Multi-edge composite cutting tools

A cutting tool and cutting edge technology, applied in the field of multi-edge combined cutting tools, can solve problems such as low cutting efficiency, and achieve the effects of improving cutting depth, diversifying materials, and changing processing forms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

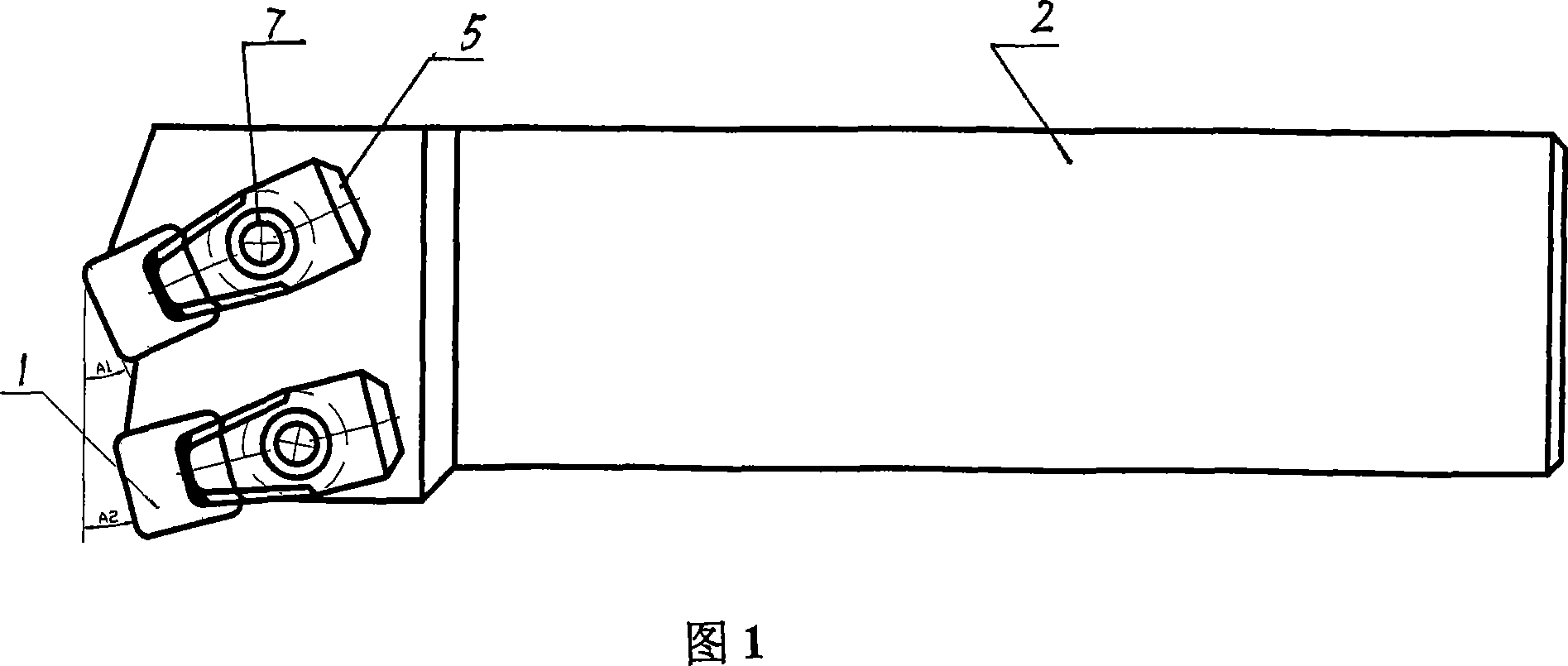

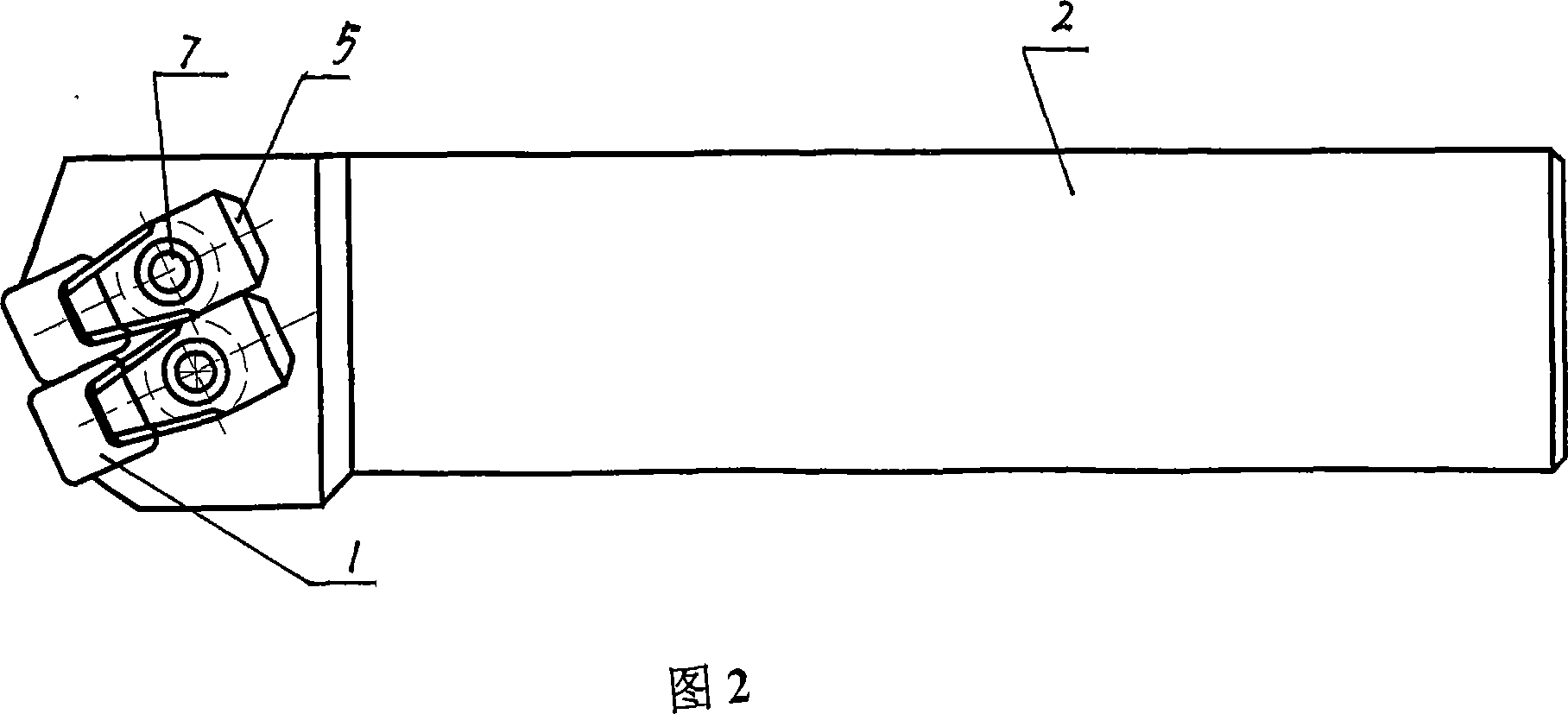

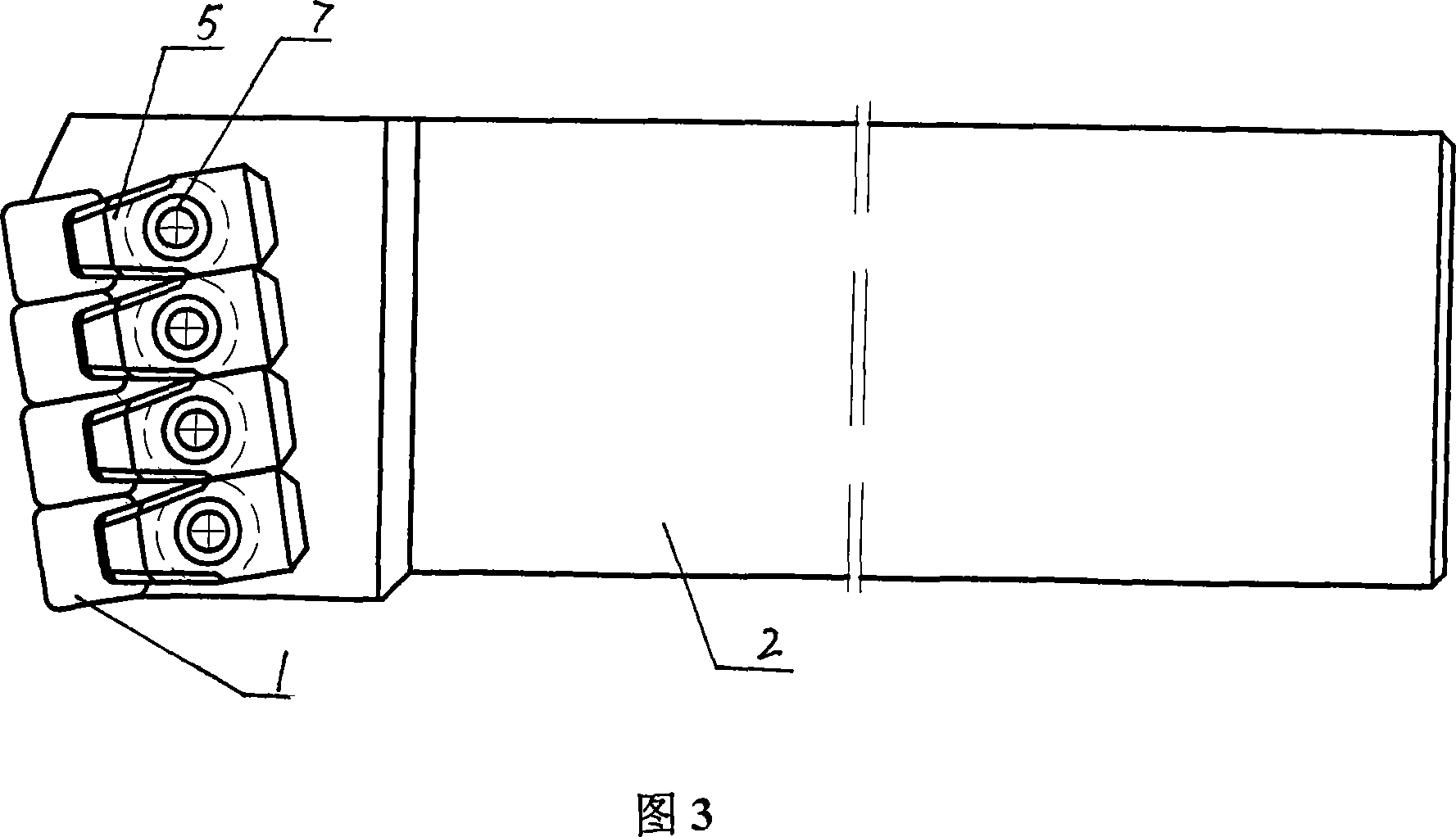

[0030] Below in conjunction with Fig. 1-Fig. 4, the present invention is described in further detail as follows:

[0031] A multi-cutting-edge combined cutting tool includes a cutter bar 2, and more than one blade mounting mechanism is arranged at the front end of the cutter rod 2, and blades 1 are respectively arranged on the blade mounting mechanism.

[0032] The blade mounting mechanism is as follows: a blade mounting groove 8 is set at the front end of the knife bar 2, a groove 9 is established behind the blade mounting groove 8, a knife pad 3 is placed at the bottom of the blade mounting groove 8, and a blade 1 is arranged on the knife pad 3. The bottom of the T-shaped pressing plate 5 is embedded in the groove 9 , the front end of the T-shaped pressing plate 5 presses the blade 1 tightly, and the pressing plate screw 7 fixes the T-shaped pressing plate 5 on the cutter bar 2 .

[0033] In order to achieve linkage between the T-shaped pressure plate 5 and the pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com