Aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof

An aluminum alloy sheet, aluminum alloy technology, applied in shoe uppers, footwear, applications, etc., can solve the problems of unsatisfactory performance and thick thickness, and achieve the effects of improving work efficiency, low thickness and shortening molding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing an aluminum alloy plate used for the toe cap of labor insurance leather shoes, comprising:

[0050] a) Provide an aluminum alloy ingot; the aluminum alloy ingot includes the following elements by weight percentage:

[0051] Fe 0.50%~1%;

[0052] Mn 0.40%~1.0%;

[0053] Mg 0.4%~0.80%;

[0054] Si 0.20%~0.80%;

[0055] Zr 0.2%~0.3%;

[0056] Ti 0.10%~0.2%;

[0057] Cu 3.5%~4.5%;

[0058] The balance of Al;

[0059] b) homogenizing, planing, sawing and milling the aluminum alloy ingot;

[0060] c) hot-rolling and cold-rolling the milled aluminum alloy ingot;

[0061] d) Annealing the cold-rolled aluminum alloy prefabricated plate;

[0062] e) pre-shearing and finishing the annealed aluminum alloy prefabricated panel;

[0063] f) Cleaning and drying the finished aluminum alloy prefabricated plate to obtain an aluminum alloy plate for the toe cap of labor insurance leather shoes.

[0064] According to the present inven...

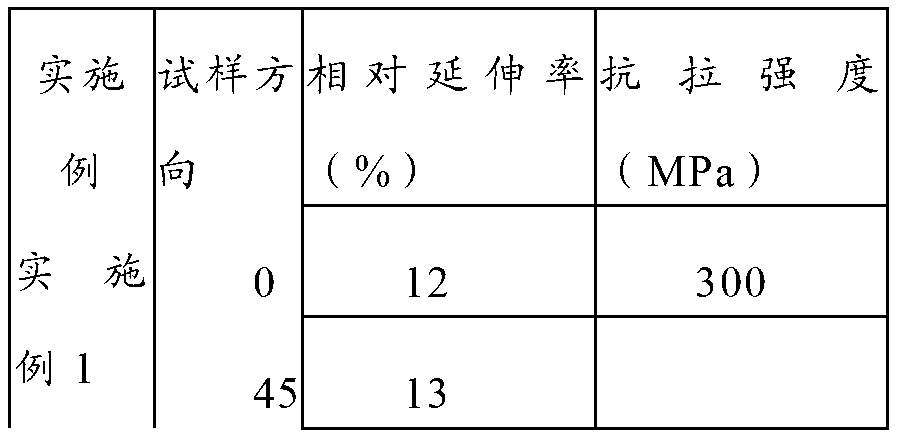

Embodiment 1

[0079] Fe 0.50%;

[0080] Mn 0.40%;

[0081] Mg 0.4%;

[0082] Si 0.20%;

[0083] Zr 0.2%;

[0084] Ti 0.10%;

[0085] Cu 3.5%;

[0086] The balance of Al;

[0087] Mix the metal powders in the above weight percentages, prepare an ingot by powder metallurgy, and mill the ingot on a milling machine. .

[0088] Then heat the aluminum alloy ingot after milling, and perform homogenization treatment. The heating temperature is 580°C,

[0089] The homogenized ingot is immediately hot-rolled, the starting temperature is preferably 580°C, the final rolling temperature is preferably 500°C, and the thickness of the plate is 1% of the thickness of the ingot.

[0090] The hot-rolled ingot is subjected to the first cold rolling. According to the present invention, the first cold rolling adopts a larger reduction, which is 1% of the thickness of the hot-rolled ingot. The rolling start temperature was 300°C. The finishing temperature is preferably 250°C. A preform is obtained aft...

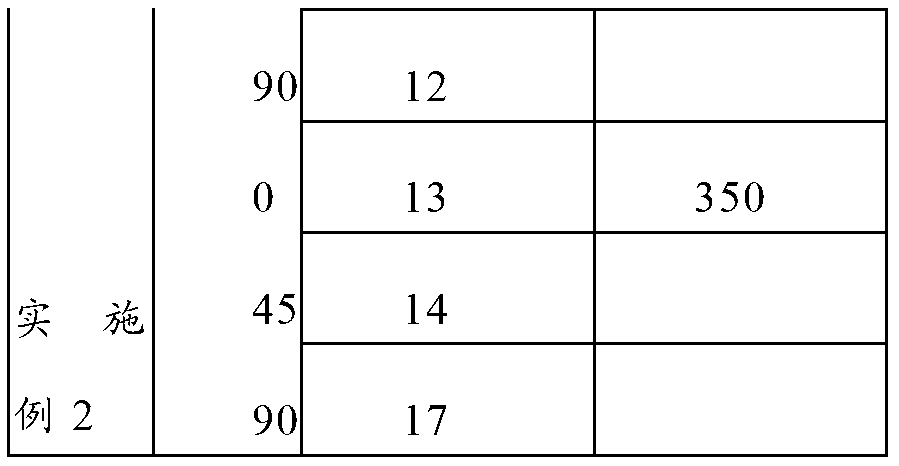

Embodiment 2

[0093] Fe 1%;

[0094] Mn 1.0%;

[0095] Mg 0.80%;

[0096] Si 0.80%;

[0097] Zr 0.3%;

[0098] Ti 0.2%;

[0099] Cu 4.5%;

[0100] The balance of Al.

[0101] The ingot is milled on a milling machine, the amount of milling on one side is 8mm, to ensure that the defects on both sides are milled clean, and the side milling cutter mills the small face.

[0102] Then heat the aluminum alloy ingot after milling, and perform homogenization treatment. The heating temperature is 500°C,

[0103] The homogenized ingot is immediately hot-rolled, the starting temperature is preferably 500°C, the final rolling temperature is preferably 450°C, and the thickness of the plate is 10% of the thickness of the ingot.

[0104] The hot-rolled ingot is subjected to the first cold rolling. According to the present invention, the first cold rolling adopts a larger reduction, which is 10% of the thickness of the hot-rolled ingot. The rolling start temperature was 300°C. The finishing temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com