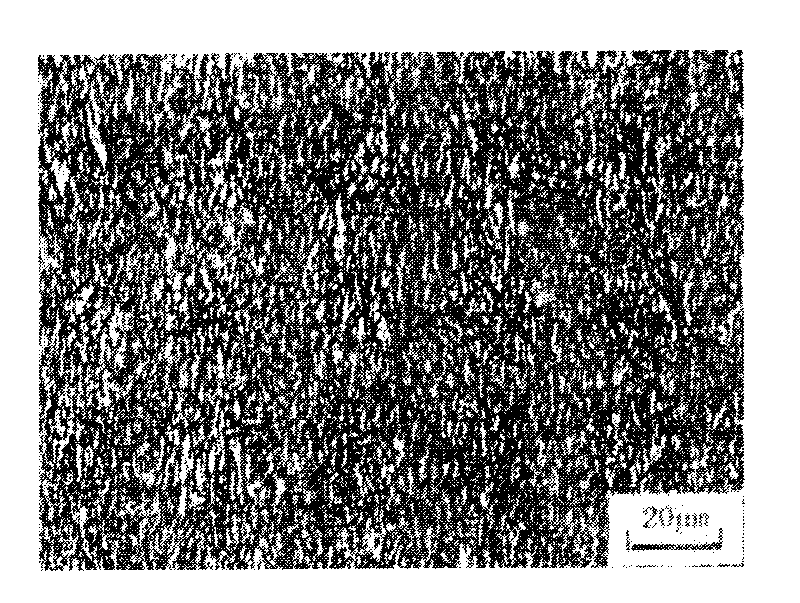

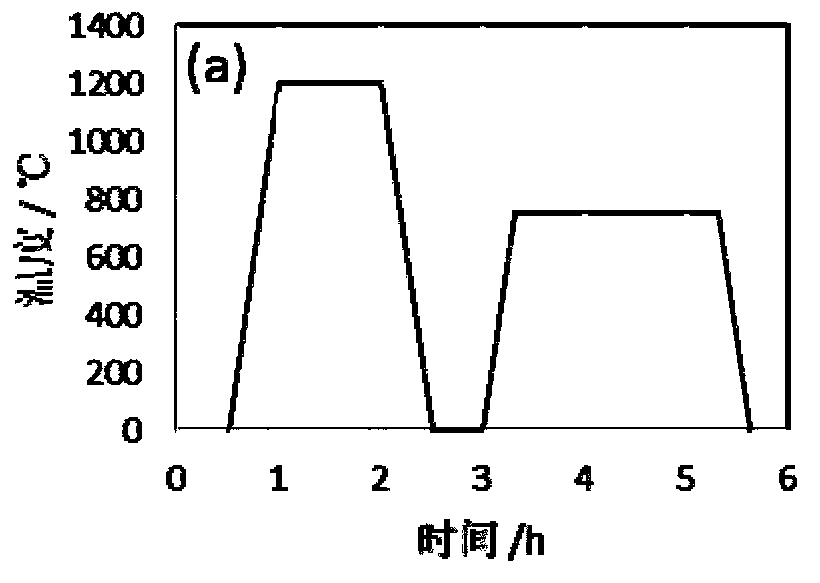

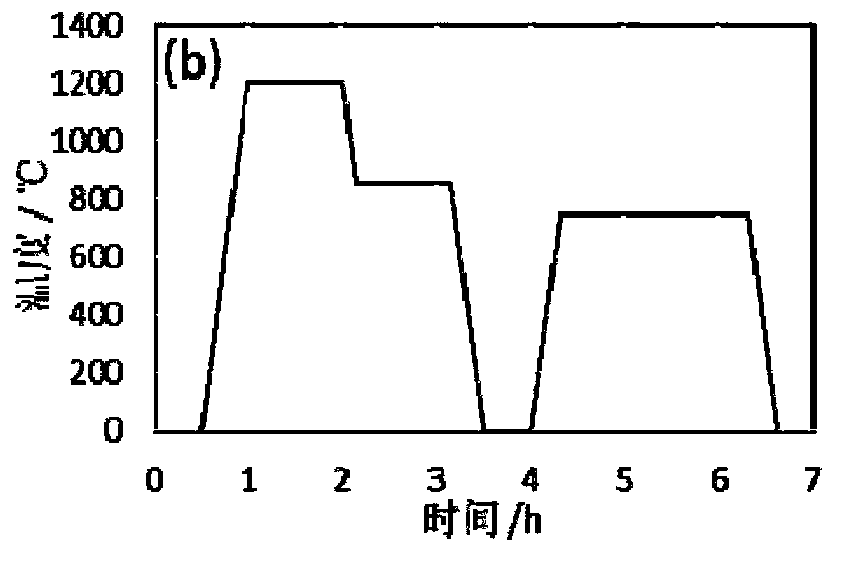

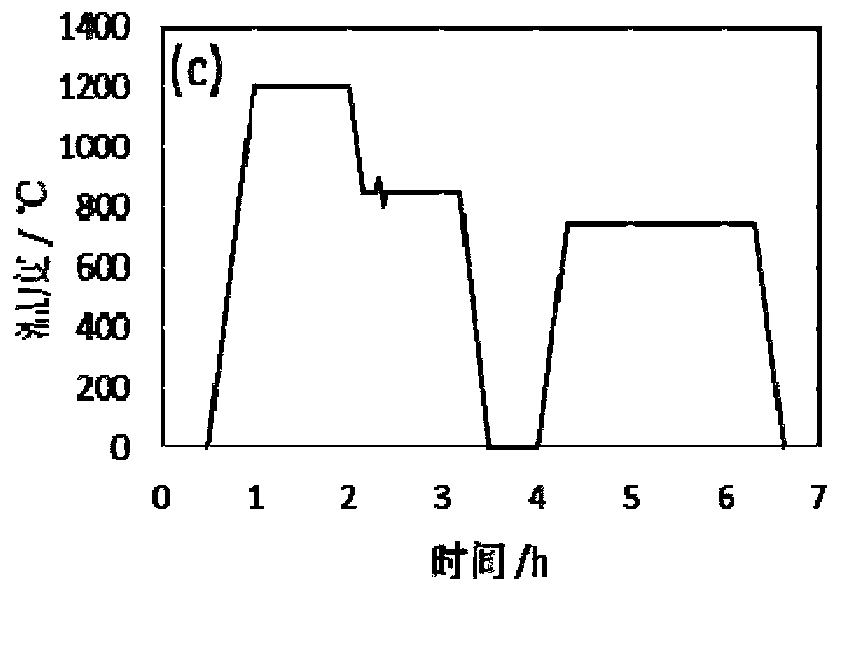

Thermal processing method of chromium-containing ferrite refractory steel

InactiveCN103290184AImprove performanceThe process steps are simpleMetallic materialsRoom temperature

The invention relates to a thermal processing method of chromium-containing ferrite refractory steel, belonging to the technical field of thermal processing of metal materials. The thermal processing method comprises the following steps of: heating a ferrite refractory steel component to 1050-1250 DEG C, and keeping the temperature for 1h-2h; cooling down to 800-900 DEG C, keeping the temperature for 1h-2h, water quenching to room temperature, or cooling down to 800-900 DEG C, carrying out deformation treatment on the ferrite refractory steel component so as to reduce the thickness of the ferrite refractory steel component by 20%-70%, keeping the temperature for 1h-2h, and water quenching to room temperature; finally, heating to 700-800 DEG C, keeping the temperature for 1h-5h, and air cooling to room temperature. By adopting the thermal processing method, MX phase precipitation is controlled through moderate-temperature heat treatment, and M23C6 phase precipitation is controlled by tempering, thus achieving the effect of regulating an MX phase and an M23C6 phase respectively. The method of the invention has the characteristics of simple process steps, easy operation and the like, and is an effective means for performance optimization of ferrite refractory steel.

Owner:TSINGHUA UNIV

Low welding crack sensitivity steel plate with yield strength of 690MPa grade and method for producing the same

ActiveCN101418418BReduce C contentLow costTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD

Thick-gauge steel plate with excellent low-temperature aging performance, and manufacturing method thereof

The invention provides a thick-gauge steel plate with excellent low-temperature aging performance, and a manufacturing method thereof. The thick-gauge steel plate with excellent low-temperature aging performance is composed of the chemical components of, by weight: no more than 0.20wt% of C, no more than 0.50wt% of Si, no more than 1.60wt% of Mn, 0.020-0.050wt% of Nb, 0.010-0.050wt% of Ti, 0.015-0.050wt% of Als, no more than 0.015wt% of P, no more than 0.012wt% of S, and balance of Fe and unavoidable impurities. Through low-carbon micro-alloying, and through the controlling over rolling, cooling, and normalizing treatment, the steel plate has good low-temperature aging impact performance. The thick-gauge steel plate provided by the invention satisfies -50 DEG C impact work requirements before and after aging, and has uniform tissue and excellent properties. With the steel plate, an ultrasonic flaw detection requirement is satisfied, and the requirement for a structural steel plate for an offshore oil platform is satisfied.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Strip-casting 700-MPa-level weathering resistant steel and production method thereof

The invention discloses strip-casting 700-MPa-level weathering resistant steel and a production method thereof. The method comprises the steps of 1), smelting: the chemical components of molten steelcomprises C lower than 0.03%, 0.20-0.80% of Si, Mn lower than 1.0%, 0.03-1.50% of P, S lower than or equal to 0.008%, N lower than or equal to 0.008%, 0.40-1.50% of Cu, 0.80-1.50% of Cr, Ni lower than0.10%, 0.05-0.20% of Nb, 0.05-0.20% of V and the balanced Fe and unavoidable impurities; 2), strip casting: continuous casting is conducted on molten steel on which qualified smelting is conducted bya pair of copper casting rolls which are rotated in the same directions to produce a casting strip with the thickness of 1.4-2.5 mm, and the superheating of the molten steel is controlled to be lowerthan 80 DEG C; 3), casting strip online hot rolling: the hot rolling pressing amount is 15-65%, the temperature of pressed strip steel is 950-1050 DEG C; 4), cooling and winding: the temperature of strip steel on which hot rolling is conducted is cooled down to 300-450 DEG C through atomizing cooling to obtain fine and uniform ferrite and less amount of pearlite tissues. The 700-MPa-level weathering resistant steel has the advantages of short production procedure, low production cost, good strip steel shape and easy welding.

Owner:SHAGANG GROUP +2

High-strength bolt steel capable of shortening wire rod procedures and wire rod modifying process thereof

ActiveCN105624563AImprove high temperature tempering strengthReduce C contentProcess efficiency improvementWire rodEconomic benefits

The invention discloses a high-strength bolt steel capable of shortening wire rod procedures and a wire rod modifying process thereof, and belongs to the technical field of high-strength bolt steel. The steel is composed of, by weight, 0.25-0.32% of C, Si smaller than or equal to 0.10%, 0.15-0.30% of Mn, P smaller than or equal to 0.010%, S smaller than or equal to 0.005%, 1.10-1.20% of Cr, 0.15-0.40% of Mo, 0.001-0.003% of B, 0.08-0.14% of Ti, 0.015-0.030% of Al, N smaller than or equal to 0.004% and the balance Fe and inevitable impurities. The wire rod modifying process comprises the steps of acid pickling, rough drawing, spheroidizing annealing, acid pickling, phosphatizing, saponifying and fine drawing. Compared with the prior art, the content of carbon of steel with the same strength grade is greatly lowered, the grain structure is refined, the carbon diffusion distance is shortened, single-time large-deformation drawing and single-time spheroidizing annealing can be realized, the wire modifying procedure of the high-strength bolt steel with the grade higher than 10.9 can be shortened, and the economic benefit is obvious.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com