Fermentation process for preparing cephalosporin C and fermentation medium used in fermentation process

A technology of fermentation medium and fermentation method, applied in the field of biopharmaceuticals, to achieve broad industrial application prospects, improve fermentation titer, and promote the effect of biosynthesis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

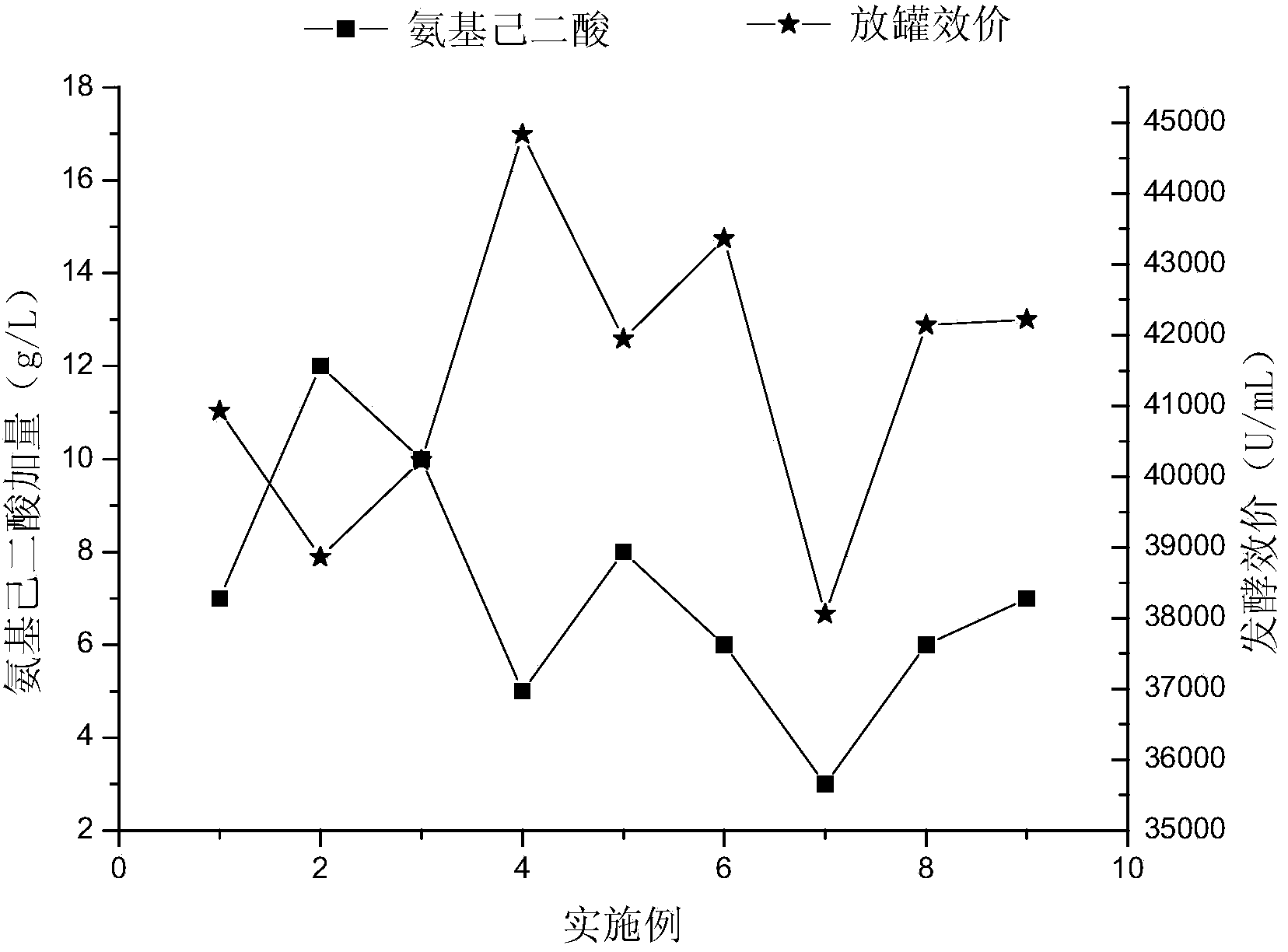

Examples

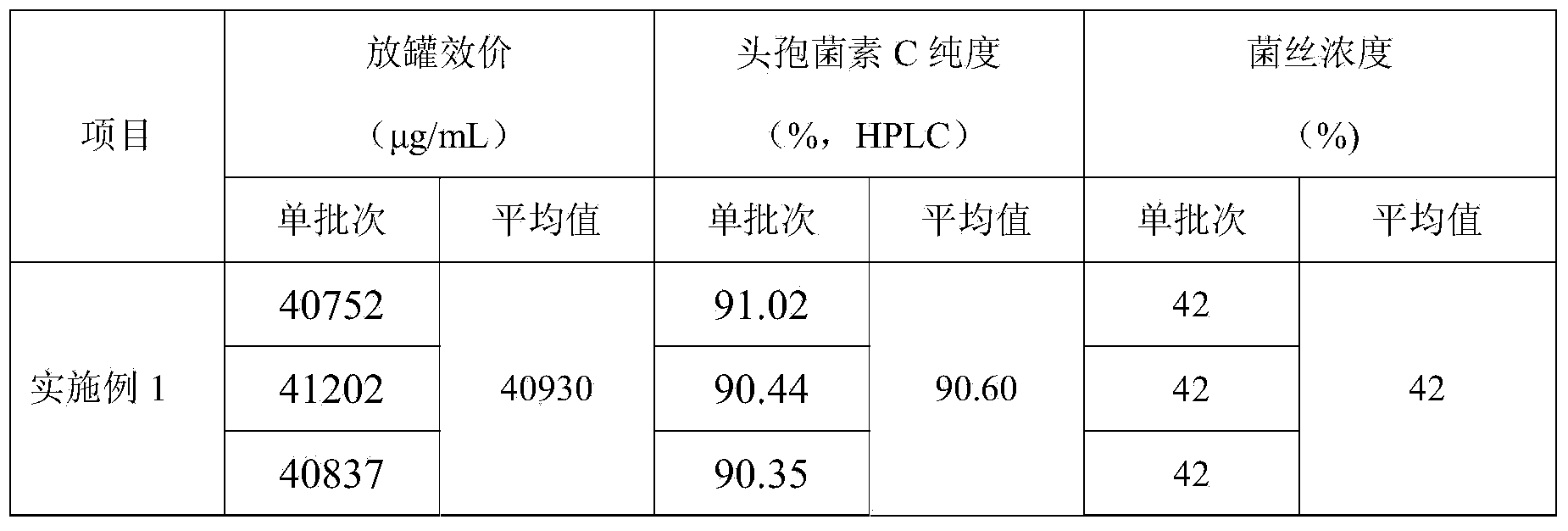

Embodiment 1

[0054] Fermentation medium

[0055] The composition is as follows: D-α-aminoadipic acid 7g / L; peanut powder 35g / L; cottonseed protein 22g / L; gluten powder 45g / L; bean cake powder 24g / L; corn steep liquor 48mL / L; glucose 7g / L ; sucrose 12g / L; methionine 11g / L; ammonium sulfate 13g / L; calcium sulfate 14g / L; calcium carbonate 7g / L; soybean oil 105mL / L; and PPG20001mL / L.

[0056] Preparation: Mix and dissolve gluten powder and soybean oil, and dissolve other raw materials with deionized water as a solvent. After dissolving, mix and settle in a fermenter. Use 20% (w / v) sodium hydroxide solution to adjust the initial pH of the medium to 7.2 ~7.4 (during fermentation, as the fermentation proceeds, the pH of the fermentation broth gradually drops to 5.2~5.8).

[0057] Fermentation for the preparation of cephalosporin C

[0058] step 1:

[0059] Get Cephalosporium acremonium and carry out slant culture activation, and slant culture medium is composed of: take deionized water as ...

Embodiment 2

[0075] Fermentation medium

[0076] The composition is as follows: L-α-aminoadipic acid 12g / L; peanut powder 45g / L; cottonseed protein 30g / L; gluten powder 50g / L; bean cake powder 35g / L; corn steep liquor 70mL / L; glucose 10g / L ; sucrose 20g / L; methionine 15g / L; ammonium sulfate 20g / L; calcium sulfate 18g / L; calcium carbonate 9g / L; soybean oil 120mL / L; and PPG20002mL / L.

[0077] Preparation: Mix and dissolve gluten powder and soybean oil, and dissolve other raw materials with deionized water as a solvent. After dissolving, mix and settle in a fermenter. Use 20% (w / v) sodium hydroxide solution to adjust the initial pH of the medium to 7.2 ~7.4.

[0078] Fermentation for the preparation of cephalosporin C

[0079] step 1:

[0080] Get Cephalosporium acremonium and carry out slant culture activation, and slant medium is composed of: take deionized water as medium, wort juice 12g / L, peptone 10g / L, and agar 22g / L, pH before eliminating is 7.2; Slant culture method is: Cultiv...

Embodiment 3

[0096] Fermentation medium

[0097] The composition is as follows: D-α-aminoadipic acid 10g / L; peanut powder 40g / L; cottonseed protein 25g / L; gluten powder 45g / L; bean cake powder 32g / L; corn steep liquor 65mL / L; glucose 9g / L ; sucrose 19g / L; methionine 14g / L; ammonium sulfate 19g / L; calcium sulfate 17g / L; calcium carbonate 8g / L; soybean oil 115mL / L;

[0098] Preparation: Mix and dissolve gluten powder and soybean oil, and dissolve other raw materials with deionized water as a solvent. After dissolving, mix and settle in a fermenter. Use 20% (w / v) sodium hydroxide solution to adjust the initial pH of the medium to 7.2 ~7.4.

[0099] Fermentation for the preparation of cephalosporin C

[0100] step 1:

[0101] Get Cephalosporium acremonium and carry out slant culture activation, and slant culture medium is composed of: take deionized water as medium, wort juice 10g / L, peptone 10g / L, and agar 22g / L, pH before eliminating is 7.4; Slant culture method is: Cultivate for 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com