Method for producing coenzyme Q10 by industrial fermentation

A coenzyme and industrial technology, applied in the field of coenzyme Q10 preparation, can solve problems such as difficult control of industrial salt quality, incomplete consumption of medium, excessive COD discharge, etc., to reduce the risk of bacterial contamination, save material loss, and increase environmental protection costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

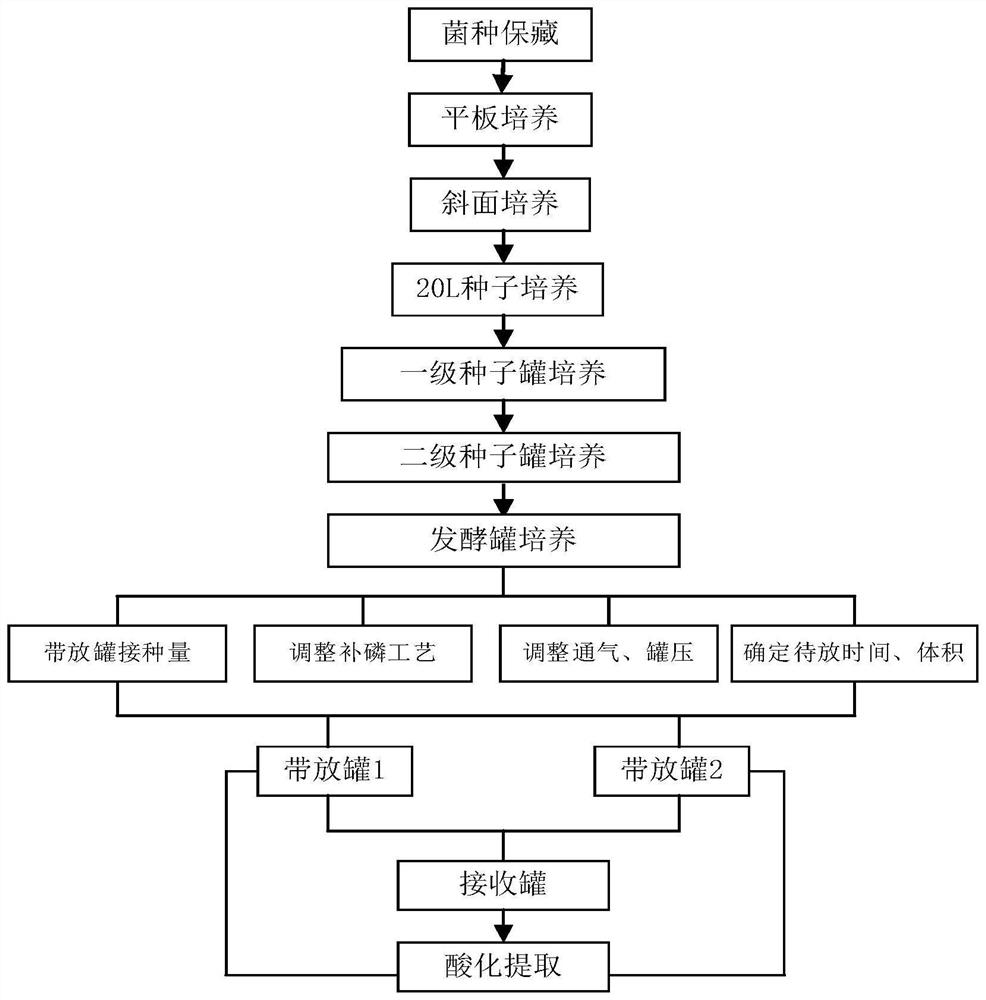

Method used

Image

Examples

Embodiment 1

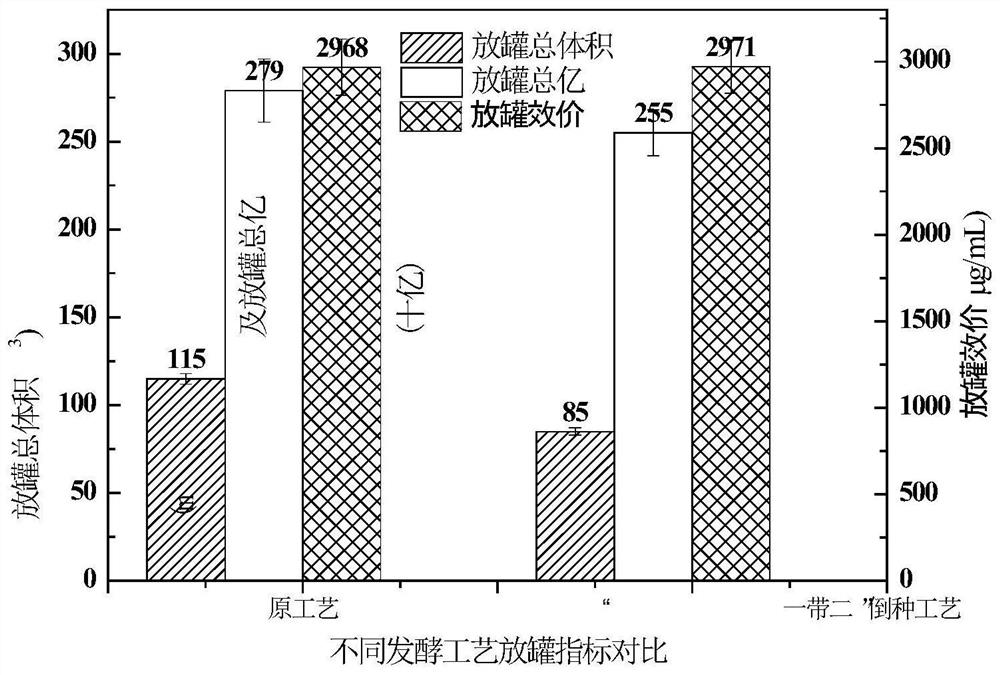

[0048] Embodiment 1 "One Belt Two" Planting Process Method

[0049] Plate culture of S1 strain: After preparing the medium according to the formula of medium A and sterilizing, pour the plate under aseptic conditions. Pipette 1 mL of glycerol bacterial suspension into a test tube filled with 9 mL of sterile water with a pipette, shake on a vortex shaker, disperse and mix, and then use a pipette to double-dilute. Use a dilution of 10 -5 Inoculate the plate with 200-300 μL of bacterial suspension in each plate and spread evenly with a sterilized spreader. Put the evenly coated plate into an incubator with a temperature of 32.0±0.5°C and a humidity of 35%-45% for 5-7 days.

[0050] Slope culture of strain S2: After preparing the medium according to the formula of medium A and sterilizing it, pour the slope under aseptic conditions. From the mature mother plate, use an inoculation shovel to select a few full, raised, and uniformly sized single colonies, transfer them into a tes...

Embodiment 2

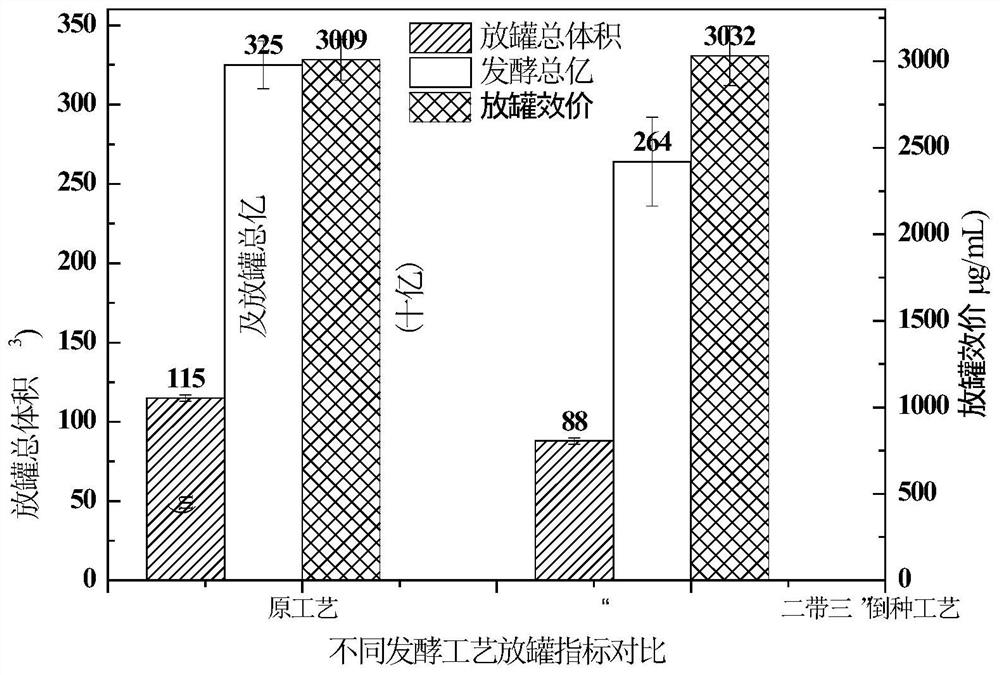

[0058] Example 2 Implementation of "two-band three" seeding process

[0059] In the early stage, the fermentation process control of "flat seeds-slanted seeds-20 L seeds- primary seeds- secondary seeds" was basically the same. In the "two with three" inverted seed re-cultivation process, the fermenter that has been fermented for 45-65 hours and tested to meet the pure-bred culture standard is selected as the fermentation liquid supply tank, and the fermentation liquid in it is equally divided into another sterilization completed. continued cultivation in the receiving tank. by attaching image 3 It can be seen that the potency of the "two belt three" pouring process is slightly higher than that of the original process, mainly because the volume of the fermentation broth is reduced after the two belts are put in the tank to effectively improve the fermenter's filling coefficient and increase the fermentation dissolved oxygen. level, thereby promoting the improvement of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com