Strip-casting 700-MPa-level weathering resistant steel and production method thereof

A production method and technology of weathering steel, which is applied in the field of weathering steel strips, can solve problems such as poor welding performance, segregation of billet center, and poor surface quality, so as to improve strength and welding performance, ensure convexity and plate shape, and reduce The effect of molten steel superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

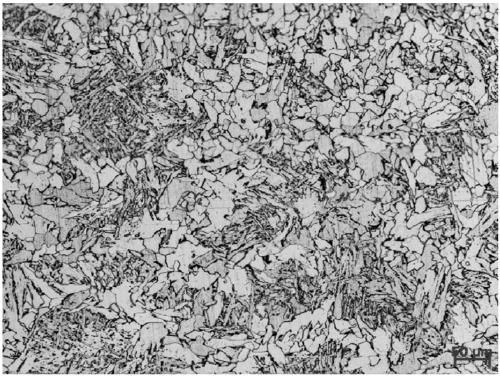

Image

Examples

Embodiment 1

[0038] This embodiment proceeds according to the following steps:

[0039] 1) Smelting

[0040] The chemical composition of molten steel is: C: 0.28%, Si: 0.58%, Mn: 0.75%, P: 0.05%, S: 0.002%, N: 0.002%, Cu: 0.80%, Cr: 1.40%, Ni: 0.07%, Nb: 0.08%, V: 0.05%, the rest is Fe and unavoidable impurities;

[0041] 2) Thin strip continuous casting

[0042] The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 2.3mm through a pair of counter-rotating copper casting rolls, and the superheat of the molten steel is 58°C;

[0043] 3) On-line hot rolling of cast strip

[0044] The reduction in hot rolling is 52%, and the temperature after strip rolling is 1025°C;

[0045] 4) Cooling and coiling

[0046] The hot-rolled steel strip is cooled to 350°C by air mist and coiled into coils.

[0047] The thin strip of weathering steel obtained through the above steps has a thickness of 1.1mm. The mechanical performance test of the thin strip sh...

Embodiment 2

[0049] This embodiment proceeds according to the following steps:

[0050] 1) Smelting

[0051] The chemical composition of molten steel is: C: 0.17%, Si: 0.66%, Mn: 0.55%, P: 0.06%, S: 0.003%, N: 0.002%, Cu: 1.20%, Cr: 1.10%, Ni: 0.03%, Nb: 0.11%, V: 0.07 and the rest are Fe and unavoidable impurities;

[0052] 2) Thin strip continuous casting

[0053]The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 2.0mm through a pair of counter-rotating copper casting rolls, and the superheating degree of the molten steel is 32°C;

[0054] 3) On-line hot rolling of cast strip

[0055] The reduction in hot rolling is 45%, and the temperature after strip rolling is 1015°C;

[0056] 4) Cooling and coiling

[0057] The hot-rolled strip is cooled to 410°C by air mist and coiled into coils.

[0058] The thin strip of weathering steel obtained through the above steps has a thickness of 1.1mm. The mechanical performance test of the thin st...

Embodiment 3

[0060] This embodiment proceeds according to the following steps:

[0061] 1) Smelting

[0062] The chemical composition of molten steel is: C: 0.22%, Si: 0.47%, Mn: 0.35%, P: 0.04%, S: 0.002%, N: 0.003%, Cu: 0.70%, Cr: 0.90%, Ni: 0.05%, Nb: 0.90%, V: 0.18%, the rest is Fe and unavoidable impurities;

[0063] 2) Thin strip continuous casting

[0064] The molten steel qualified for smelting is continuously cast into a casting strip with a thickness of 2.1mm through a pair of counter-rotating copper casting rolls, and the superheating degree of the molten steel is 49°C;

[0065] 3) On-line hot rolling of cast strip

[0066] The reduction in hot rolling is 33%, and the temperature after strip rolling is 975°C;

[0067] 4) Cooling and coiling

[0068] The hot-rolled steel strip is cooled to 380°C by air mist and coiled into coils.

[0069] The weather-resistant steel thin strip obtained through the above steps has a thickness of 1.4 mm. The mechanical performance test of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com