High-toughness high-mirror pre-hardened die steel and manufacturing process thereof

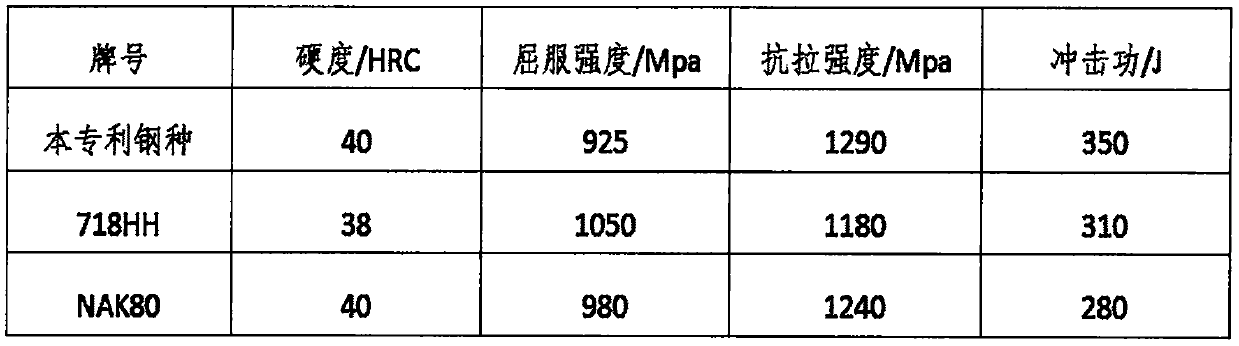

A manufacturing process and high-mirror technology, applied in the field of die steel, can solve the problems such as the inability to effectively guarantee the hardness uniformity and hardenability of large die, the influence of die production cycle and production cost, poor die polishability and welding performance, etc. Achieve superior polishing performance, improve mold manufacturing level and market competitiveness, and ensure the effect of hardness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw materials of high toughness and high mirror surface pre-hardened die steel include the following components: 0.12 parts of C, 0.25 parts of Si, 2.5 parts of Mn, 3.1 parts of Cr, 0.4 parts of Mo, 0.9 parts of Ni, 0.1 parts of V, 0.015 parts of P, and 0.001 parts of S and Fe balance.

[0031] S1. Batching smelting: Melt scrap steel and ferroalloy raw materials in a converter, electric furnace or induction furnace. After smelting, use slag blocking and add a corresponding weight ratio of deoxidizer to tap;

[0032] S2. Ladle refining: adjust the alloy composition through LF refining, and add deoxidizer and refining slag in corresponding weight proportions for deoxidation and desulfurization, control S to 0.003%, deoxidizer is silicon aluminum barium calcium iron, silicon calcium cored wire, Compositions of aluminum wire, almanganese ferromanganese, steel core aluminum, calcium carbide and silicon carbide;

[0033] S3. Vacuum degassing and pouring: VD vacuum degass...

Embodiment 2

[0039] The raw materials of high toughness and high mirror surface pre-hardened die steel include the following components: 0.14 parts of C, 0.28 parts of Si, 2.6 parts of Mn, 2.9 parts of Cr, 0.3 parts of Mo, 1.0 parts of Ni, 0.1 parts of V, 0.016 parts of P, and 0.0005% of S parts and Fe balance.

[0040] S1. Batching smelting: Melt scrap steel and ferroalloy raw materials in a converter, electric furnace or induction furnace. After smelting, use slag blocking and add a corresponding weight ratio of deoxidizer to tap;

[0041] S2. Ladle refining: adjust the alloy composition through LF refining, and add deoxidizer and refining slag in corresponding weight proportions for deoxidation and desulfurization, control S to 0.003%, and deoxidizer is a composition of silicon aluminum barium calcium iron and silicon carbide;

[0042] S3. Vacuum degassing and pouring: Use VD vacuum degassing equipment to reduce the content of N, H, and O gas elements in molten steel. The vacuum degree ...

Embodiment 3

[0048] The raw materials of high toughness and high mirror surface pre-hardened die steel include the following components: 0.15 parts of C, 0.3 parts of Si, 2.4 parts of Mn, 2.8 parts of Cr, 0.3 parts of Mo, 0.9 parts of Ni, 0.1 parts of V, 0.014 parts of P, and 0.0005 parts of S and Fe balance.

[0049] S1. Batching smelting: Melt scrap steel and ferroalloy raw materials in a converter, electric furnace or induction furnace. After smelting, use slag blocking and add a corresponding weight ratio of deoxidizer to tap;

[0050] S2. Ladle refining: adjust the alloy composition through LF refining, and add deoxidizer and refining slag in corresponding weight proportions for deoxidation and desulfurization, control S to 0.002%, and deoxidizer is silicon aluminum barium calcium iron;

[0051] S3. Vacuum degassing and pouring: Use VD vacuum degassing equipment to reduce the content of N, H, and O gas elements in molten steel. The vacuum degree is 67Pa, and the degassing time is 30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com