Cottonseed protein for fermentation and preparation method and application thereof

A cottonseed protein and cottonseed technology, applied in the field of fermented cottonseed protein and its preparation, can solve the problems of shortening of rapid utilization, no improvement of lag period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

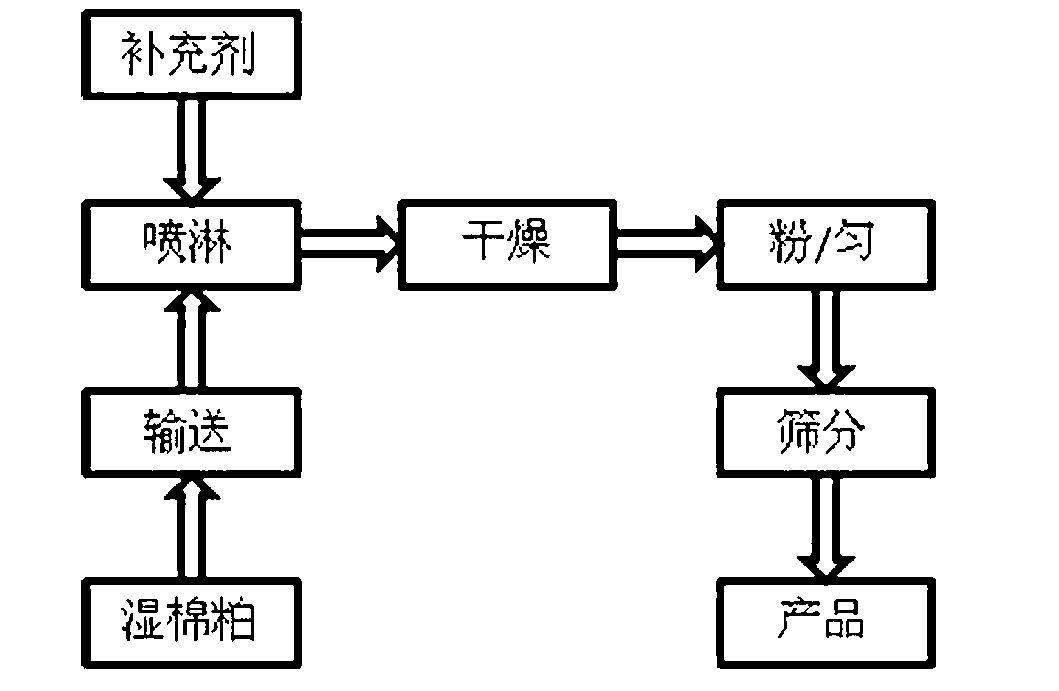

[0025] Adopt conventional methods in this field to carry out the treatment of cottonseed delinting, shelling, cotton kernel softening, embryo pressing, drying, oil extraction, phenol removal, and partial desolvation, after obtaining wet cotton meal, such as figure 1 Shown is prepared according to the following process and conditions:

[0026] Step 1. The wet cotton meal is transported to the dryer at a uniform speed by the feeder. The wet meal passes through the sprayer before entering the dryer. During the forward process of the wet cotton meal, the nutrient solution is evenly distributed by the sprayer. Spray onto wet cottonseed meal.

[0027] Preparation of nutrient solution: 3.75g / 100mL CuSO 4 ·5H 2 O, 7g / 100mL MgSO 4 ·7H 2 O, 0.6g / 100mL CoCl 2 ·7H 2 O, 10g / 100mL betaine, 20g / 100mL enzymatic cottonseed peptone, 0.05g / 100mL Triton X100. The amount of nutrient solution added was 10 mL of nutrient solution per kilogram of cottonseed meal.

[0028] Step 2. After the we...

Embodiment 2

[0031] The nutrient solution adopted in the present embodiment is: 1.5g / 100mL CuSO 4 ·5H 2 O, 10.0g / 100mL MgSO 4 ·7H 2 O, 0.1g / 100mL CoCl 2 ·7H 2 O, 5g / 100mL betaine, 40g / 100mL enzymatic cottonseed peptone, 0.01g / 100mL Triton X100. The amount of nutrient solution added was 10 mL of nutrient solution per kilogram of cottonseed meal. Other steps and conditions are with embodiment 1.

Embodiment 3

[0033] 1. Product processing:

[0034]The nutrient solution adopted in the present embodiment is: 7.5g / 100mL CuSO 4 ·5H 2 O, 2.5g / 100mL MgSO 4 ·7H 2 O, 0.8g / 100mL CoCl 2 ?7H 2 O, 10g / 100mL betaine, 5g / 100mL enzymatic cottonseed peptone, 0.05g / 100mL Triton X100. The amount of nutrient solution added was 10 mL of nutrient solution per kilogram of cottonseed meal. Other steps and conditions are with embodiment 1.

[0035] Two, the protein and gossypol content detection index of embodiment 1-3

[0036] The protein and gossypol content values of cottonseed protein are shown in Table 1:

[0037]

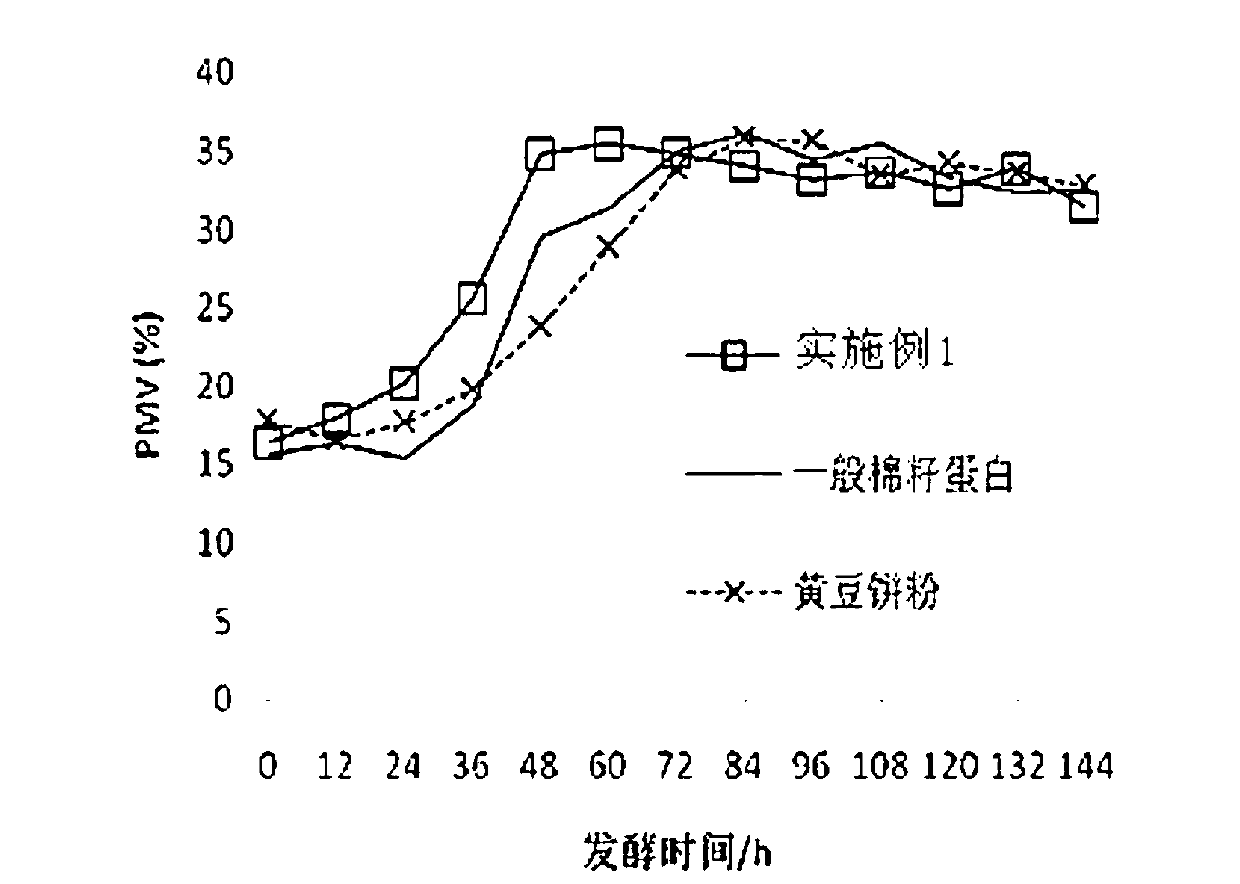

[0038] Three, embodiment 1 improves the effect detection of erythromycin output

[0039] Taking Example 1 and general cottonseed protein as the nitrogen source tested, and taking the most commonly used soybean meal in erythromycin fermentation as a control, the effect of Example 1 on the increase of erythromycin fermentation titer was investigated.

[0040] The detection met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com