High-thermal-stability wrought aluminium alloy and preparation method thereof

A technology of deformed aluminum alloy and high thermal stability, which is applied in the field of non-ferrous metals, can solve the problems that the thermal stability of deformed aluminum alloy has not been reported, and achieve high thermal stability and improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) Add Al-6wt.%Er and Al-4wt.%Zr master alloys to the molten aluminum, so that the element content in the melt is: erbium: 0.3%, zirconium: 0.3%, the rest is aluminum and unavoidable Impurities. When making aluminum alloy, high-purity aluminum ingots are added to the resistance furnace, the heating temperature is 750°C, and the intermediate alloy is added to the molten aluminum. The temperature of the molten metal is 850°C. After being fully stirred, it is poured into an iron mold. After the ingot is solidified, the ingot is quickly taken out and cooled to room temperature. The ingot size is: 200*100*35mm.

[0015] 2) For the cold-rolled deformation of the ingot in step 1), the height of the ingot before rolling is 35 mm, and the cold-rolled plate is made into a 3.5 mm thick plate, and the deformation is 90%.

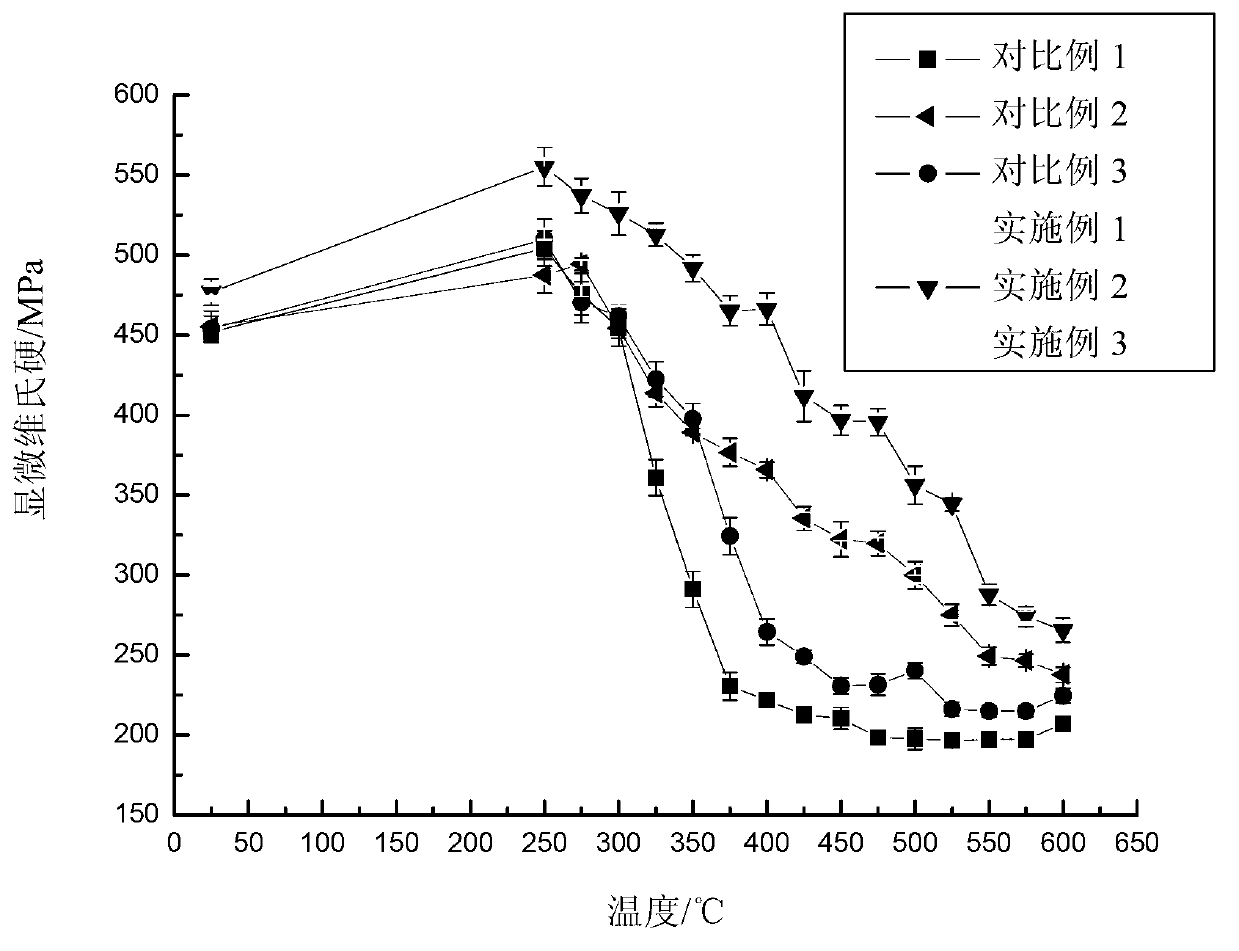

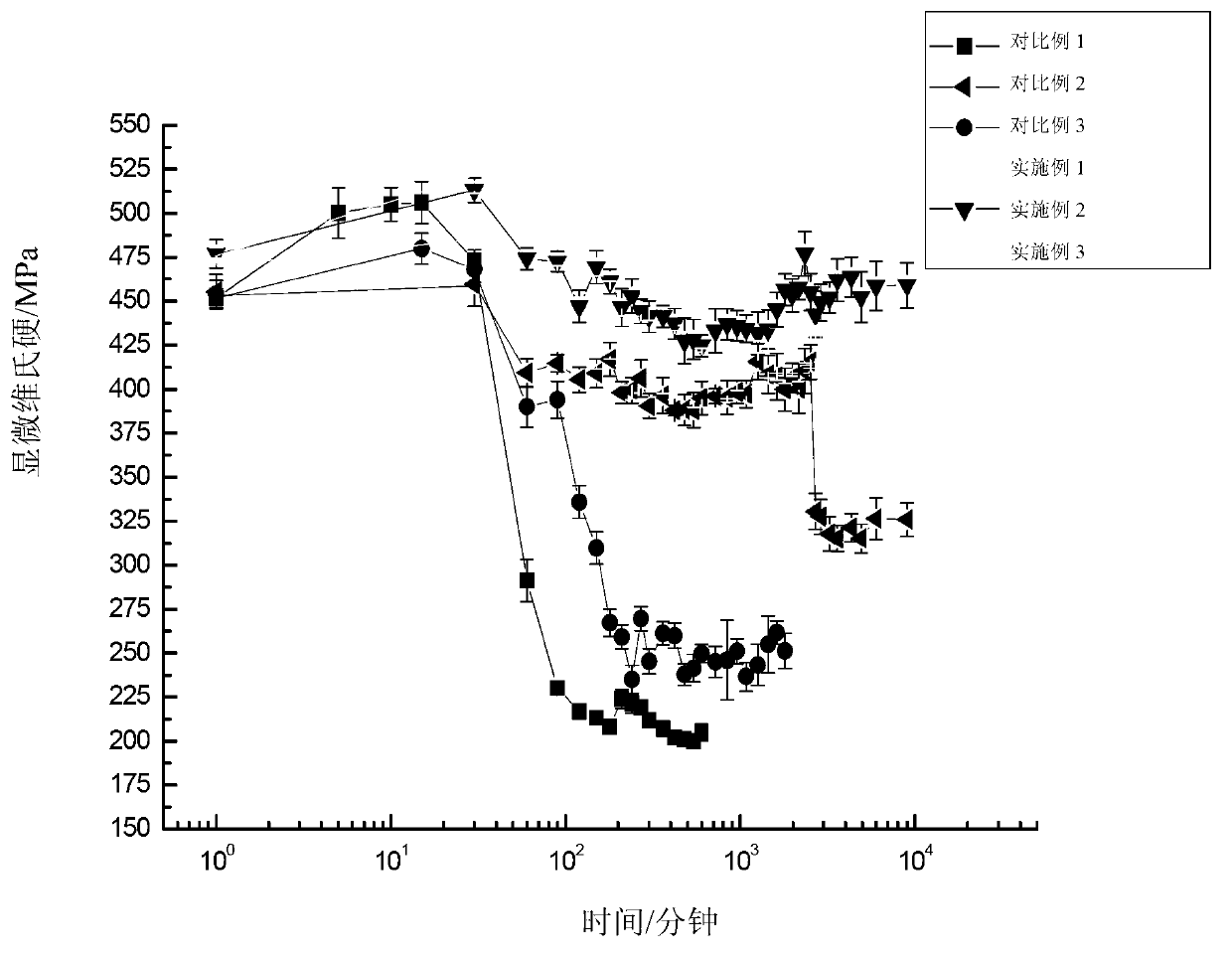

[0016] 3) The deformed aluminum alloy in step 2) is annealed at different temperatures for 1 hour, and the annealing temperature is up to 600°C. At the same t...

Embodiment 2

[0018] Step 1) is the same as in Example 1, except that the alloy composition content is: erbium: 0.3%; zirconium: 0.4%; the rest is aluminum and unavoidable impurities. Step 2) is the same as in Example 1. Step 3) is the same as in Example 1.

Embodiment 3

[0020] Step 1) is the same as in Example 1, except that the alloy composition content is: erbium: 0.3%; zirconium: 0.6%; the rest is aluminum and unavoidable impurities. Step 2) is the same as in Example 1. Step 3) is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com