Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve fermentation titer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

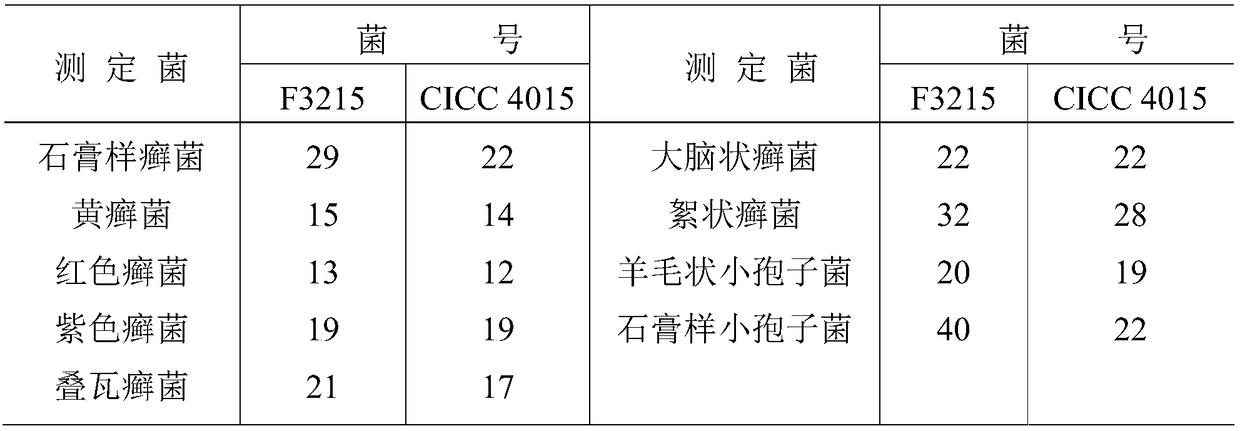

Method for preparing bactericidal agent using antagonizing bacteria M18 strain

InactiveCN1802927AControl sheath blightGood broad spectrumBiocideBacteriaHigh concentrationMetabolite

The invention relates to a method for preparing bactericide by using derivative bacterial of growth promoting antagonist bacterial M18, preparing fermentation liquor with high concentration of under phenazine-1-carboxyl acid and pyoluteorin under optimized culture medium and condition by using derivative bacterial M18G and M18R of growth promoting antagonist bacterial M18, preparing the fermentation liquor M18G and M18R into dry powder, double crossing physically the phenazine-1-carboxyl acid in M18G powder and pyoluteorin in M18R according to the weight ratio of 90%-10% and 10%-90%, and finally getting bactericide of high efficiency for preventing plant disease. Compared with current technology, the bactericide provided in this invention is wet powder taking metabolite of microorgsanism as active element but not live bacterial agent, as a result of which the product is characterized by high stability, not easy to be influenced by environment and better prevention and curing effect for multiple plant disease under low consumption.

Owner:SHANGHAI JIAO TONG UNIV

Biological method for processing spiramycin bacteria residue

InactiveCN101624605ASafe and reliable performanceImprove fermentation titerMicroorganismsAnimal feeding stuffBiotechnologyMicroorganism

The invention provides a biological method for processing spiramycin bacteria residue. Through the use of a composite microbe fermenting agent and a composite enzyme preparation, the spiramycin bacteria residue is used as a main raw material and added with other auxiliary materials together to form a fermenting substrate for solid fermentation; a fermenting product is subjected to high-temperature drying and inactivation to obtain a product; and the obtained product can be used as a microbe culture medium nitrogen source or a feed protein source. The method has the characteristics of simple process, easy operation, short processing time and high processing efficiency; and the processed product has safety, reliability and excellent performance, thereby solving the problem of pollution of the spiramycin bacteria residue and realizing resource reutilization.

Owner:武汉烁森生态科技有限公司

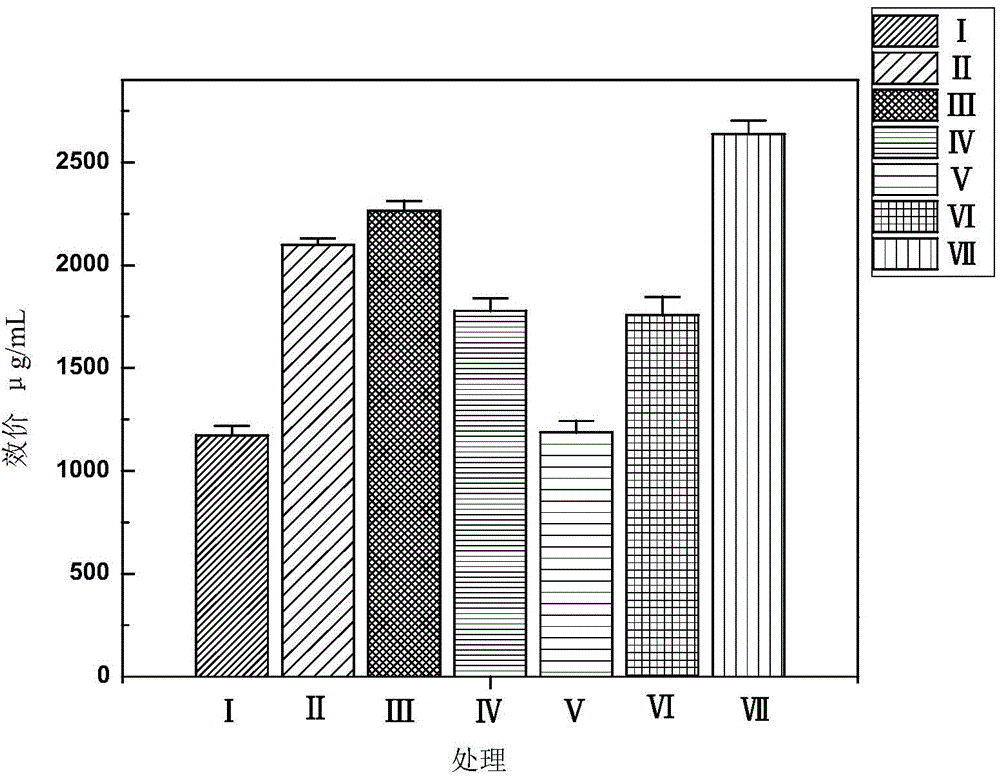

Streptomyces and multi-antibiotics metabolic regulation fermentation process

ActiveCN102643764AImprove fermentation titerGood control effectBacteriaMicroorganism based processesStreptomyces aureochromogenesInorganic salts

The invention discloses a streptomyces and a multi-antibiotics metabolic regulation fermentation process. According to the method, nutrient media components are optimized, inorganic salt is added to disturb a metabolic network of streptomyces aureochromogenes, and a target production way is strengthened, so that the generation of products is promoted. Meanwhile, the multi-antibiotics fermentationprocess is optimized, and a method of flowing-feeding glucose is adopted for a feed supplement batch fermentation method, so that the fermentation unit and the production output are greatly improved,and the production cost is reduced.

Owner:NANJING UNIV OF TECH

A method for fermenting and producing riprestatin and its culture medium components

ActiveCN102268466AImprove stabilityImprove fermentation titerMicroorganism based processesFermentationBiotechnologyStreptomyces toxytricini

The invention provides a method for fermentation production of lipstatin, belonging to the field of fermentation production of microorganisms. The method takes streptomyces toxytricini as an initial bacterium and mainly comprises the steps of preparation of a slope strain, preparation of a seed solution, control of a fermentation process and the like. In the invention, by taking soybean meal, bean oil and glycerol as main nitrogen sources and carbon sources of a fermentation culture medium and regulating and controlling the fermentation process and the components of the culture medium, the production cost of the lipstatin is greatly lowered, and the fermentation titer is increased, thus the defects of high production cost and low fermentation titer in the prior art are overcome.

Owner:鲁南新时代生物技术有限公司

Method for producing erythrocin by virtue of fermentation

ActiveCN104419739ALow costThe fermentation process is simpleBacteriaMicroorganism based processesBiotechnologyCottonseed oil

The invention belongs to the field of biological fermentation and production and provides a method for producing erythrocin by virtue of fermentation. By taking saccharopolyspora erythraea as a starting germ, the method mainly comprises four steps of preparation of slant strains, preparation of shake-flask seed liquid, culture of seed liquid and process control of a fermentation tank. According to the method, soybean oil is replaced by refined cottonseed oil in a seed tank culture medium, a fermentation tank culture medium and the material supplementing process of a fermentation process, so that the fermentation cost is lowered; the fermentation valence and the content of erythrocin A are greatly increased based on an optimized fermentation process. The method is suitable for large-scale industrial production.

Owner:鲁南新时代生物技术有限公司

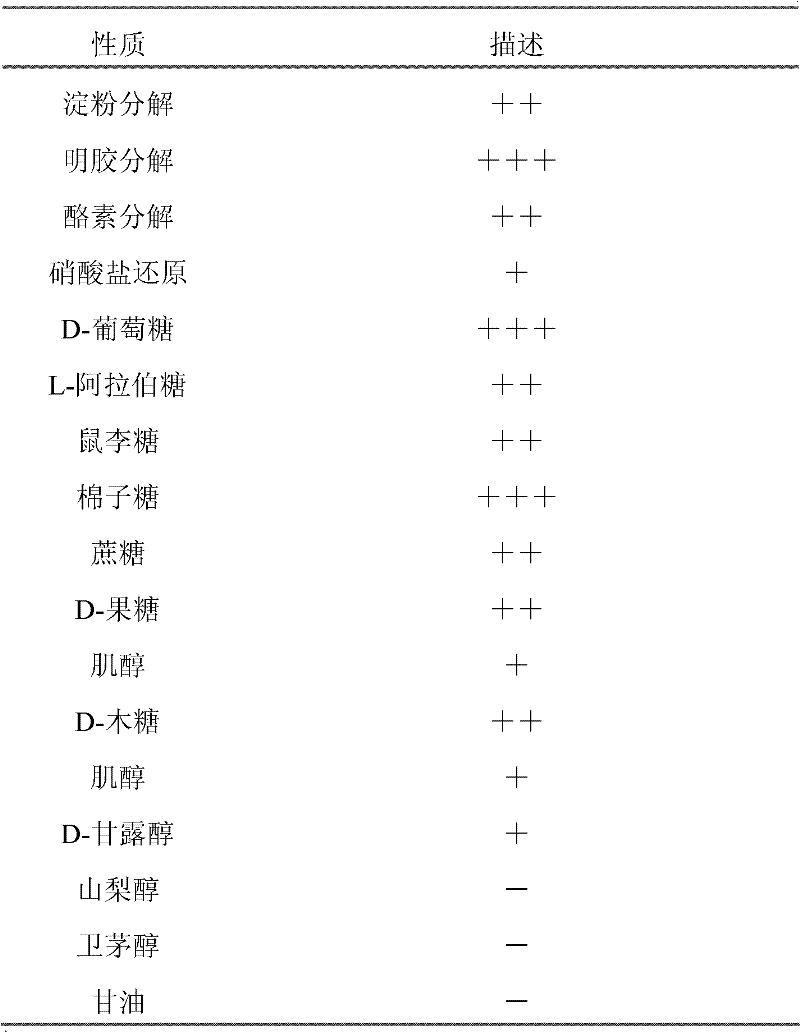

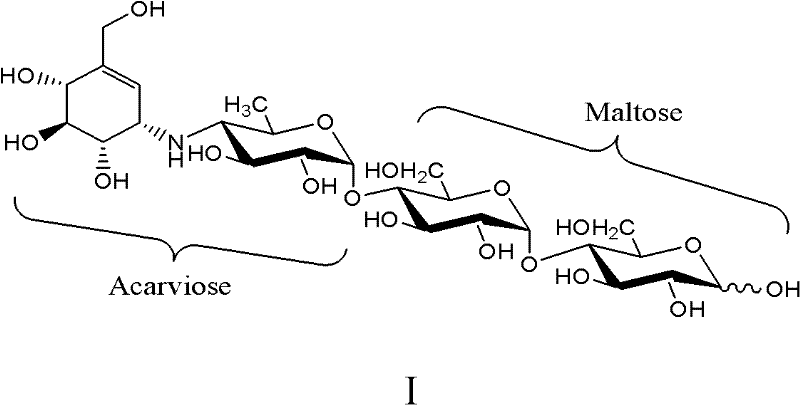

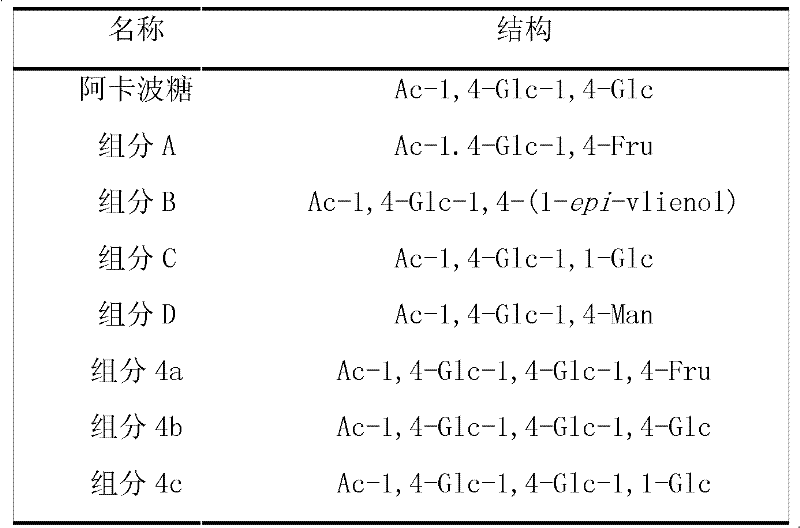

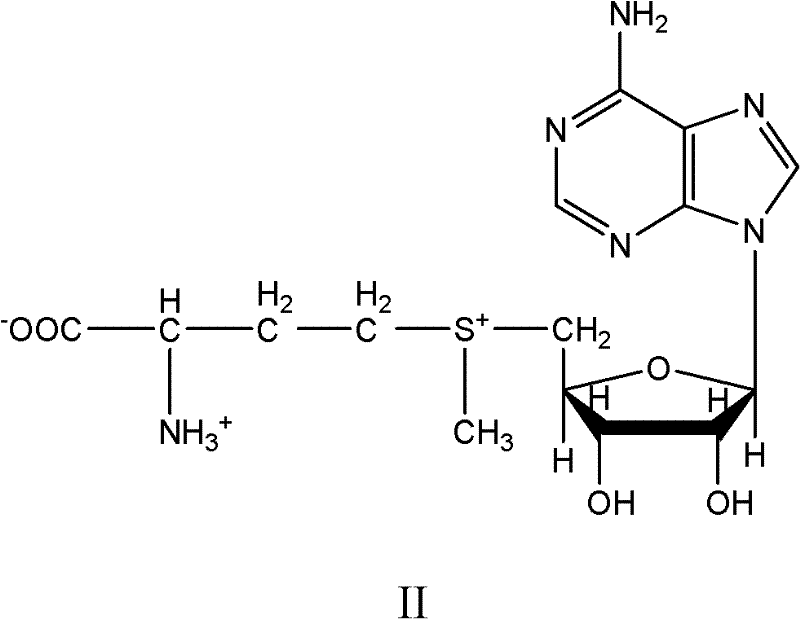

Method for synthesizing acarbose through microbial fermentation

ActiveCN102399837ARaise the level of fermentationImprove fermentation titerMicroorganism based processesFermentationBiotechnologyInorganic salts

The invention discloses a method for synthesizing acarbose through microbial fermentation, which comprises the following steps that acarbose producing strains CCTCC NO: M 209022 are inoculated to a fermentation culture medium containing carbon sources, nitrogen sources and inorganic salt applicable to all strains, the fermentation culture is carried out for 96 to 192hours at 20 to 32 DEG C, afterthe fermentation is completed, the obtained fermentation liquid is extracted and separated, and the acarbose is obtained. The method is characterized in that the fermentation culture is carried out for 0 to 60h, and water solution of ademetionine is added, so the ademetionine concentration in the fermentation culture medium is 1 to 300 mu mol / L. Through the supplementary addition of the ademetionine in the acarbose fermentation process, the fermentation level of the acarbose is improved.

Owner:ZHEJIANG UNIV OF TECH +2

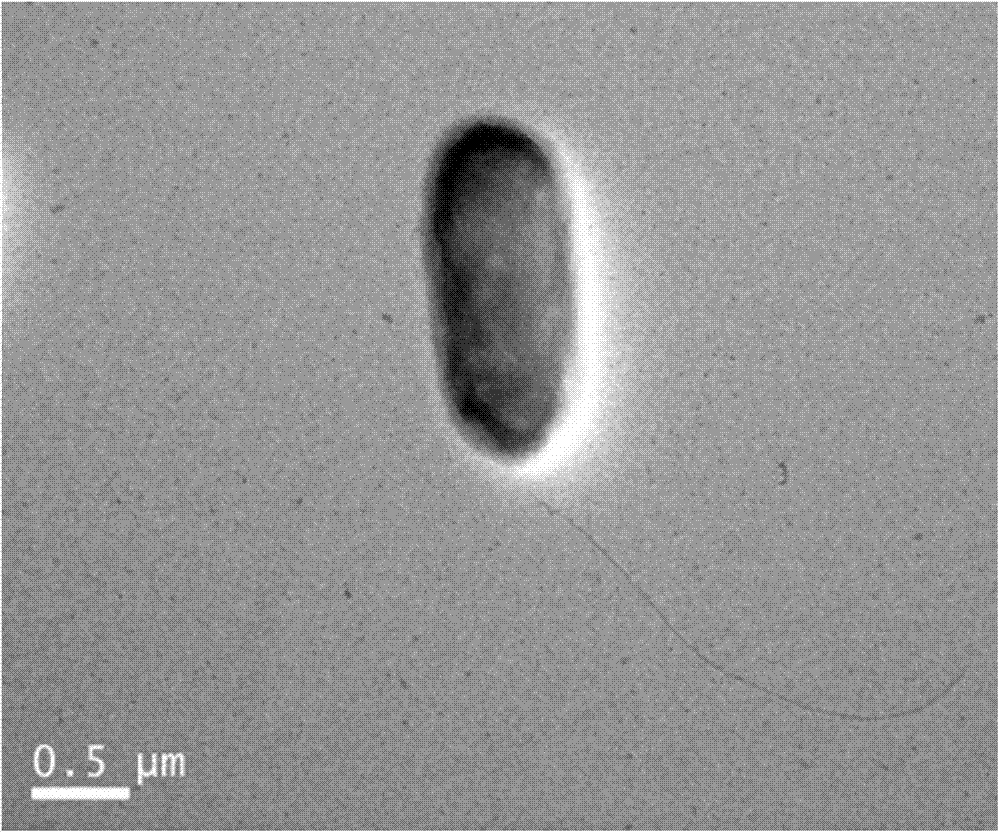

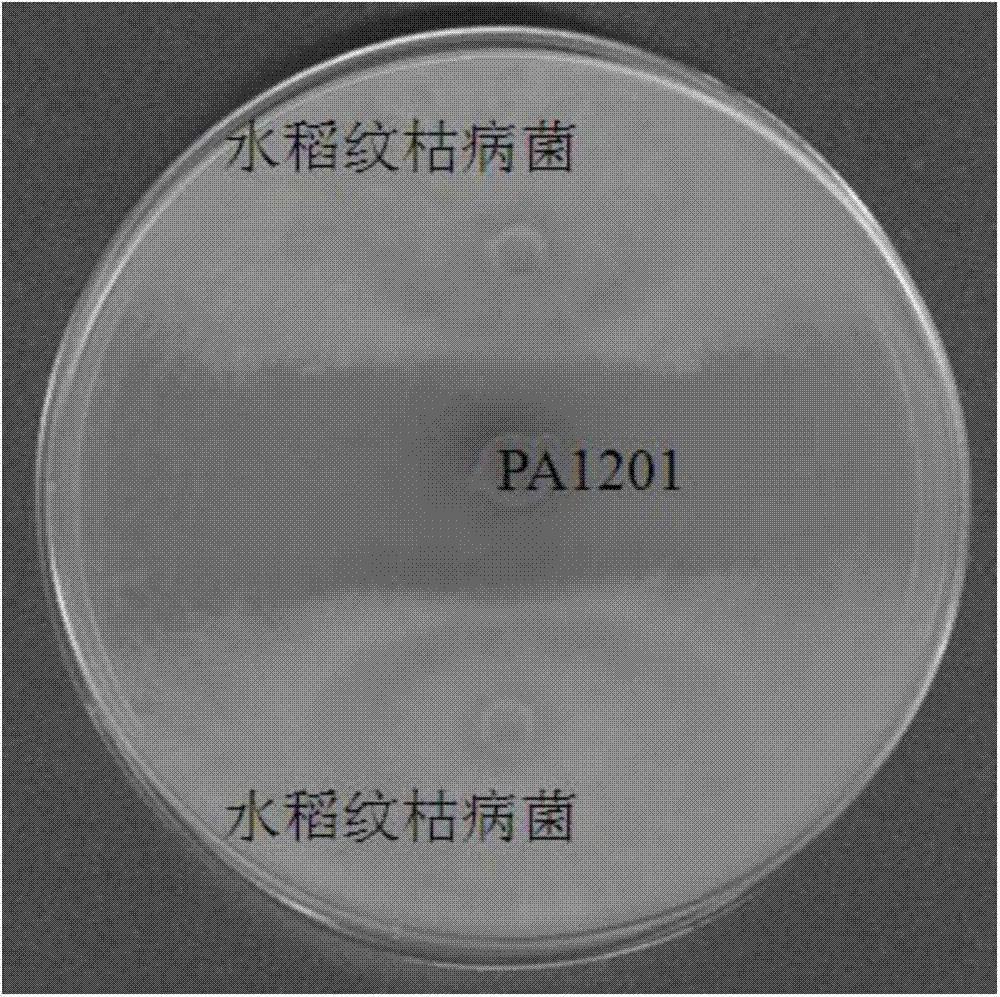

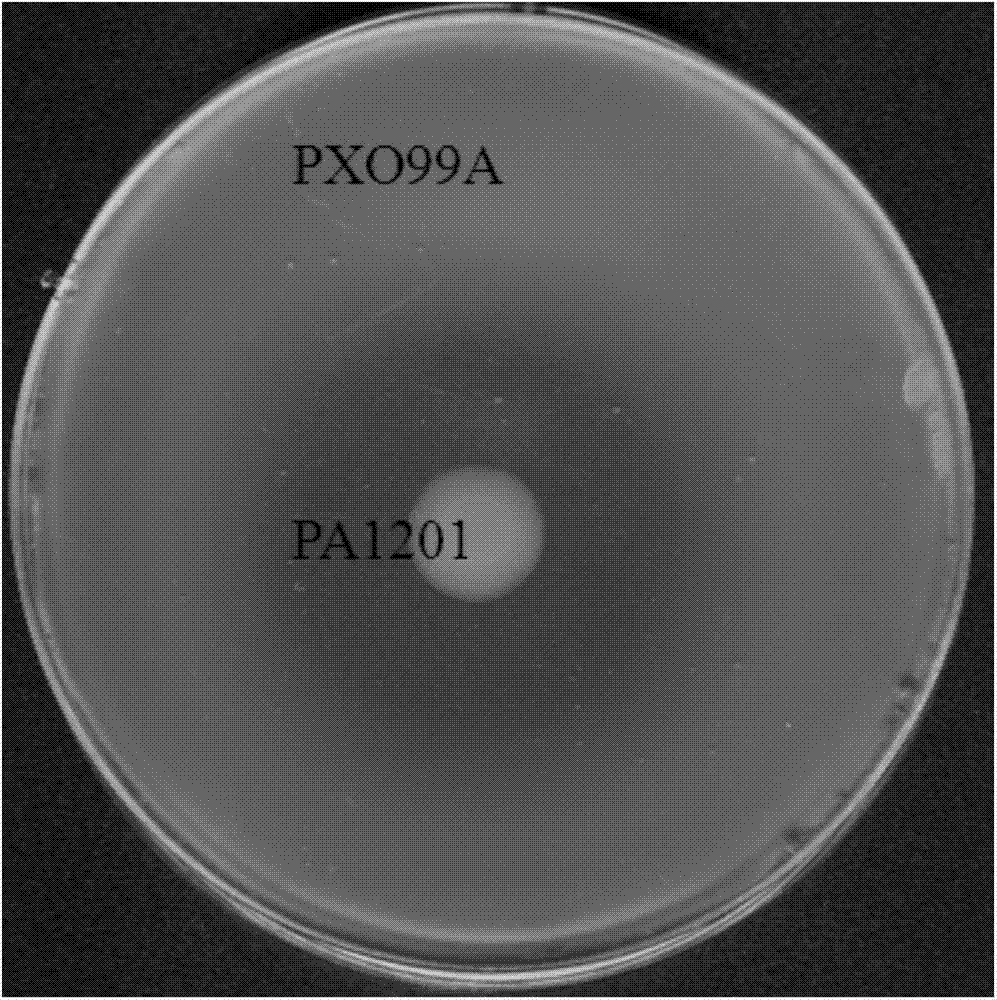

Rhizospheric pseudomonad capable of largely producing phenazine-1-carboxylic acid and phenazine-1-amide

The invention discloses a rhizospheric pseudomonad capable of largely producing phenazine-1-carboxylic acid and phenazine-1-amide. The rhizospheric pseudomonad is Pseudomonas aeruginosa PA1201CCTCC No: M2013441. The strain PA1201 is a wild type environmental microorganism separated and purified when a root system soil sample is collected in a rice field in the suburb of Chongqing. The strain disclosed by the invention can be used for stably and efficiently producing the bactericidal agent phenazine-1-carboxylic acid and the novel bactericidal compound phenazine-1-amide, effectively inhibits the growth of rice diseases: Rhizoctonia solani and Xanthomonasoryzae pv.oryzae and can be used for preparing a microbial source pesticide capable of effectively controlling the fungous diseases and bacterial diseases of plants by utilizing the fermentation secondary metabolite of the strain.

Owner:周莲

Recombinant escherichia coli capable of high-yielding L-methionine and application thereof

ActiveCN109055289AHigh potencyImprove fermentation titerBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention discloses a recombinant escherichia coli capable of high-yielding L-methionine and an application thereof. The recombinant escherichia coli is constructed according to a method as follows: adopting a CRISPR-Cas9 gene editing technology for respectively replacing L-methionine synthase gene promoters with trc promoters in escherichia coli genomes, introducing a host strain genome and screening, thereby acquiring the recombinant escherichia coli capable of high-yielding L-methionine. The host strain is E.coli W3110 Delta metJ Delta metI / pTrc99A / metA* / yjeH which is constructed by knocking out metJ and metI in escherichia coli E.coli W3110 and then introducing a pTrc99A / metA* / yjeH plasmid. The maximal titer of L-methionine can reach up to 2.8g / L and DAP of by-products is obviouslyreduced to above 60% (reduced from 1g / L to below 0.4g / L).

Owner:ZHEJIANG UNIV OF TECH

Modified vegetable fat and its application in erythromycin fermentation process

ActiveCN102732383AImprove utilization speedUse fastFatty acid chemical modificationFermentationBiotechnologyVegetable oil

The invention relates to a modified vegetable fat and its application in an erythromycin fermentation process. The modified vegetable fat is prepared by: mixing vegetable fat with water and lipase, with the water and the lipase respectively accounting for 20-50wt% and 0.1-0.5wt% of the vegetable fat, conducting heat preservation for 4-6 hours at PH of 5.5-8.5 and a temperature of 35-45DEG C, and carrying out standing and layering so as to obtain a fat layer, i.e. the modified vegetable fat, which has an enzymolysis rate of 30-60% and an acid value of 50-100mgKOH / g. In the invention, natural vegetable fat is modified, and lipase is utilized to make the fat in fermentation, the oil system is decomposed into mixed fat composed of free fatty acid, glycerol and monoglyceride or diglyceride andthe like, so that the fat residue in an erythromycin fermentation solution is reduced, the fat utilization speed is enhanced, and the oxygen consumption during fermentation is reduced, thus effectively improving the fermentation titer and reducing the fermentation cost.

Owner:NINGXIA QIYUAN PHARMA

Carbohydrate supplementing method in fermentation process of mycophenolic acid

ActiveCN101671706AImprove utilizationEasy to operateMicroorganism based processesFermentationCulture mediumsBasal medium

The invention belongs to the field of biological fermentation, more particularly relates to a method for realizing the purpose of producing high-density mycophenolic acid through continuously or intermittently supplementing high-density solution of monosaccharide, disaccharide or polysaccharide into a fermentation liquor to culture penicillium brevicompactum. In the method, high-density solution of monosaccharide, disaccharide or polysaccharide is supplemented as a supplementary carbon source during the fermentation process of mycophenolic acid in a basic culture medium which takes glucose asa carbon source. The carbohydrate supplementing method in the fermentation process provided by the invention is easy to be operated and implemented, can improve the fermentation titer by 80-100 percent, and is very applicable to the demands of industrial production.

Owner:SHANDONG NEWTIME PHARMA

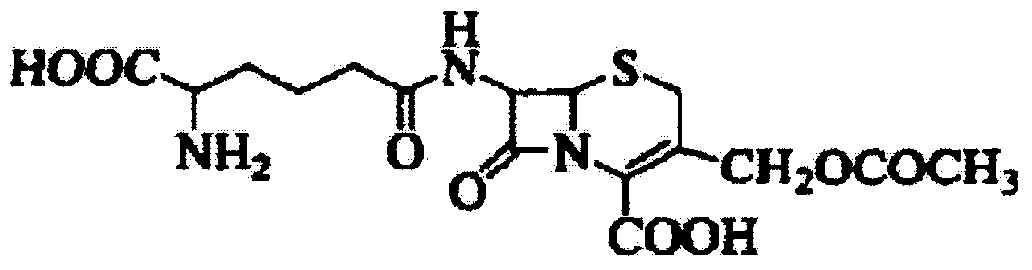

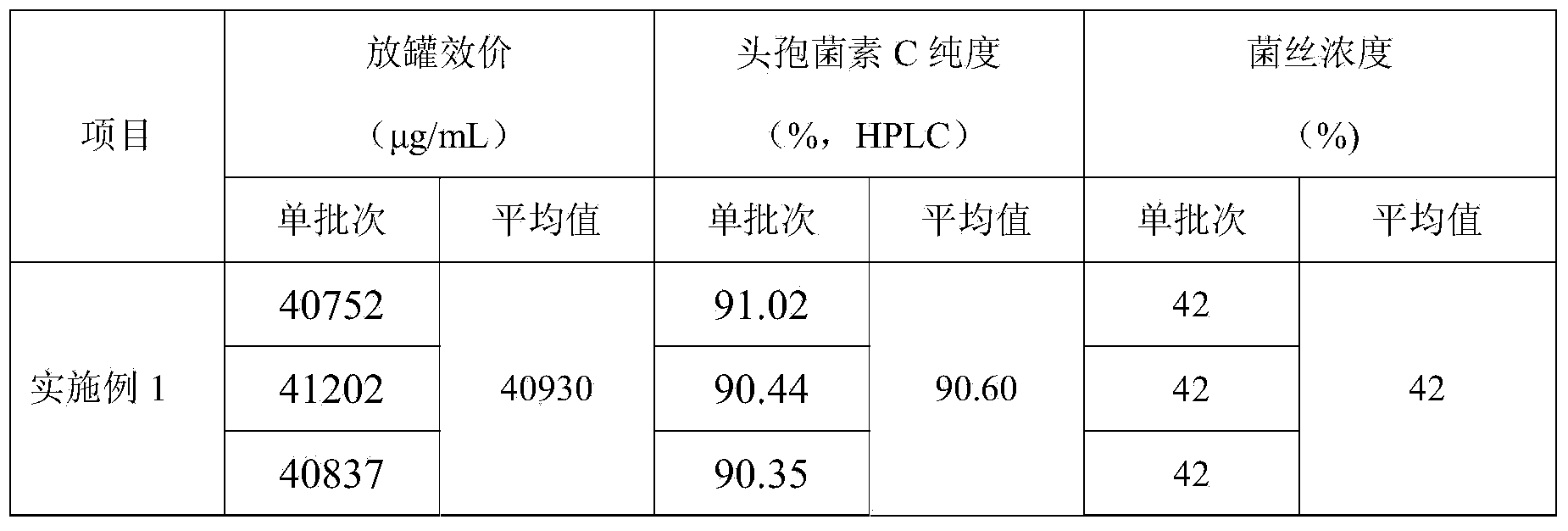

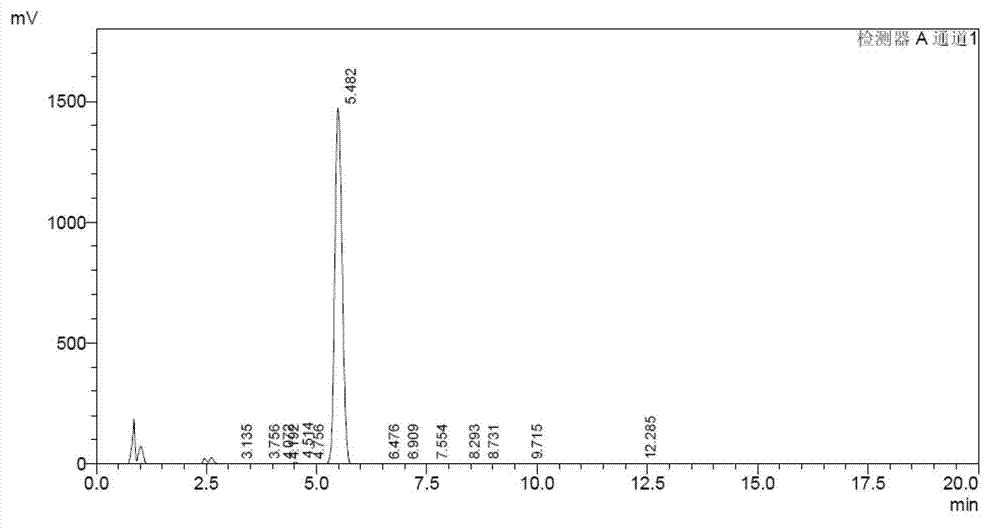

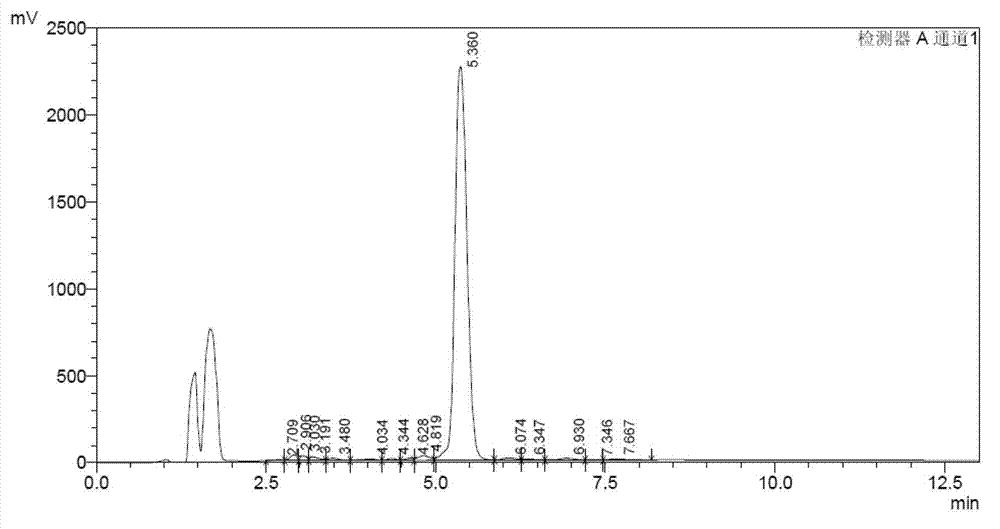

Fermentation process for preparing cephalosporin C and fermentation medium used in fermentation process

ActiveCN104263792AOptimizationPromote biosynthetic abilityMicroorganism based processesFermentationTiterFermentation

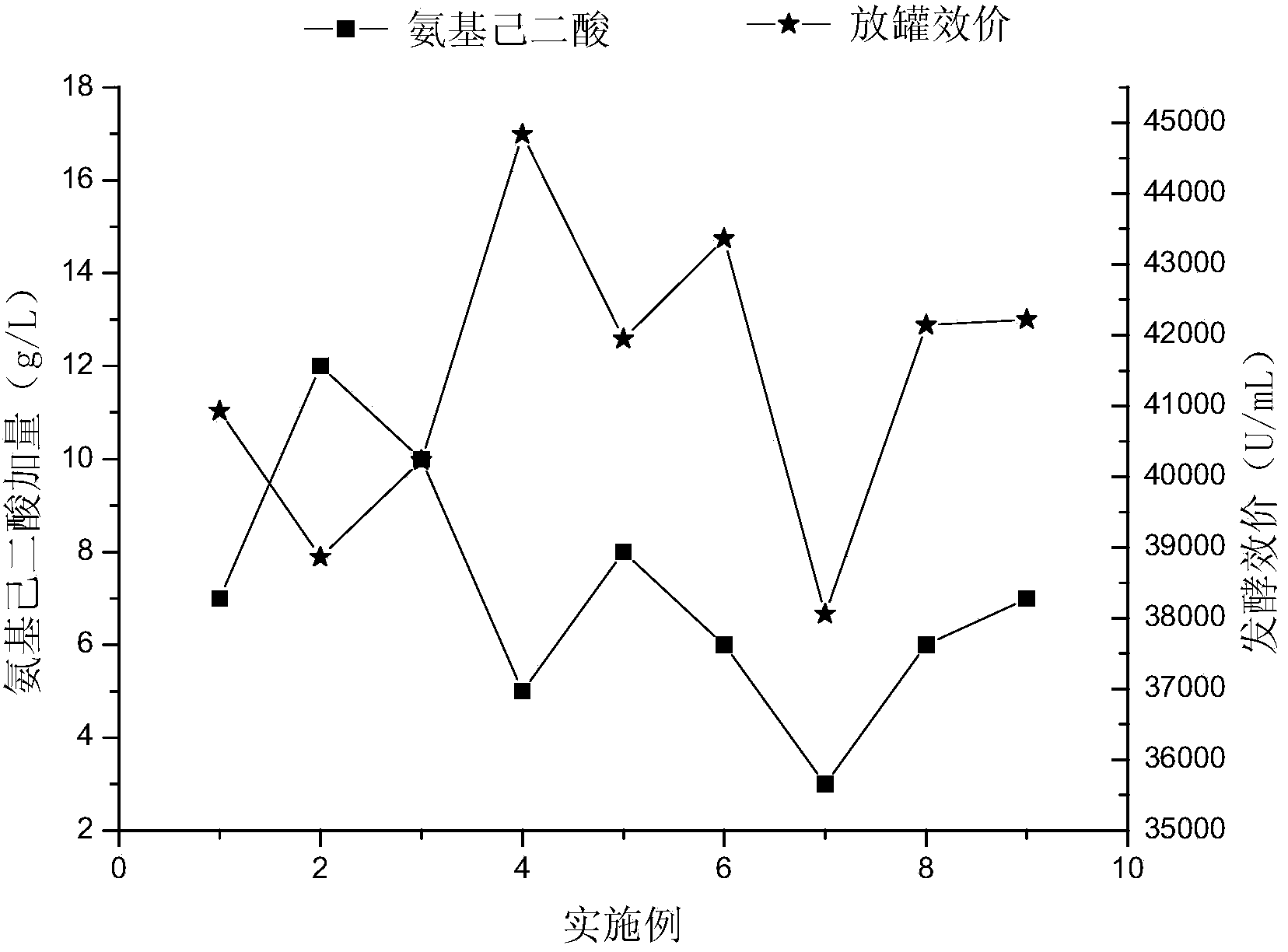

The invention relates to a fermentation process for preparing cephalosporin C and a fermentation medium used in the fermentation process. The fermentation process for preparing the cephalosporin C comprises the following steps: firstly, taking cephalosporium acremonium, activating, inoculating the activated cephalosporium acremonium to a seed culture medium, and culturing for 60-80 hours at the pH value of 6.8-7.2 at the temperature of 27-30 DEG C for preparing seeds; secondly, inoculating the seeds obtained in the step one to the fermentation medium, and fermenting for 110-150 hours at the pH value of 5.2-5.8 at the temperature of 24-29 DEG C; thirdly, carrying out centrifugal separation on fermentation liquor obtained in the step two, and taking supernatant liquid at the upper layer, so as to obtain cephalosporin C supernatant liquor. The fermentation process for preparing the cephalosporin C has the advantages that aminoadipic acid is added into the fermentation medium, a nutrient composition formula of the fermentation medium and fermentation technological conditions are optimized, biosynthesis capacity of the cephalosporin C is enhanced, fermentation titer is obviously increased, titer of the cephalosporin C is 38061-44837 microgram / mL, and quality of the cephalosporin C is not influenced, so that the fermentation process for preparing the cephalosporin C has a broad industrial application prospect.

Owner:SHANXI WEIQIDA PHARMA IND

Production process of Lipstatin

InactiveCN102965407AReduce manufacturing costImprove fermentation titerMicroorganism based processesFermentationStreptomyces toxytriciniGlycerol

The invention discloses a production process of Lipstatin, which adopts a special fermentation medium to ferment and culture streptomyces toxytricini; and the Lipstatin can be prepared by fermenting, purifying and refining the streptomyces toxytricini. According to the production technology, soybean meal, sunflower oil, glycerol and the like are taken as nitrogen source and carbon source of the fermentation medium; the high-purity Lipstatin can be prepared by regulation fermentation technology and purification technology, so that the production cost of the Lipstatin is greatly reduced, the fermentation valence is improved, and the problems of high production cost and low fermentation valence in the prior art can be solved.

Owner:GUANGZHOU MINGSHIN PHARMA

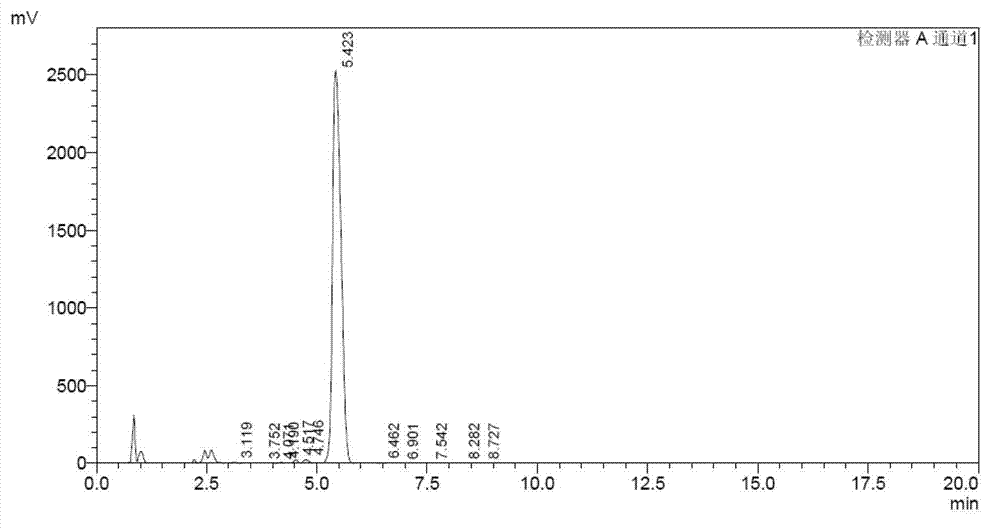

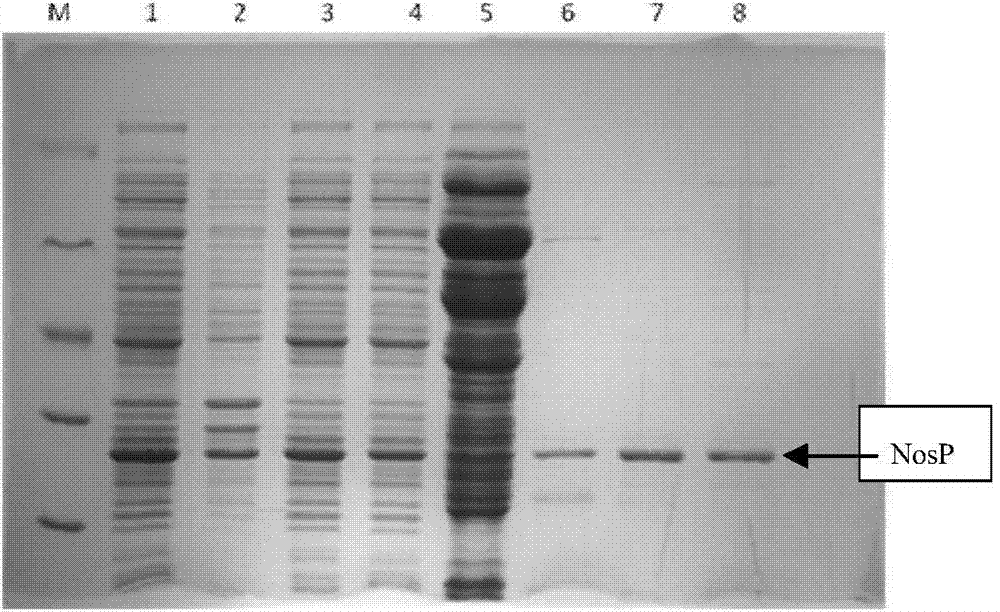

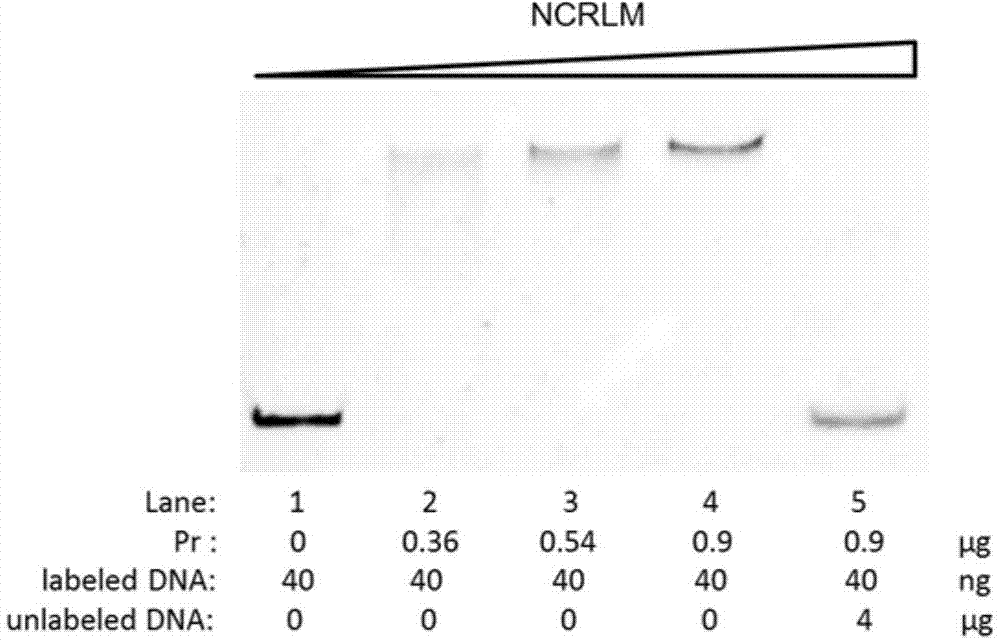

Nosiheptide biosynthetic regulatory protein NosP specific binding sequence and related application thereof

InactiveCN104762304AImprove fermentation titerReduce manufacturing costFermentationPlant genotype modificationEscherichia coliHeterologous

The invention discloses a nosiheptide biosynthetic regulatory protein NosP specific binding sequence and an influence thereof upon nosiheptide biosynthesis effectiveness. The invention comprises the following contents: recombinant plasmids comprising specific affinity purification tags and truncated NosP gene are established; a NosP protein pure product is prepared through Escherichia coli heterologous expression and an affinity chromatography method; and with EMSA and DNase I footprinting assay technologies, the NosP specific binding sequence in a streptomyces actuosus nosiheptide biosynthetic gene cluster is found and verified. On this basis, through nosiheptide biosynthetic pathway renovation, nosiheptide biosynthesis effectiveness is improved by 150%, such that an application prospect is good.

Owner:CHINA PHARM UNIV

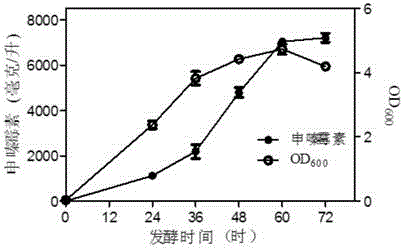

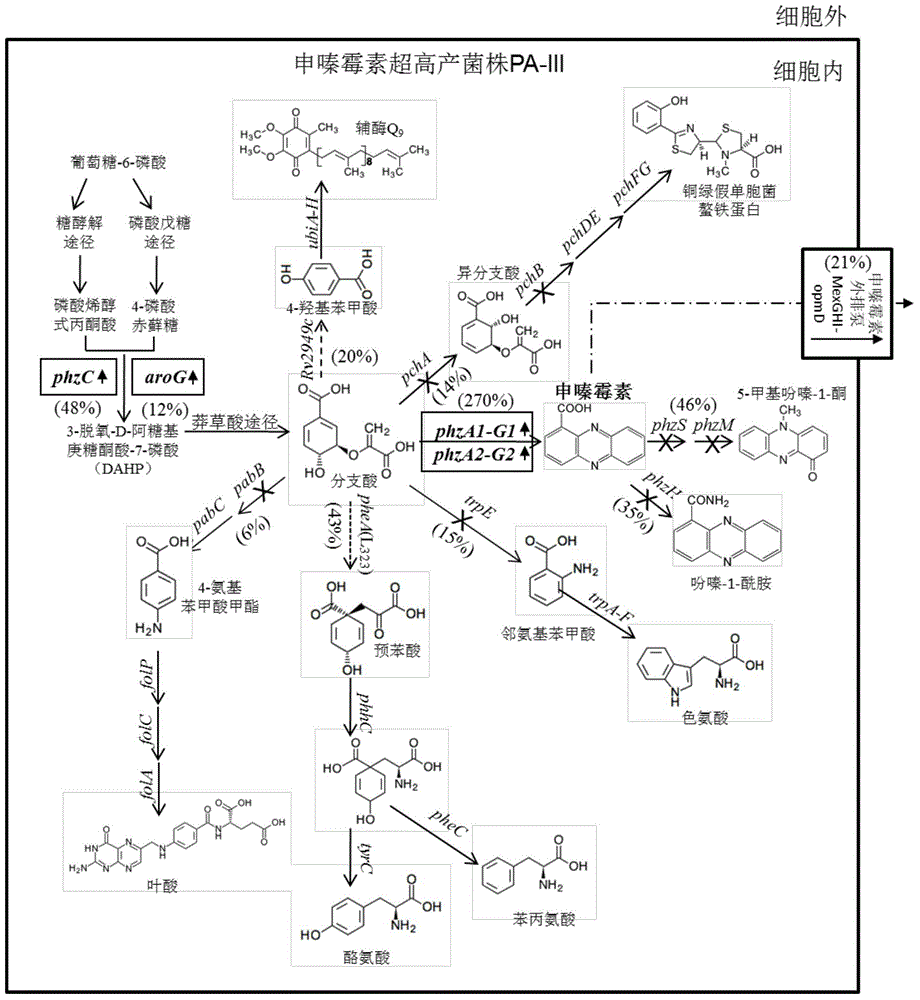

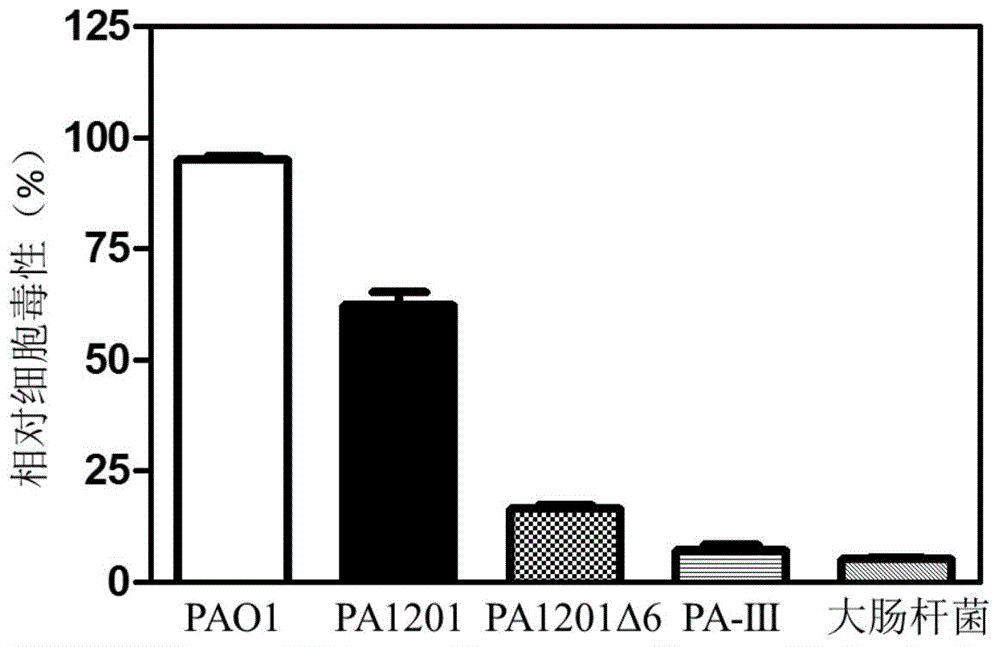

Gene engineering strain capable of safely and efficiently producing Phenazino-1-carboxylic acid and application thereof

ActiveCN104946552AImprove securityDisease controlBacteriaMicroorganism based processesBiotechnologyBiosynthetic genes

The invention discloses a gene engineering strain capable of safely and efficiently producing Phenazino-1-carboxylic acid. The gene engineering strain is Pseudomonas aeruginosa with a collection number of CCTCC No. M2015040. The gene engineering strain is prepared according to the following steps: performing pathogenic gene knockout on a strain PA1201; then, performing Shenqinmycin metabolizing gene knockout and metabolize metabolizing gene knockout; then, performing point mutation to reduce the bioactivity of PheA; performing isozyme substitution method to reduce the bioactivity of chorismic acid / pyruvic acid lyase; increasing a phzC gene copy number in a genome; replacing an aroG promoter with a strong promoter Ptac so as to enhance the gene expression level of DAHP synthase; and enhancing the Phenazino-1-carboxylic acid biosynthetic gene cluster expression level and Phenazino-1-carboxylic acid efflux pump MexGHI-OpmD expression level by a promoter replacement method. The obtained strain is capable of safely and economically producing Phenazino-1-carboxylic acid with superhigh yield.

Owner:周莲

Method for fermentation production of lipstatin and culture medium components thereof

ActiveCN102268466BImprove stabilityImprove fermentation titerMicroorganism based processesFermentationStreptomyces toxytriciniMicroorganism

The invention provides a method for fermentation production of lipstatin, belonging to the field of fermentation production of microorganisms. The method takes streptomyces toxytricini as an initial bacterium and mainly comprises the steps of preparation of a slope strain, preparation of a seed solution, control of a fermentation process and the like. In the invention, by taking soybean meal, bean oil and glycerol as main nitrogen sources and carbon sources of a fermentation culture medium and regulating and controlling the fermentation process and the components of the culture medium, the production cost of the lipstatin is greatly lowered, and the fermentation titer is increased, thus the defects of high production cost and low fermentation titer in the prior art are overcome.

Owner:鲁南新时代生物技术有限公司

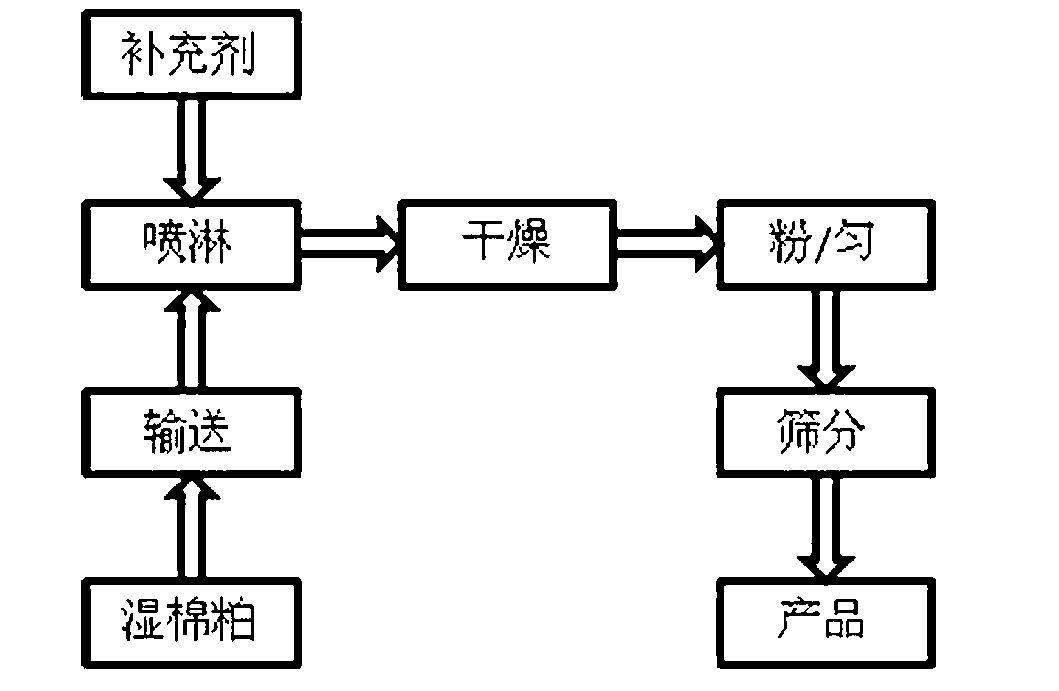

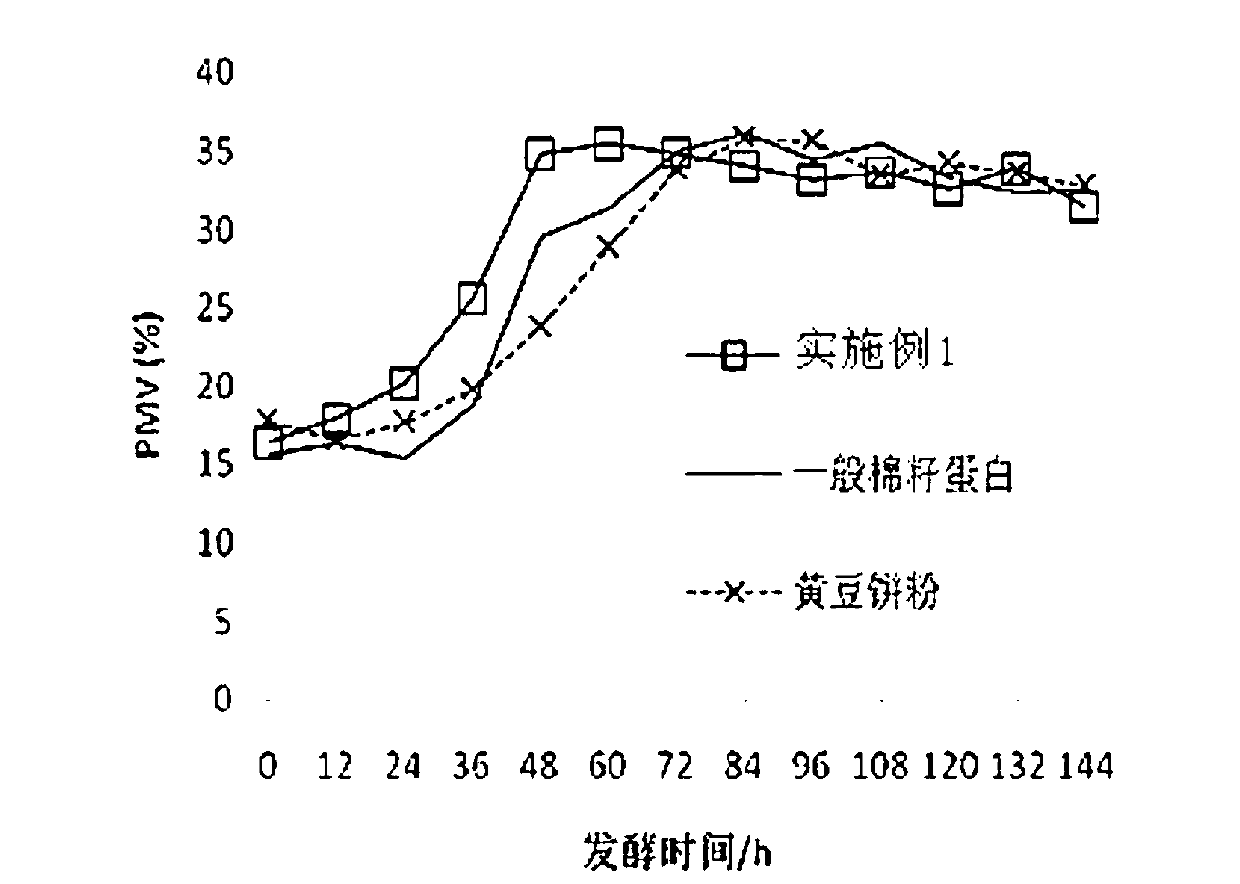

Cottonseed protein for fermentation and preparation method and application thereof

InactiveCN103215310APromote secretionImprove component contentMicroorganism based processesFermentationMetaboliteBetaine

The invention discloses a cottonseed protein for fermentation and a preparation method and application thereof. A nutrient solution is sprayed to wet cottonseed meal, and then the cottonseed protein is obtained by drying and velvet removal, wherein every 100mL of nutrient solution contains 1.0-5.0g of enzymolysis cottonseed peptone, 1.0-40g of betaine, 1.0-10g of CuSO4.5H2O, 1.0-10g of MgSO4.7H2O, 0.1-1.0g of CoCl2.7H2O and 0.01-0.5g of Triton X100. According to the invention, thallus reproduction is promoted while maintaining the advantages of the fermentation technology of the existing cottonseed protein product, the cell growth rate is improved, the biomass of the growing period is increased, and the growing period is shortened; and meanwhile, the release of metabolite from the cell inside to outside can be promoted so as to increase the output of target products and even improve the product quality or shorten the fermentation period.

Owner:中棉紫光生物科技(上海)有限公司 +1

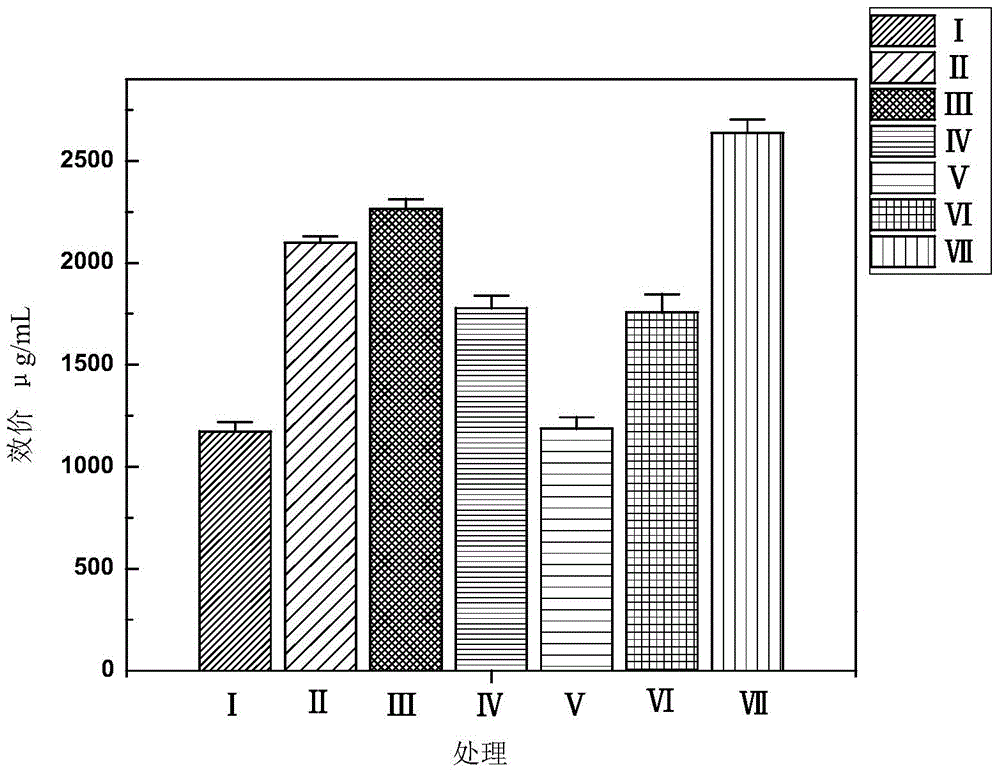

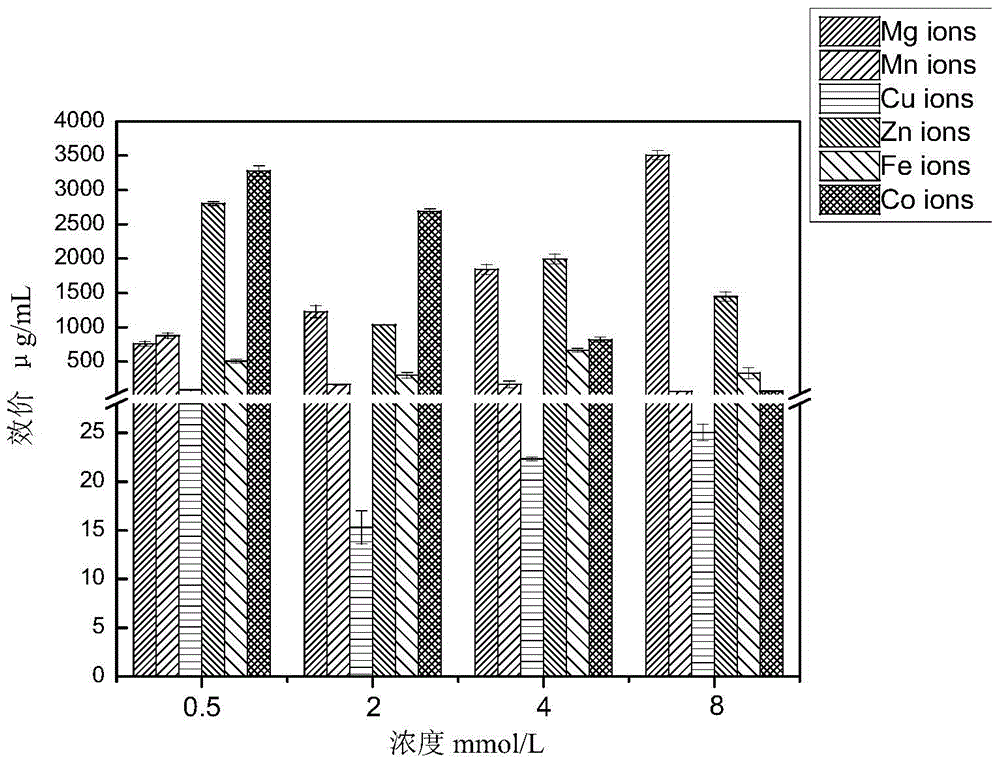

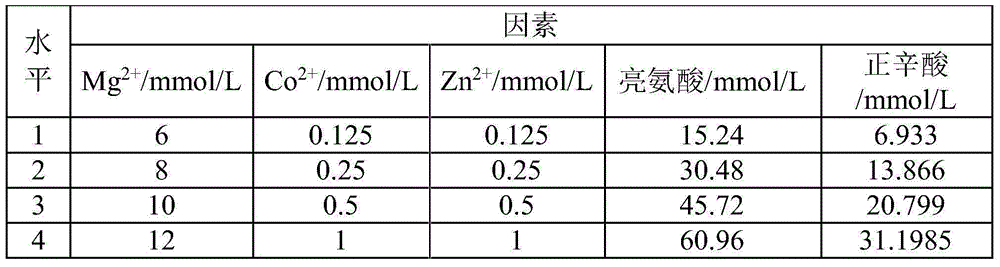

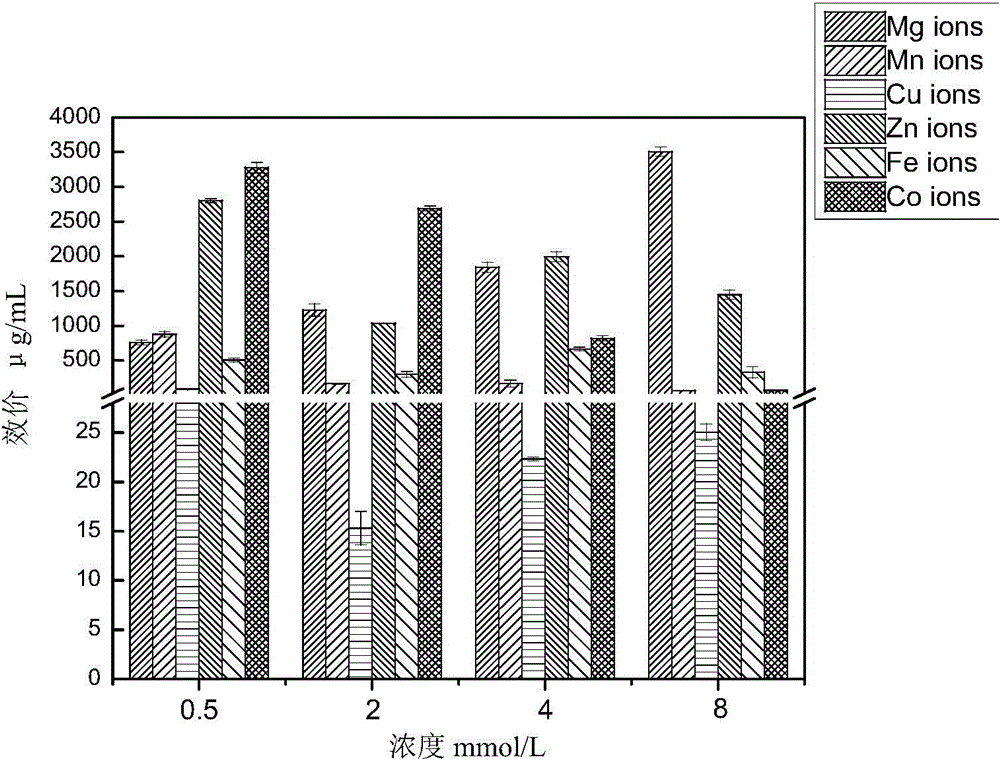

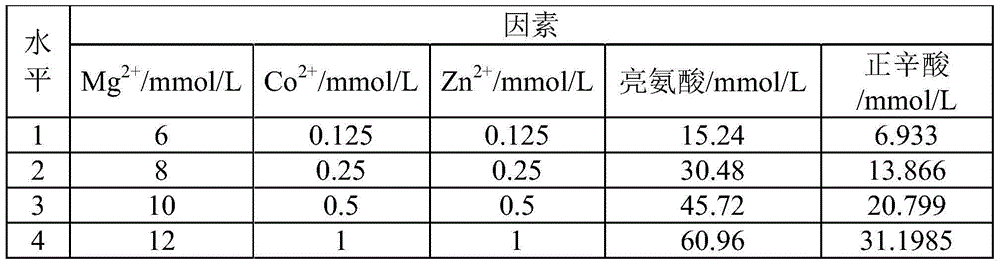

Method and culture medium for producing riprestatin by microbial fermentation

InactiveCN103820510BIncrease varietyIncrease dosageMicroorganism based processesFermentationMicroorganismStreptomyces toxytricini

The invention provides a method for producing lipstatin through microbial fermentation, and a used fermentation culture medium. The method comprises the following steps: inoculating streptomyces toxytricini into the fermentation culture medium, adding Mg<2+>, Co<2+> and Zn<2+> with the final concentrations of 10-15 mmol / L, 0.5-2.0 mmol / L and 0.1-0.5 mmol / L respectively in the culture medium, conducting fermental cultivation at 220 r / min and at the temperature of 28 DEG C, adding aminocaproic acid on the fourth day of fermental cultivation to enable the final concentration of the aminocaproic acid to be 40-50 mmol / L, adding n-caprylic acid on the sixth day of fermental cultivation to enable the final concentration of the n-caprylic acid to be 30-40 mmol / L, and keeping the total fermental cultivation time to be 150-180 hours, so as to obtain the lipstatin from the fermentation liquid after the fermentation is completed. According to the invention, the addition combination of a precursor and metal ions affecting the fermentation and synthesis of the lipstatin is optimized, and the best combination of the precursor and the metal ions is found, so that the yield of the lipstatin is remarkably increased, the potency is remarkably improved after the method and the culture medium are applied to the industrial production of the lipstatin, and the cost is lowered.

Owner:ZHEJIANG UNIV OF TECH +1

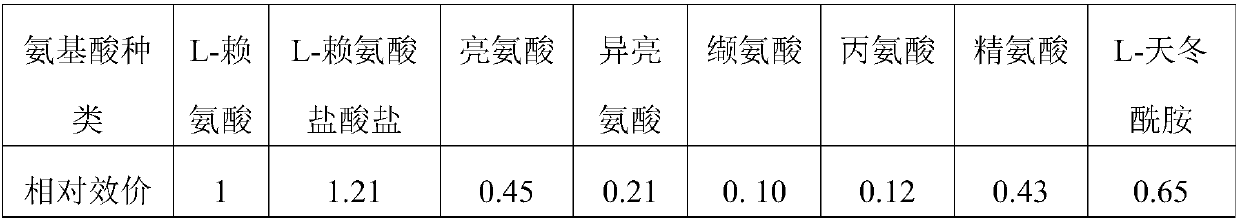

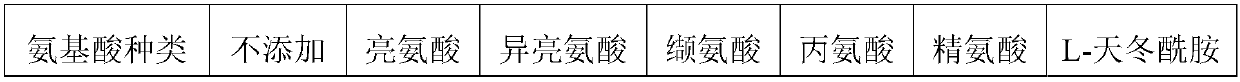

Culture medium for fermenting demeclocycline and fermentation method of demeclocycline

ActiveCN108018328ALow priceSuitable for industrial productionMicroorganism based processesFermentationInorganic saltsTrace element

The invention discloses a culture medium for fermenting demeclocycline and a fermentation method of the demeclocycline. The culture medium for fermenting the demeclocycline includes a carbon source, anitrogen source, amino acids, inorganic salts, alpha-amylase, vegetable oil and water, the content of the carbon source is 9-13%, and the content of the nitrogen source is 2.8-4.0%. Through adjustingof the content of the carbon source and the nitrogen source, especially the replacement of the nitrogen source and the addition of trace elements, the fermentation yield of the demeclocycline is improved. The provided fermentation method of the demeclocycline significantly increases the fermentation unit of the demeclocycline, and is suitable for the large-scale production of the demeclocycline.

Owner:SHANGHAI INST OF PHARMA IND +1

Method for producing penicillium griseofulvum, main ingredient of Songgang mycin, through microbial fermentation

ActiveCN108841889AImprove fermentation titerReduce manufacturing costMicroorganism based processesFermentationBiotechnologyMicroorganism

The invention discloses a method for producing penicillium griseofulvum, a main ingredient of Songgang mycin, through microbial fermentation. The method comprises the following steps: fermenting and culturing penicillium griseofulvum FH1816, to obtain penicillium griseofulvum from a fermented product, wherein the preservation number of the penicillium griseofulvum FH1816 in the China Center for Type Culture Collection is CCTCC NO:M 2018187. The provided penicillium griseofulvum FH1816 is used to produce the penicillium griseofulvum, a material route using no lactose or corn syrup and the novelprocess of feeding in batches, supplementing chlorine and fermenting are adopted, the fermentation potency of the penicillium griseofulvum is greatly improved, the production cost is lowered, and themethod provides reliable material sources for developing the antifungal biopesticide, namely the Songgang mycin.

Owner:福州工微生物科技有限公司

Method for manufacturing high-yield nattokinase

InactiveCN101603040AImprove fermentation titerReduce manufacturing costBacteriaHydrolasesBiologyMutagenic Process

The invention relates to a method for manufacturing a high-yield nattokinase, which comprises a strain obtained by a special mutagenesis method and a special fermentation process formulation. The invention can greatly improve the fermentation potency and reduce the production cost of nattokinase.

Owner:丁之铨

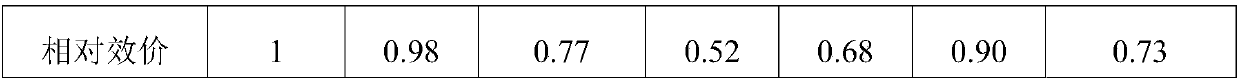

Production process for preparing lipstatin

InactiveCN103131739AReduce manufacturing costImprove fermentation titerMicroorganism based processesFermentationPhosphateGlycerol

The invention discloses a production process for preparing lipstatin. The production process comprises the following process flow: preparing a culture medium of a fermentation solution, fermenting and purifying a fermentation product. The culture medium of the fermentation solution contains 3.5%-7.0% of glycerol, 4.5%-8.0% of soybean flour, 1.0%-3.5% of lecithin, 5%-12% of soybean oil, 0.05-0.2% of magnesium sulfate, 0.05-0.2% of calcium carbonate and 0.05-0.2% of potassium dihydrogen phosphate. According to the production process disclosed by the invention, the soybean flour, the soybean oil, the glycerol and the like are taken as a main nitrogen source and a carbon source of the fermentation culture medium, ultrasonic disruption is performed on cells, oscillating extraction is performed to get a lipstatin crude product, and then recrystallization is performed on the crude product to get a lipstatin pure product. The production process disclosed by the invention has the characteristics of simple process, short production cycle, high extraction rate and low production cost.

Owner:GUANGZHOU MEDCAN PHARMATECH

Method for producing lipstatin through microbial fermentation and culture medium

InactiveCN103820510AIncrease productionHigh potencyMicroorganism based processesFermentationMicroorganismStreptomyces toxytricini

The invention provides a method for producing lipstatin through microbial fermentation, and a used fermentation culture medium. The method comprises the following steps: inoculating streptomyces toxytricini into the fermentation culture medium, adding Mg<2+>, Co<2+> and Zn<2+> with the final concentrations of 10-15 mmol / L, 0.5-2.0 mmol / L and 0.1-0.5 mmol / L respectively in the culture medium, conducting fermental cultivation at 220 r / min and at the temperature of 28 DEG C, adding aminocaproic acid on the fourth day of fermental cultivation to enable the final concentration of the aminocaproic acid to be 40-50 mmol / L, adding n-caprylic acid on the sixth day of fermental cultivation to enable the final concentration of the n-caprylic acid to be 30-40 mmol / L, and keeping the total fermental cultivation time to be 150-180 hours, so as to obtain the lipstatin from the fermentation liquid after the fermentation is completed. According to the invention, the addition combination of a precursor and metal ions affecting the fermentation and synthesis of the lipstatin is optimized, and the best combination of the precursor and the metal ions is found, so that the yield of the lipstatin is remarkably increased, the potency is remarkably improved after the method and the culture medium are applied to the industrial production of the lipstatin, and the cost is lowered.

Owner:ZHEJIANG UNIV OF TECH +1

High efficiency fermentation method for pristinamycin

InactiveCN1607245AImprove fermentation titerIncrease productionBacteriaFermentationMicrobiologyFermentation

Said invention relates to Streptomyces pristinaespiralis CGMCC 0957 and production and method of pristinamycin by same, which is that a method for high effectively producing Streptomyces pristinaespiralis CGMCC 0957 in culture medium under proper condition.

Owner:ZHEJIANG UNIV +1

Griseofulvin-producing strain and application thereof

ActiveCN108823110AImprove fermentation titerReduce manufacturing costBiocideFungiAntifungalBiotechnology

The invention discloses a griseofulvin-producing strain and application thereof. The invention provides Penicillium griseofulvum FH1816, which has a preservation number of CCTCC NO: M 2018187 in ChinaCenter for Type Culture Collection. The Penicillium griseofulvum FH1816 provided by the invention is utilized to produce griseofulvin, a raw material route without using lactose and corn syrup and anew process of fed-batch fermentation with continuous feeding of chlorine are adopted, the fermentation potency of griseofulvin can be greatly increased, and the production cost can be reduced, and areliable raw material source is provided for development of the antifungal biopesticide songgangmeisu.

Owner:福州工微生物科技有限公司

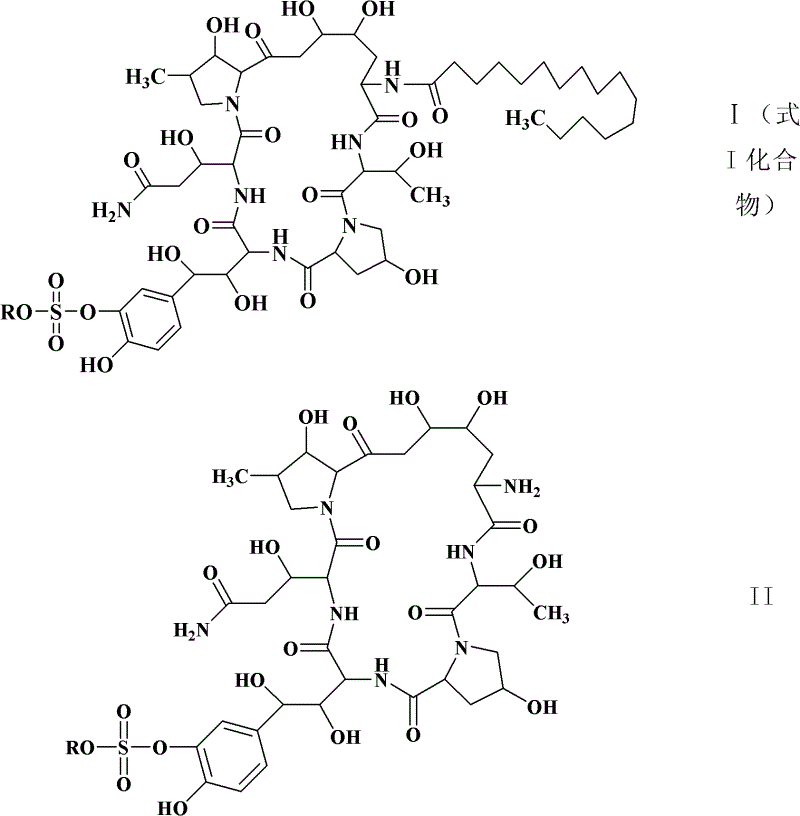

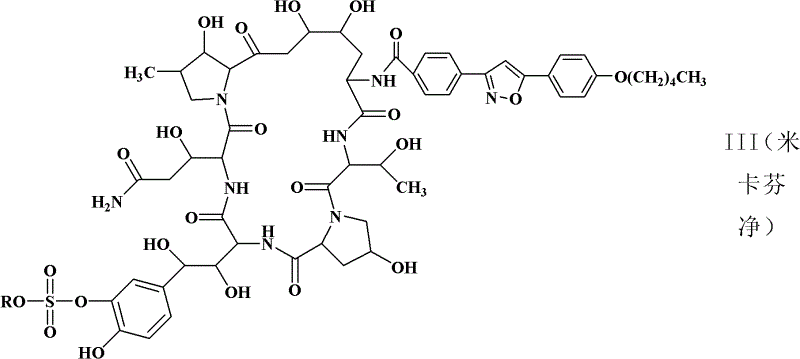

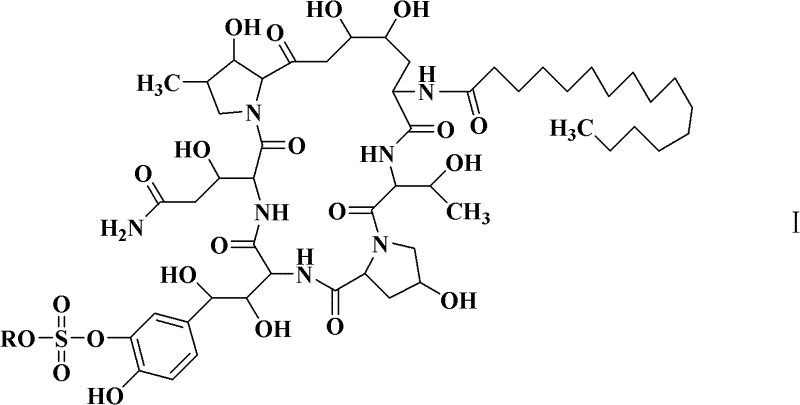

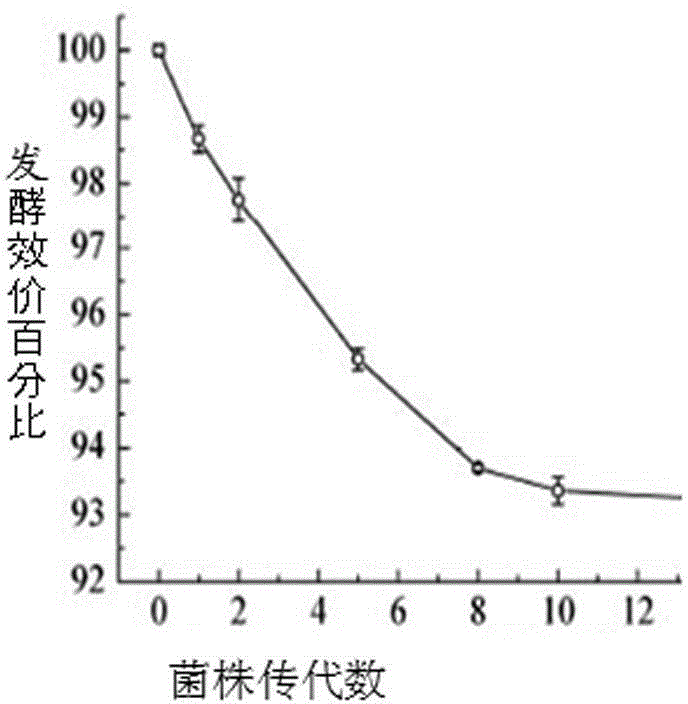

Preparation method of cyclic lipopeptide compound

ActiveCN102618604AImprove fermentation titerReduce usageFungiAntimycoticsOrganic solventNitrogen source

The invention discloses a fermentation medium which comprises 0.5-5.0 wt% of amino acid or its derivative, 0.5-3.0 wt% of hard-soluble organic nitrogen source, and 1.0-10.0 wt% of carbon source. By using the medium of the invention to carry out biologic fermentation of the compound of formula I, the fermentation level can stably reach more than 0.5g / L, with the highest fermentation level being 1.0g / L. By using the strain mutagenized with Coleophoma empetri F-11899 (FERM BP2635), the fermentation level can even reach 1.5 g / L. Because the fermentation level is high and the amount of organic solvent used in the post-treatment is relatively reduced, the production cost is reduced, and the invention has high economic value and meets the need of industrial production.

Owner:SHANGHAI TECHWELL BIOPHARMACEUTICALS CO LTD

Culture medium for fermentation production of erythromycin with red streptomyces and fermentation method thereof

ActiveCN107653285ALow costReduce consumptionBacteriaMicroorganism based processesDefoaming AgentsCorn steep liquor

The invention relates to culture medium for fermentation production of erythromycin with red streptomyces and a fermentation method thereof. The culture medium includes seed culture medium and fermentation culture medium, wherein the seed culture medium is prepared from starch, corn steep liquor, ammonium sulfate, light calcium carbonate, zinc sulfate, magnesium sulfate and a right amount of defoaming agent, and the fermentation culture medium is prepared from starch, corn steep liquor, ammonium sulfate, calcium carbonate, magnesium sulfate, zinc sulfate and a right amount of defoaming agent.According to the culture medium and the fermentation method, through change of the formula structures of the seed culture medium and the fermentation culture medium, change of the formula structure and control means of additional medium and introduction of several trace elements, the metabolic pathway of cells is changed, so that tertiary fermentation is shortened to secondary fermentation, and the fermentation time is shortened; meanwhile, the cost of fermentation raw materials is reduced, the fermentation culture medium is diluted, oxygen supply in the fermentation process is improved, and energy consumption of oxygen supply is reduced; through implementation of the technology, the fermentation level of erythromycin is significantly improved, and erythromycin E in the product is significantly reduced.

Owner:NINGXIA QIYUAN PHARMA

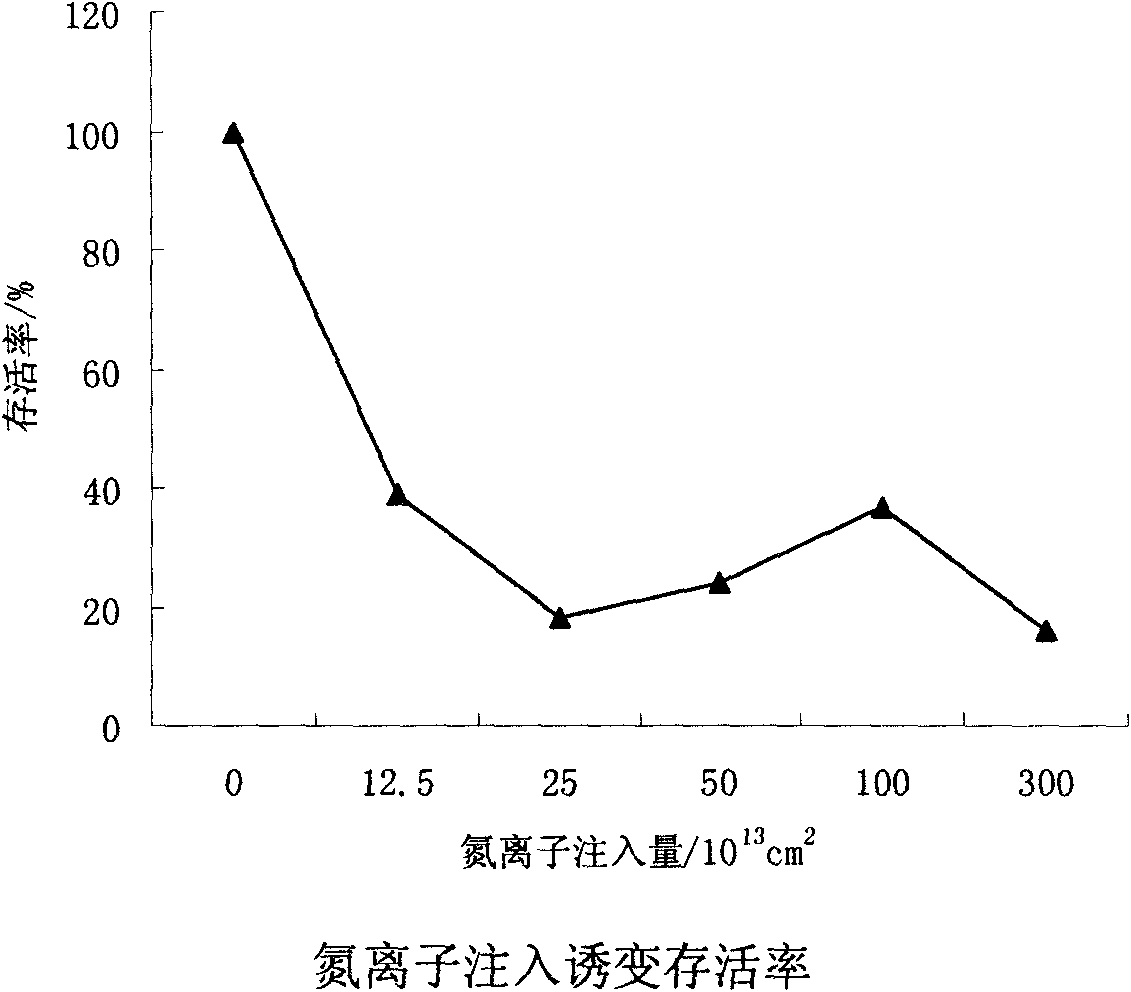

Method for breeding gibberellic acid high-producing strains by performing low-energy ion induced mutation on gibberella

InactiveCN104388418AImprove fermentation titerAvoid damageMutant preparationMicroorganism based processesBiotechnologyGibberellic acid

The invention discloses a method for breeding gibberellic acid high-producing strains by performing low-energy ion induced mutation on gibberella. The method comprises the following steps: firstly, preparing a protoplast suspension of 108-109 / mL by use of a gibberella strain and sterile water; applying the protoplast suspension to a culture dish for air drying; injecting a pulsed nitrogen ion beam into the air-dried protoplasts to induce the mutation of the protoplasts; adding the mutated protoplasts to sorbitol solution ice bath for suspending, and then applying the suspension to a PDAS regeneration medium plate for cultivation; performing inoculation of the well growing individual strains into a shake flask filled with a liquid fermentation culture medium for shake cultivation, thereby obtaining the gibberellic acid high-producing strains. The method for breeding the gibberellic acid high-producing strains by performing low-energy ion induced mutation on the gibberella has the advantages that the mutation of the gibberella is induced in a pulsed nitrogen ion beam injection manner and the high-producing mutant gibberella strains can be bred; according to the method, the direct mutation rate of the mutant strains can be 10%-40%, and the fermentation titer is increased by 30-90% in contrast with that of the original strain.

Owner:ZHENGZHOU UNIV +1

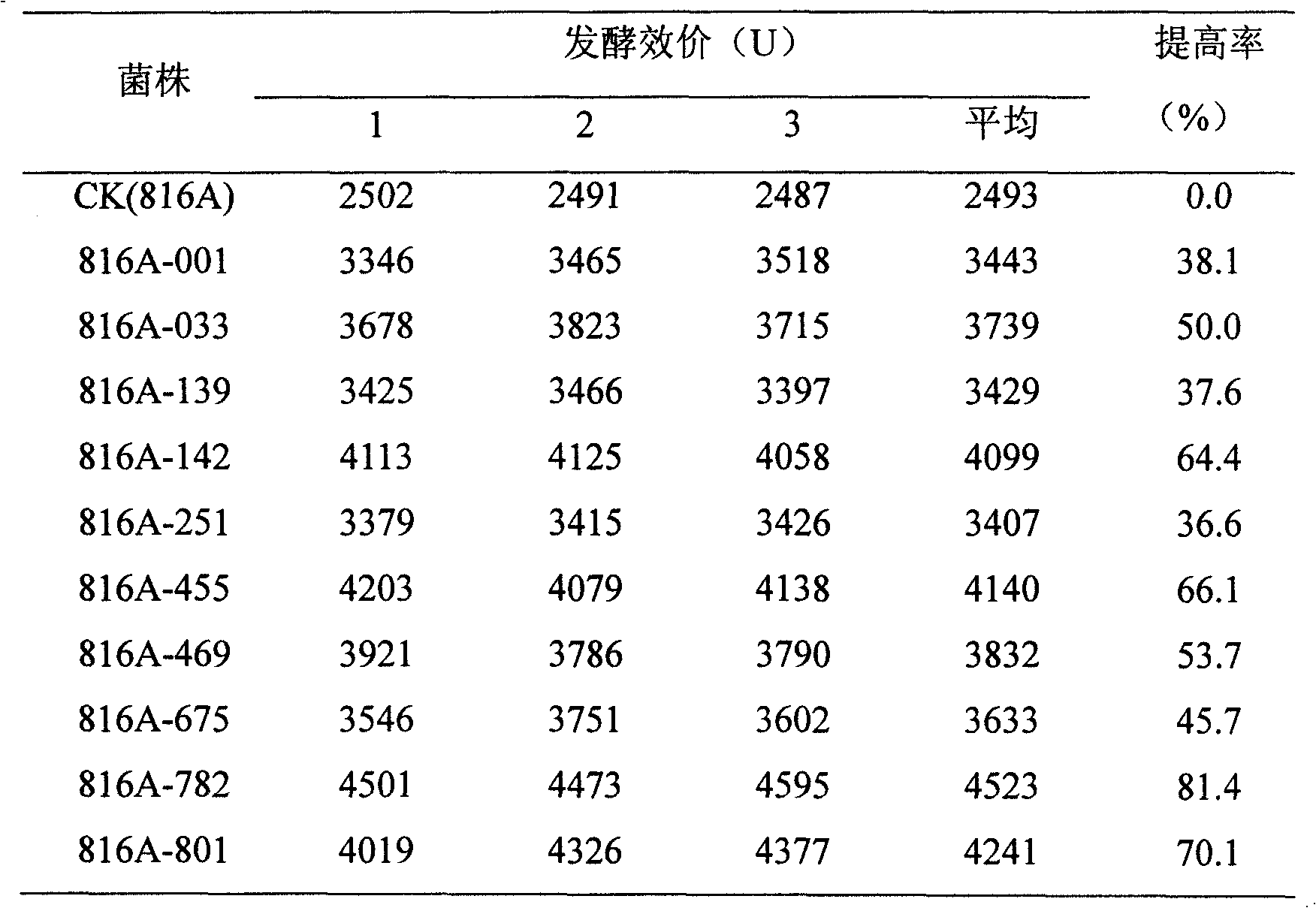

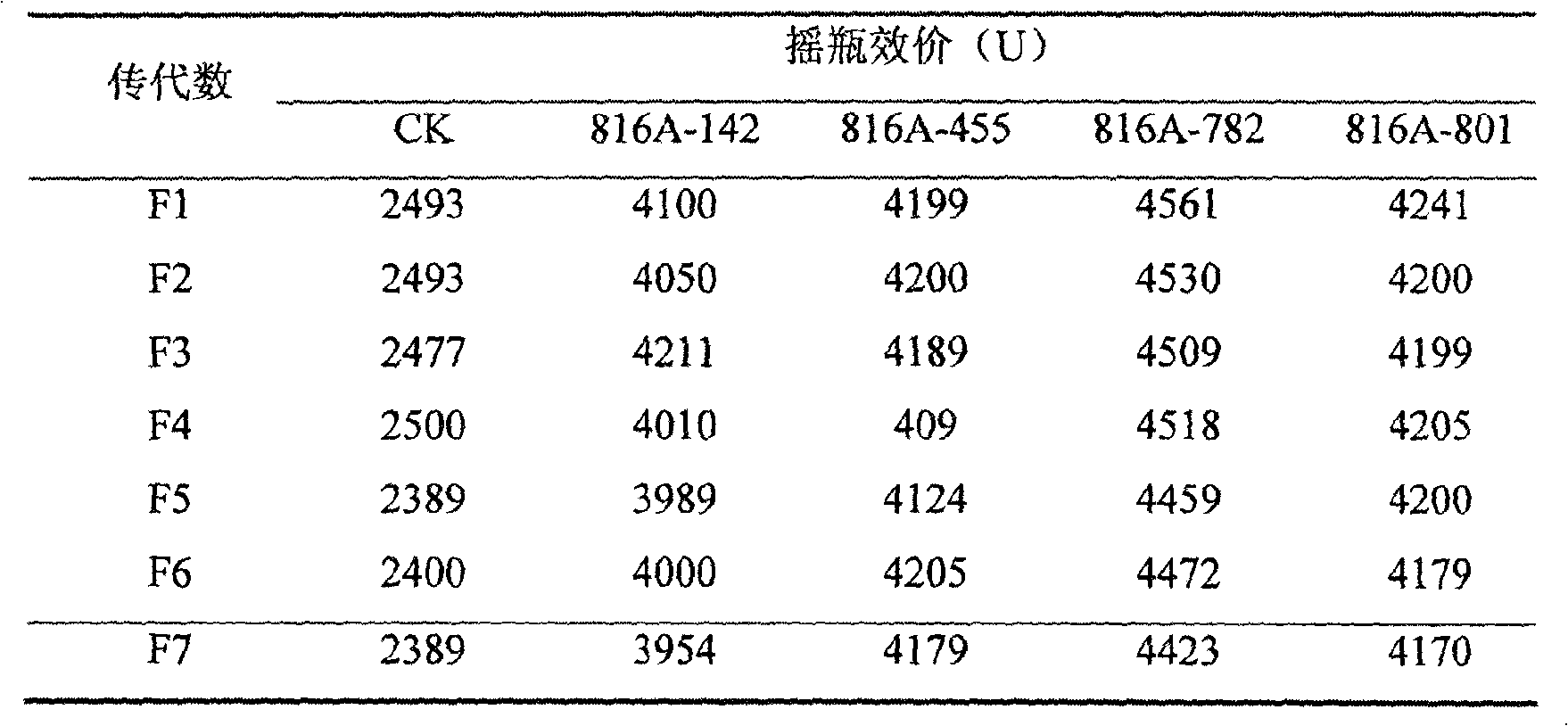

Screening method of lincomycin producing strain

InactiveCN101638650AScale upSpeed up the processMicrobiological testing/measurementMutant preparationScreening methodMicrobiology

The invention discloses a screening method of lincomycin producing strain. In the screening method, composite treatment of mutagenesis and resistance screening is conducted to streptomyces lincolnensis of the lincomycin producing strain by adopting an ion implantation technology, N<+> is used as an ion source, the biological effect of N<+> implantation on the lincomycin producing strain is studied, and a lincomycin precursor which is the product of the lincomycin producing strain is used for obtaining a plurality of high-yield mutant strains with better genetic stability by the resistance screening method, so as to lead the fermentation unit of the mutant strains to be improved by 81.4% than that of original strains.

Owner:南阳普康药业有限公司

Fermentation medium for fermenting riboflavin and using method of fermentation medium

ActiveCN110777184AImprove certaintyImprove fermentation titerBacteriaMicroorganism based processesMonopotassium phosphateFermentation

The invention discloses a fermentation medium for fermenting riboflavin and a using method of the fermentation medium, and relates to the technical field of microorganisms. The fermentation medium comprises a basic medium and a fed-batch medium, wherein the basic medium is prepared from the components with content as follows: 10-20 g / L of glucose, 30-60 g / L of molasses, 15-25 mL / L of sodium oleate, 5-8 g / L of yeast powder, 1.5-2 g / L of monopotassium phosphate, 0.1-0.3 g / L of magnesium sulfate heptahydrate, 0.3-0.5 g / L of zinc gluconate, 10-15 mL / L of Tween, 5-15 mg / L of erythromycin and 5-15 mg / L of chloramphenicol; and the fed-batch medium is prepared from the components with content as follows: 5-10 g / L of inositol, 5-8 g / L of ammonium sulfate, 30-50 g / L of glucose and 500-900 mg / L of compound factors. The technical problem that the riboflavin fermentation unit is relatively low due to the fact that the operation relies on experience more than theories in the prior art is solved.

Owner:HEBEI SHENGXUE DACHENG PHARMA

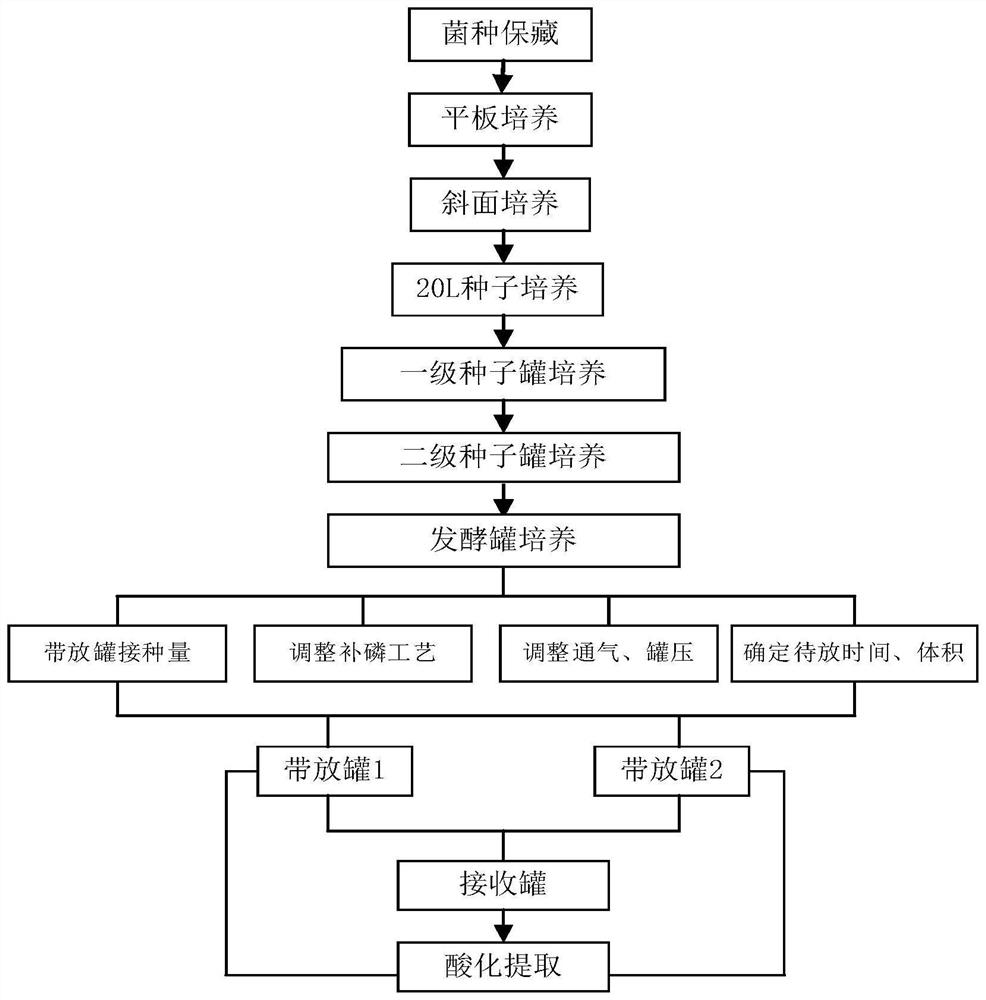

Method for producing coenzyme Q10 by industrial fermentation

PendingCN111763636AReduce the number of transfersShortened cultureBacteriaMicroorganism based processesBiotechnologyIndustrial fermentation

The invention relates to a preparation method of coenzyme Q10, in particular to a method for producing coenzyme Q10 by industrial fermentation. A strain used in the method is Rhodobacter sphaeroides.The method includes the following steps: plate culture of the strain, inclined plane culture of the strain, 20 L seed culture, primary seed tank culture, secondary seed culture, tertiary fermentationculture, seed-pouring culture and fermentation. The method can solve problems that a culture medium in fermentation liquor is incompletely consumed and the fermentation liquor has high impurity content, low effective units, and accordingly low in refining yield, the quality of industrial salt is not easy to control, low-unit hyphae causes low yield and high sewage discharge, and unused organic matter in emissions causes excessive COD emissions, thereby increasing environmental protection costs. The method has simple process flow and low bacteria contamination risk, saves fermentation cost, improves fermentation output, increases process reserves, and increases production scheduling.

Owner:SHENZHOU BIOLOGY & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com