Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Increase the amount of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

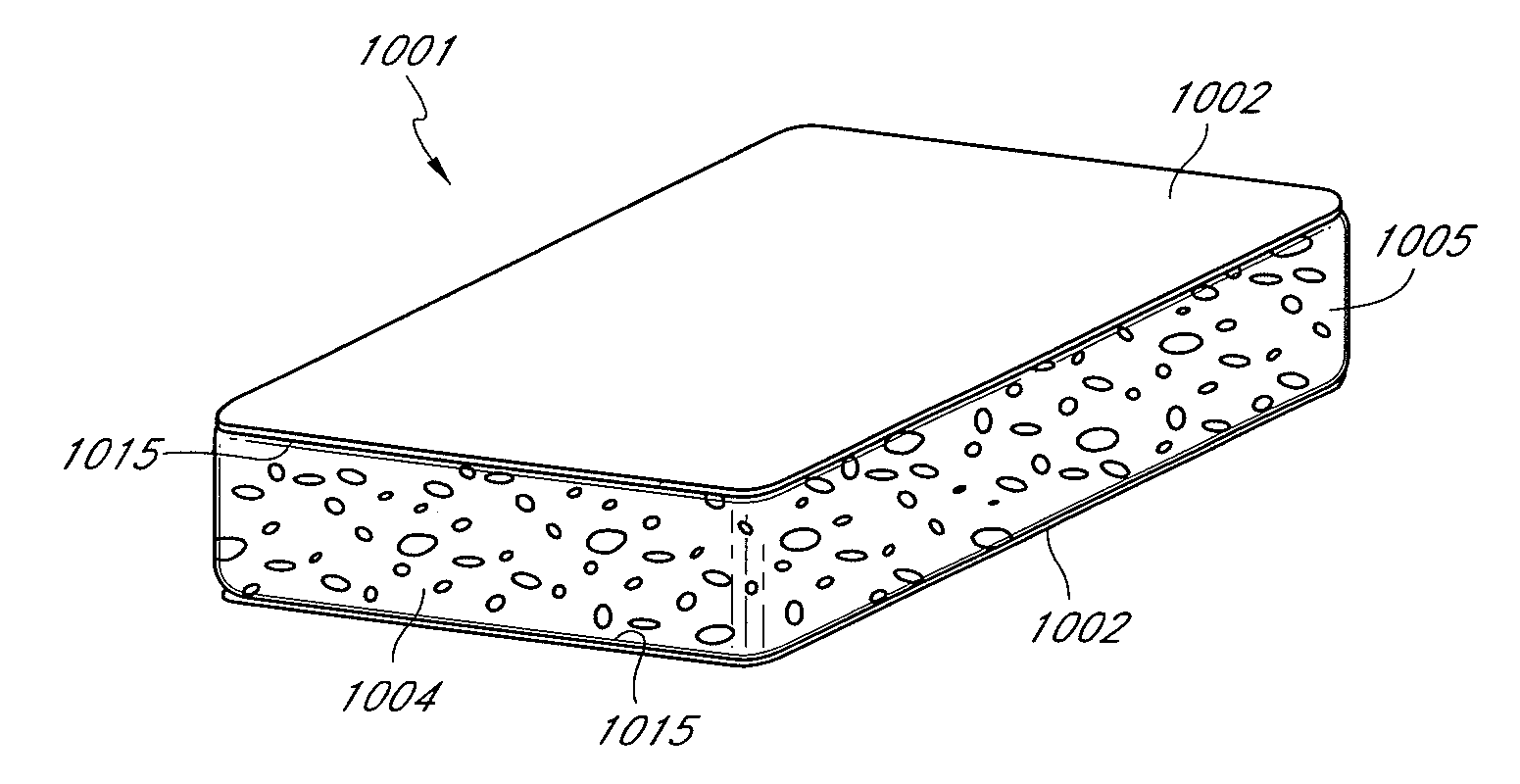

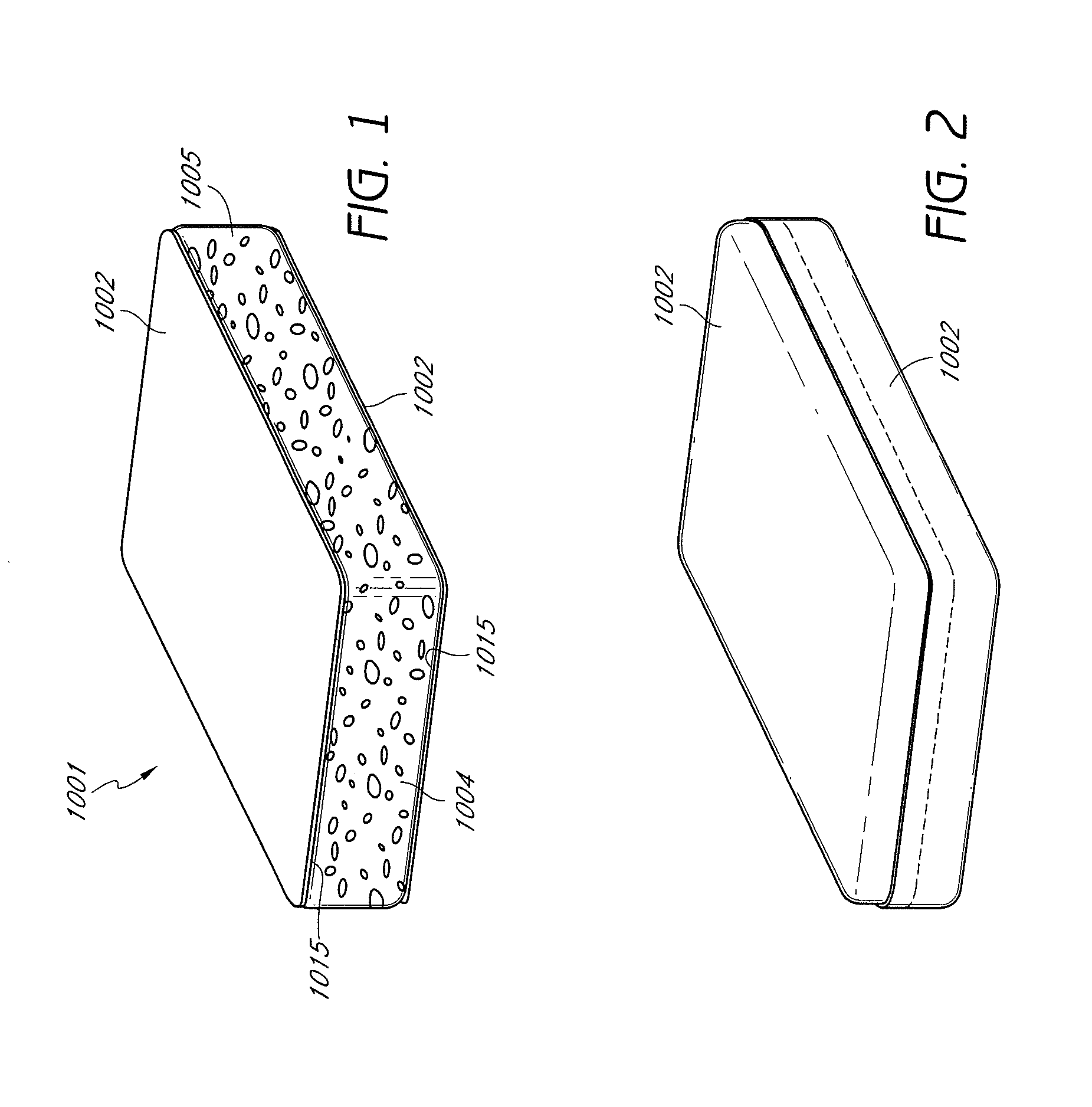

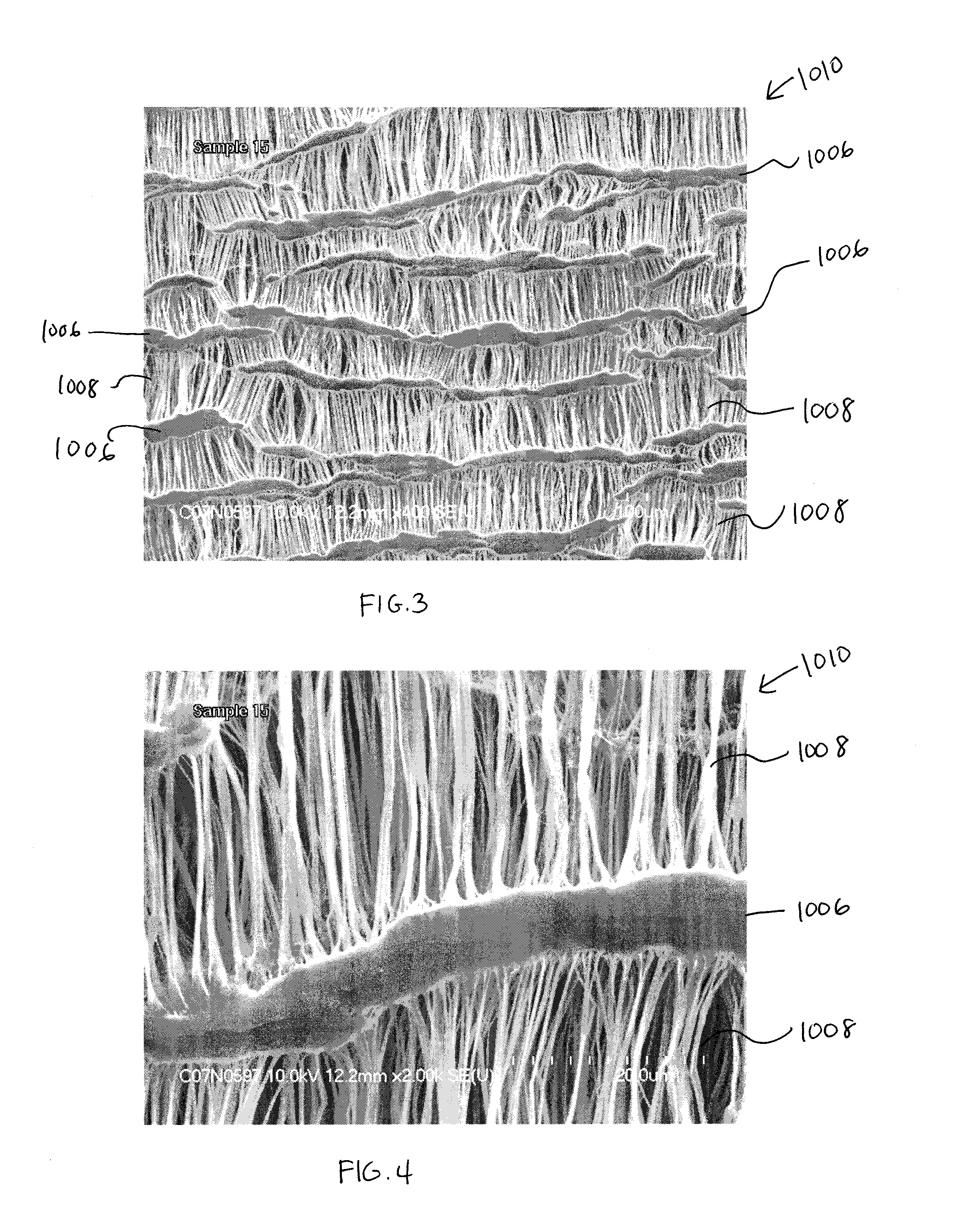

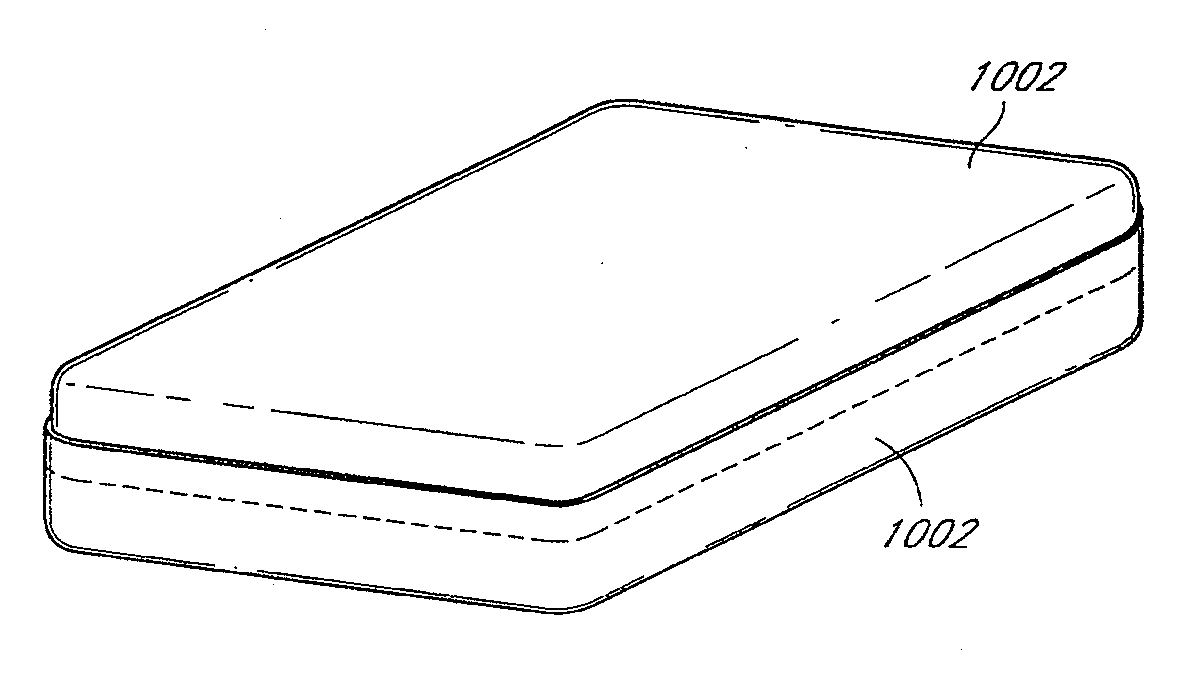

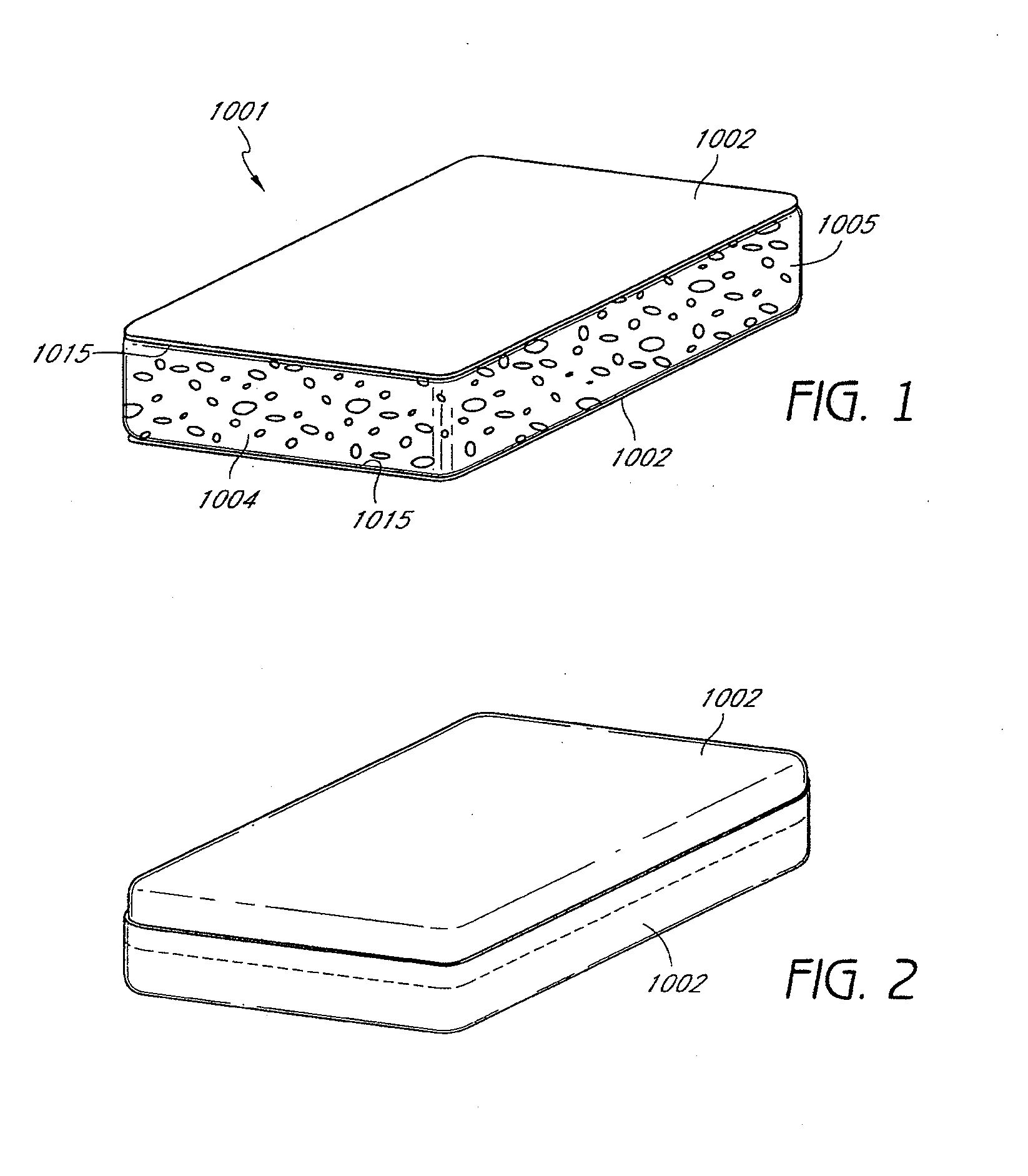

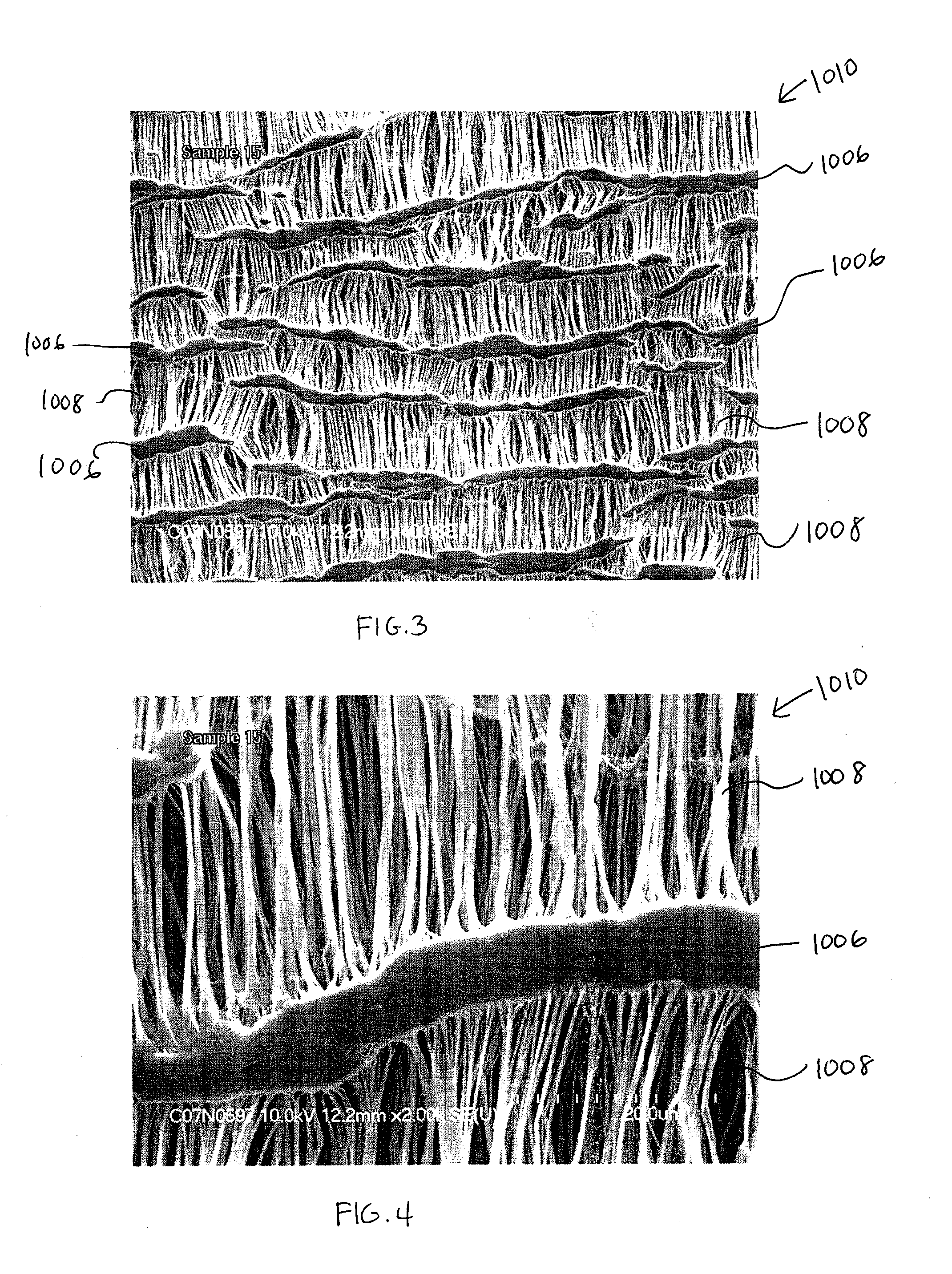

Porous implant with effective extensibility and methods of forming an implant

The implant includes an outer layer of ePTFE which exhibits extensibility normally not associated with ePTFE. The ePTFE is reduced in length by deforming the fibrils between the nodes while maintaining the nodes in a substantially flat configuration. Various implant configurations that can include the outer layer described are also disclosed.

Owner:EVERA MEDICAL

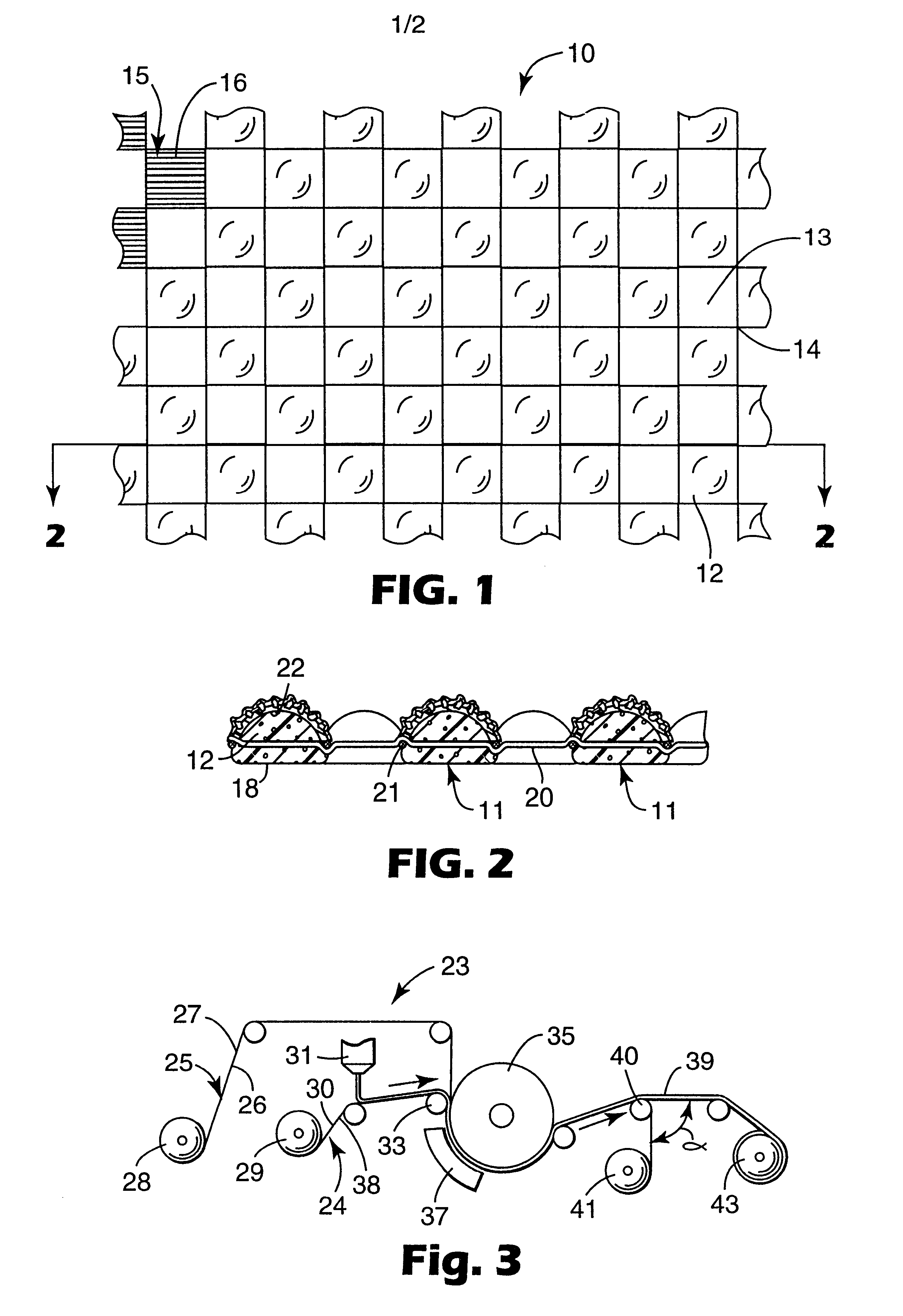

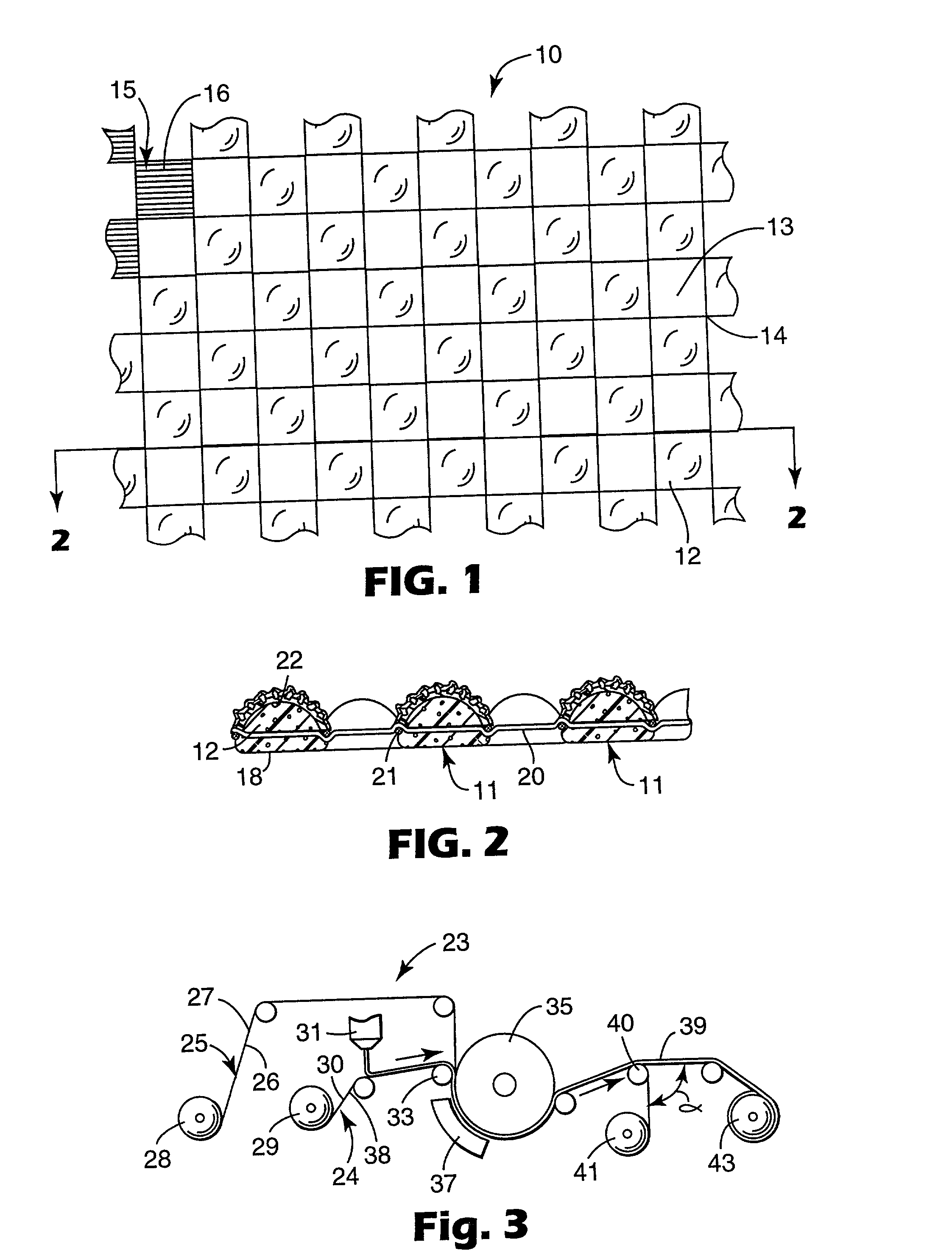

Abrasive product and method of making the same

InactiveUS6613113B2Effectively removing the sanding dust from the abrasive surfaceLess abrasive surfacePigmenting treatmentOther chemical processesElastomerMaterials science

The invention provides a flexible abrasive product comprising a flexible sheet-like substrate comprising a multiplicity of separated resilient bodies connected to each other in a generally planar array in a pattern which provides open spaces between adjacent connected bodies, each body having a first surface and an opposite second surface; and abrasive particles to cause at least the first surface to be an abrasive surface. A method of making the abrasive is provided by providing the substrate and providing abrasive particles to at least the first surface to provide an abrasive surface.

Owner:3M INNOVATIVE PROPERTIES CO

High power low RPM D.C. motor

InactiveUS6037692AIncrease motor powerHigh strengthAC motor controlAsynchronous induction motorsEngineeringConductor Coil

A high power low RPM direct current electric motor is disclosed whereby the high power output is achieved in one of two ways or both. In the first case, the need for cooling is reduced simultaneously along with an increase in the utilization of the magnetic field present in the motor permanent magnets. This is achieved by wrapping the electromagnet core with windings that are capable of demagnetizing the rotor permanent magnets under stall conditions. Interlocking motor circuitry is provided which prevents the full activation of these motor windings until motor RPM values reach a safe level. This increases motor power while decreasing resistive losses in electromagnet windings. In the second case, the rotary portion consists of a large diameter relatively flat rotor containing permanent magnets and having built in vanes for moving air over the electromagnet stator windings providing forced air cooling.

Owner:MAGNETIC MOTORS

Abrasive product and method of making the same

InactiveUS20030121212A1Effectively removing the sanding dust from the abrasive surfaceLess abrasive surfacePigmenting treatmentOther chemical processesElastomerMaterials science

The invention provides a flexible abrasive product comprising a flexible sheet-like substrate comprising a multiplicity of separated resilient bodies connected to each other in a generally planar array in a pattern which provides open spaces between adjacent connected bodies, each body having a first surface and an opposite second surface; and abrasive particles to cause at least the first surface to be an abrasive surface. A method of making the abrasive is provided by providing the substrate and providing abrasive particles to at least the first surface to provide an abrasive surface.

Owner:3M INNOVATIVE PROPERTIES CO

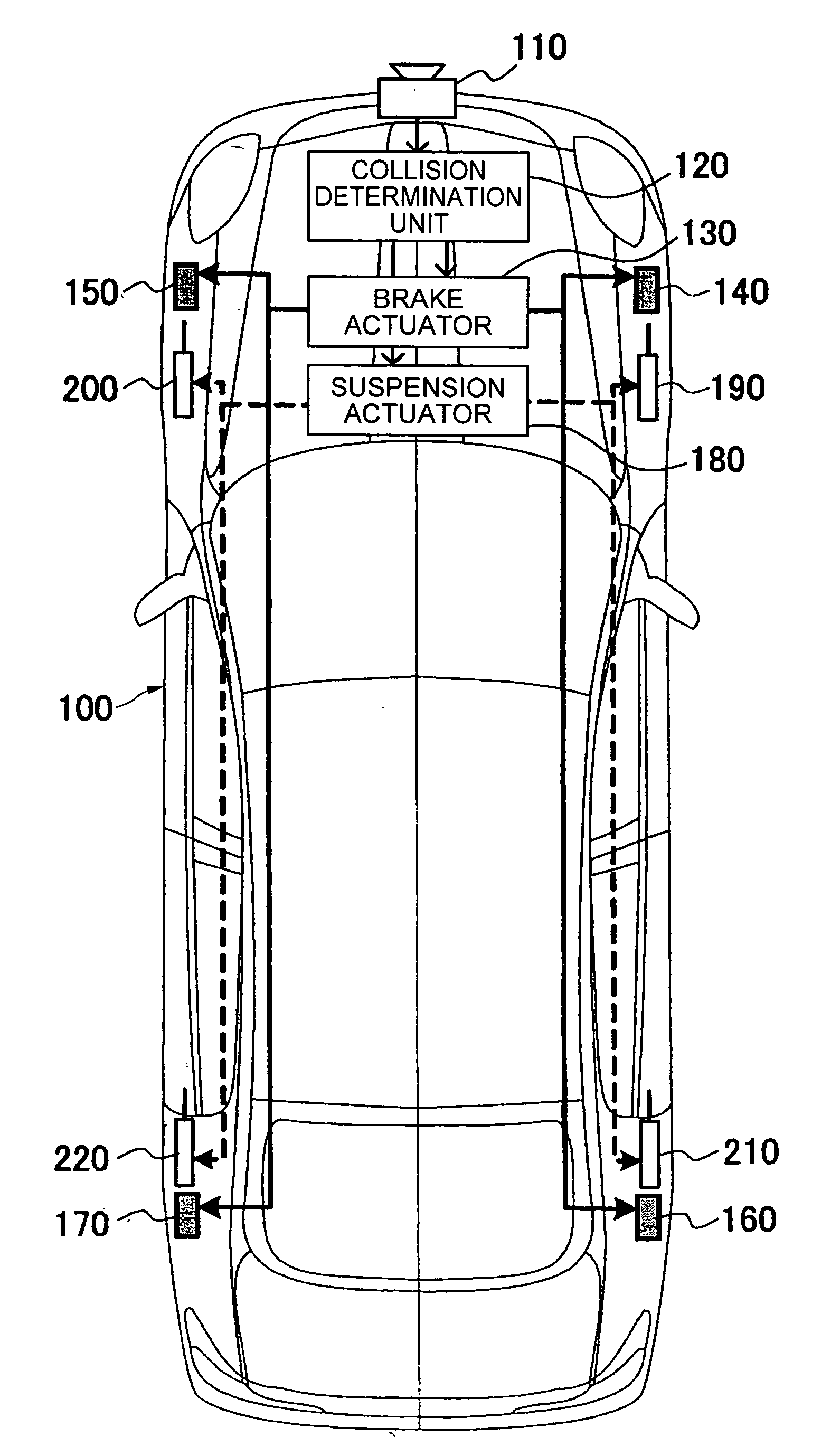

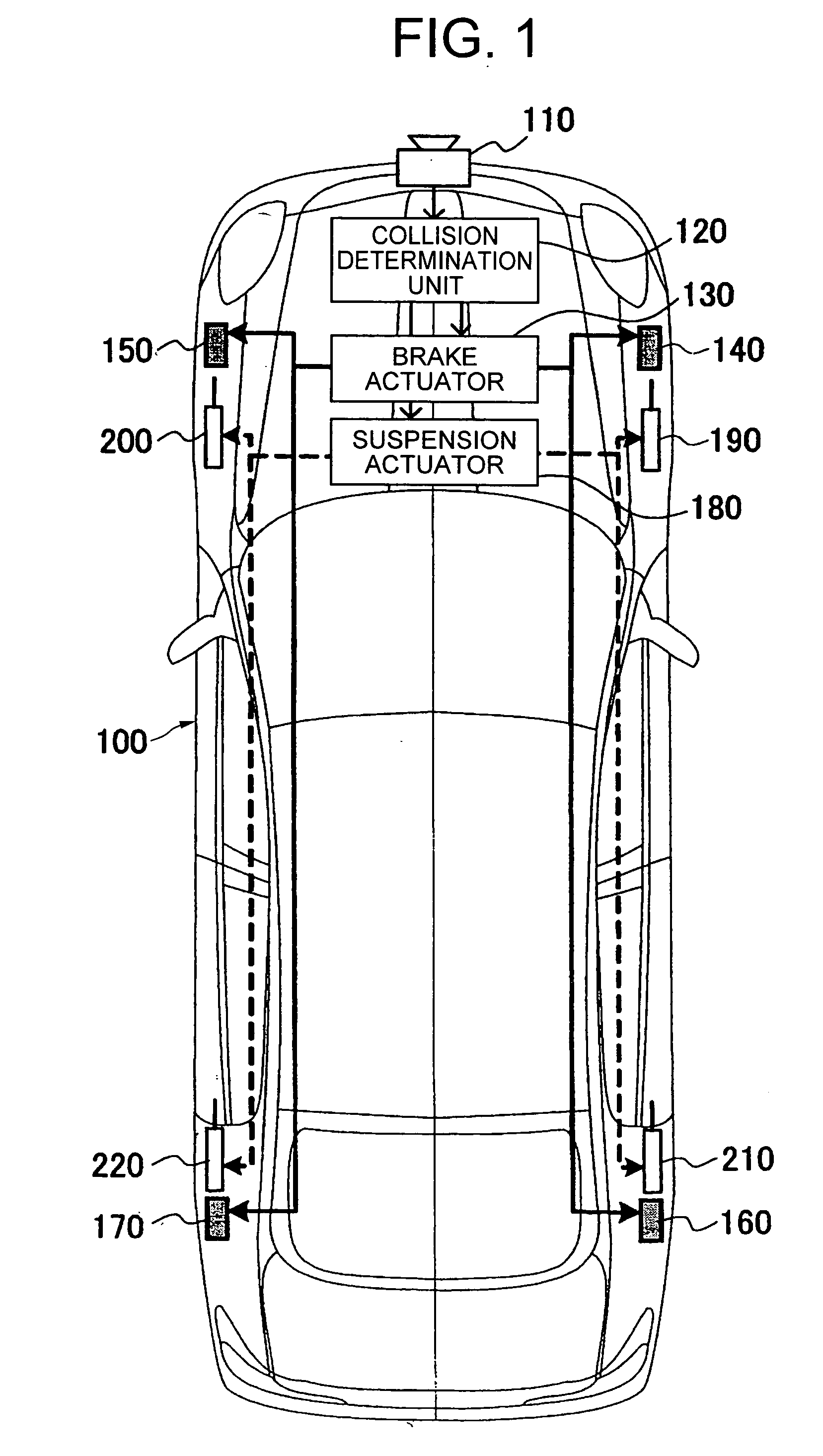

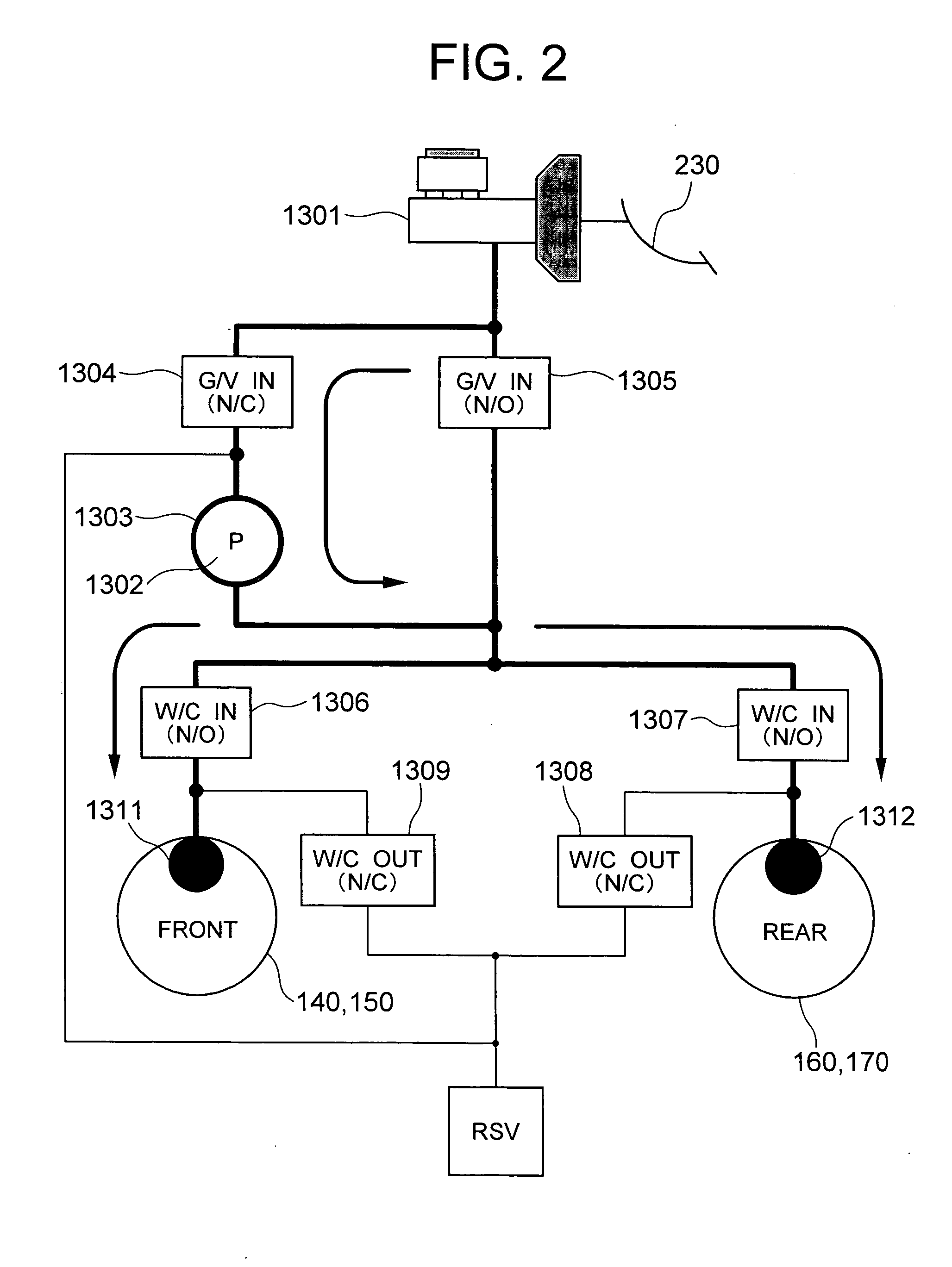

Vehicle safety control apparatus for avoiding collision

InactiveUS20070192030A1Improve friction forceShorten braking distanceDigital data processing detailsAnimal undercarriagesWheel loadEstimation result

A collision between a vehicle and an obstacle is estimated, and based on the estimation result, vehicle deceleration control is performed by a brake actuator to reduce the collision and vehicle wheel load is controlled by a suspension actuator.

Owner:HITACHI LTD

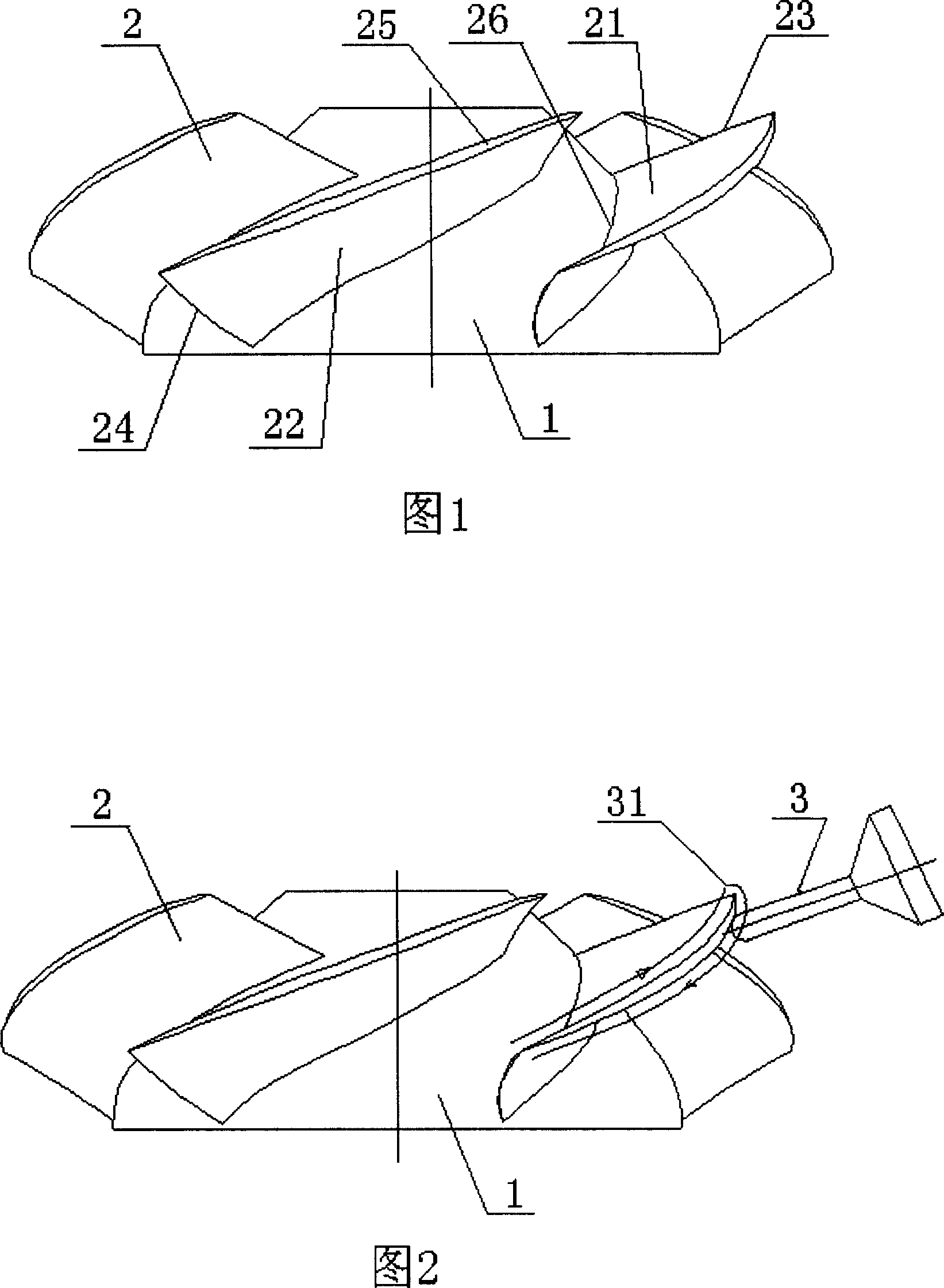

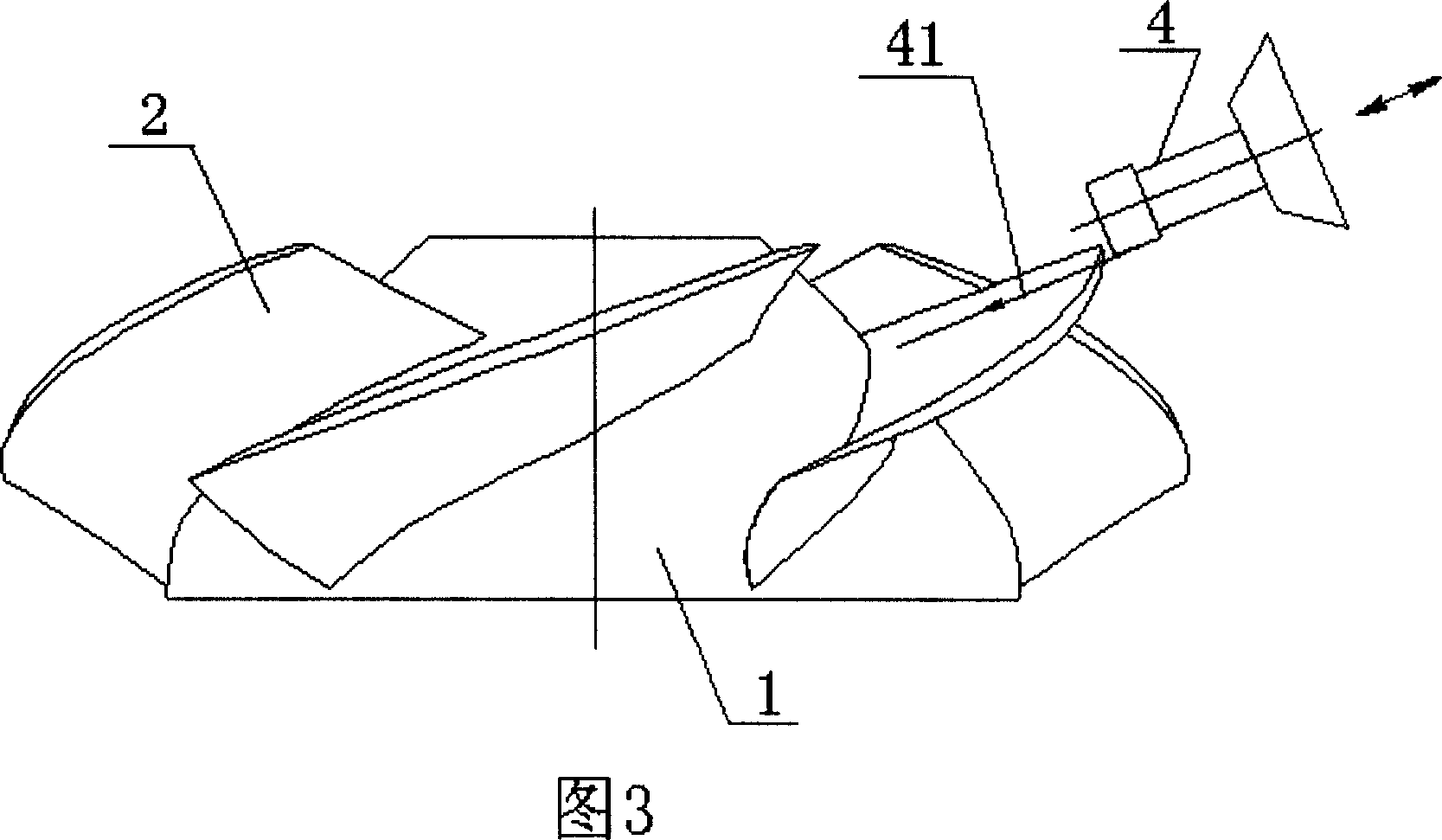

Slotting and milling process for vane of integral vane wheel

InactiveCN1986127ASmall radial componentSmall amount of deformationMilling cuttersImpellerNumerical control

The slotting and milling cutter process for vane of integral vane wheel is completed in a numerically controlled machine tool with slotting and milling cutter advancing in the radial direction of the vane wheel and axial direction of the cutter. It has small radial force component caused by cutting, less vibration of the workpiece and the cutter, smooth cutting, small and controllable vane deformation, high machining quality and high machining efficiency. The present invention can meet the requirement of machining great diameter and high precision vane wheel product.

Owner:WUHAN MARINE MACHINERY PLANT

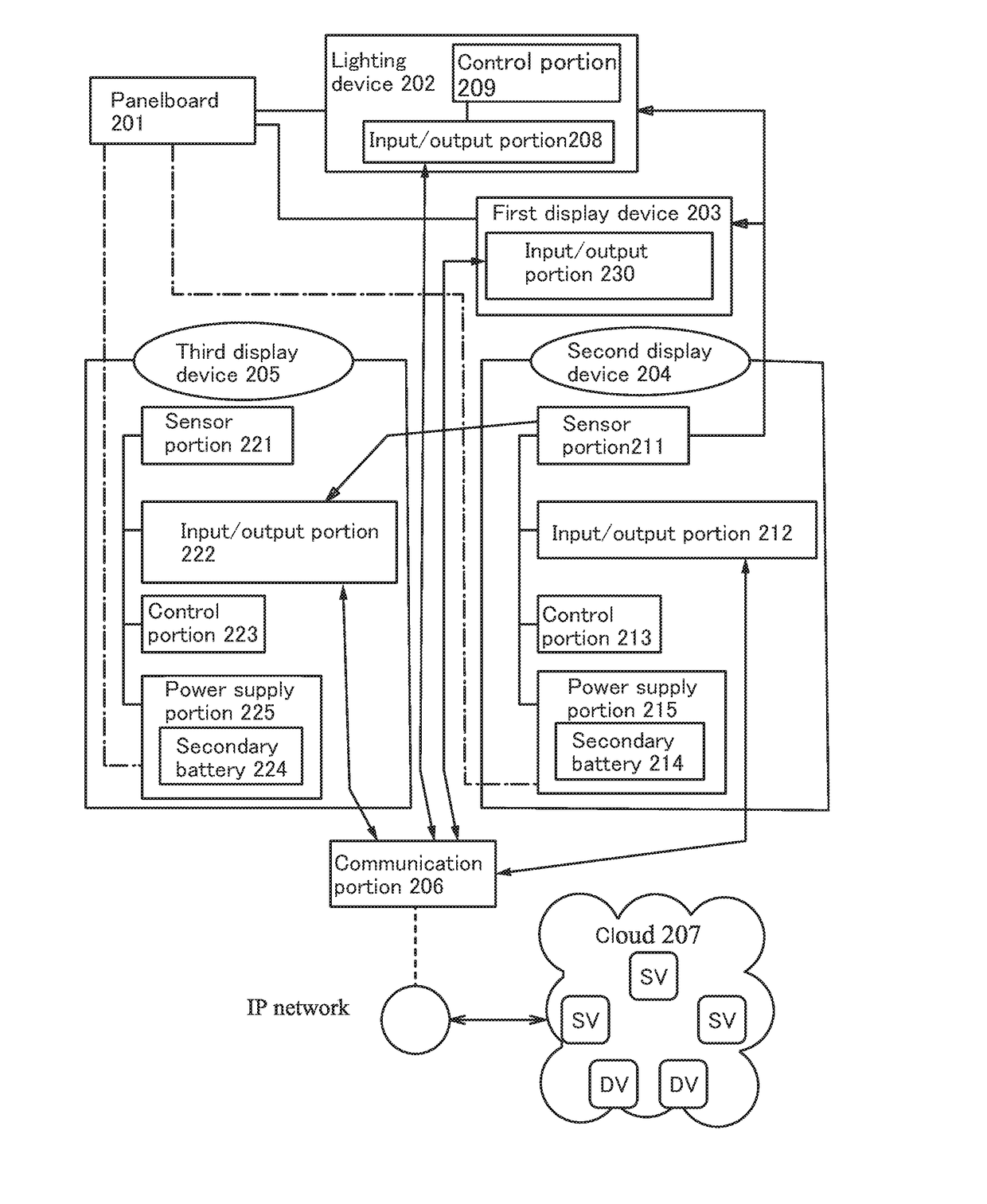

Electronic device, display device, method for manufacturing the same, and system including a plurality of display devices

ActiveUS20170092230A1Reduce harmReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceElectric devices

A power saving system using a plurality of flexible display devices placed on various places is provided. A structure of a bendable portion in a display device is improved. Specifically, a wiring partly including a metal nanoparticle is used. Openings are formed in an insulating layer so that the wiring becomes substantially longer by meandering in cross section. When a plurality of openings are formed and aligned, a portion that is easy to bend is formed along the line where they are aligned. A plurality of display panels are used for one display portion. The flexible display portion can be provided on a surface, specifically, a curved surface of furniture such as a chair or a sofa.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing A1-Mg-Si series alloy plate excellent in thermal conductivity and intensity

InactiveUS20020174923A1Improve thermal conductivityImprove cutting effectThermal conductivityAluminium

An Al-Mg-Si series alloy ingot consisting essentially of Si:0.2-0.8 wt %, Mg:0.3-0.9 wt %, Fe:0.35 wt % or less, Cu:0.20 wt % or less and the balance of aluminum and inevitable impurities is prepared. The alloy ingot is homogenized, then subjected to rough hot rolling and finish hot rolling, and finally to cold rolling. One of the rough hot rolling is controlled such that material temperature immediately before one of the rough hot rolling is from 350 to 440° C., cooling rate between one of the rough hot rolling and rough hot rolling subsequent thereto is 50° C. / min or more, material temperature immediately after one of the rough hot rolling is from 250 to 340° C. and plate thickness immediately after one of the rough hot rolling is 10 mm or less. The cold rolling is controlled such that rolling reduction is 30% or more.

Owner:SHOWA DENKO KK

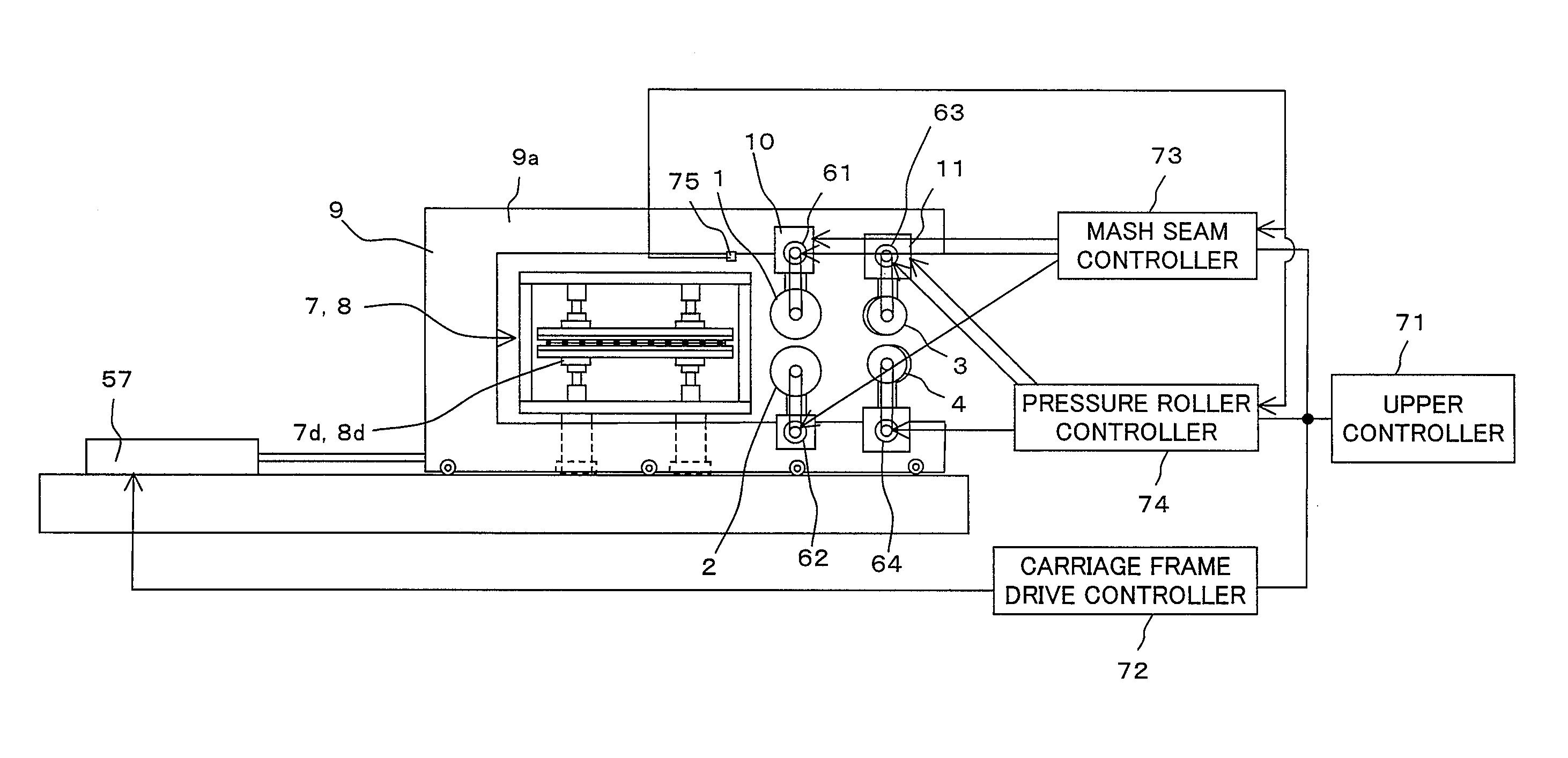

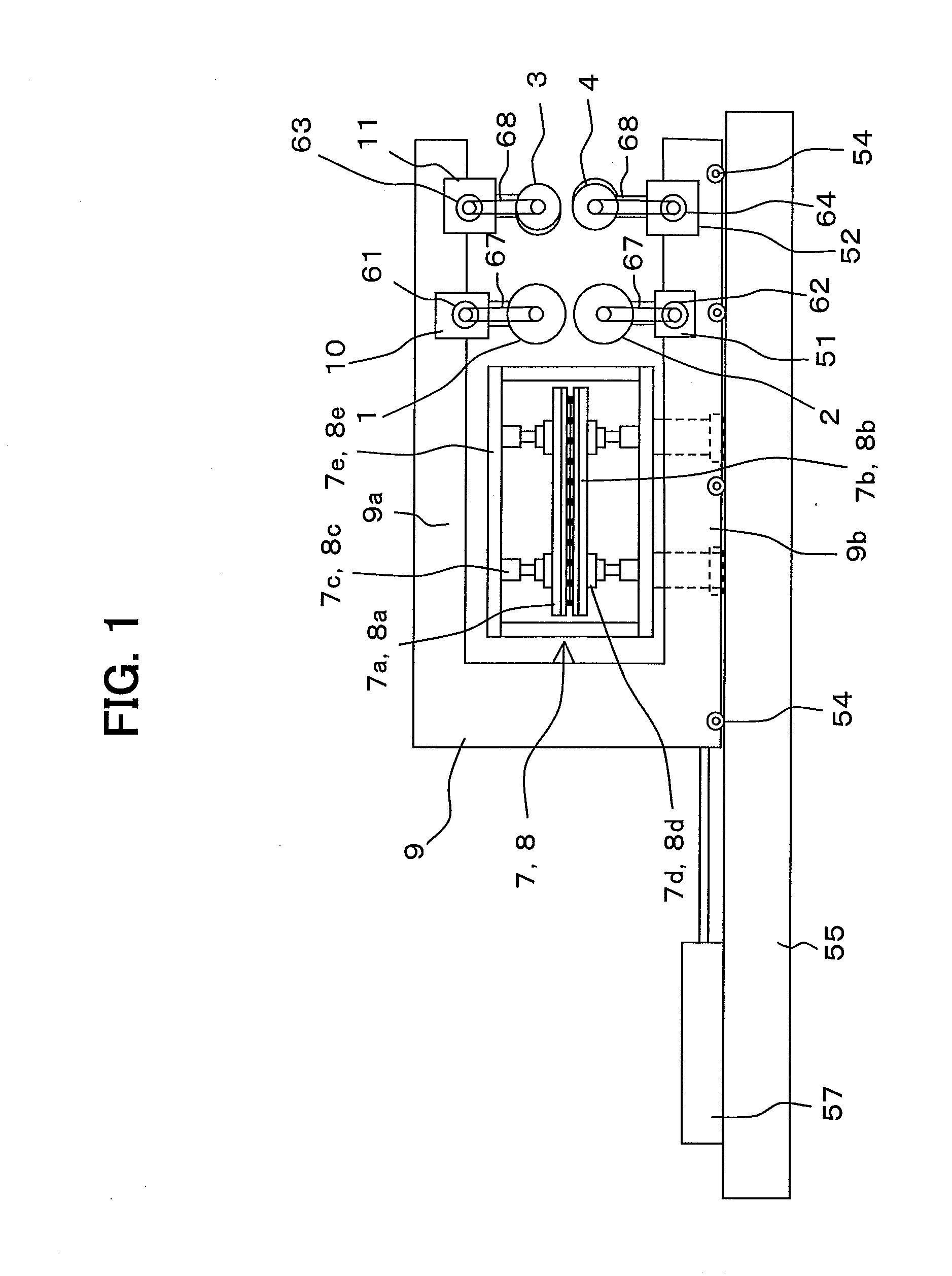

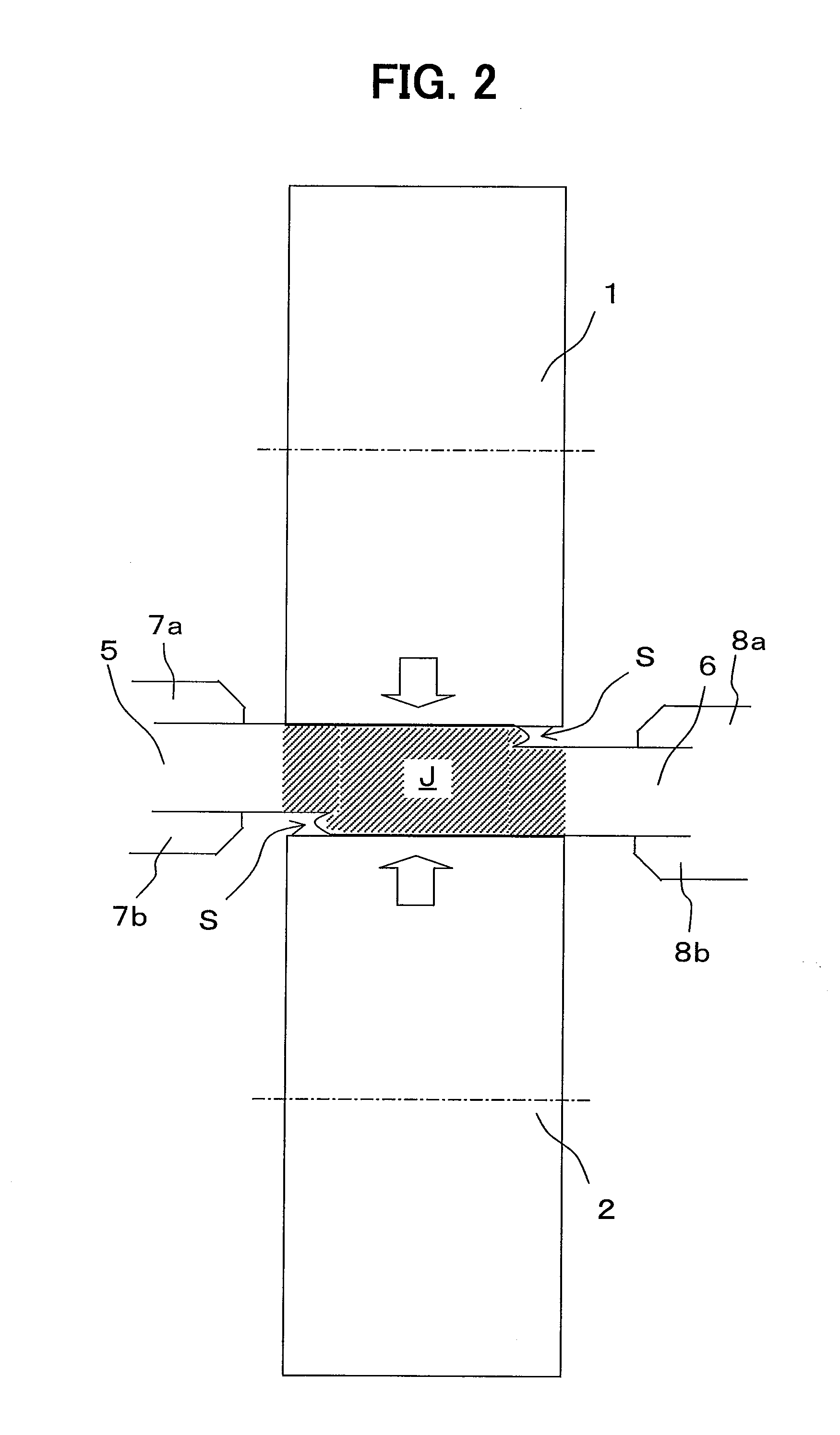

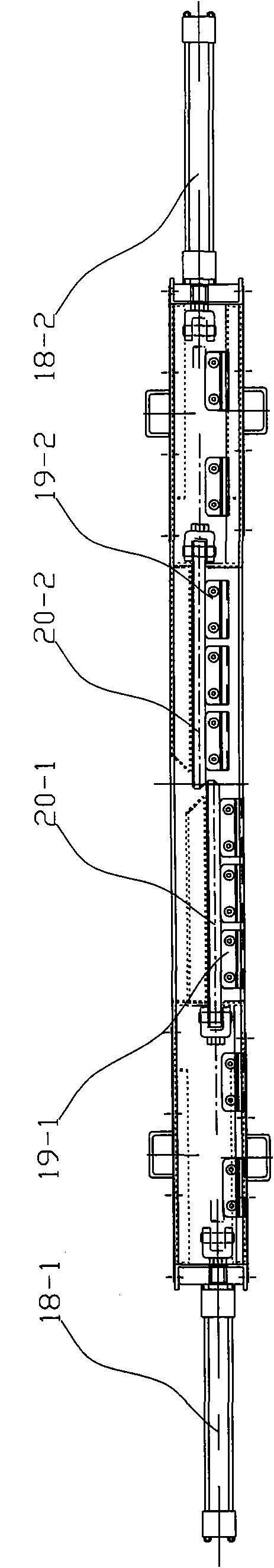

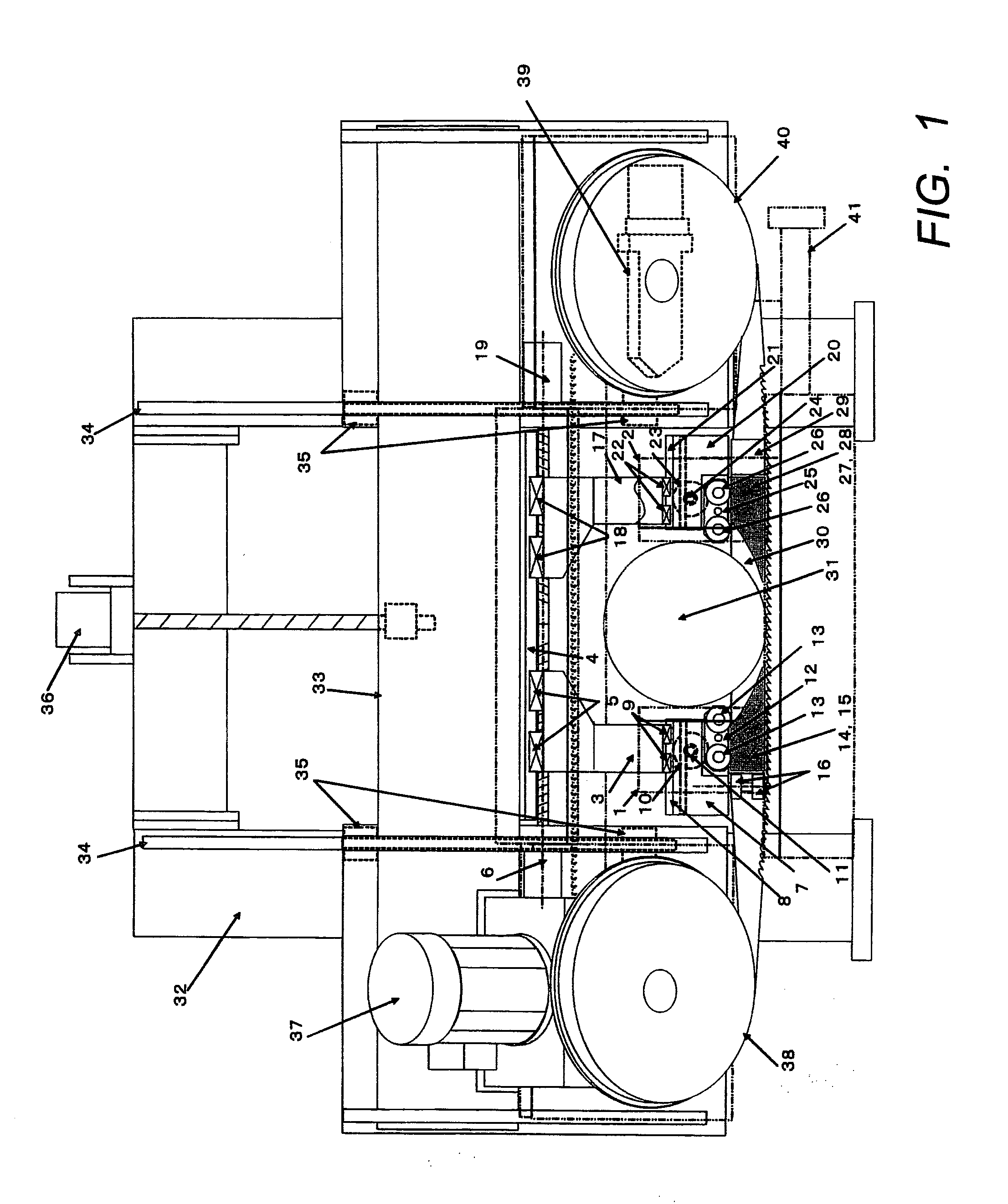

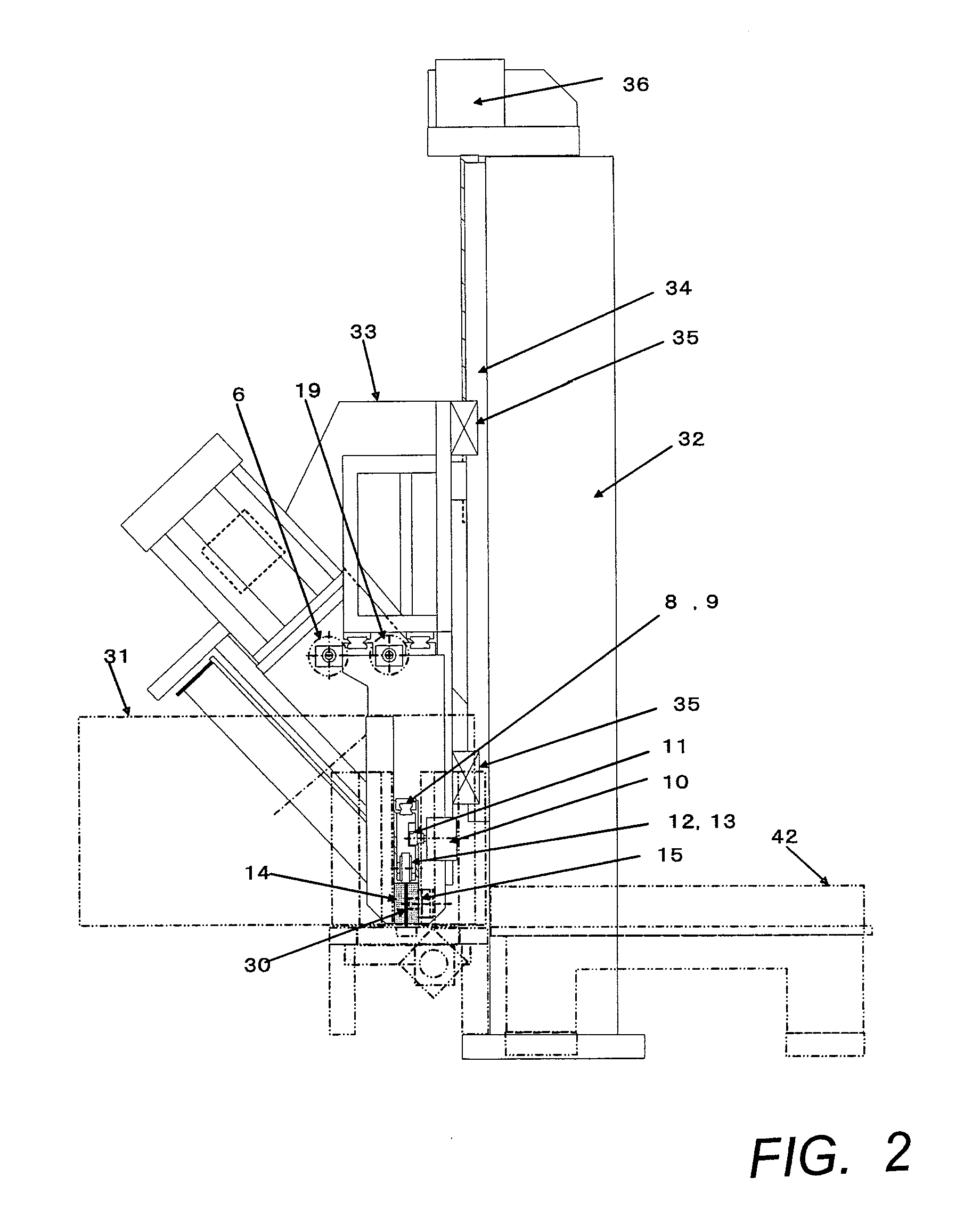

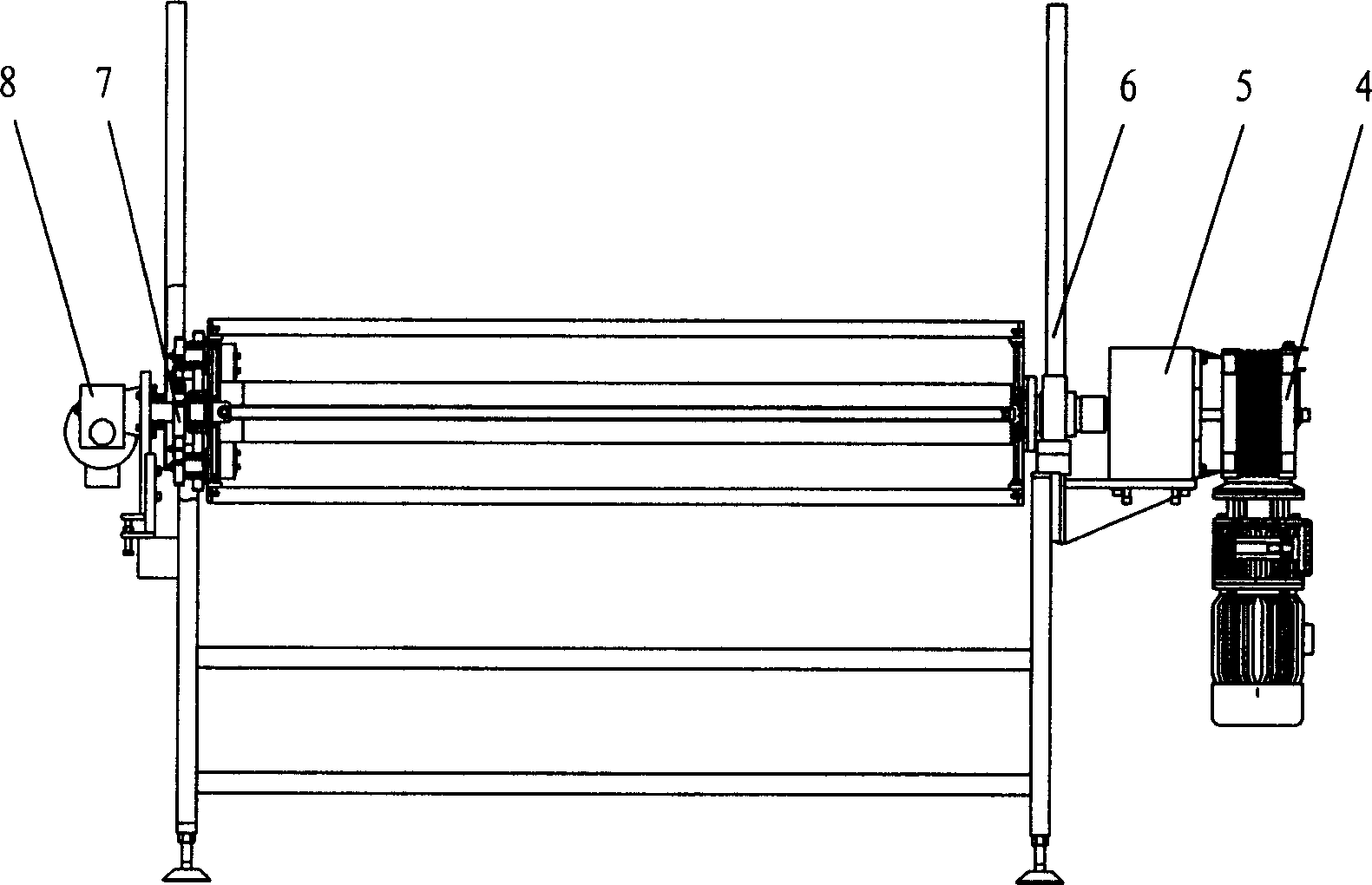

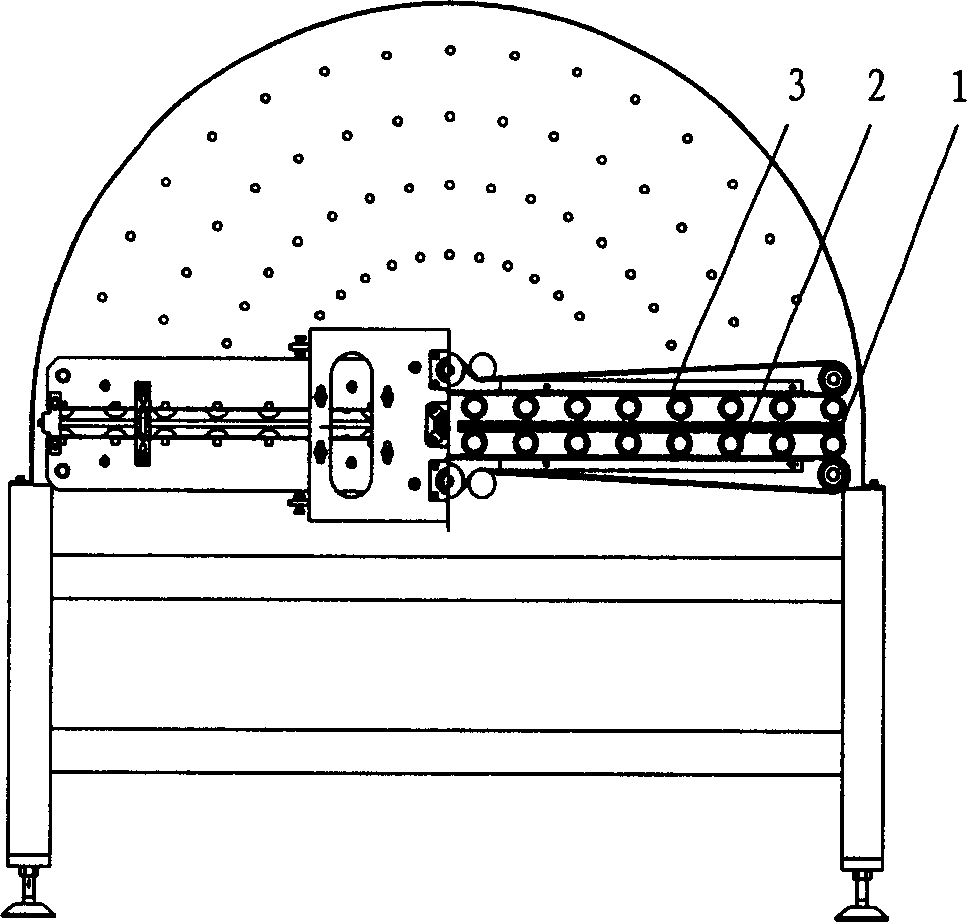

Metal plate joining method and apparatus

ActiveUS20110163074A1High degreeIncrease the amount of cuttingWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMetal

A pair of upper and lower pressure rollers 3, 4 is disposed so that their axes 15, 16 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line perpendicular to a welding line of a joint portion J. The pressure rollers 3, 4 are positively driven by corresponding electric motors 63, 64 to thereby roll the joint portion. Thus, steps defined at the joint portion can be smoothed and a step gradient can be reduced to ensure a high degree of joint strength.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

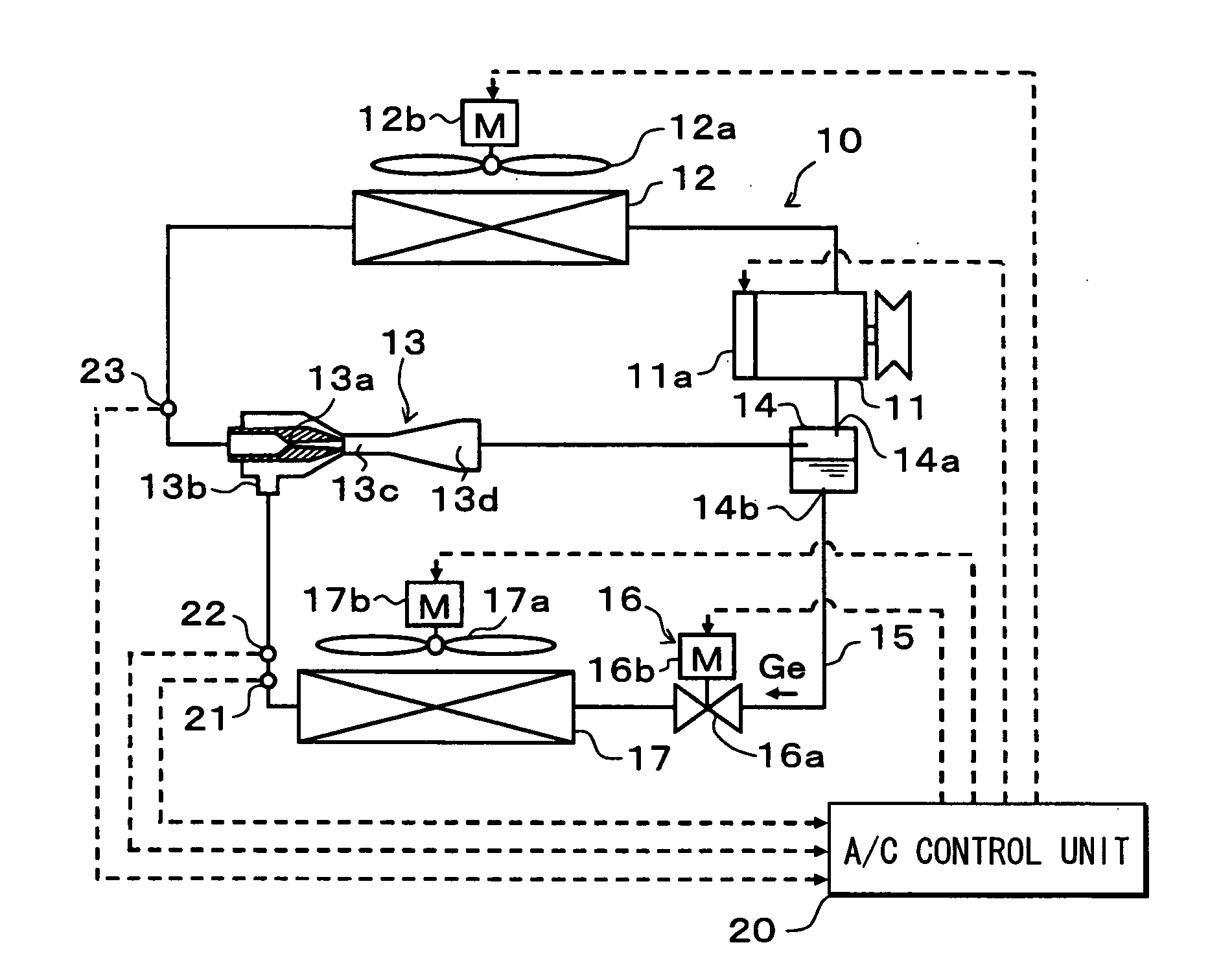

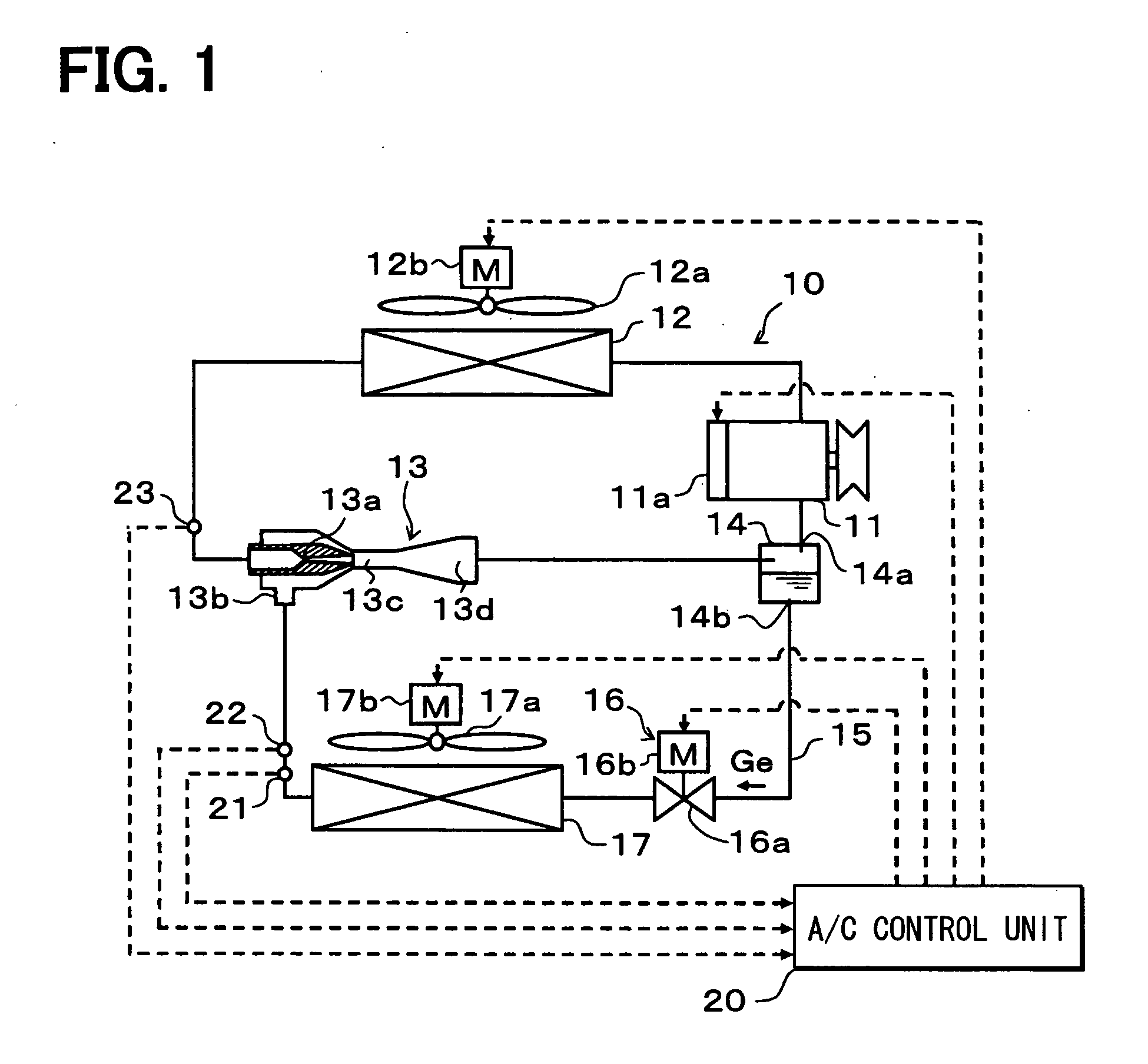

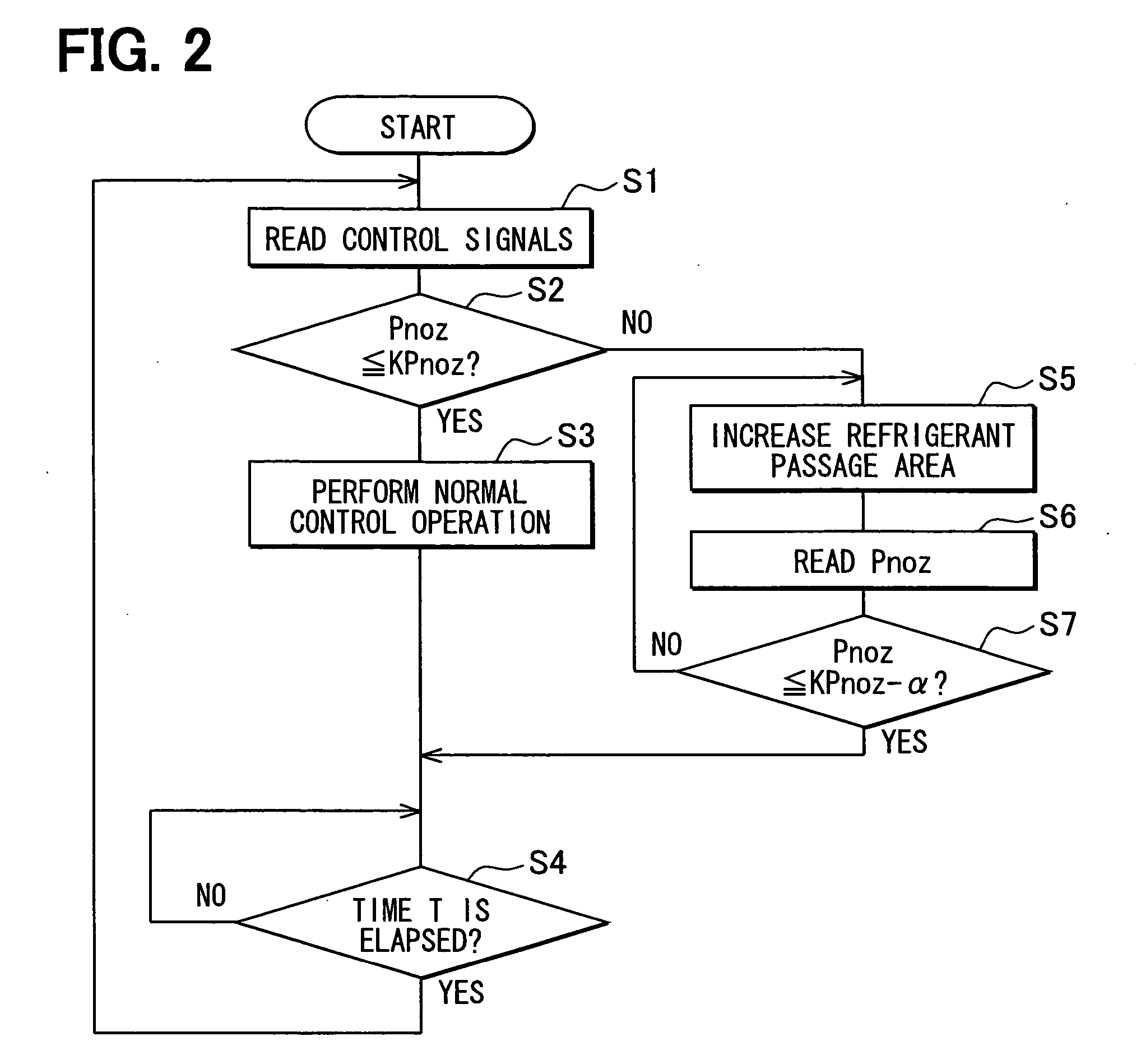

Ejector refrigerant cycle device and control method thereof

InactiveUS20070180852A1Relieve stressShorten speedCompression machines with non-reversible cycleVehicle heating/cooling devicesHigh pressureRefrigerant

An ejector refrigerant cycle device includes an ejector that has a nozzle portion for reducing pressure of refrigerant on a downstream side of a radiator to expand the refrigerant, and a refrigerant suction port from which refrigerant is drawn by a high-velocity refrigerant flow jetted from the nozzle portion, an evaporator that evaporates refrigerant and flows out the evaporated refrigerant to the refrigerant suction port, a flow amount changing unit that changes a refrigerant flow amount flowing into the evaporator, and a pressure abnormality detecting portion for detecting a pressure abnormality of a high-pressure refrigerant on an upstream side of the nozzle portion. In the ejector refrigerant cycle device, when the pressure abnormality detecting portion detects the pressure abnormality, the flow amount changing unit makes the refrigerant flow amount flowing into the evaporator larger than that in a normal pressure state of the high-pressure refrigerant.

Owner:DENSO CORP

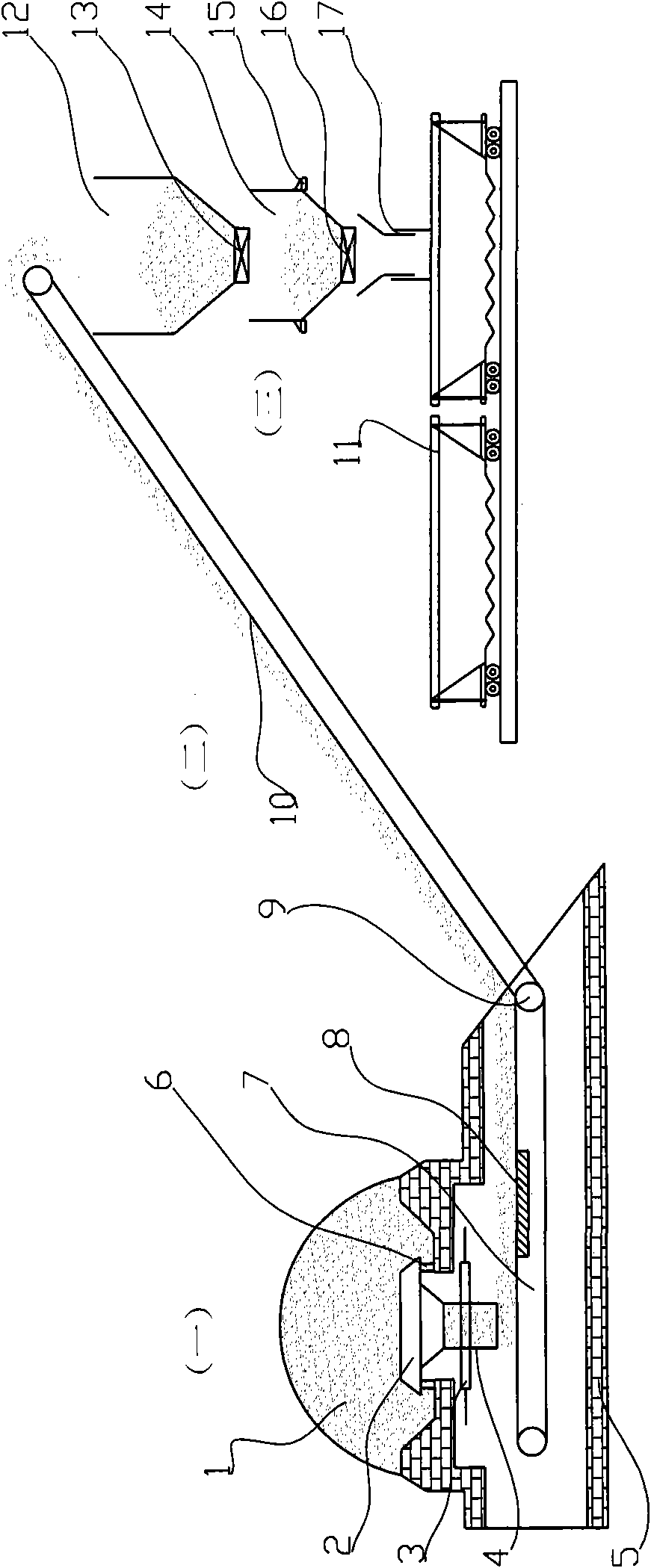

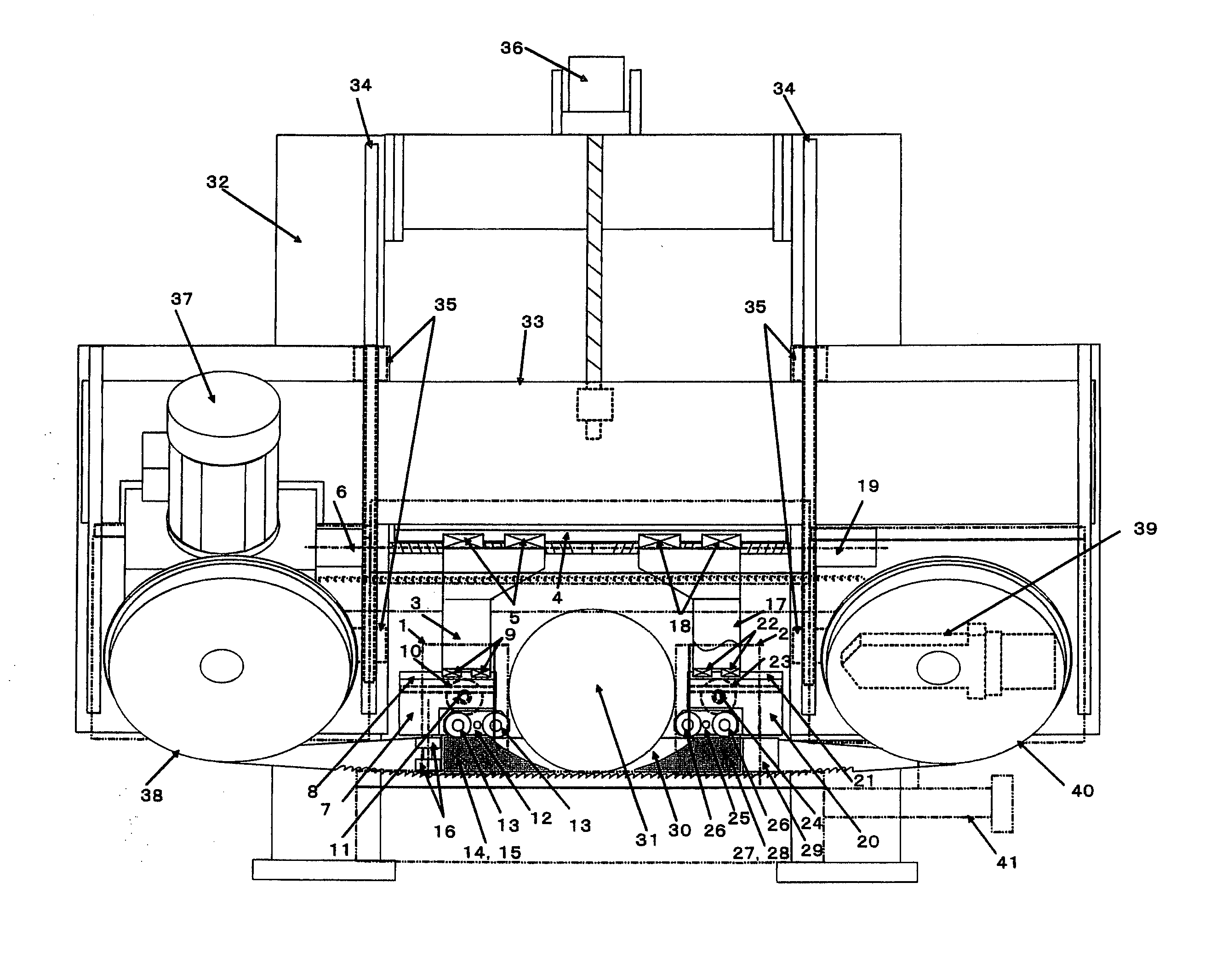

Method and system for transporting and loading bulk materials in storage yard

ActiveCN101786553ANo splashHigh measurement accuracyWeighing apparatus for continuous material flowLoading/unloadingTransport systemUnderground tunnel

The invention particularly relates to a method and a system for transporting and loading bulk materials in a storage yard, which are suitable for bulk material accurate loading of railways, public roads and ships. The invention comprises a storage yard transporting system, a belt transport system and an accurate and rapid quantitative loading system. The invention provides an economical and effective transporting and loading system for bulk materials in a storage yard, which has the following advantages: 1) the storage yard transport system combing a disc vibrating feeder with a low clearance flow control gate is adopted, thus greatly lowering the upper height of an underground tunnel and improving the capability of transporting the materials in the storage yard; 2) the accurate and rapid quantitative loading system is adopted, thus having the characteristics of rapid loading speed, high loading precision and high automation degree; and 3) a four-roller belt weigher is adopted, thus realizing the linkage of the storage yard transport system, the belt transport system and the accurate and rapid quantitative loading system effectively and greatly improving the operation efficiency of the system.

Owner:BIRTLEY TIANJIN IND EQUIP

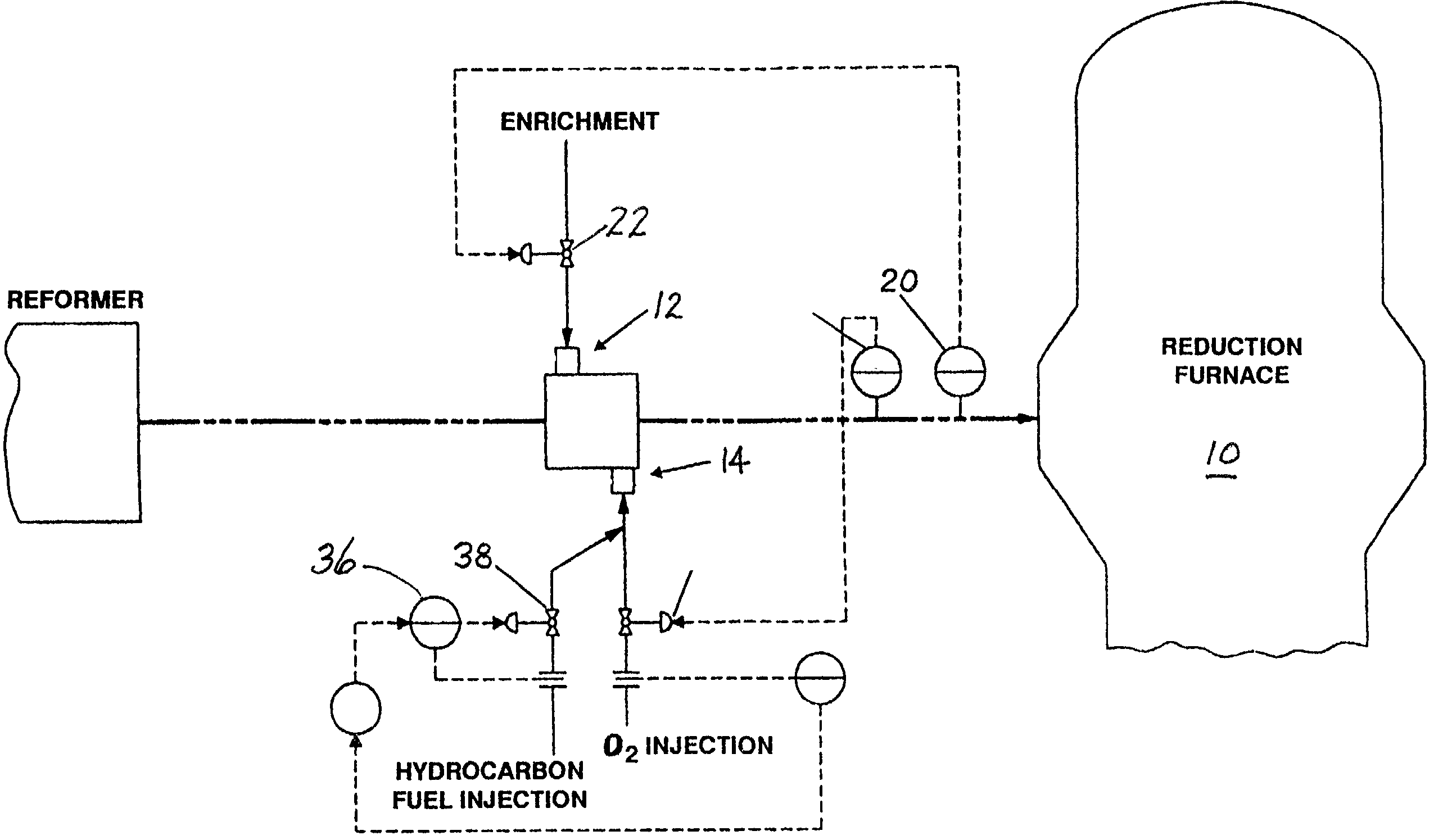

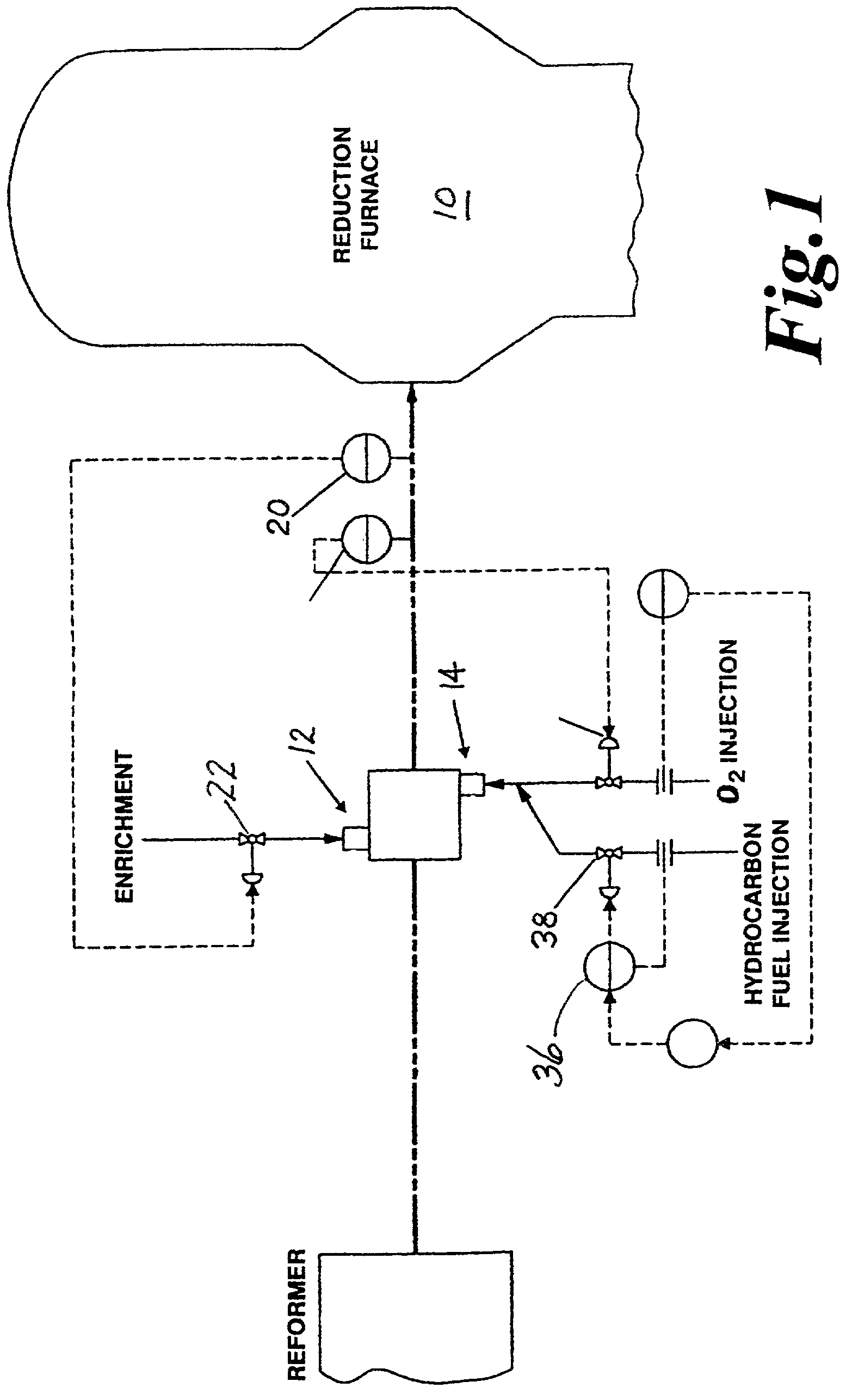

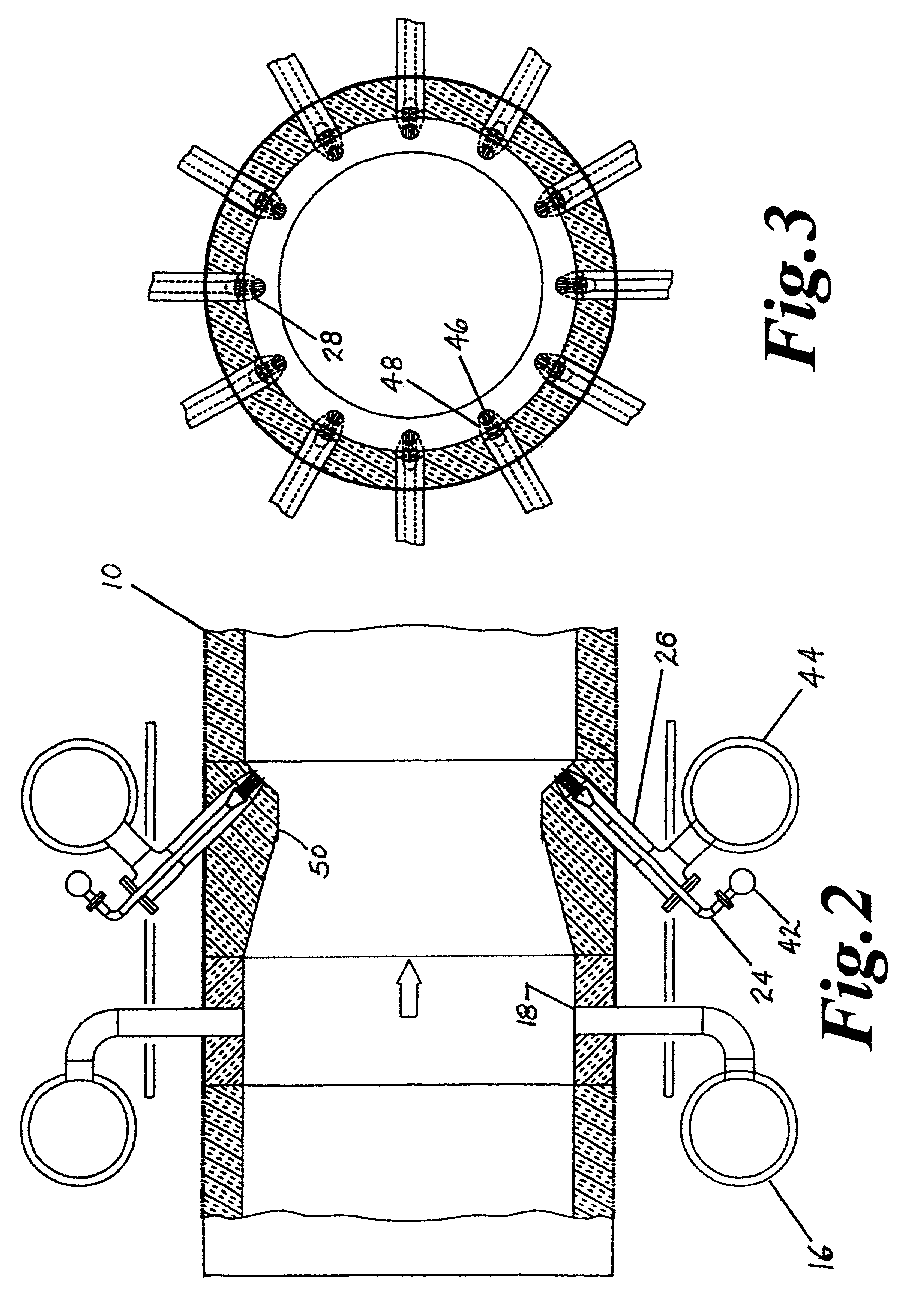

Apparatus and method for optimizing the use of oxygen in the direct reduction of iron

InactiveUS20020007699A1Increase volumeQuality improvementHydrogenChemical industryHydrogen contentProcess engineering

An apparatus and method for adjusting the parameters of a reducing gas stream prior to introduction into a direct reduction furnace, such parameters including temperature of the gas stream, and amount of hydrocarbon, carbon monoxide, and hydrogen contained in the reducing gas. The apparatus is placed in-line with the reducing gas recycle loop of a direct reduction furnace, which has an enrichment section which introduces hydrocarbon components to the main stream, and an oxygen / fuel injection system, located downstream from the enrichment section, which injects a shrouded stream of oxygen and hydrocarbon gas into the reducing gas stream. Temperature, carbon monoxide content, and hydrogen content of the reducing gas are adjusted by controlling the flow of oxygen and the ratio of hydrocarbon to oxygen injected in the oxygen / fuel injection system. Hydrocarbon content of the reducing gas is adjusted primarily by controlling the flow rate of the enrichment section.

Owner:MIDREX TECH INC

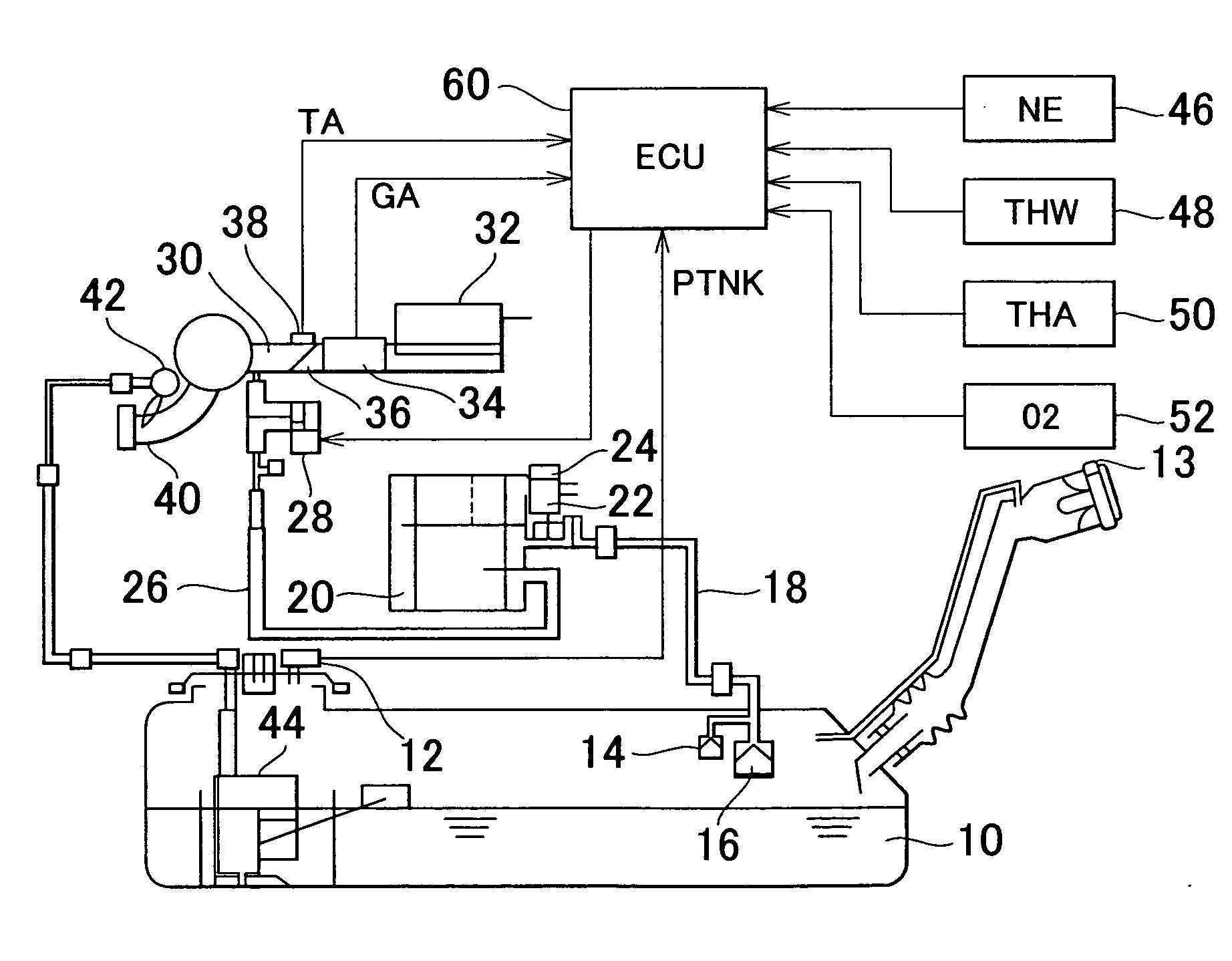

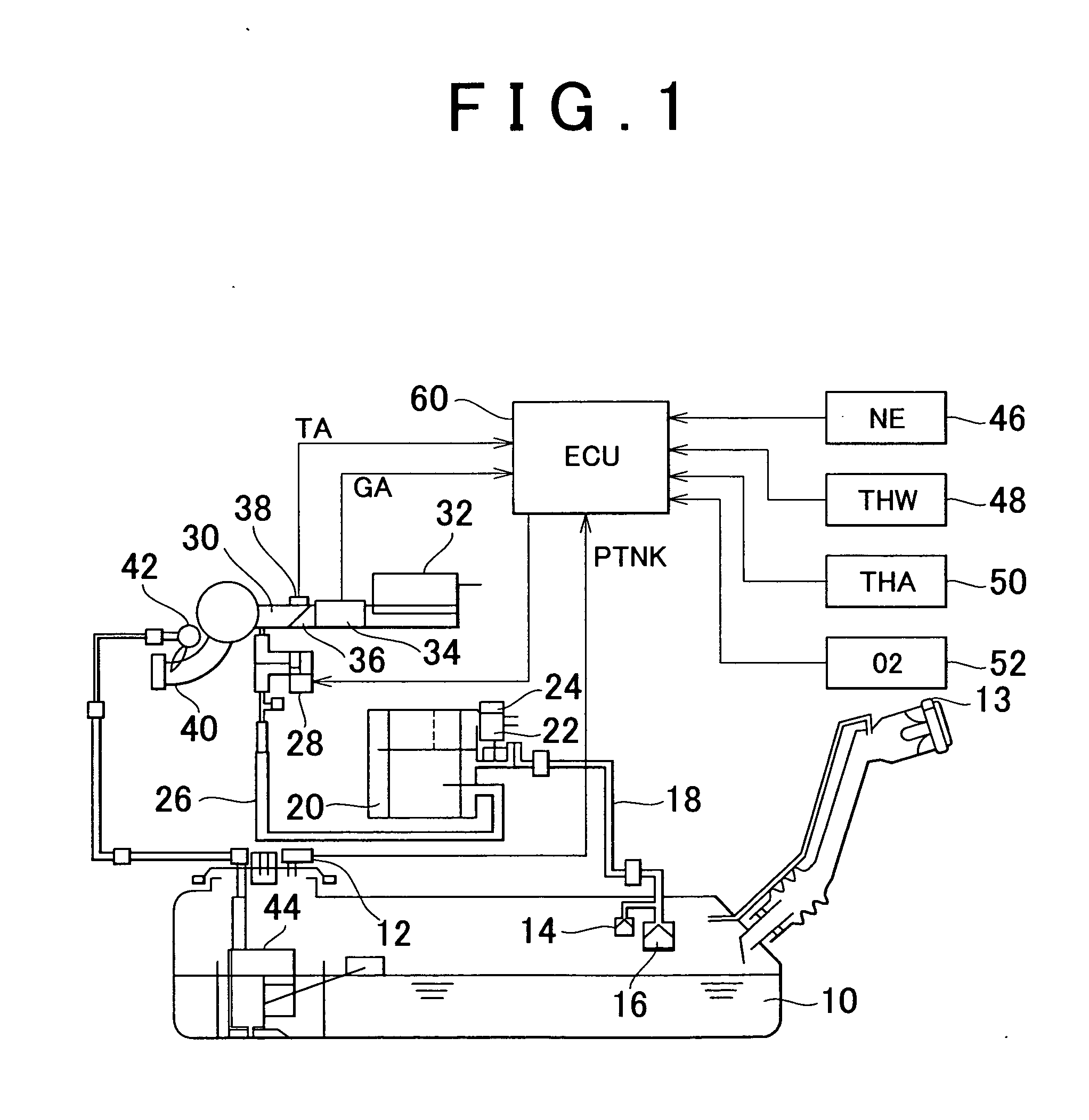

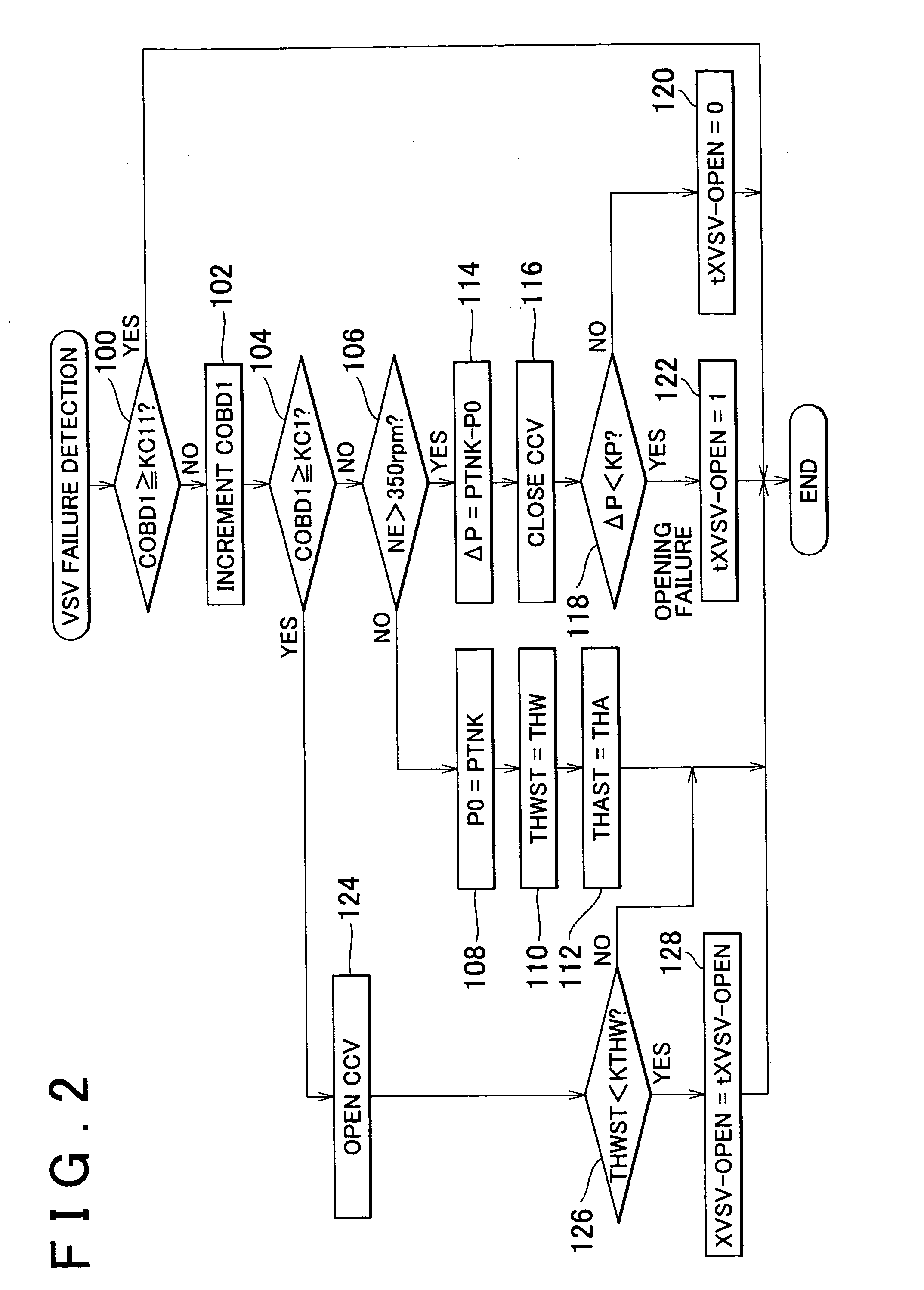

Evaporative emission control system

InactiveUS20040261765A1Improved air-fuel ratio controlEasy to controlElectrical controlNon-fuel substance addition to fuelControl systemEngineering

An evaporative emission control system detects an opening failure of a purge control valve that controls the amount of purge gas flowing from a canister into an intake passage of the engine, and determines whether a significant shift occurs in an air / fuel ratio feedback factor when the opening failure is detected. If the air / fuel ratio feedback factor is shifted to the rich side, a rich-side initial value is set to a vapor concentration learned value, and, if the feedback factor is shifted to the lean side, a lean-side initial value is set to the vapor concentration learned value. These initial values give larger changes to the vapor concentration learned value than update amounts by which the learned value is updated during normal learning control.

Owner:TOYOTA JIDOSHA KK

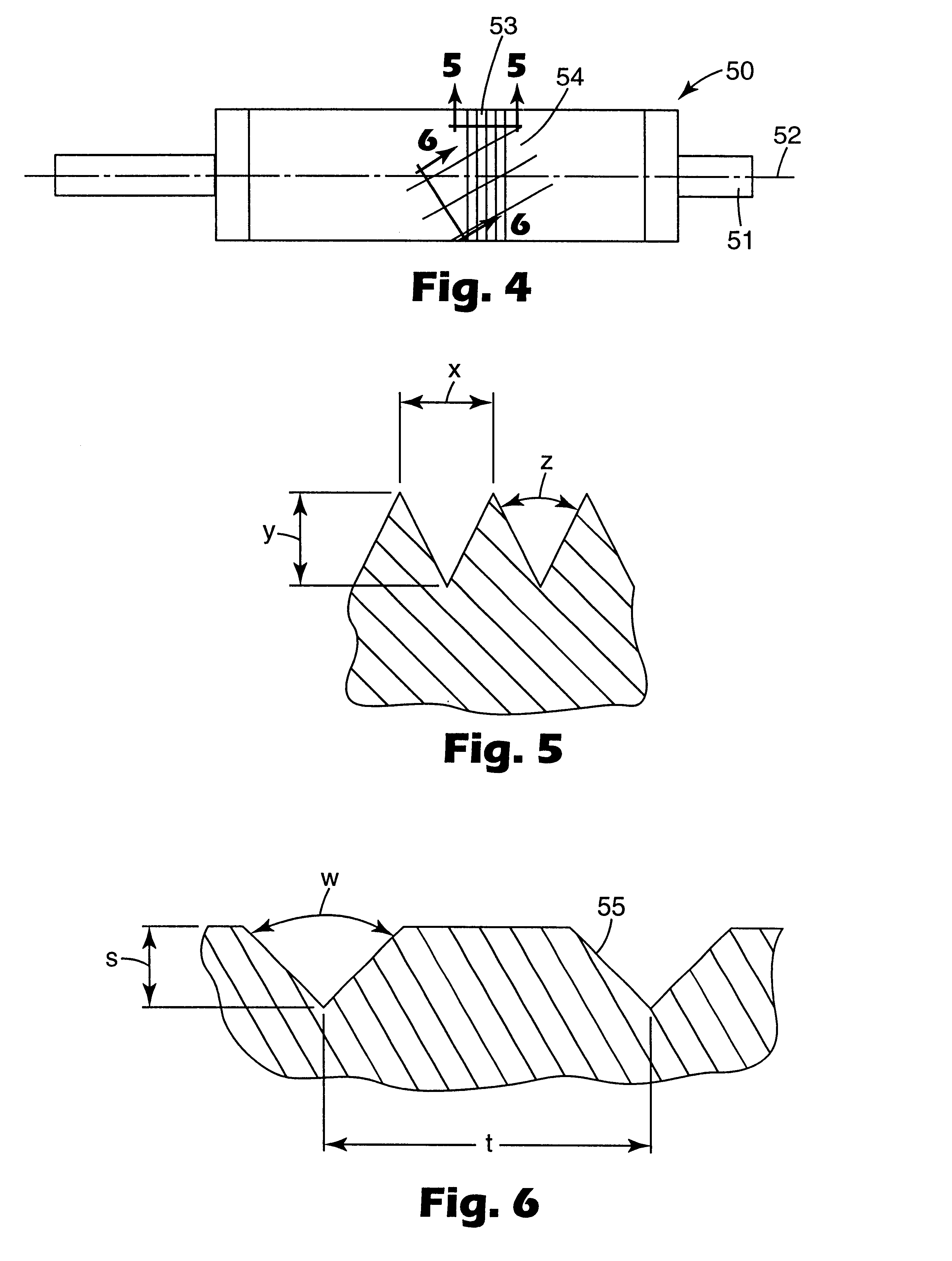

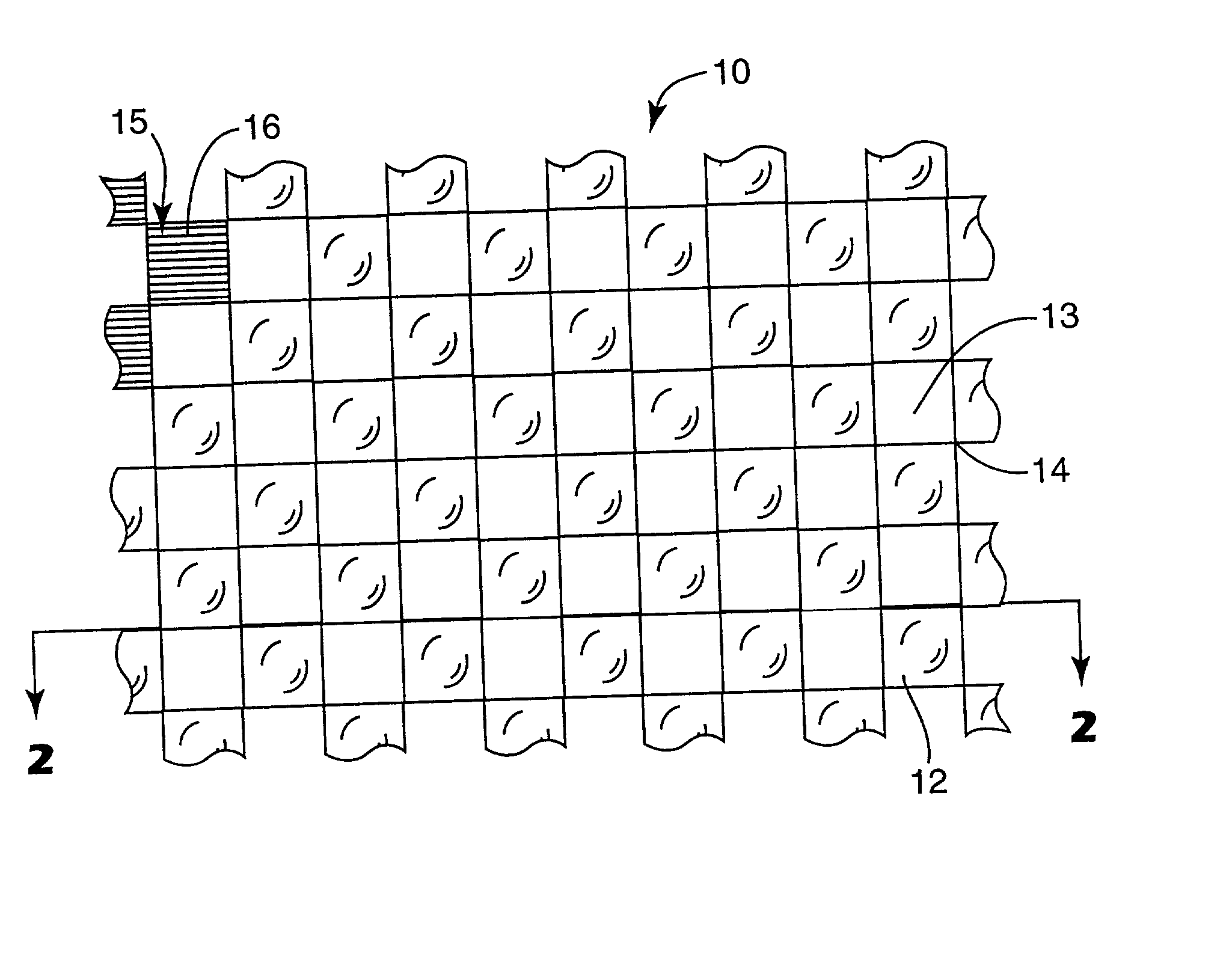

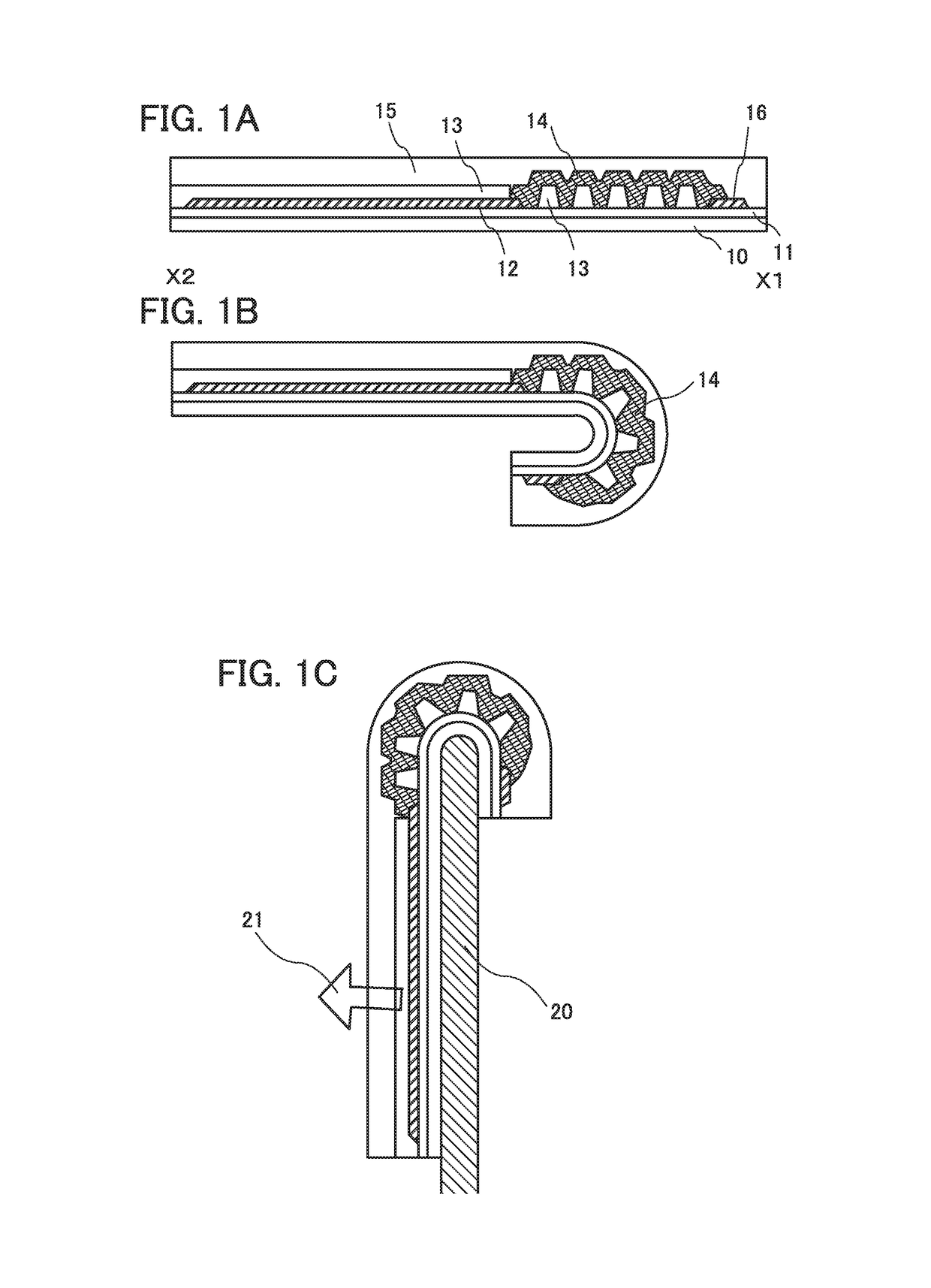

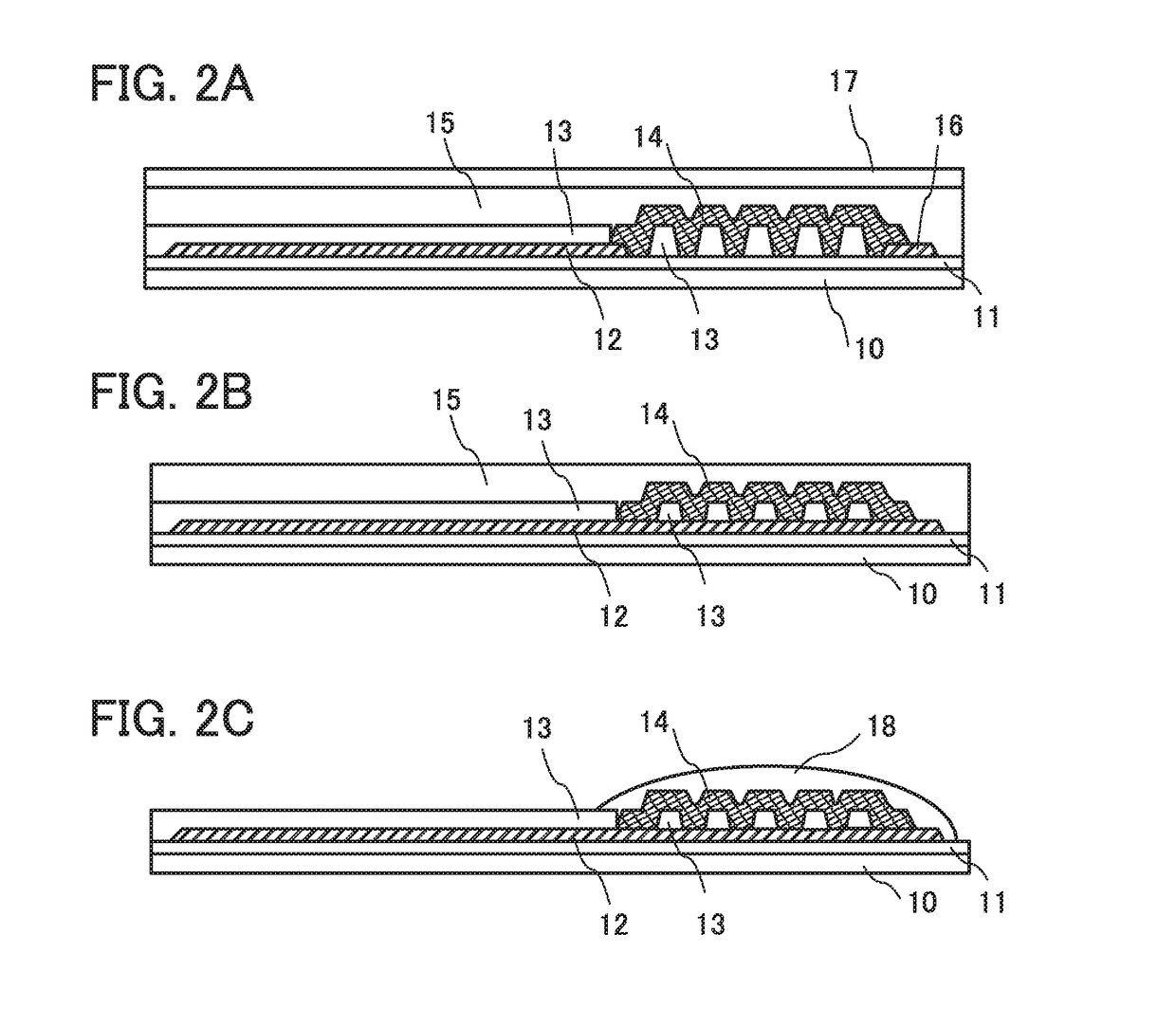

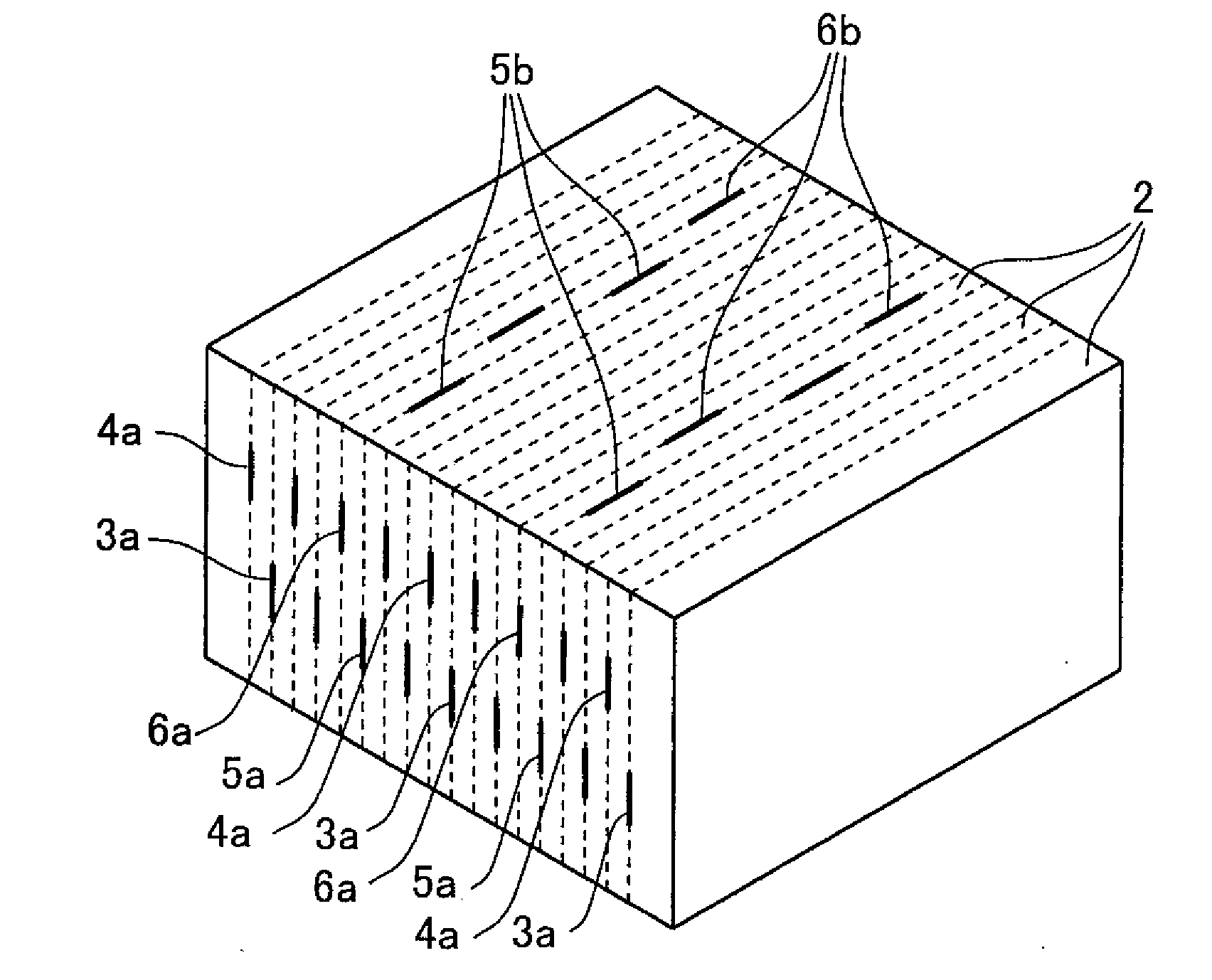

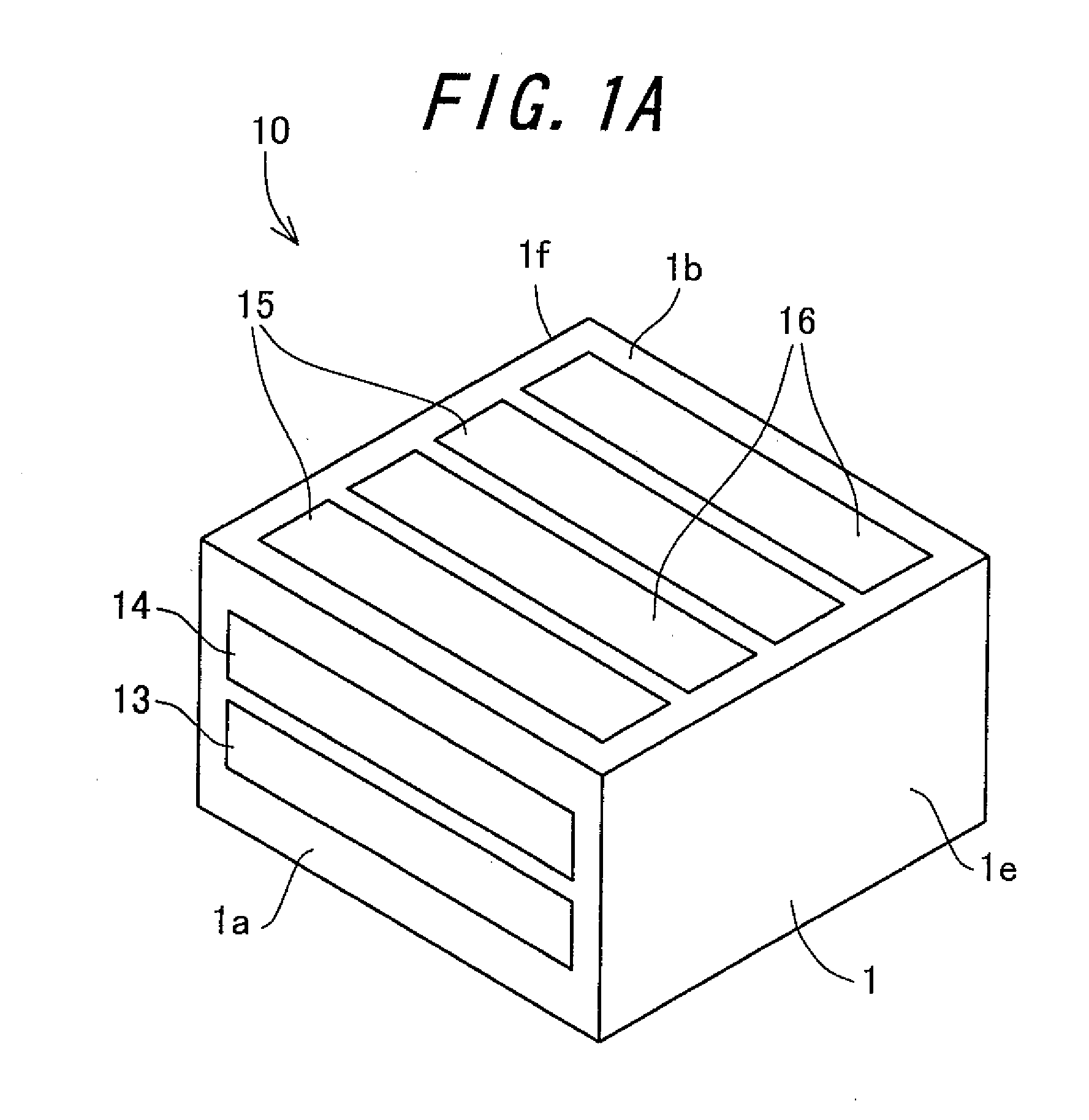

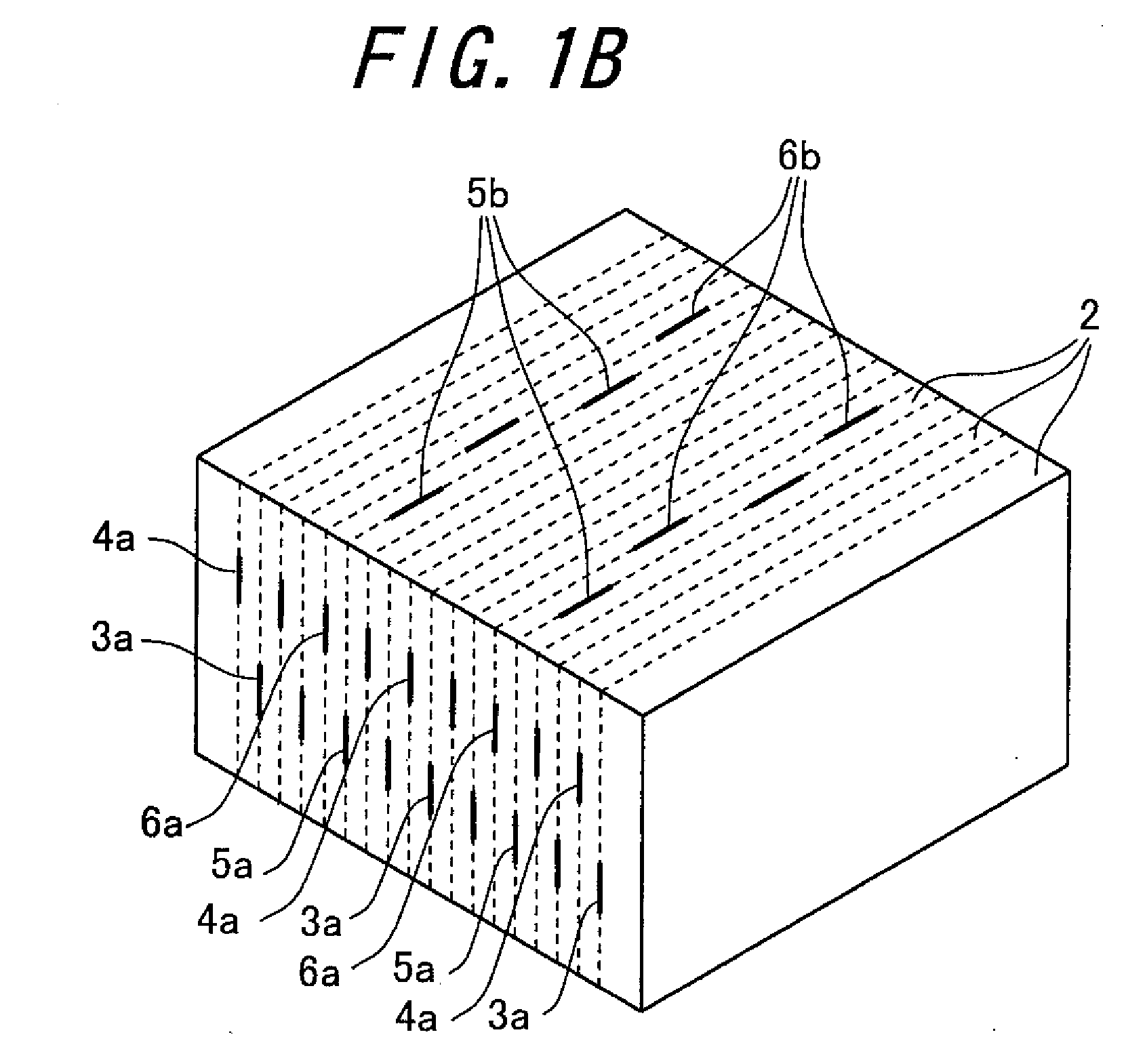

Multilayer Capacitor

ActiveUS20100321860A1Increase the amount of cuttingMaintain standardFixed capacitor electrodesStacked capacitorsDielectric layerRight hand surface

The invention relates to a multilayer capacitor capable of controlling ESR while maintaining the level of ESL low. A multilayer capacitor (10) includes a plurality of first and second internal capacitor electrodes (3, 4) which are formed inside a multilayer body (1) of rectangular parallelepiped shape constructed by stacking a plurality of rectangular dielectric layers (2) on top of one another in a stacking direction; first and second external relay electrodes (13, 14) which are disposed on left-hand and right-hand surfaces of the multilayer body (1); first and second internal relay electrodes (5, 6) which are disposed inside the multilayer body (1) and arranged so as to be opposed to each other with the dielectric layer (2) interposed therebetween; and first and second external terminal electrodes (15, 16) which are disposed on upper and lower surfaces of the multilayer body (1).

Owner:KYOCERA CORP

High-yield processing method of ultra-fine crystal magnesium alloy thin plate

InactiveCN102989764AReduce edge crackingHigh yieldMetal rolling arrangementsThin slabUltimate tensile strength

The invention relates to a high-yield integrated processing technology of an ultra-fine crystal magnesium alloy thin plate, and belongs to the technical field of plastic working of magnesium alloys. A high-yield processing method comprises the following steps of: firstly, carrying out equal channel angular pressing for a plurality of times; putting a magnesium alloy billet into a preheated die to carry out heat preservation, and then carrying out equal channel angular pressing on the billet for more than eight times, so as to obtain an ultra-fine crystal magnesium alloy block; and secondly, subsequently milling and processing, rolling the ultra-fine crystal magnesium alloy block obtained in the first step for a plurality of times, so as to prepare a magnesium alloy thin plate, wherein the rolling temperature range is 100-350 DEG C. The magnesium alloy micro-structure is refined by equal channel angular pressing to improve the plastic deformation ability, and then processed into the magnesium alloy thin plate and a wide plate by a continuous rolling technology. Therefore, the produced magnesium alloy thin plate is an ultrafine-grained microstructure, even in structure, good in strength and plasticity, and high in yield.

Owner:HOHAI UNIV

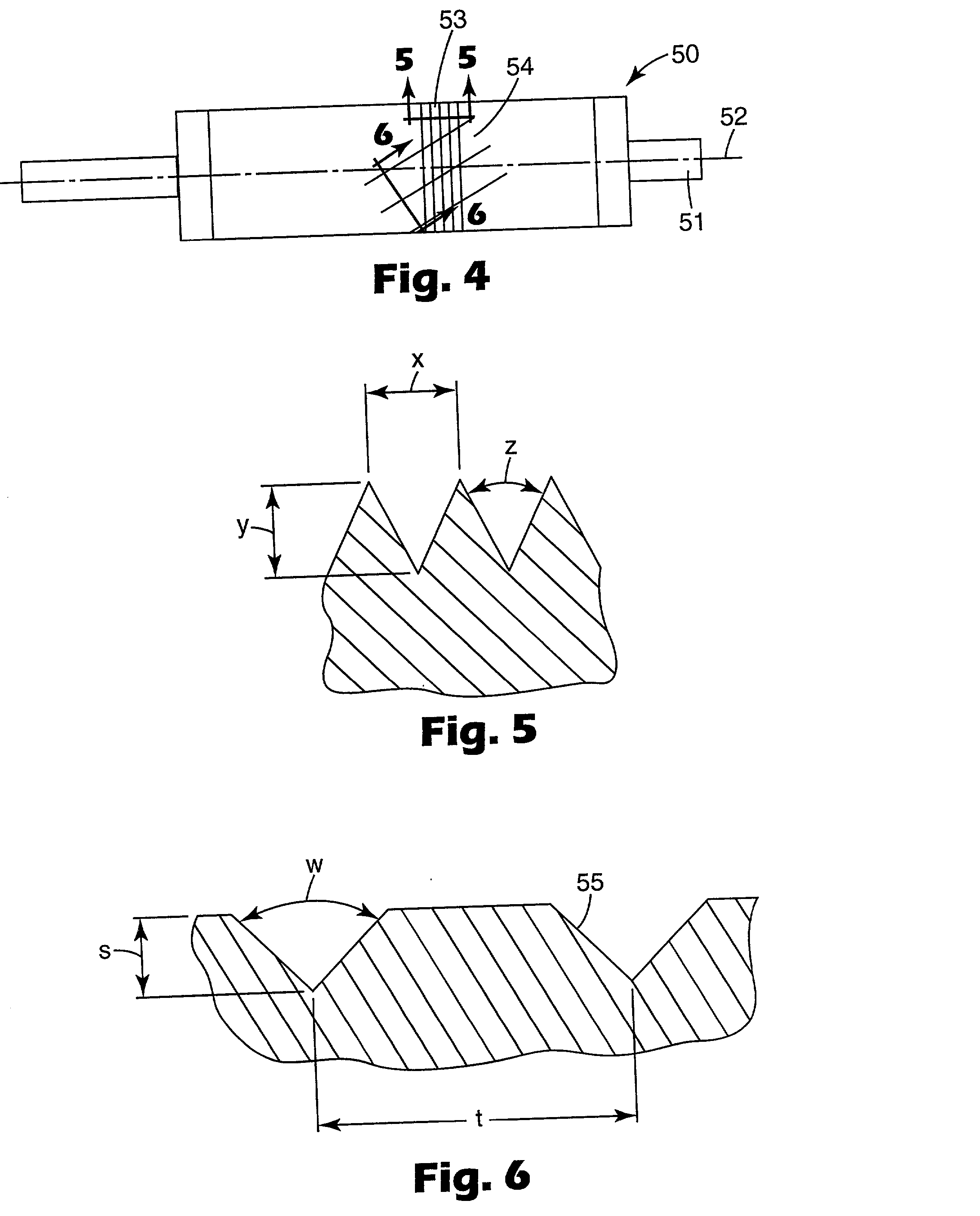

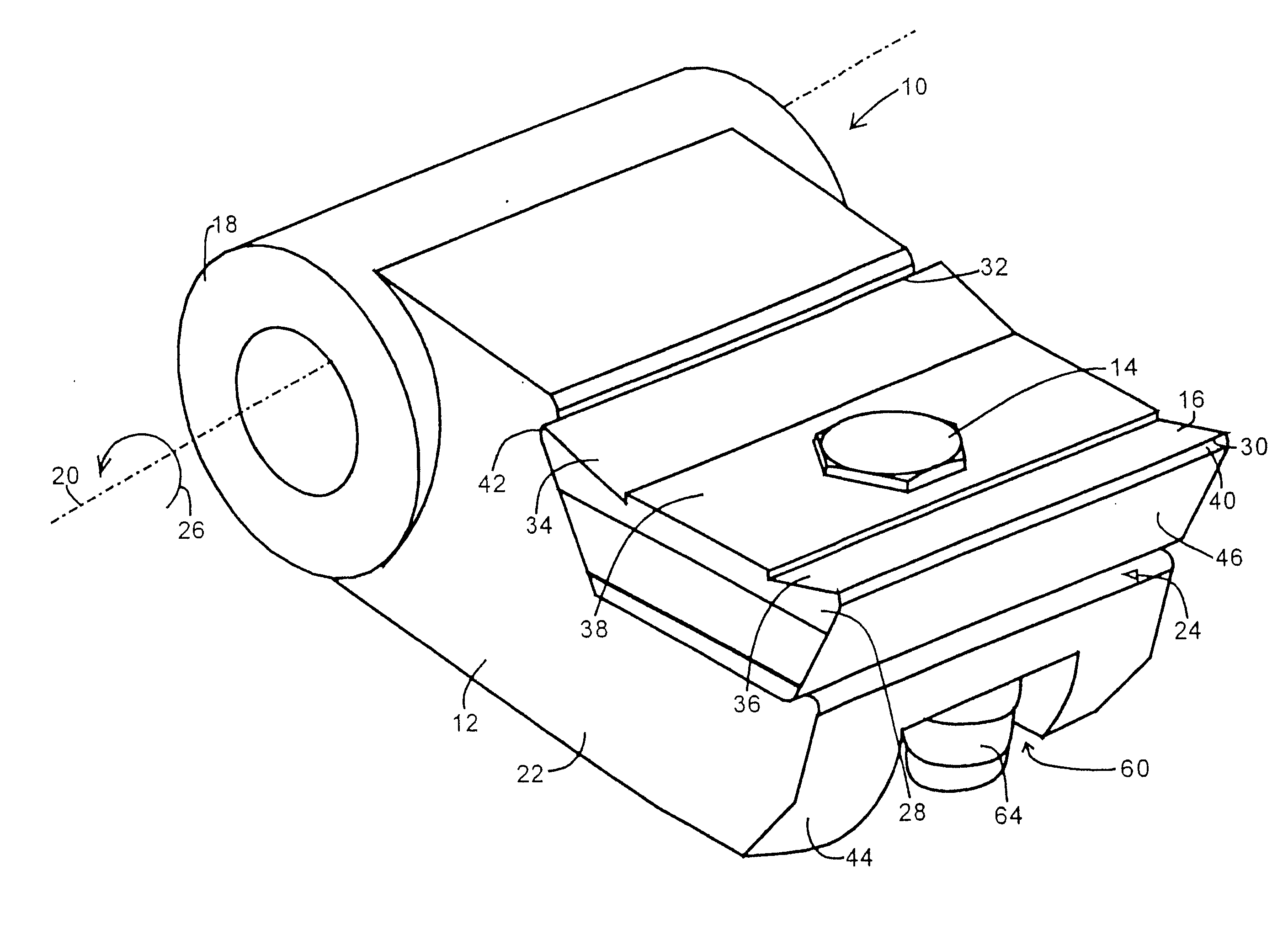

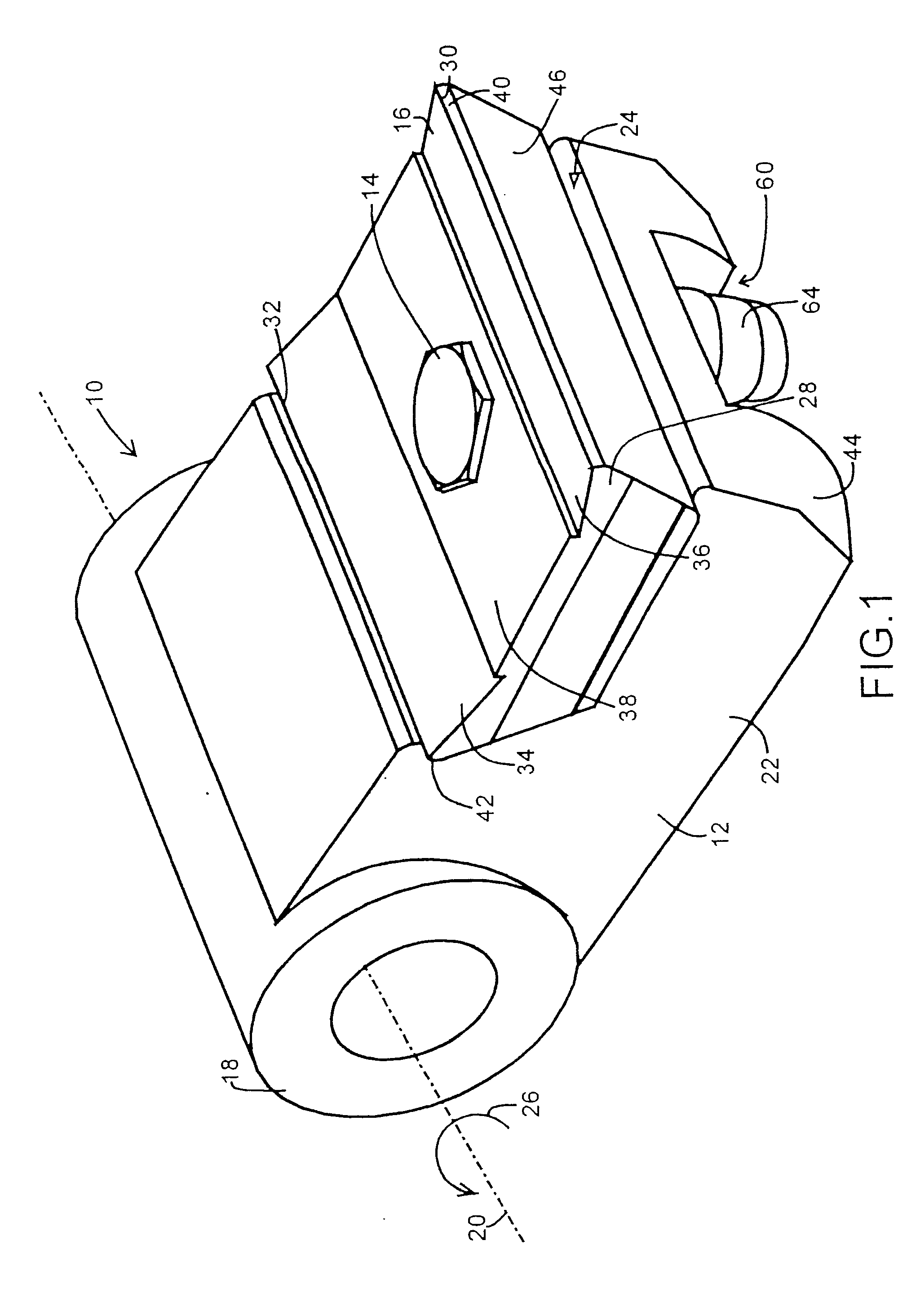

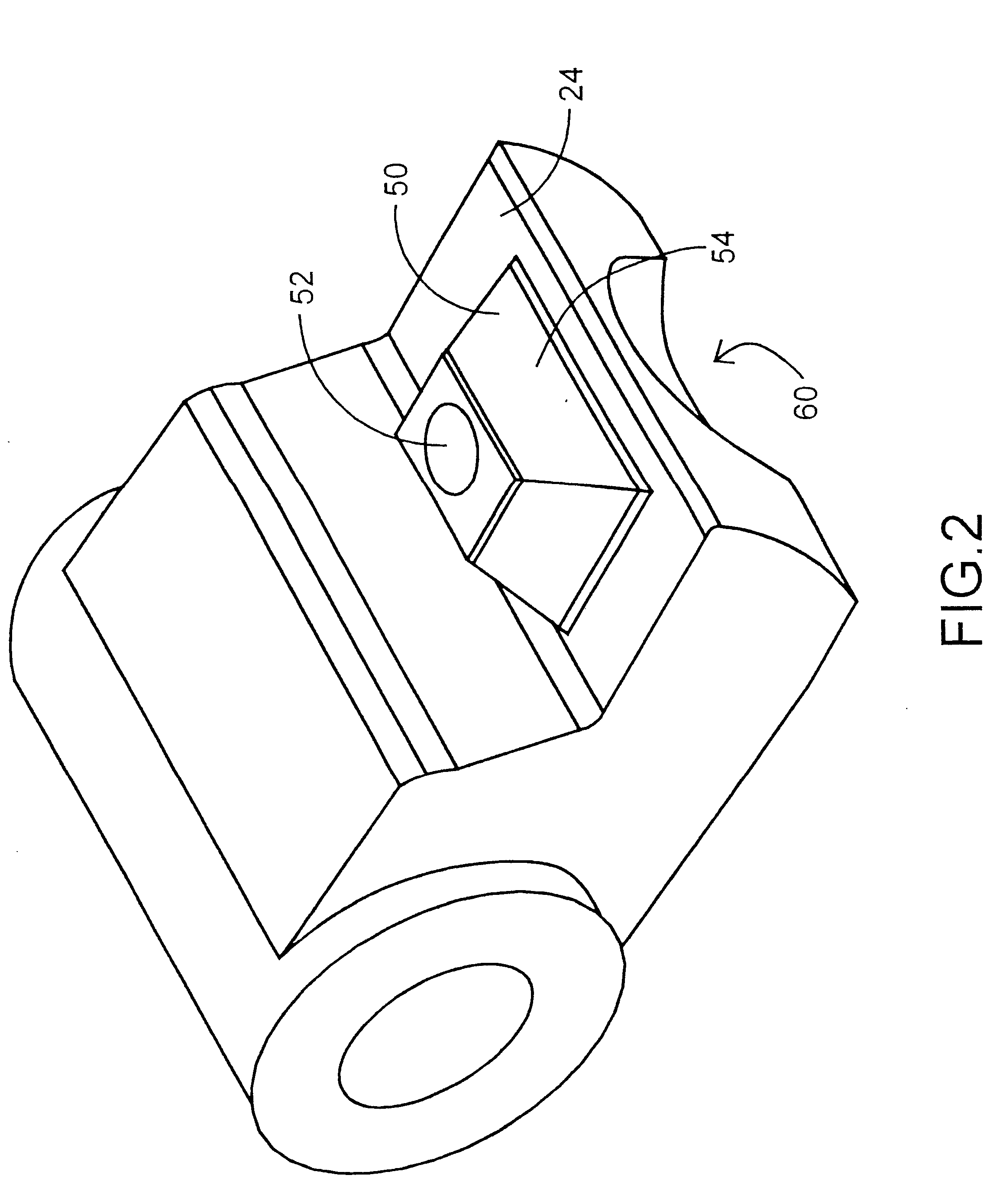

Beating arrangement

InactiveUS20040056129A1Easy to manufactureReduce material consumptionGrain treatmentsMechanical engineeringPyramid

The invention relates to a beating arrangement for a rotary shredder, comprising a base body (12) which is rotationally arranged around an axis (20) and a cutting body (16) which is detachably fixed onto a protruding part (22) of the base body. A protruding profile (50) is formed on the front surface thereof in the direction of rotation whereon the cutting body (16) forms a positive fit. The profile (50) can be embodied in the form of a protruding truncated pyramid, whose base surface lies on the plane of cutting edges (30, 32) which are bilaterally symmetrical in relation to a surface which extends tangentially in relation to a circumference of rotation. The cutting body can be fixed by means of a screw (14), which extends through the centre of the cutting body and the profile.

Owner:WERNER DOPPSTADT UMWELTTECHN

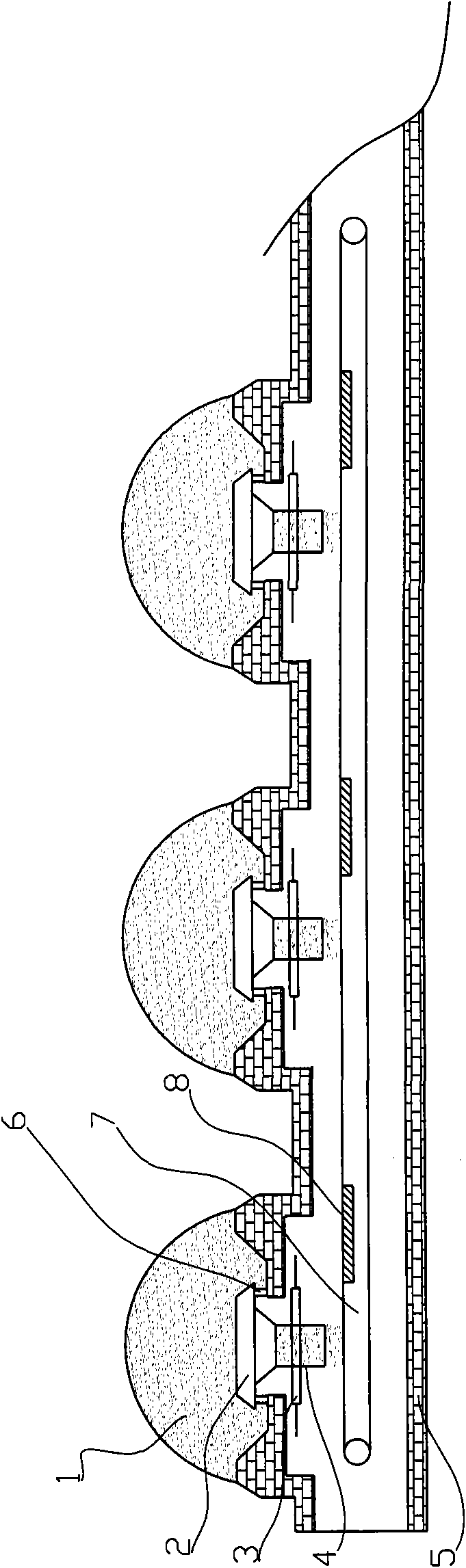

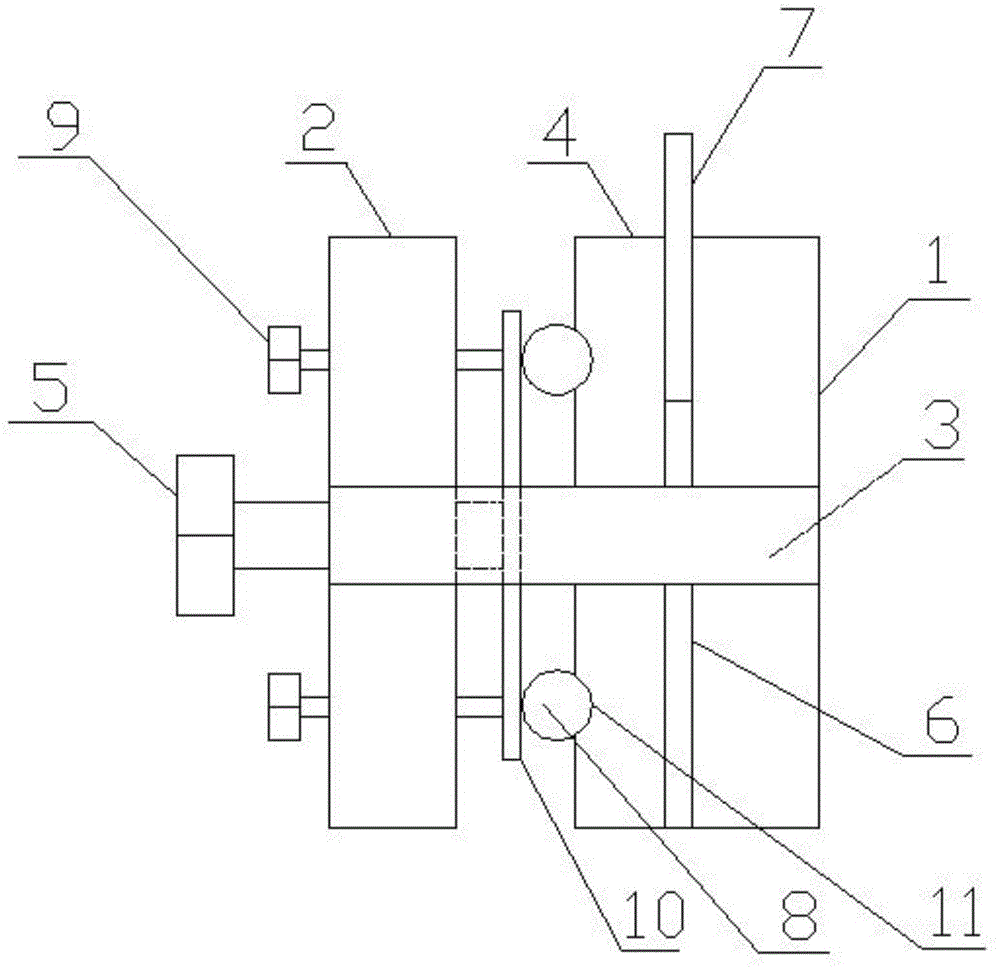

Auxiliary compression tool for thin plate material and application method thereof

InactiveCN103335883AIncrease the amount of cuttingAvoid bending instabilityStrength propertiesCompressive testEngineering

The invention relates to an auxiliary compression tool for a thin plate material and an application method thereof. The auxiliary compression tool comprises a clamping plate and a fixed plate, wherein the clamping plate is connected with the fixed plate; a pressing plate is arranged between the clamping plate and the fixed plate; the fixed plate is provided with a fastening bolt for pressing the clamping plate by using the pressing plate; a pressing head for extruding a testing sample is arranged between the pressing plate and the clamping plate; the testing sample is placed between the clamping plate and the pressing plate and the pressing head is placed above the testing sample; the fastening bolt is adjusted and the pressing plate is uniformly squeezed through a resilient sheet to clamp the testing sample; finally, a test is finished through squeezing the testing sample through the pressing head. According to the auxiliary compression tool disclosed by the invention, the pressing amount of sheet material compression is improved, a traditional sheet material compression test head is prevented from being bent and losing the stability, and the stability of the sheet material compression is reduced; the size requirement of the sheet material compression testing sample enables the sheet material compression to be convenient and simple, so that a thin sheet material can be subjected to the stable compression test and is not bent to lose the stability, and the precision and the efficiency are improved.

Owner:CHONGQING UNIV

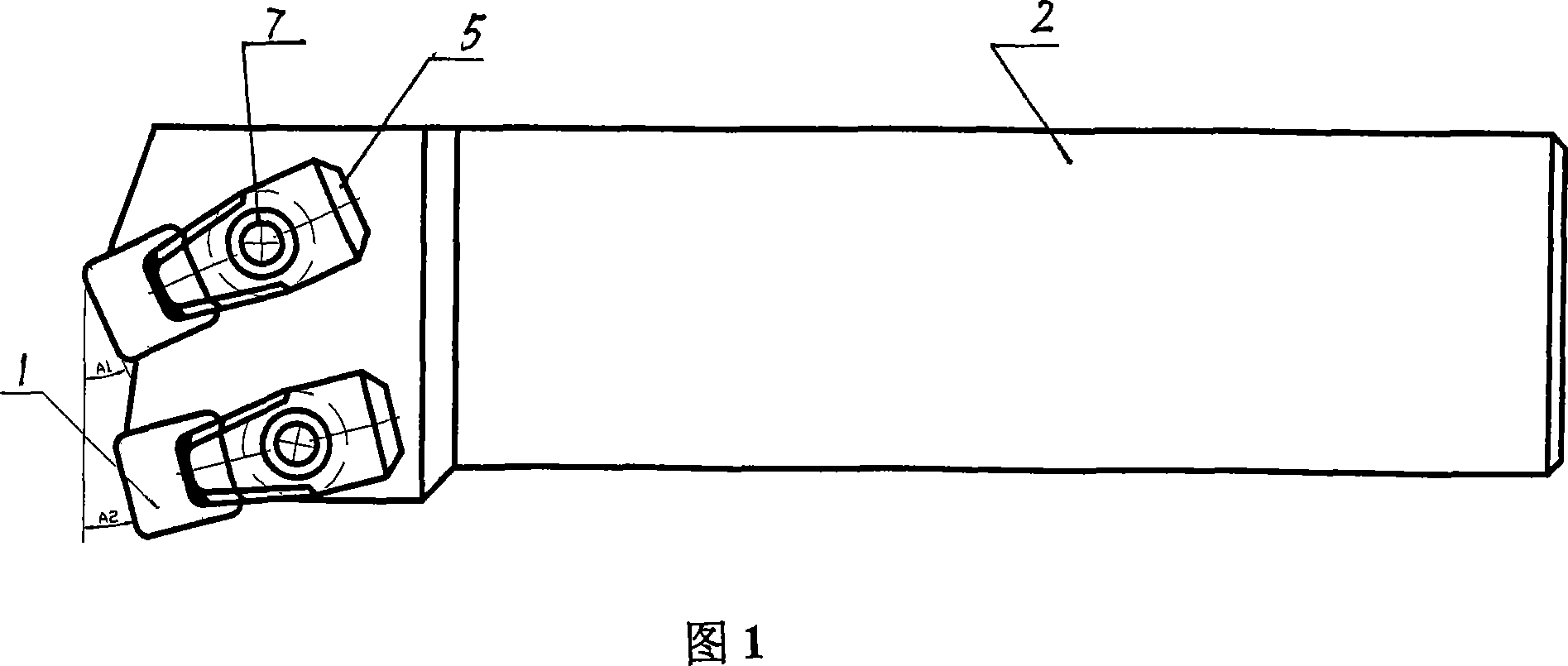

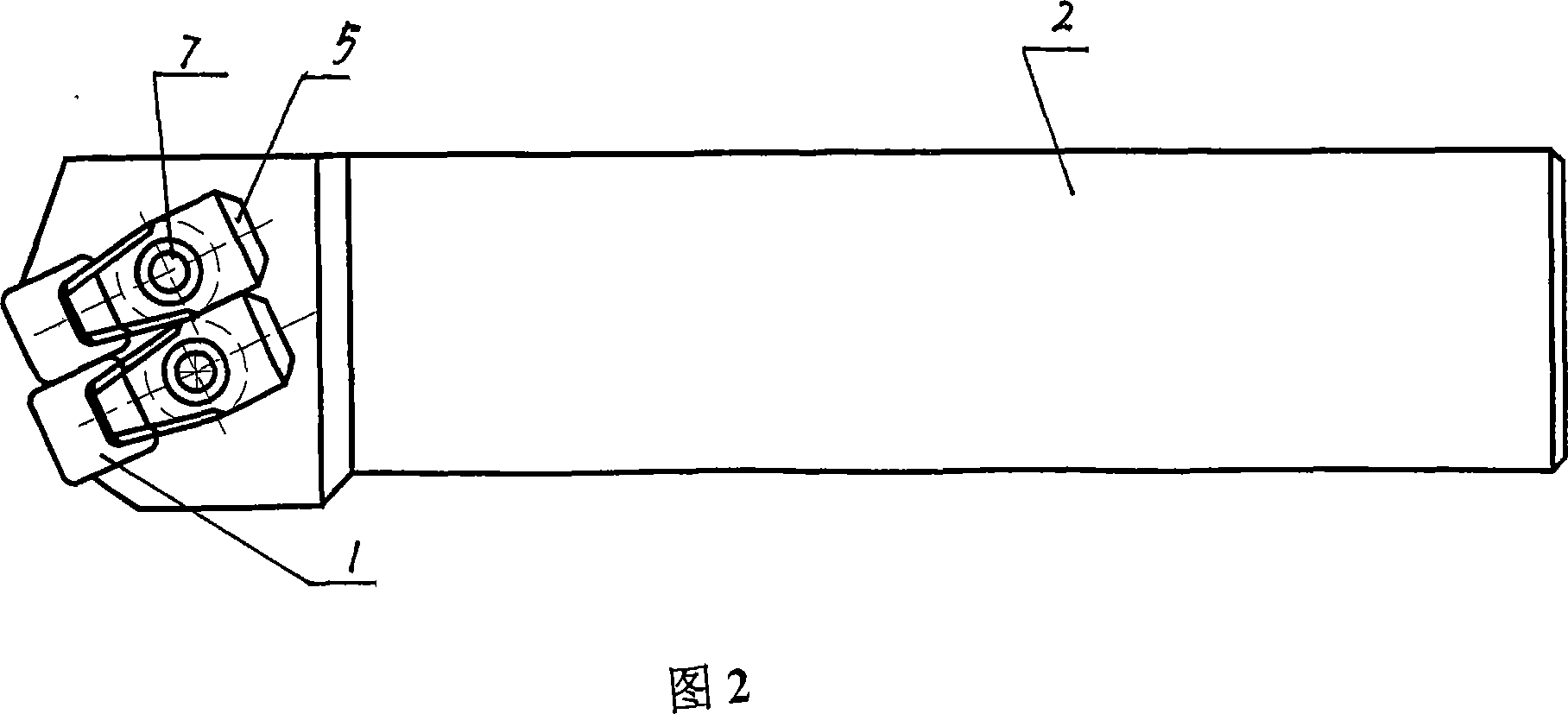

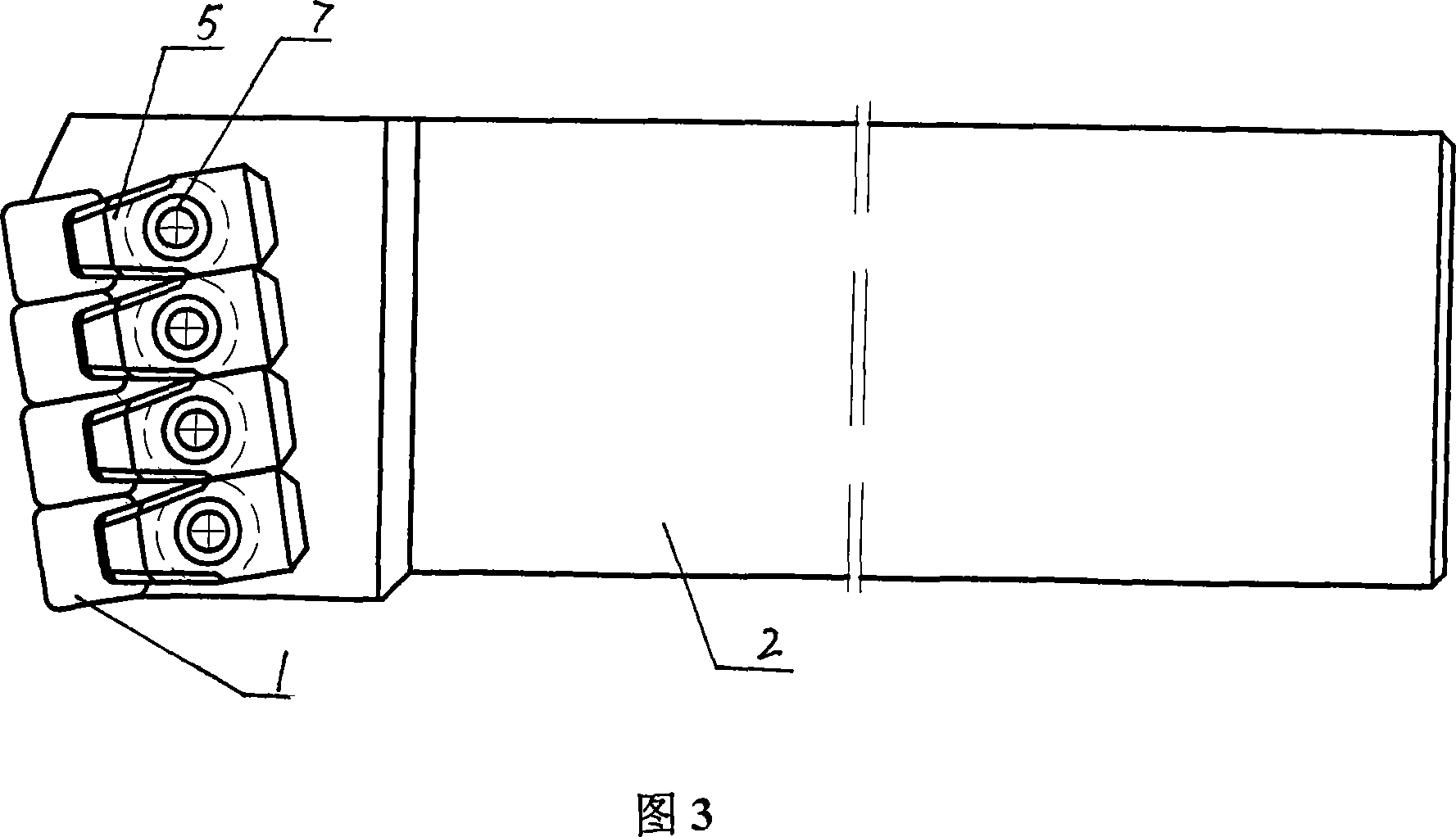

Multi-edge composite cutting tools

InactiveCN101077533AIncreased depth of cutIncrease the amount of cuttingTurning toolsBoron nitrideAlloy

The combined cutting tool with several cutting edges includes one cutter bar, and several cutting blade mounting mechanisms with separately mounted blades in the same or different entering angles. On the one hand, the combined cutting tool with several cutting edges can cut with its multiple cutting edges in doubled cutting depth, increased feed and doubled cutting efficiency. On the other hand, the present invention has flexible machining form, convenient operation, changeable number of cutting edges and adjustable entering angles. In addition, the cutting blades may be made of different materials, cubic boron nitride, diamond, hard alloy, etc. selected based on the machining requirement, machining cost and other factors.

Owner:上海美恩精密工具有限公司

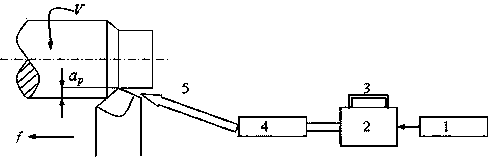

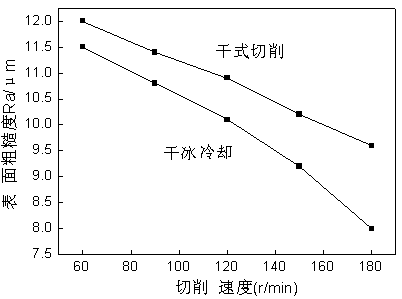

Dry cutting method for dry ice cooling

InactiveCN103801979ANo secondary wasteInhibitionMaintainance and safety accessoriesEconomic benefitsDry ice

The invention relates to the technical field of turning, in particular to a dry cutting method for dry ice cooling. The dry cutting method is characterized in that dry ice is smashed into powder, the powder and compressed air are mixed, and the powder is sprayed on a cutting machining portion of a cutting tool at the same time in the machining process. According to the dry cutting method, the problems of waste of cutting liquid and environmental pollution caused by the cutting liquid in the existing turning process are solved, the temperature of a cutting area is obviously reduced, precision of a machining surface is improved, the service life of a tool is prolonged, and economic benefits in the cutting machining process are improved.

Owner:CHANGZHOU UNIV

Sawing machine and cutting method of a sawing machine

InactiveUS20130276602A1Reduce bendingReduce vibrationMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

Traditionally, in order to avoid interfering with a work-piece such as a round material and an hexagonal material etc., an insert plate used as a saw blade side support of a band saw machine or a circular saw machine is provided at a position apart from the cutting site after passing the maximum cutting width, which results in the bending, vibration and noise of the saw blade, thereby decreasing the life of the saw blade. This problem is solved with two insert plates located at two positions on left and right of a work-piece to support the saw blade in a manner of moving them closing to the work-piece along the external shape of the work-piece from the cutting start and after passing the maximum cutting width by enabling them to move along the external side of the work-piece, therefore, one side of the insert plates takes a tapered shape so as to get into under the work-piece.

Owner:WASHIO JUNKO

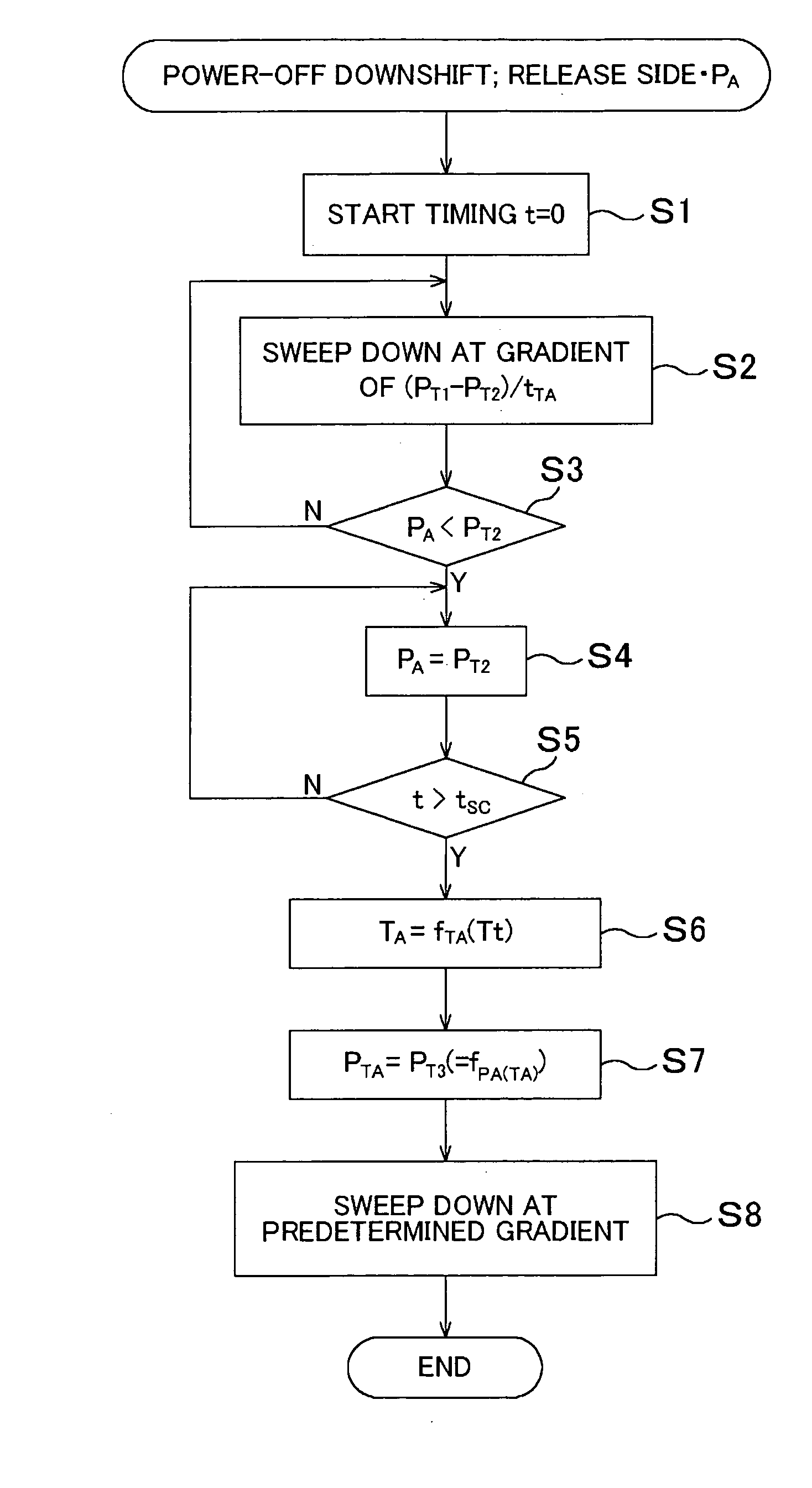

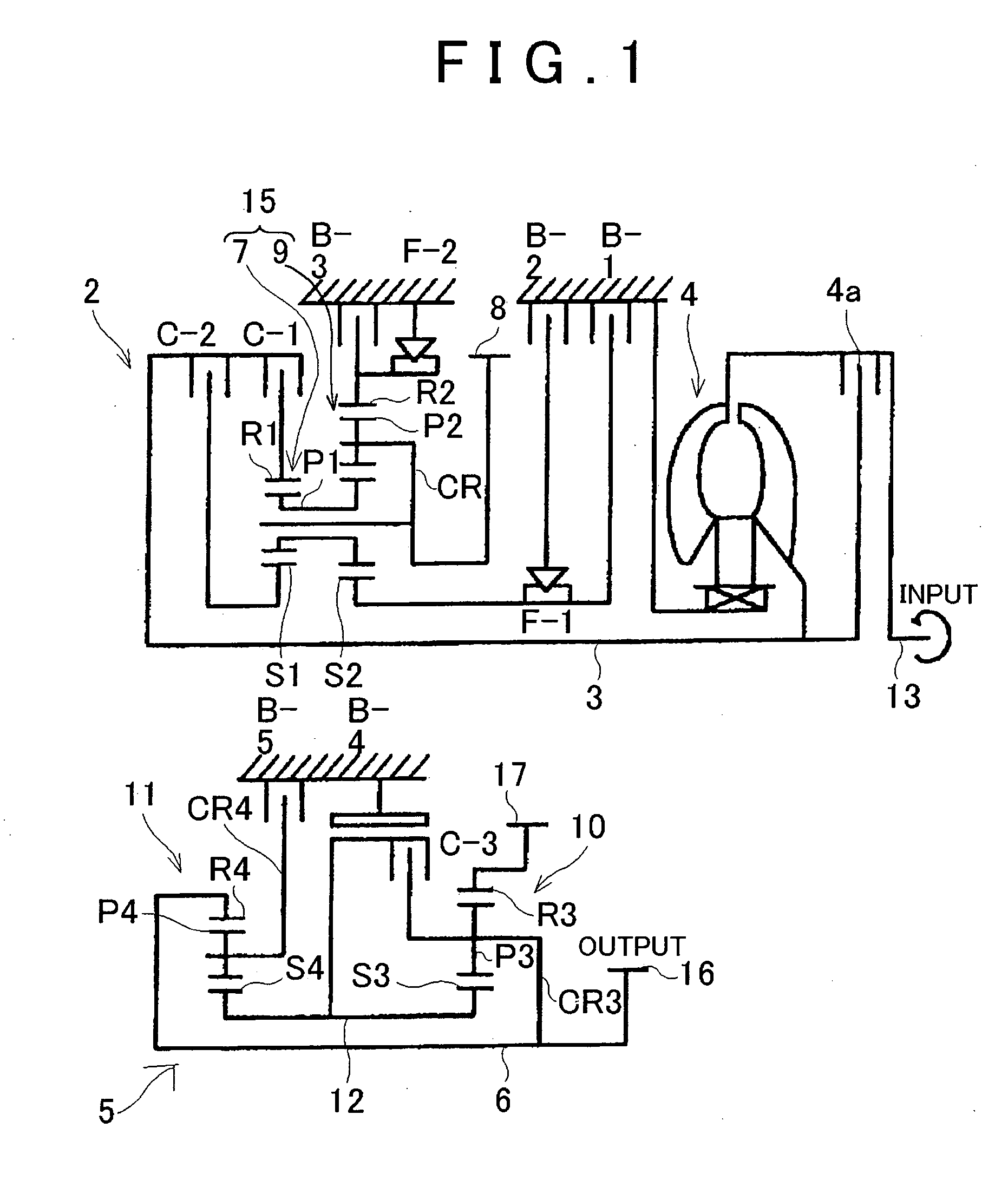

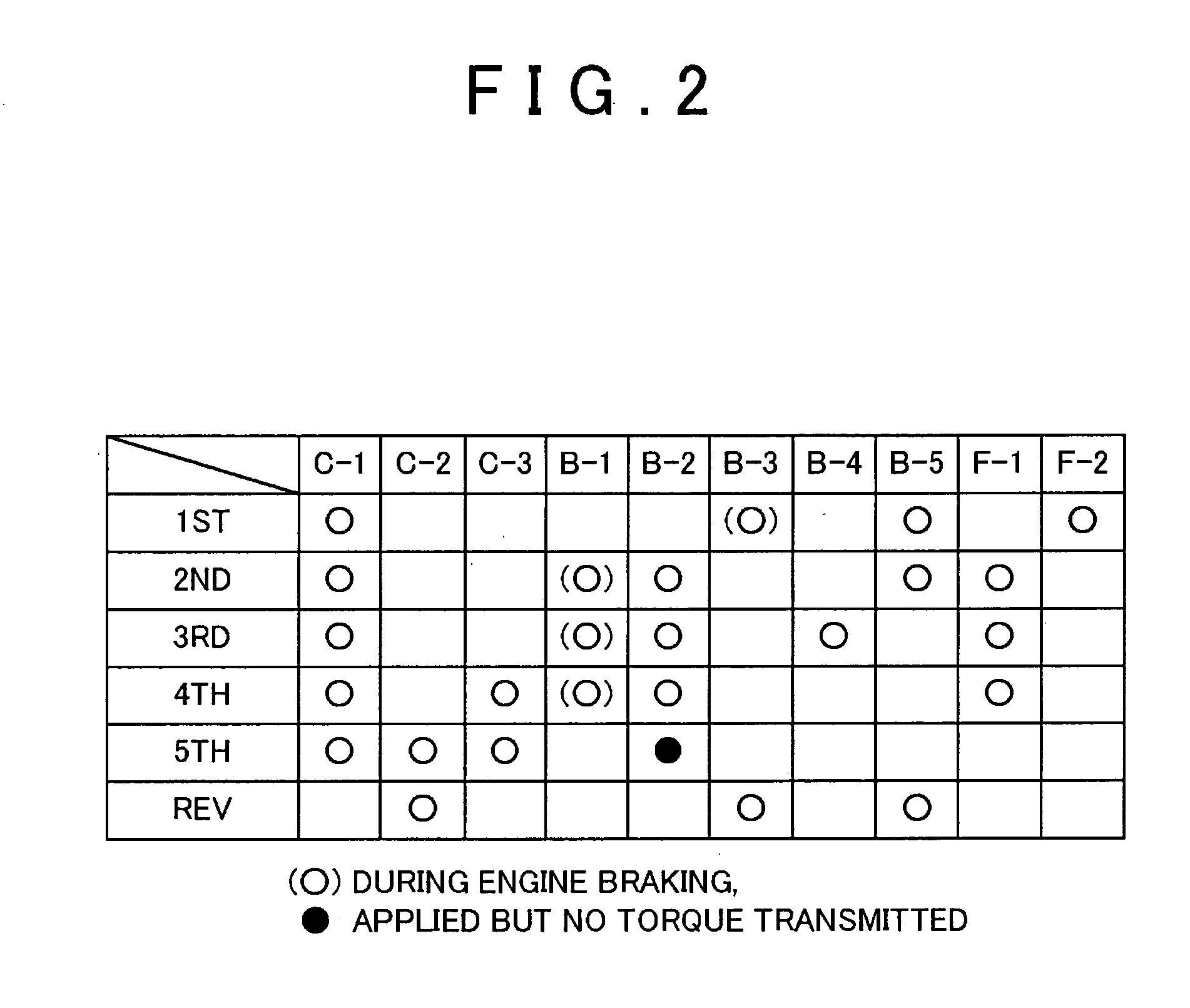

Shift control apparatus for automatic transmission

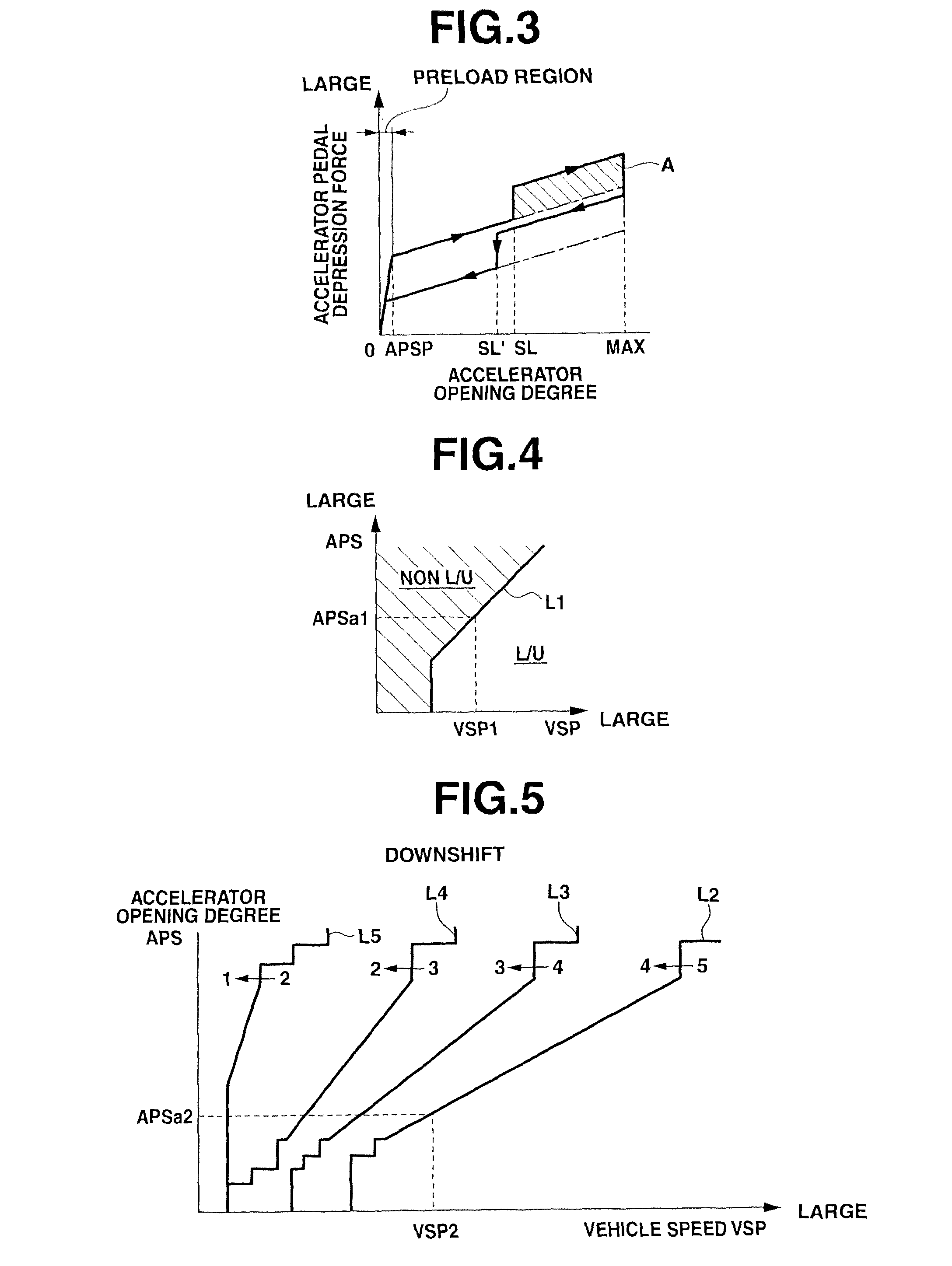

InactiveUS20060003867A1Increase output of engineIncrease the amount of cuttingElectrical controlGearing controlAutomatic transmissionControl store

An engine output controller includes a delay timer which measures the period of time elapsed from a timing of a target hydraulic pressure of a release side hydraulic pressure, and control starts a predetermined period of time after a predetermined amount of torque increase is achieved. The engine output control stores maps of the predetermined periods of time and the amounts of torque increase corresponding to normal shifts, such as 3rd to 2nd and 4th to 3rd, and skip-shifts, such as 4th to 2nd, and selects the map corresponding to the type of downshift.

Owner:AISIN AW CO LTD

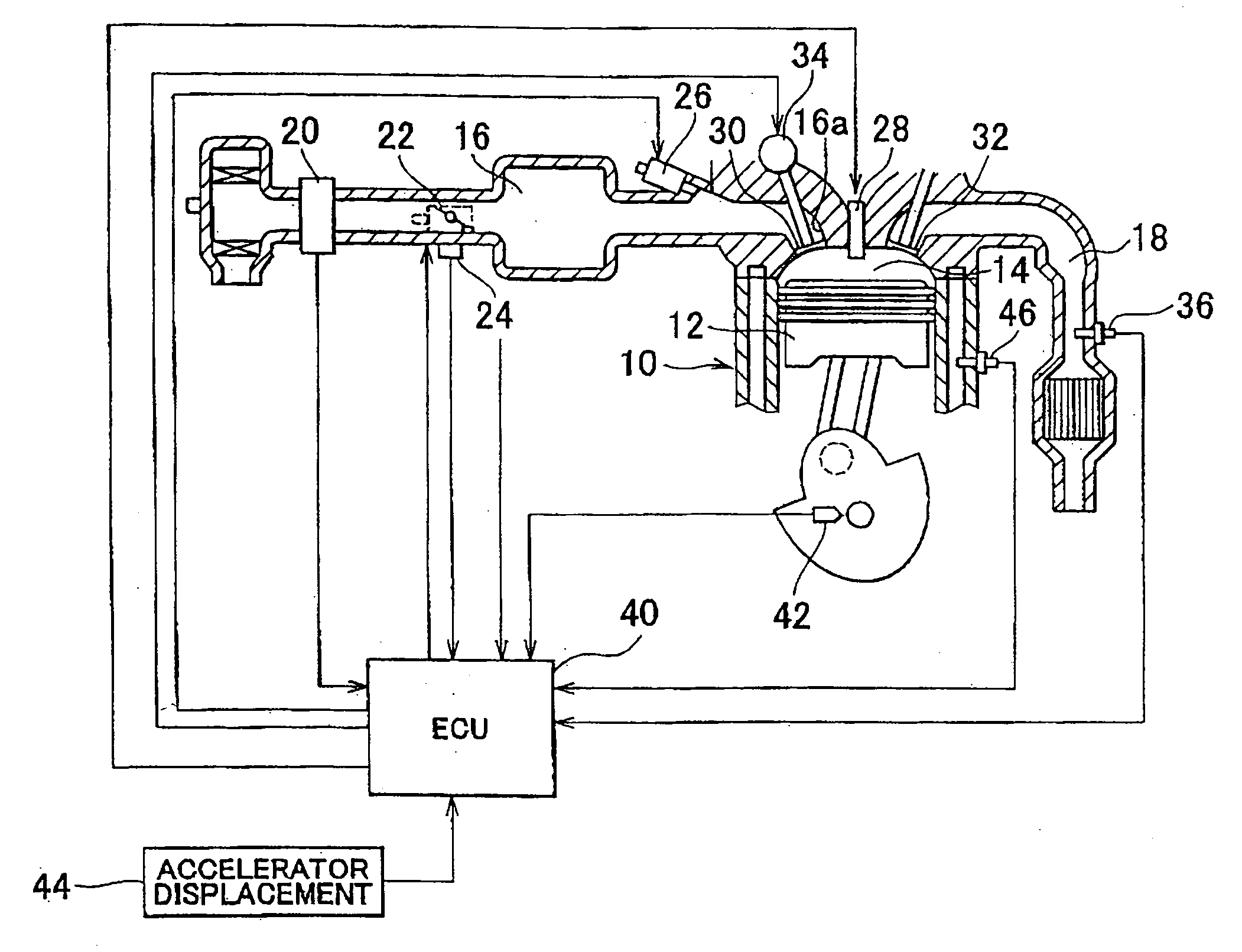

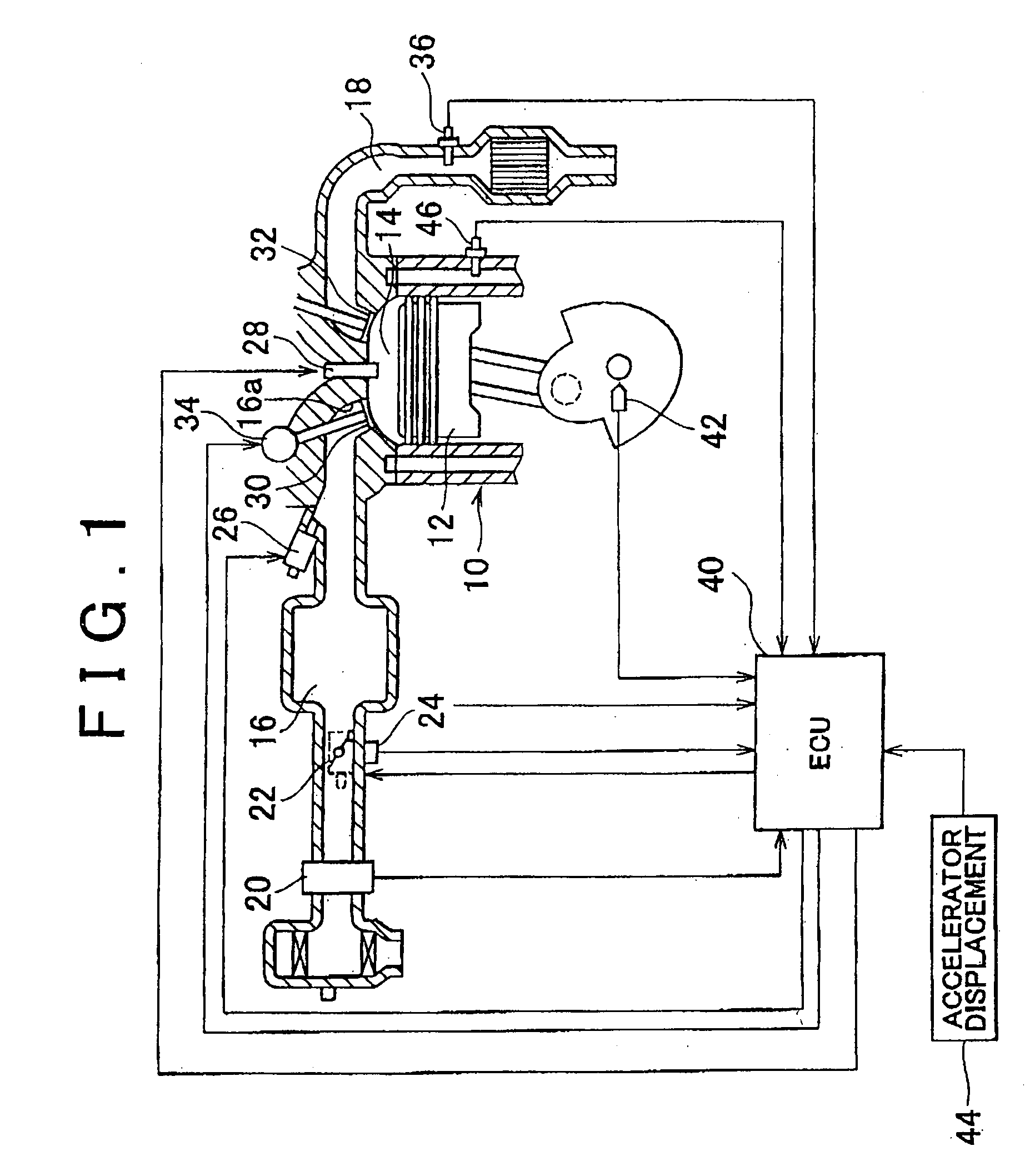

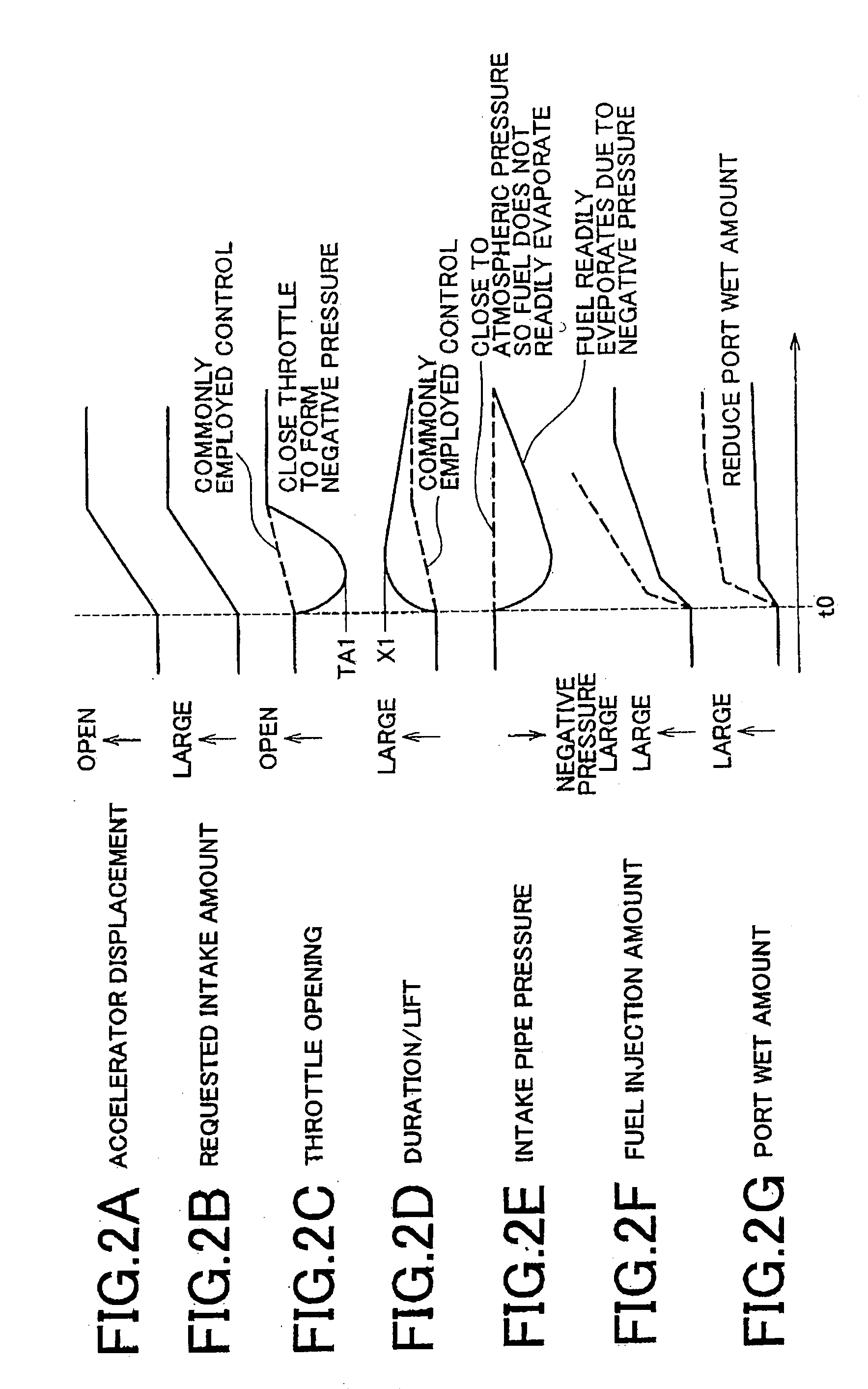

Control device and method of controlling an internal combustion engine

InactiveUS20080228377A1Reduce deteriorationIncrease evaporation rateElectrical controlInternal combustion piston enginesEngineeringExternal combustion engine

A control device of an internal combustion engine includes: a target negative pressure setting section that set a target negative intake pipe pressure during cold acceleration to a negative intake pipe pressure larger than a negative intake pipe pressure prior to the cold acceleration; a throttle valve control section that controls a throttle valve so that the negative intake pipe pressure increases during cold acceleration; and an intake valve control section that controls a variable valve mechanism of an intake valve, based on the target negative intake pipe pressure, to obtain a target intake air amount.

Owner:TOYOTA JIDOSHA KK

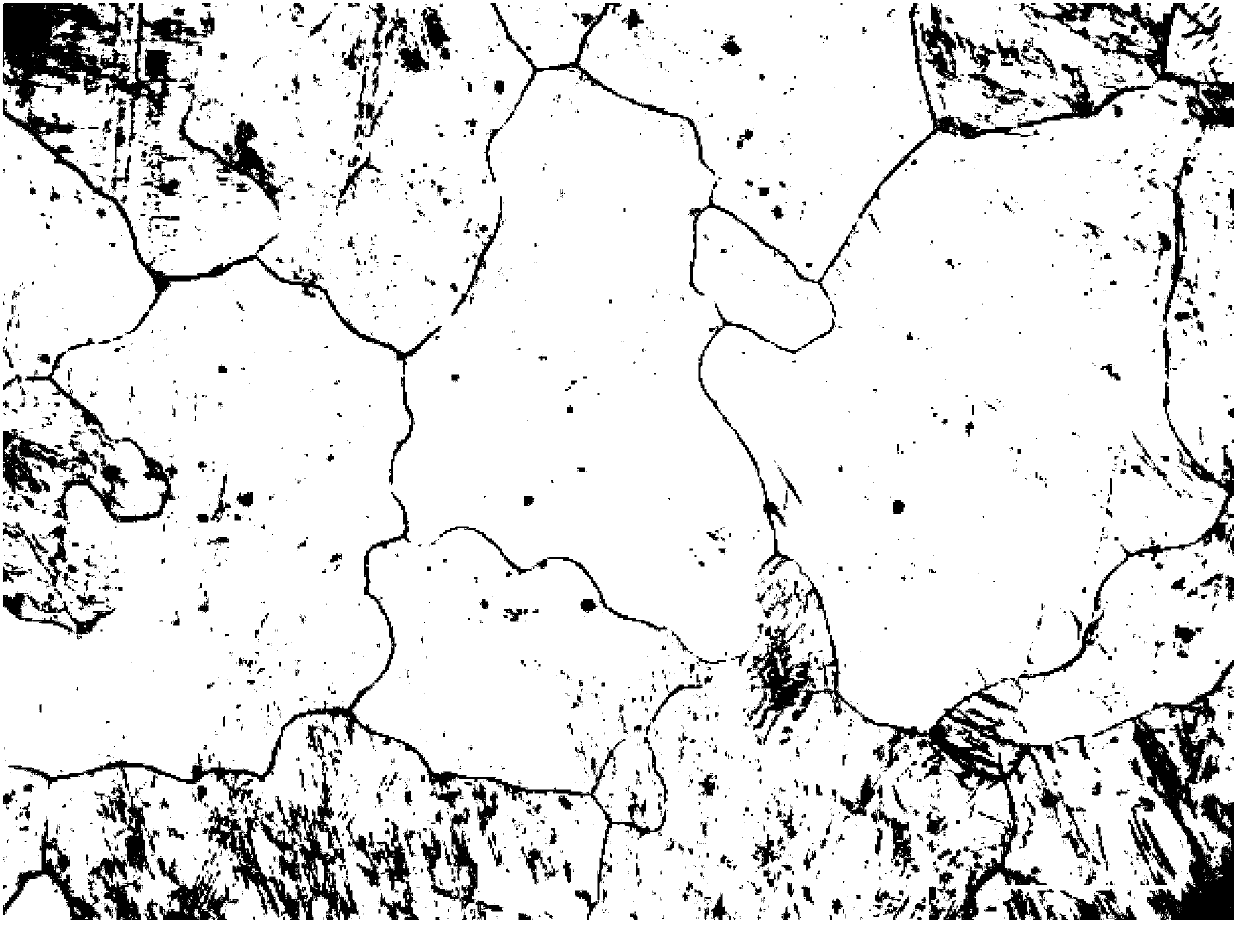

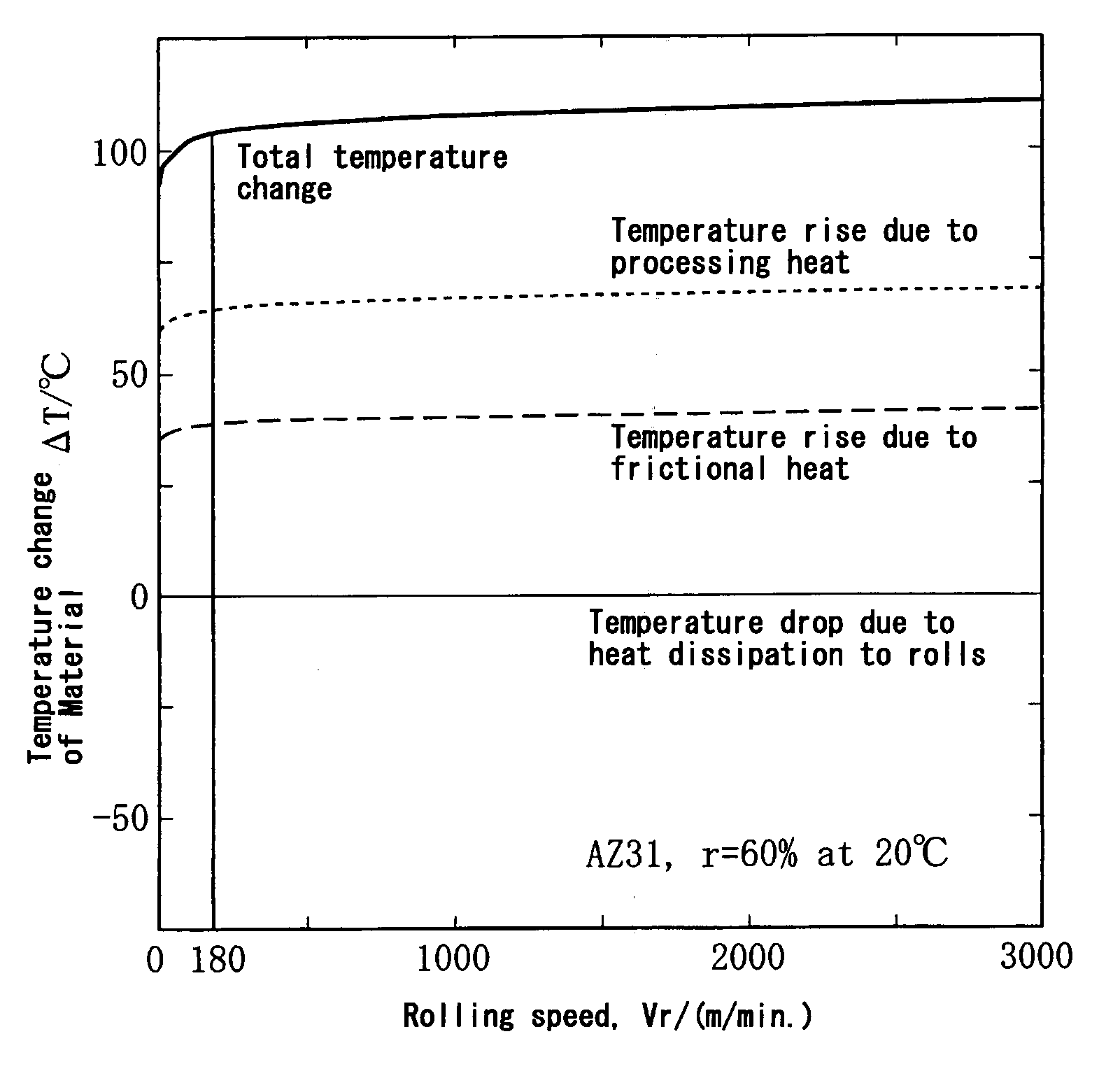

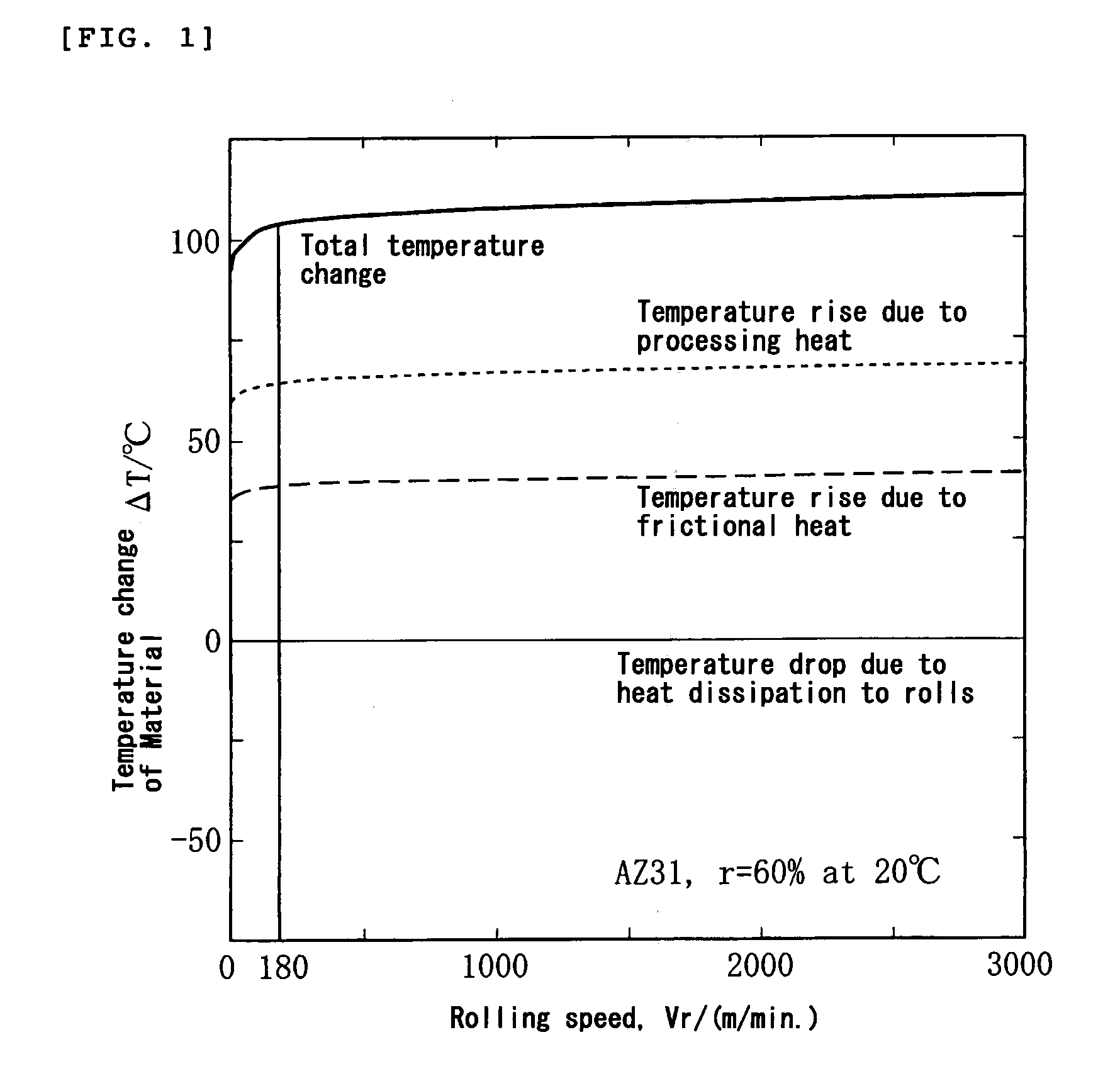

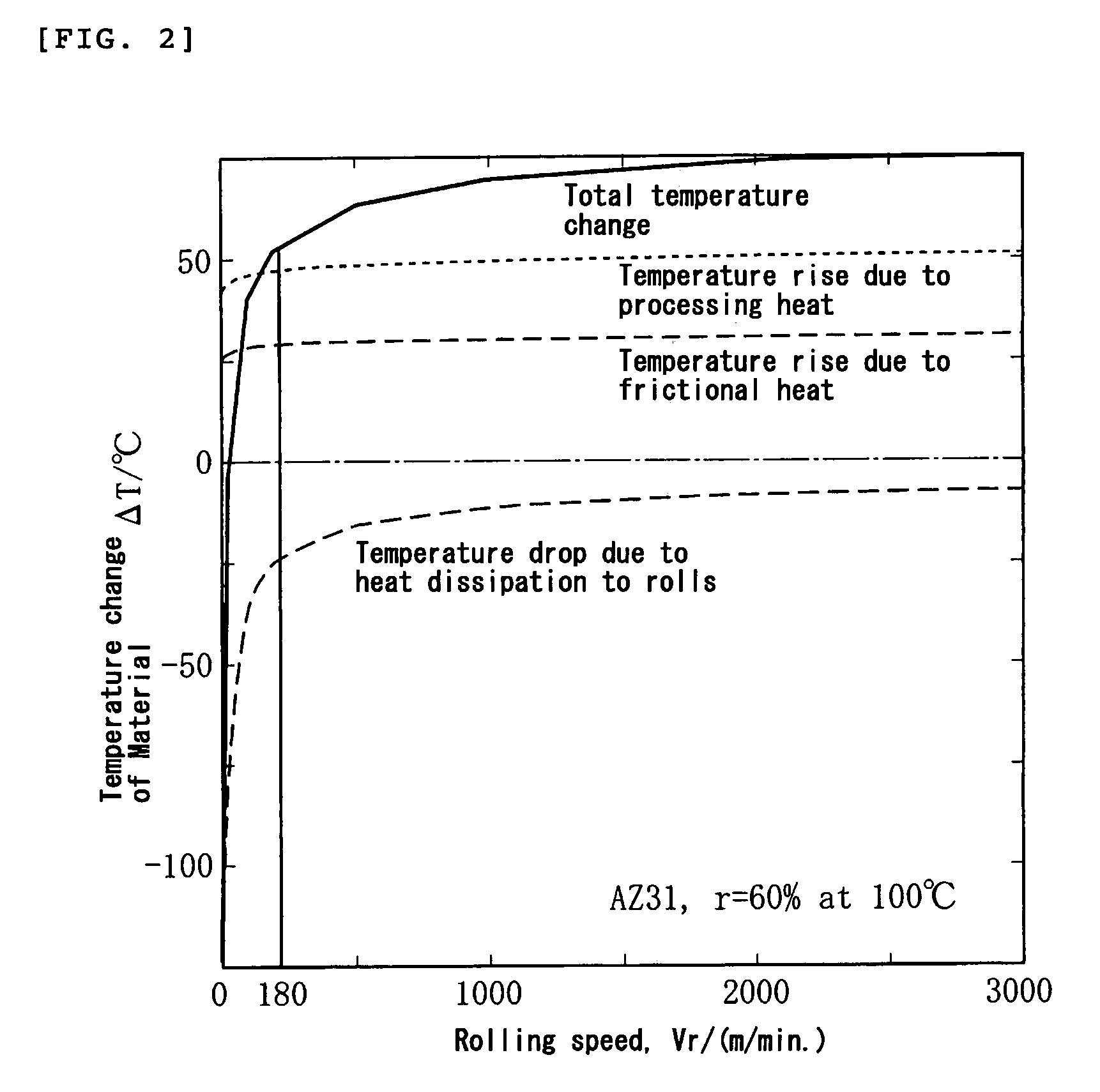

Magnesium alloy sheet processing method and magnesium alloy sheet

InactiveUS20080075624A1Increase the amount of cuttingReduced deformabilityMetal rolling arrangementsGrain boundaryMagnesium alloy

A magnesium alloy sheet processing method wherein a magnesium alloy sheet is rolled at a speed of 180 m / min or more. Particularly, a magnesium alloy sheet processing method, wherein the magnesium alloy sheet is rolled at a speed of 450 m / min or more. A magnesium alloy sheet processing method, wherein a rolling tool which is not heated is used. A magnesium alloy sheet processing method, wherein the temperature of the magnesium alloy sheet immediately before the rolling is in the range of 0° C. to 400° C. A magnesium alloy sheet, wherein the sheet has an average crystal grain of 4 μm or less, and does not internally include any unbonded interface in parallel with a direction of rolling. A magnesium alloy sheet, wherein the sheet has an average grain size of 4 μm or less, and has an internal grain boundary formed by a clean grain boundary.

Owner:OSAKA UNIV

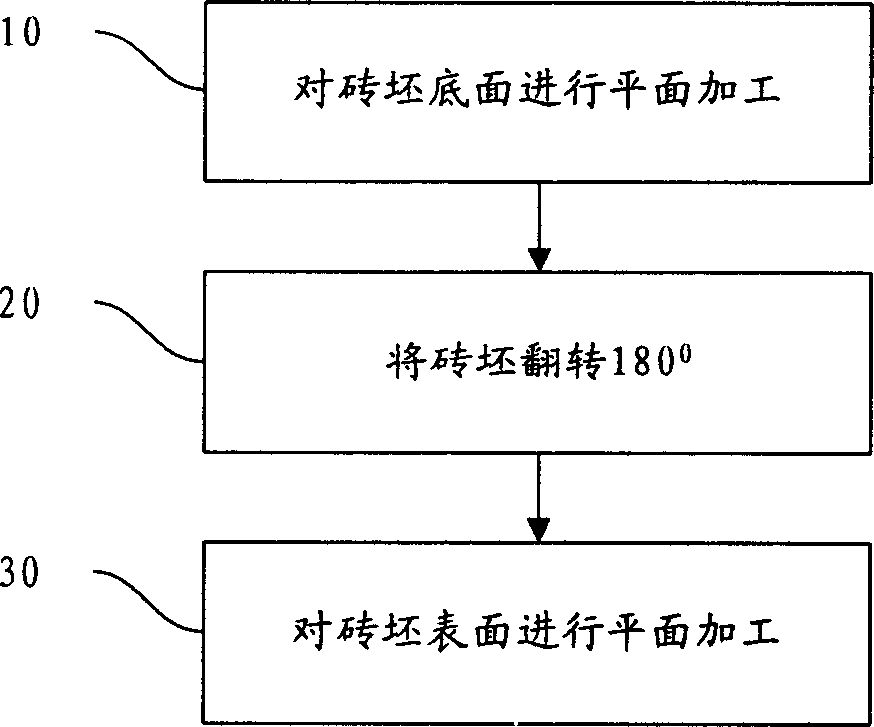

Ceramic polishing brick surface processing method and device

InactiveCN1876346ASolve rationalitySolve the accuracy problemPolishing machinesCeramic shaping plantsBrickMaterials science

The invention relates to a method for preparing ceramic burnishing brick surface and the device, the process comprises surface working for brick blank floor, inverting brick for 180 degree and surface working the brick blank, the surface working for brick blank floor is dubbing the brick blank floor, the working for brick blank surface comprising butting, surface milling and grinding and polishing brick blank surface in sequence. The preparing device comprises conveying line for brick blank, bottom milling device for surface working of brick blank bottom, reversing device and surface treating device assembly, which are connected together through conveying line. The invention is characterized by increased working efficiency by 10-20%, reduced damage rate for brick blank preparation by 20-40 %, and increased surface plainness of ceramic polishing brick by 20-30%.

Owner:KEDA INDUSTRIAL GROUP CO LTD

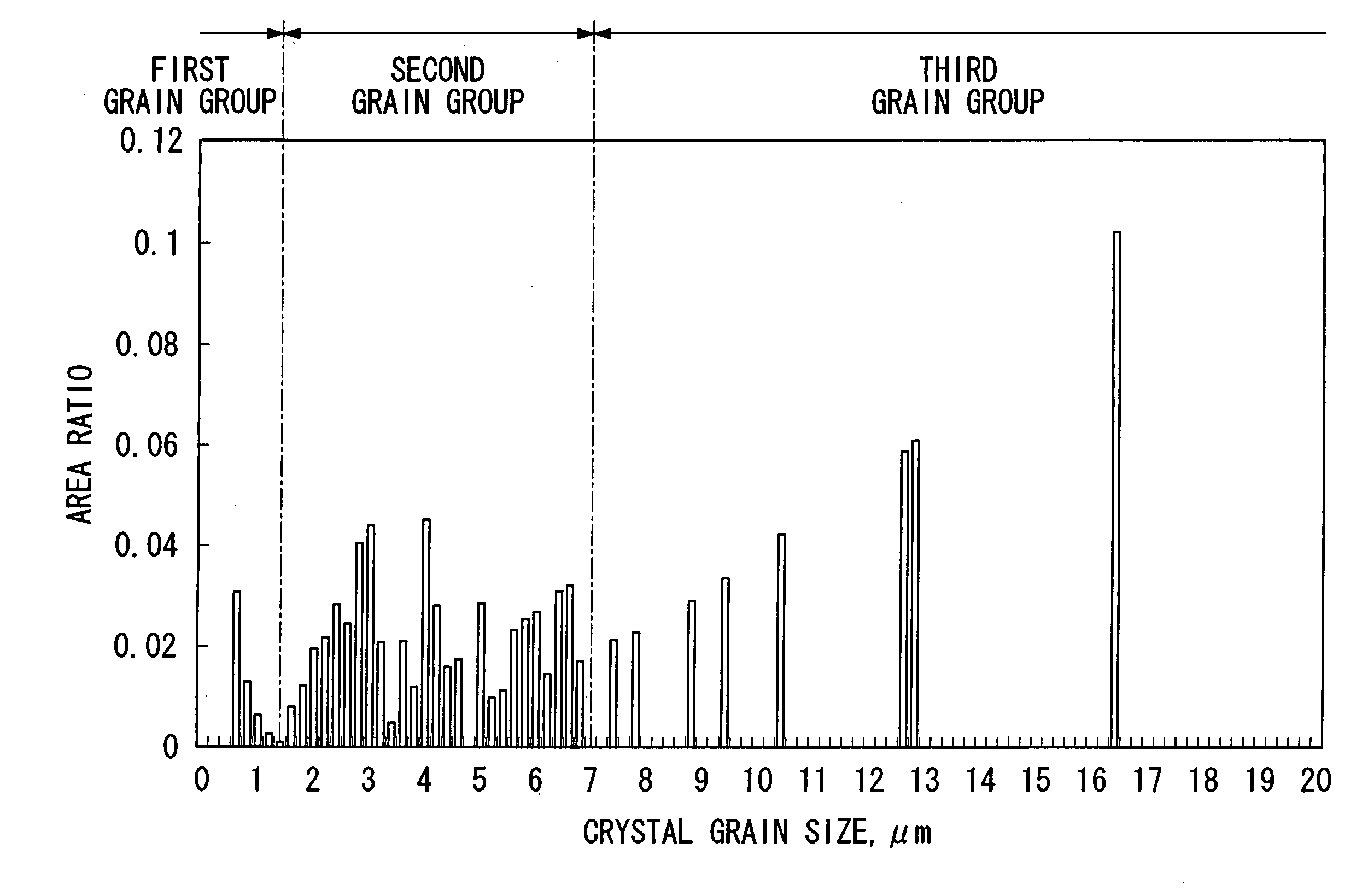

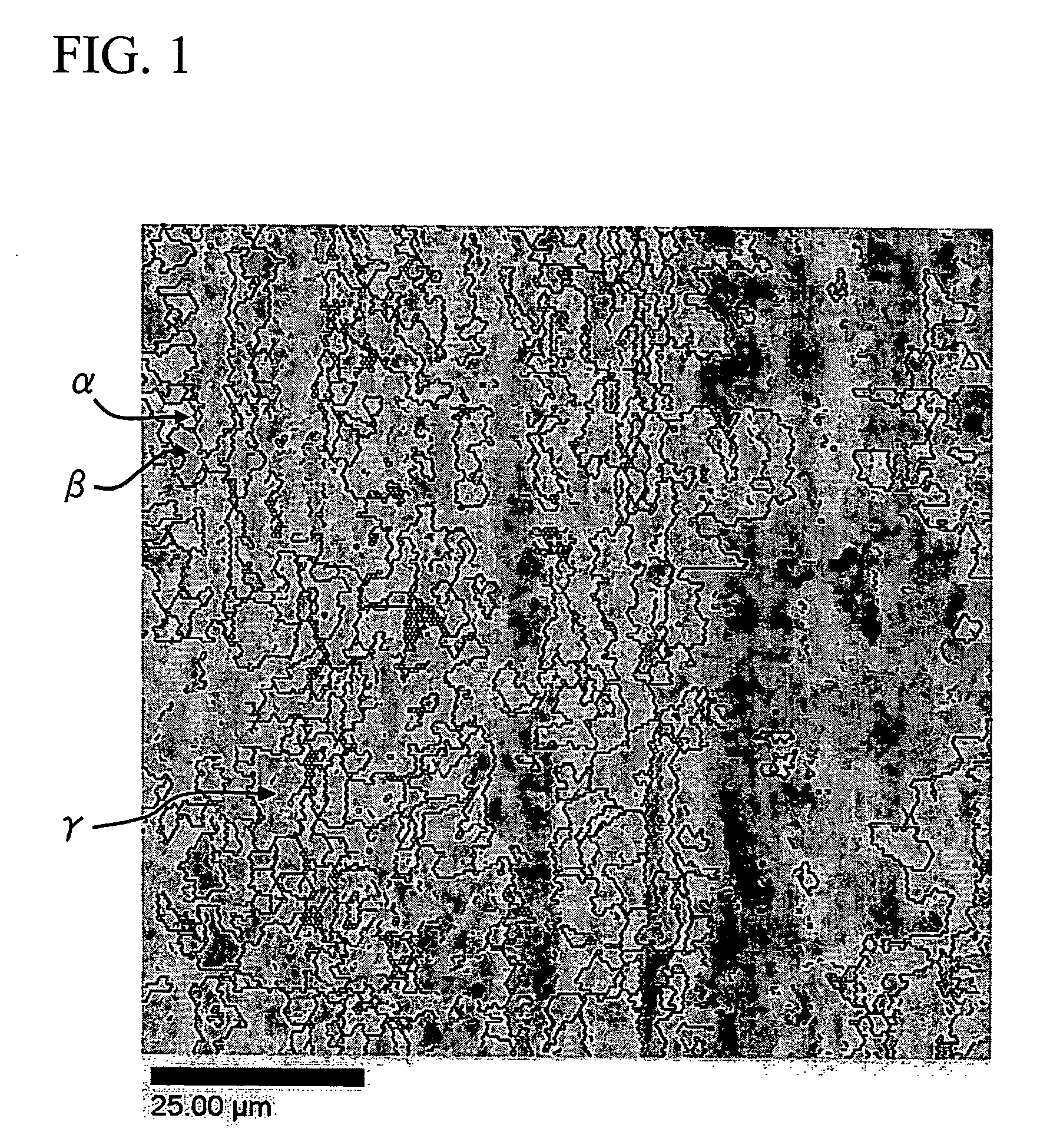

Copper alloy and method of manufacturing the same

ActiveUS20050230014A1High elongationHigh strengthMetal rolling arrangementsArea ratioMaterials science

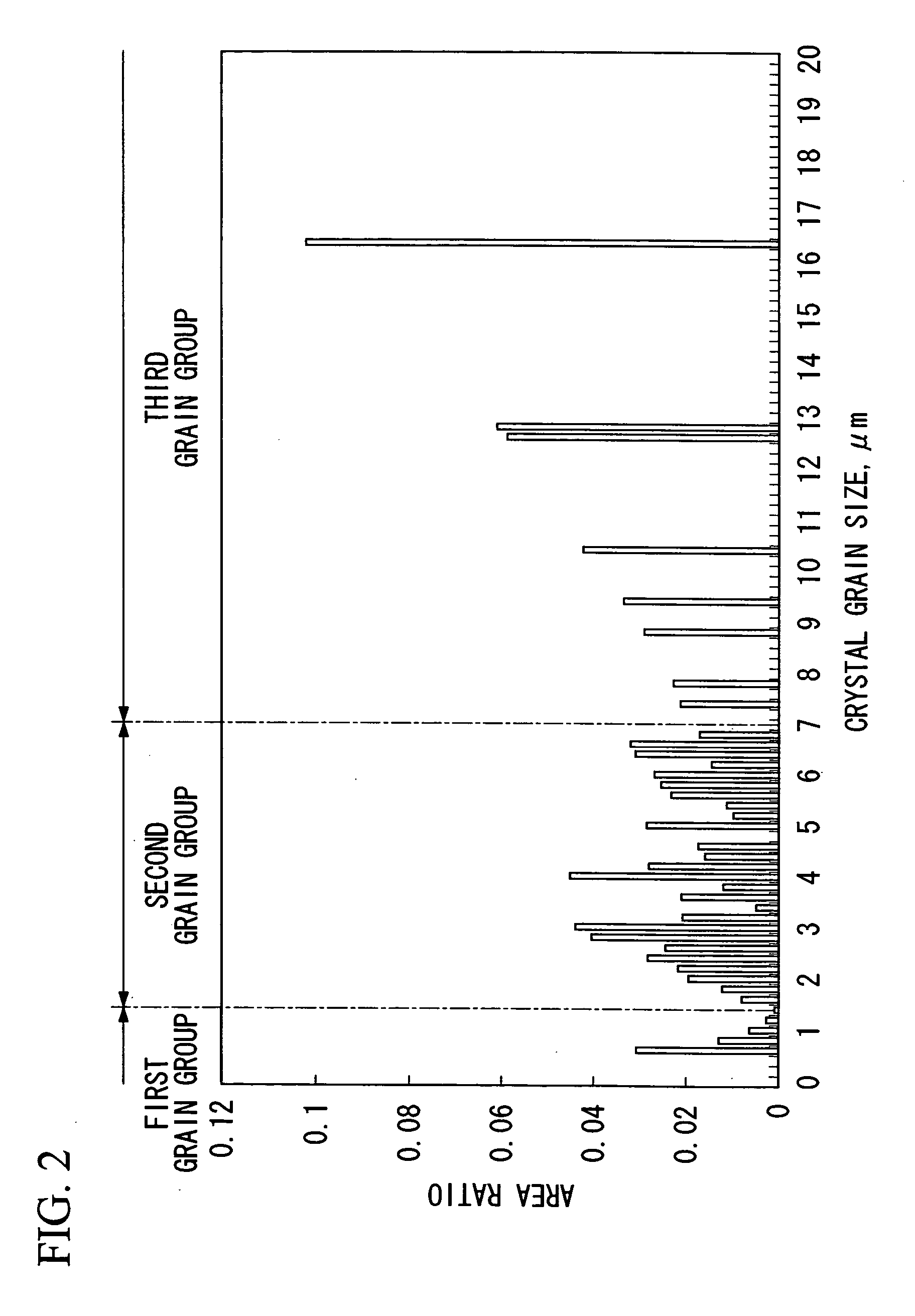

This copper alloy contains at least zirconium in an amount of not less than 0.005% by weight and not greater than 0.5% by weight, includes a first grain group including grains having a grain size of not greater than 1.5 μm, a second grain group including grains having a grain size of greater than 1.5 μm and less than 7 μm, the grains having a form which is elongated in one direction, and a third grain group including grains having a grain size of not less than 7 μm, and also the sum of α and β is greater than γ, and α is less than β, where α is a total area ratio of the first grain group, β is a total area ratio of the second grain group, and γ is a total area ratio of the third grain group, based on a unit area, and α+β+γ=1.

Owner:MITSUBISHI SHINDOH CO LTD

Method for manufacturing metal laminated substrate for semiconductor element formation and metal laminated substrate for semiconductor element formation

InactiveUS20110290380A1Low rolling reductionSmooth interfaceDecorative surface effectsSemiconductor/solid-state device detailsEtchingMetal foil

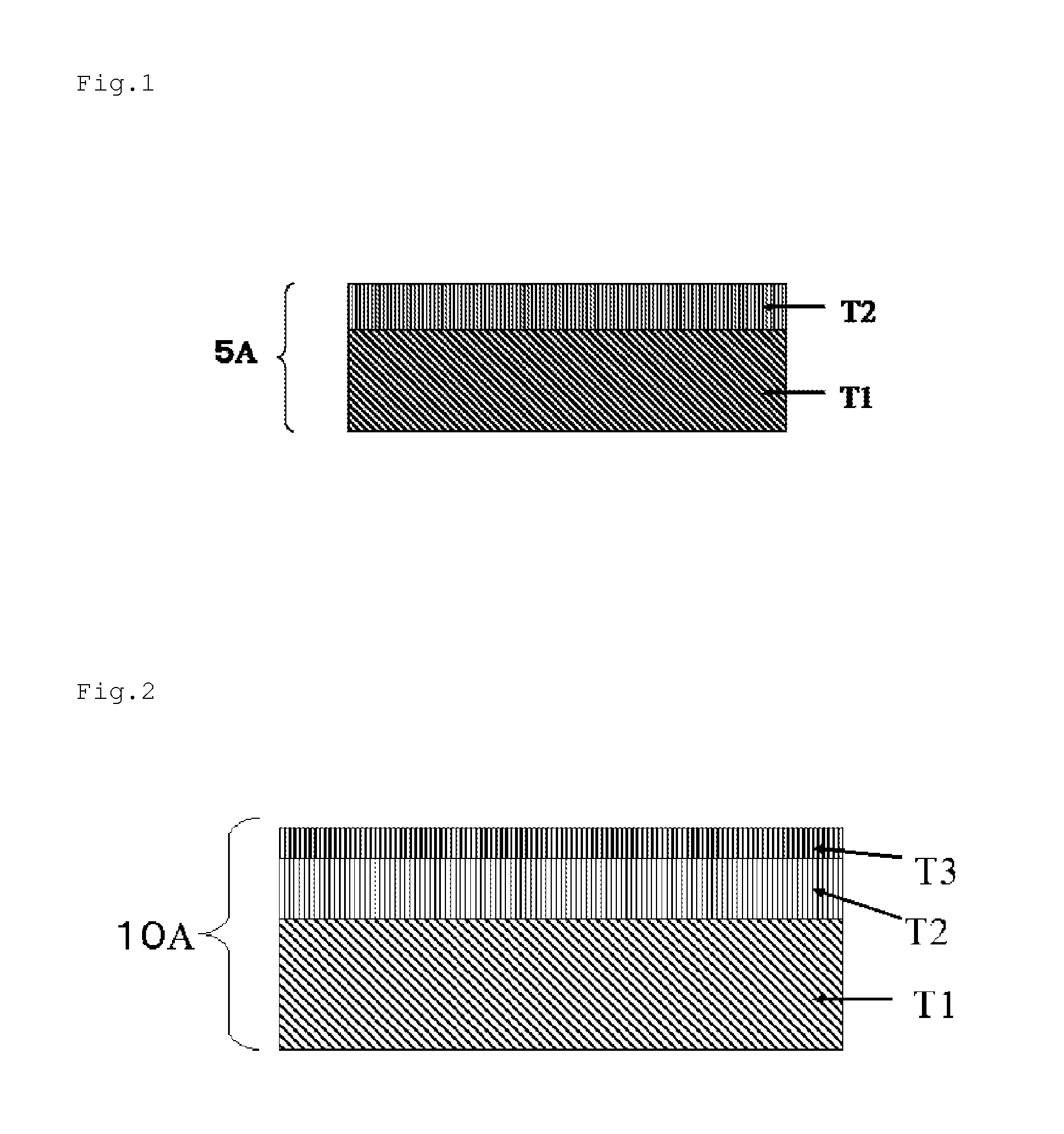

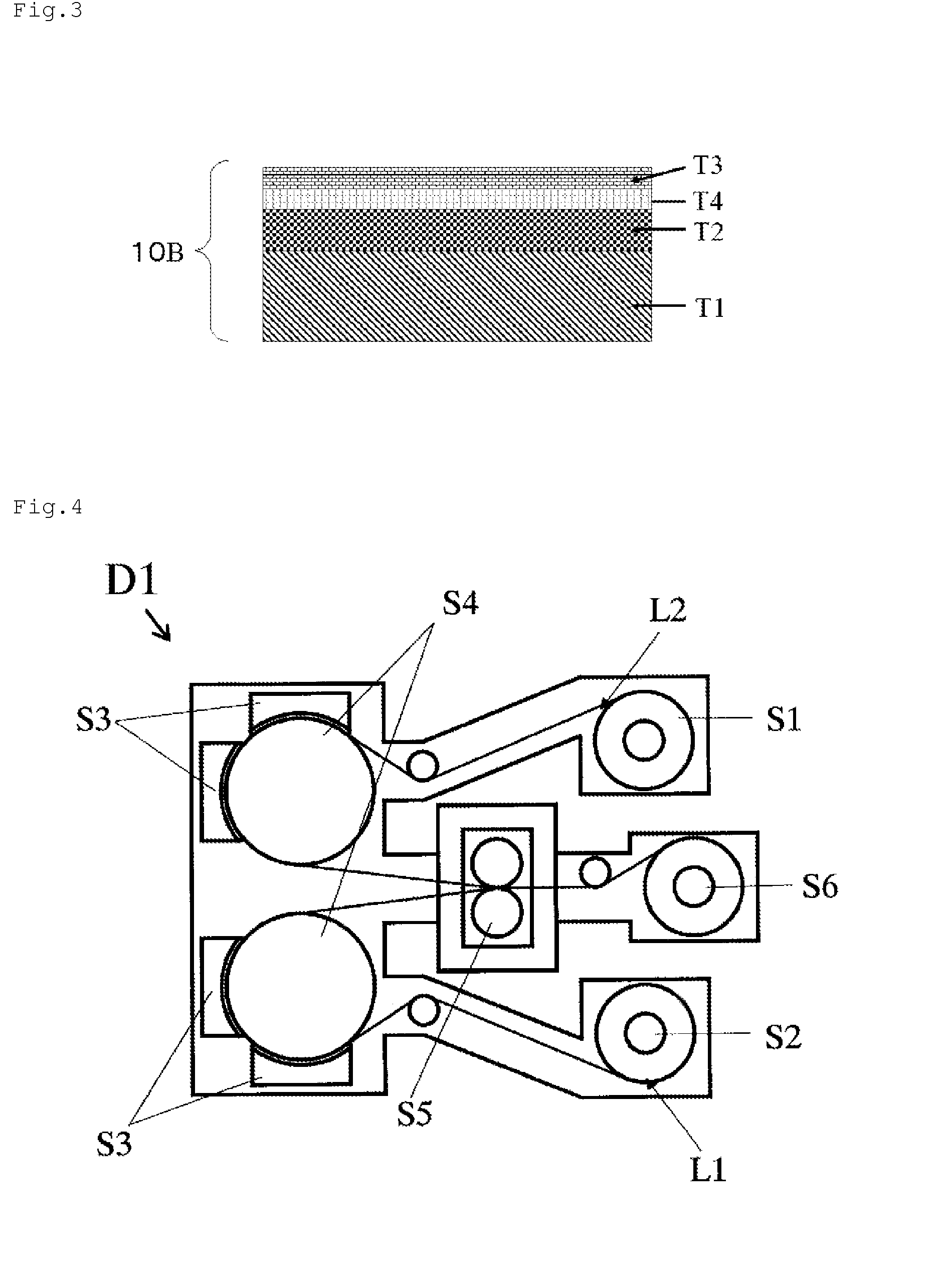

Disclosed is a metal laminated substrate for forming an epitaxial growth film for forming a semiconductor element having high biaxial crystal orientation on a surface of a metal substrate and a method of manufacturing the metal laminated substrate. The manufacturing method includes the steps of activating at least one surface of a metal plate T1 by sputter etching or the like; activating at least one surface of a metal foil T2 made of Cu or a Cu alloy which is cold-rolled at a rolling reduction of 90% or more; laminating the metal plate and the metal foil such that an activated surface of the metal plate and an activated surface of the metal foil face each other in an opposed manner and applying cold rolling to the metal plate and the metal foil which are laminated to each other at a rolling reduction of 10% or less, for example; and biaxially orienting crystals of the metal foil by heat treatment at a temperature of not lower than 150° C. and not higher than 1000° C.

Owner:TOYO KOHAN CO LTD

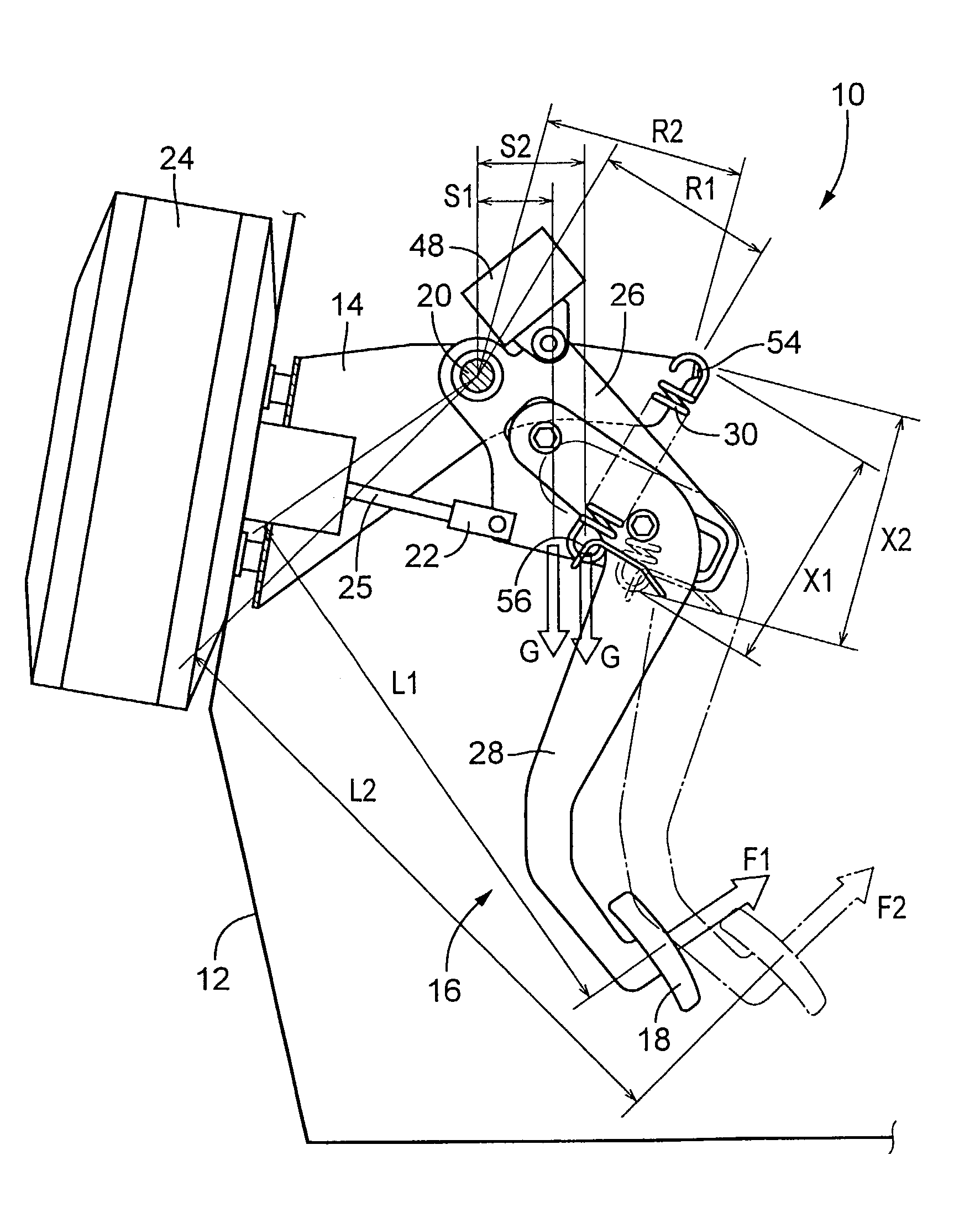

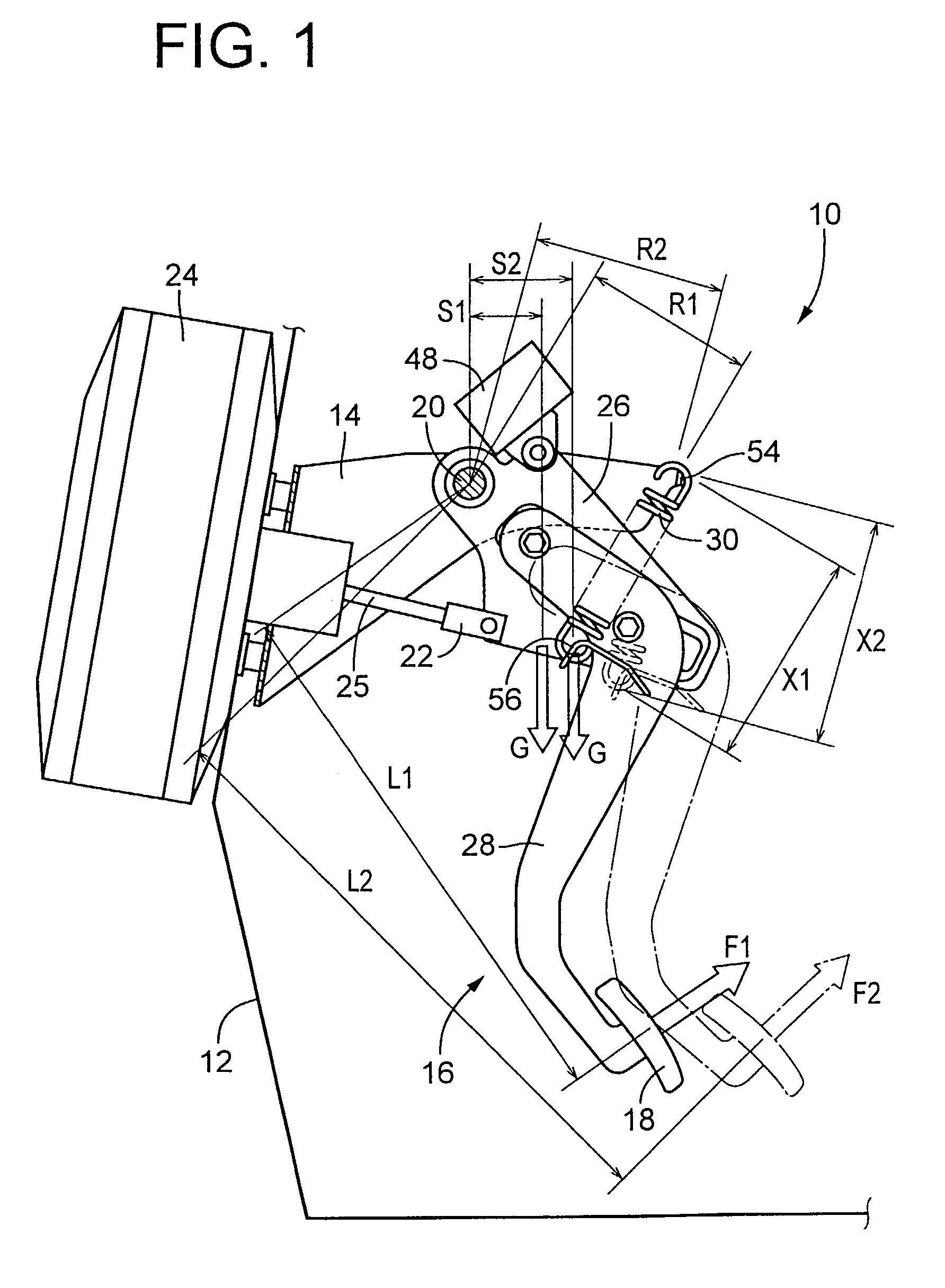

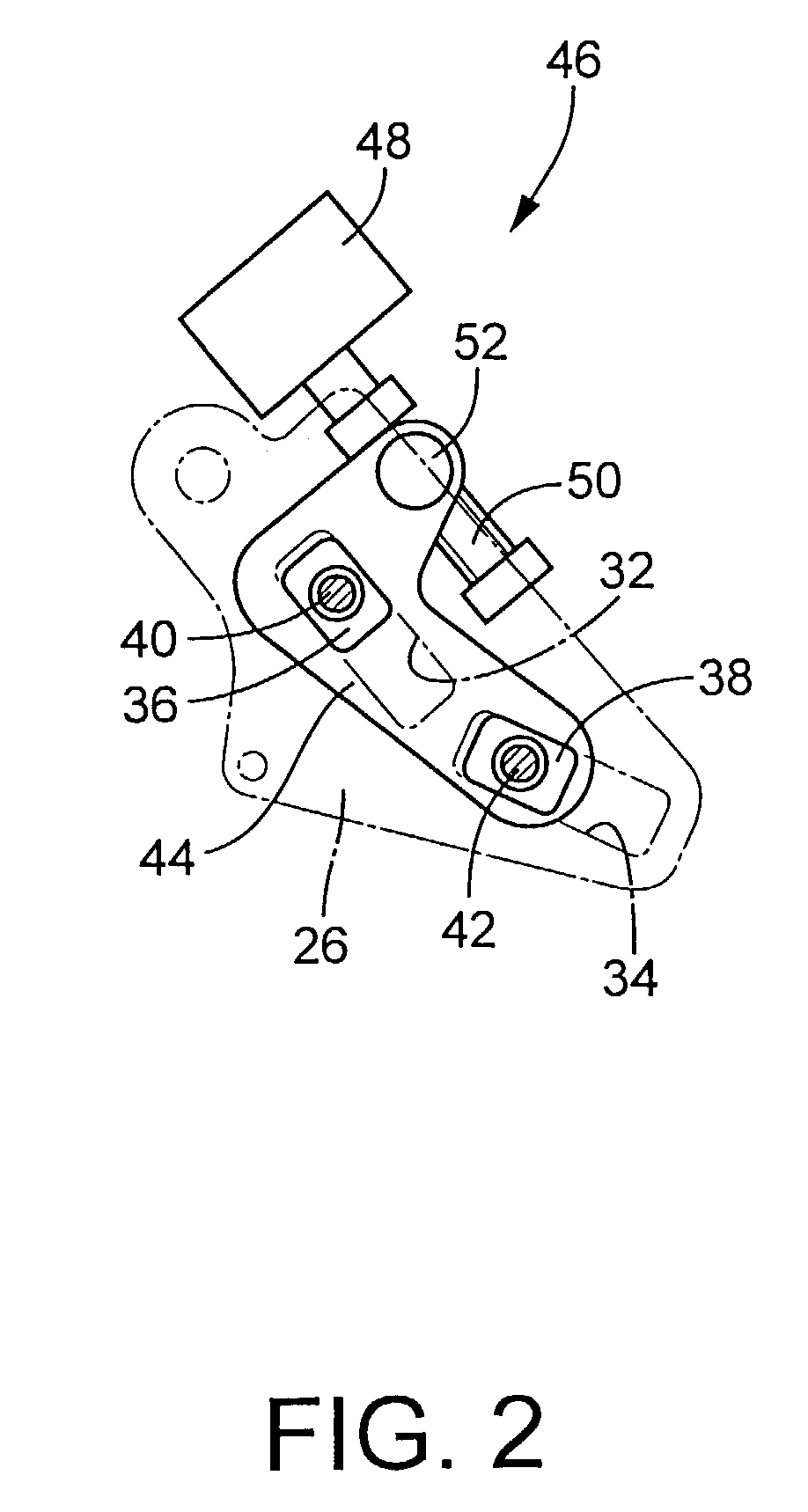

Pedal device wherein non-operated position of operating portion is adjustable

InactiveUS7069810B2Reduce the amount of variationEasy constructionControlling membersMechanical apparatusEngineeringMechanical engineering

Owner:TOYODA IRON WORKS CO LTD

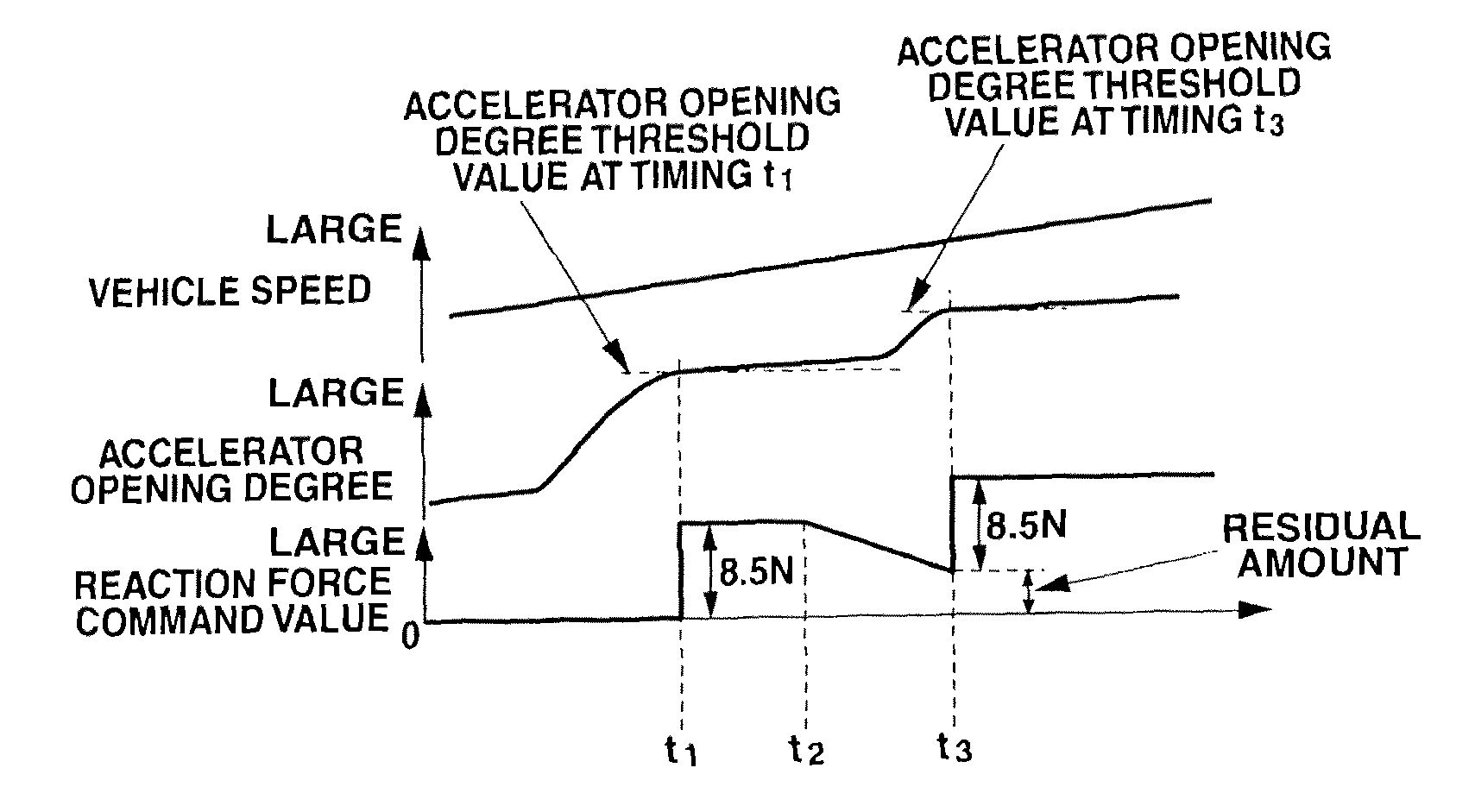

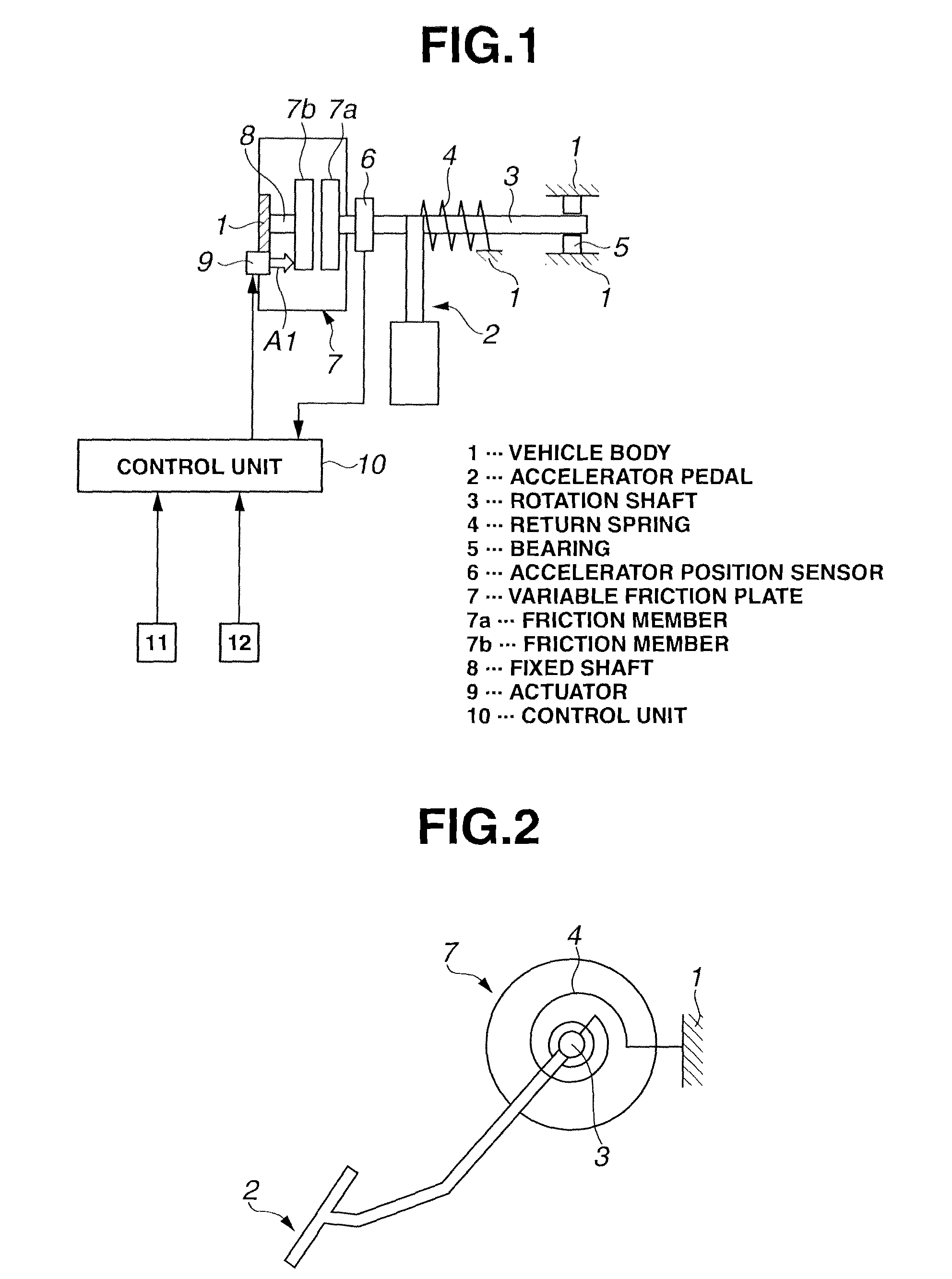

Accelerator pedal depression force control device

ActiveUS8844401B2Increase the amount of cuttingControlling membersElectrical controlEngineeringPressure increase

Owner:NISSAN MOTOR CO LTD

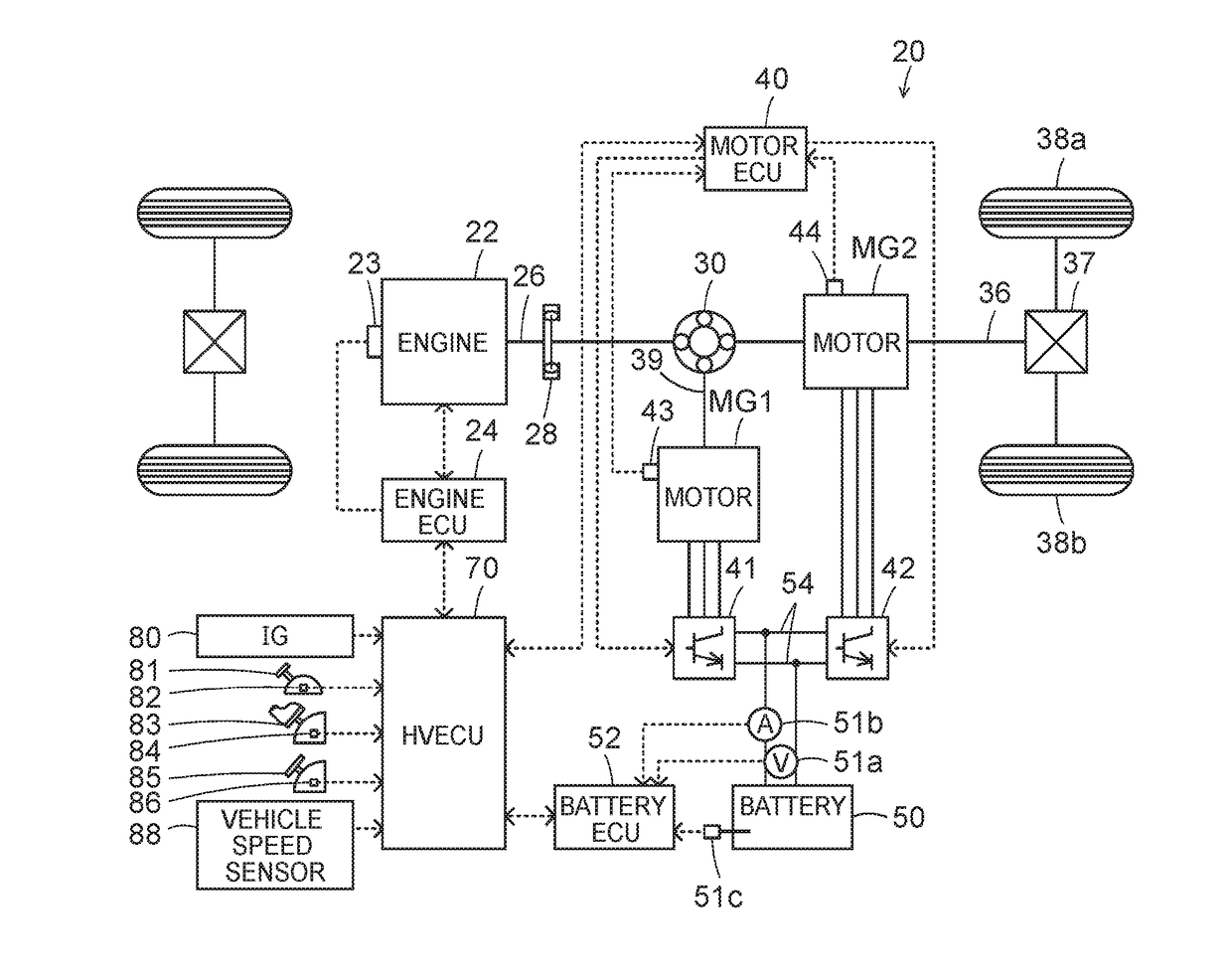

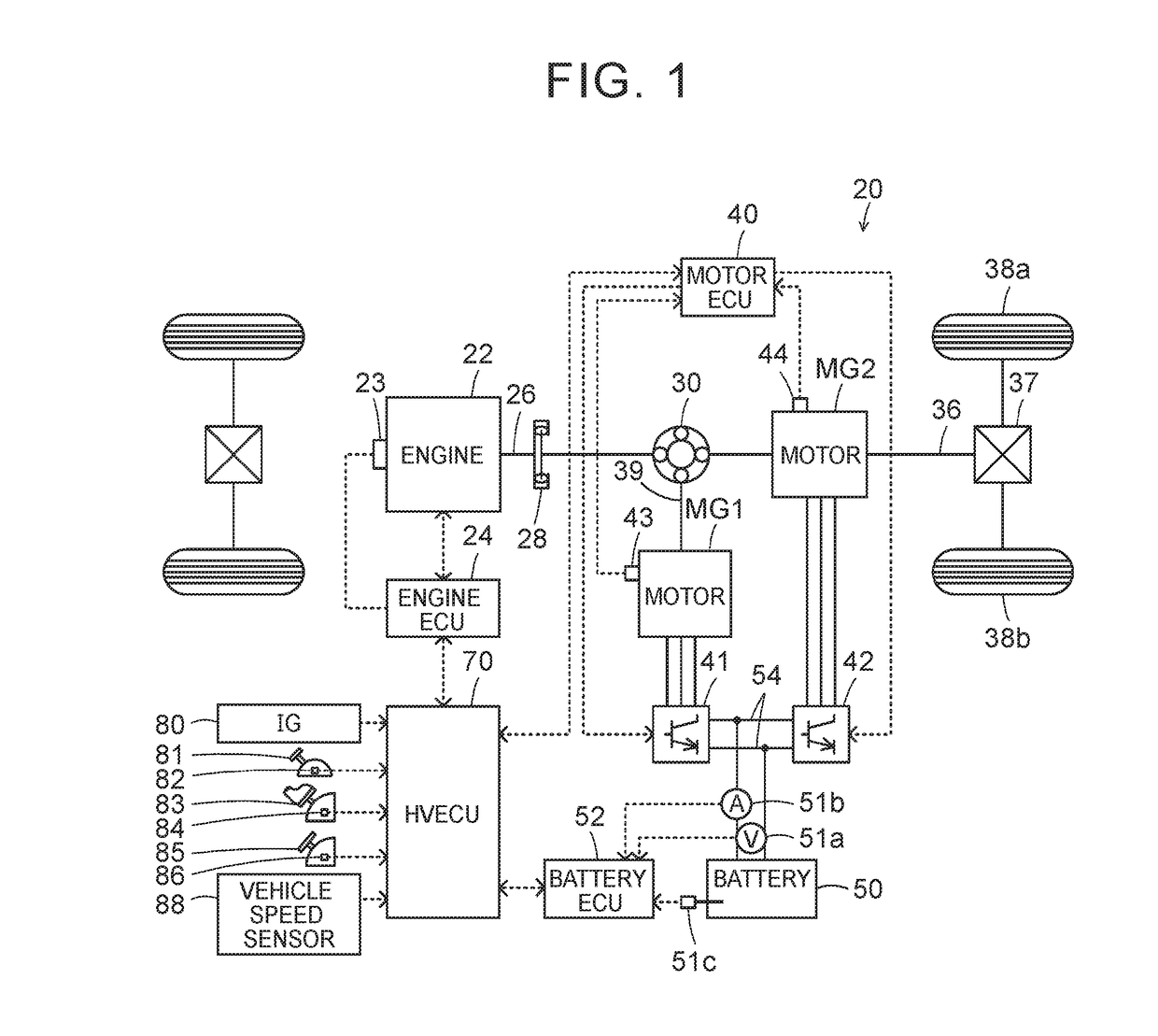

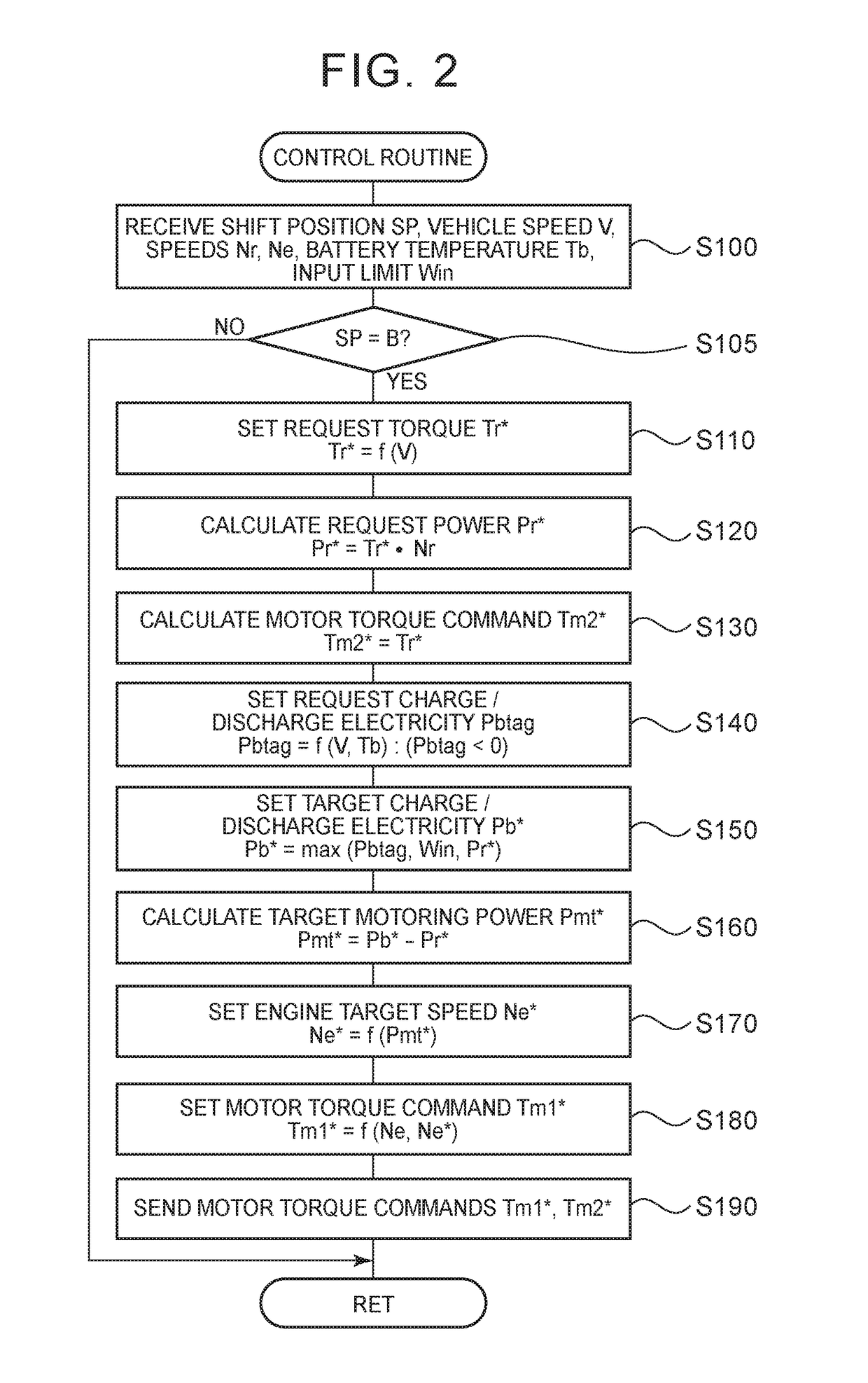

Hybrid vehicle

InactiveUS20170066433A1Low costSuppress of time periodHybrid vehiclesPropulsion using engine-driven generatorsElectricityElectric control

A hybrid vehicle includes an electric control unit. A predictable condition may be a condition that the time period from beginning of a charging of a battery to beginning of a rapid decrease in charged electricity is predicted to be within a specified time period. The electronic control unit may be configured to control a first motor such that a motoring of an engine is performed at a first speed by the first motor. The electronic control unit may be configured to prevent motoring of the engine by the first motor when the predictable condition is not satisfied. The electronic control unit may be configured to control the first motor such that the motoring of the engine is performed at a second speed that is higher than the first speed by the first motor when the predictable condition is satisfied.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com