Steel belt for spoke of vehicle wheel and manufacturing method thereof

A manufacturing method and wheel technology, which is applied in the field of manufacturing spinning spokes, can solve the problems that the wheel cannot adapt to the development trend, poor steel welding performance, complex composition design, etc., and achieve stable control of chemical composition, good welding performance, and stable dimensional control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

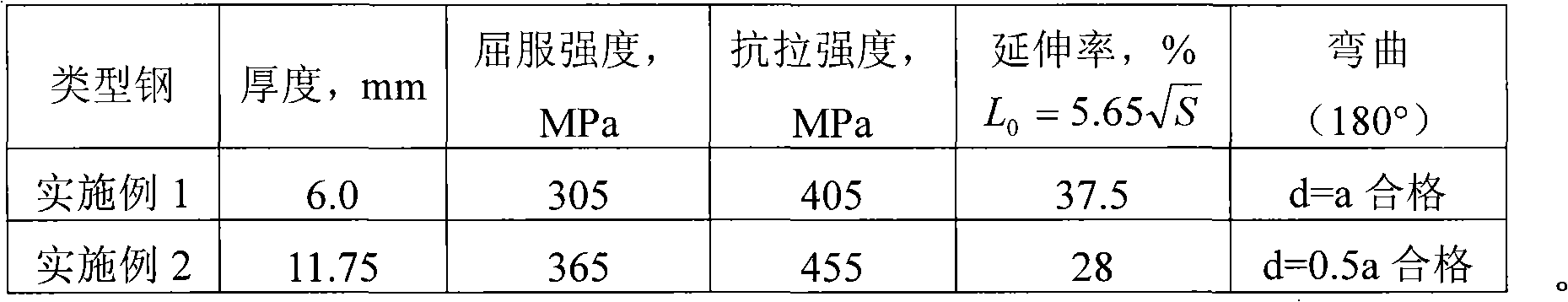

Examples

Embodiment 1

[0024] 1. The chemical composition of steel is as follows by weight percentage:

[0025] C: 0.07%, Si: 0.05%, Mn: 0.65%, P: 0.012%, S: 0.009%, Al: 0.028%, and the rest are Fe and unavoidable impurities.

[0026] 2. The manufacturing method of steel strips for automobile wheel spokes, taking 6.0mm thick steel strips as an example, the billet size is 175mm×1260mm:

[0027] (1) Preparation process route

[0028] Hot metal pretreatment - top and bottom double blowing converter smelting - LF ladle refining - slab continuous casting - hot rolling mill rolling.

[0029] (2) preparation method, the steps are as follows:

[0030] Hot metal pretreatment: control the sulfur in the hot metal below 0.035%, the temperature is: 1270°C, and remove the slag on the surface of the hot metal after desulfurization. Converter smelting endpoint control: C: 0.05%, S: 0.015%. LF refining white slag operation, feeding 350m calcium iron wire for calcification treatment before the molten steel leaves...

Embodiment 2

[0033] 1. The chemical composition of steel is as follows by weight percentage:

[0034] C: 0.10%, Si: 0.13%, Mn: 0.75%, P: 0.022%, S: 0.011%, Al: 0.042%, Nb: 0.009%, and the rest are Fe and unavoidable impurities.

[0035] 2, the manufacture method of steel strip for automobile wheel spoke, take 11.75mm thick steel strip as example, casting slab specification is 160mm * 1360mm, and production process route is the same as embodiment 1, and step is as follows:

[0036] Hot metal pretreatment: control the sulfur in the hot metal below 0.035%, the temperature is: 1300°C, and remove the slag on the surface of the hot metal after desulfurization. Converter smelting endpoint control: C: 0.08%, S: 0.015%. LF refining white slag operation, the molten steel is fed into a 500m silicon-calcium line for calcification before leaving the refining station, soft argon is blown for 12 minutes, the whole process of slab continuous casting is protected and poured, the crystallizer is cooled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com