High-strength steel plate with yield strength at 690MPa level and manufacture method thereof

A yield strength, 690mpa technology, applied in the field of high-strength steel plate and its manufacturing, can solve the problems of increasing the difficulty of smelting and continuous casting, deteriorating welding performance, increasing carbon content, etc., to reduce C content, reduce alloy costs, and reduce process costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

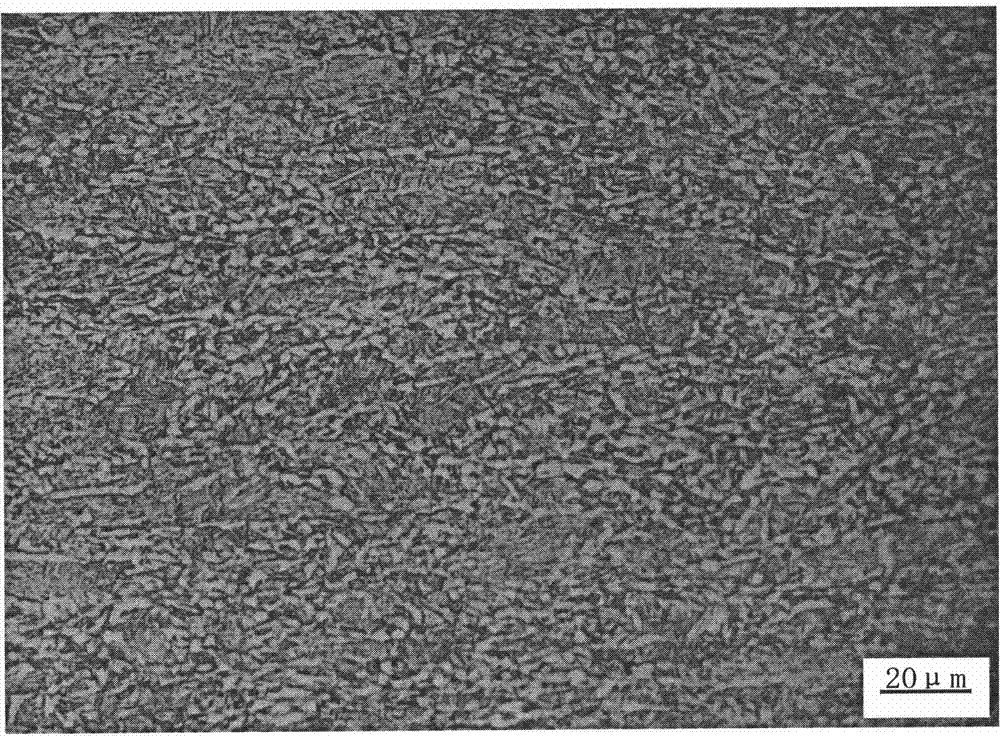

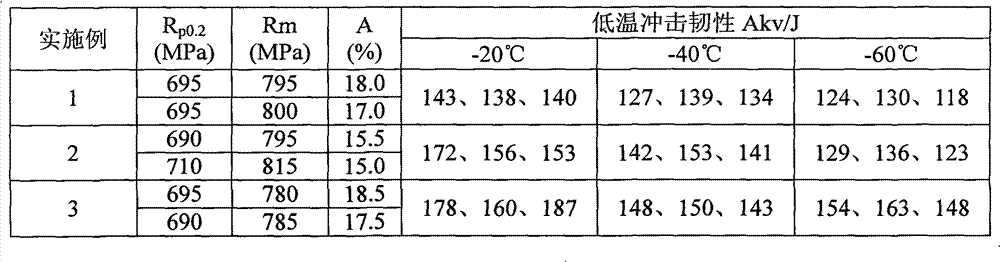

[0032] Smelted according to the chemical composition shown in Table 1, and cast into steel ingots, the steel ingots were heated to 1220 ° C, kept for 150 minutes, and the first stage of rolling was carried out on the experimental rolling mill, that is, rolling in the austenite recrystallization zone. 1170°C, the first to second pass reduction should be greater than 10%, followed by at least 1 to 2 pass reduction rate controlled at 20 to 40%, when the thickness of the rolled piece is 60mm, wait for the temperature on the roller table to 900 ° C, followed by the second stage of rolling, that is, rolling in the austenite non-recrystallized zone. The final rolling temperature is 840°C, and the thickness of the finished steel plate is 20mm. After rolling, the steel plate enters the accelerated cooling (ACC) device and is cooled to 400°C at a rate of 25°C / s, and the cooling bed is cooled after the water exits. Afterwards, the steel plate is subjected to tempering heat treatment, th...

Embodiment 2

[0034] The embodiment is the same as in Example 1, wherein the heating temperature is 1200° C., and the heat preservation is 150 minutes. The rolling start temperature of the first stage rolling is 1160° C., the thickness of the rolled piece is 54 mm, and the rolling start temperature of the second stage rolling is 910° C. The final rolling temperature is 830°C, the thickness of the finished steel plate is 18mm; the cooling rate of the steel plate is 25°C / s, and the final cooling temperature is 400°C. Afterwards, the steel plate is subjected to tempering heat treatment, the tempering temperature is 480°C, and the holding time is 20min+t×2.5min / mm, where t is the thickness of the steel plate in mm.

Embodiment 3

[0036] The implementation is the same as in Example 1, wherein the heating temperature is 1200° C., and the heat preservation is 150 minutes; the rolling start temperature of the first stage rolling is 1150° C., and the thickness of the rolled piece is 48 mm; the rolling start temperature of the second stage rolling is 910° C., The final rolling temperature is 840°C, the thickness of the finished steel plate is 16mm; the cooling rate of the steel plate is 27°C / s, and the final cooling temperature is 380°C. Afterwards, the steel plate is subjected to tempering heat treatment, the tempering temperature is 480°C, and the holding time is 20min+t×2.5min / mm, where t is the thickness of the steel plate in mm.

[0037] Table 1 Chemical composition (wt %) of embodiment 1~3 of the present invention

[0038] Example

C

Si

mn

P

S

Cr

Mo

B

Nb

V

Ti

1

0.078

0.25

1.70

0.007

0.007

0.38 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com