Modification treatment method of aluminium alloy

A modification treatment, aluminum alloy technology, applied in the field of aluminum alloy, can solve the problems of inability to meet industrial applications, limited refining effect, high Sc price, etc., and achieve the effects of fine grains, small dendrite spacing, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put the A356 aluminum alloy (Al-7Si-0.6Mg) in a graphite crucible that has been cleaned and preheated to 500 °C, and placed in a SG2-7.5-12 resistance furnace to heat up to 750 °C to melt, and the A356 aluminum alloy ( After Al-7Si-0.6Mg) is completely melted, when the temperature is 720° C. to 750° C., the Al-12Er master alloy is pressed in with a bell jar, so that the Er content reaches 0.20%. Use a graphite rod to stir evenly for 1 minute, keep warm for 4-6 minutes, so that the elements are evenly distributed, and when the temperature of the melt drops to 700 ° C ~ 720 ° C, use a bell jar to press 0.10% of the mass of hexacyanoethane into the melt for degassing and degassing Let the slag stand for 10 minutes, remove the slag, filter, and pour it into a metal mold preheated to 220°C to make a metallographic sample and observe the metallographic structure.

[0027] In the solidification structure of the A356 alloy (Al-7Si-0.6Mg) with 0.20% Er content in Example 1, the ...

Embodiment 2

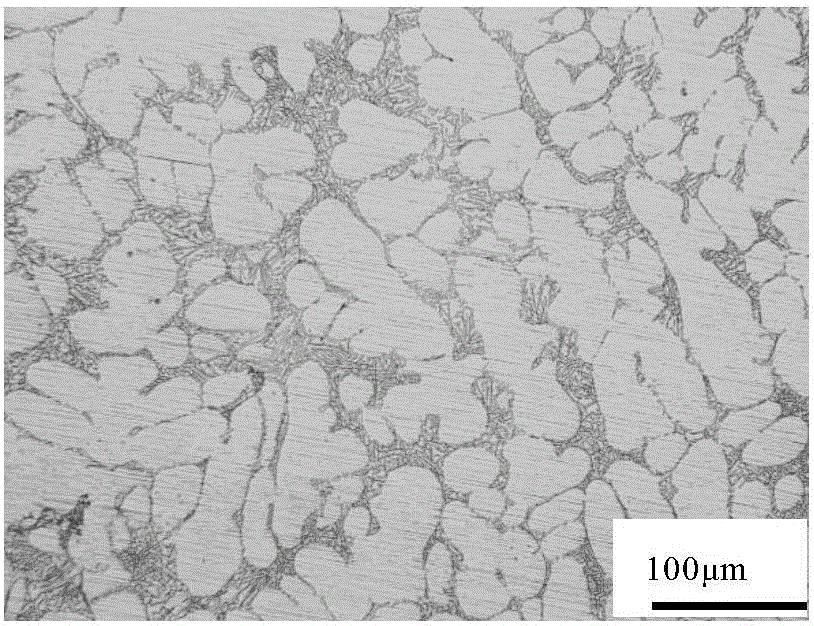

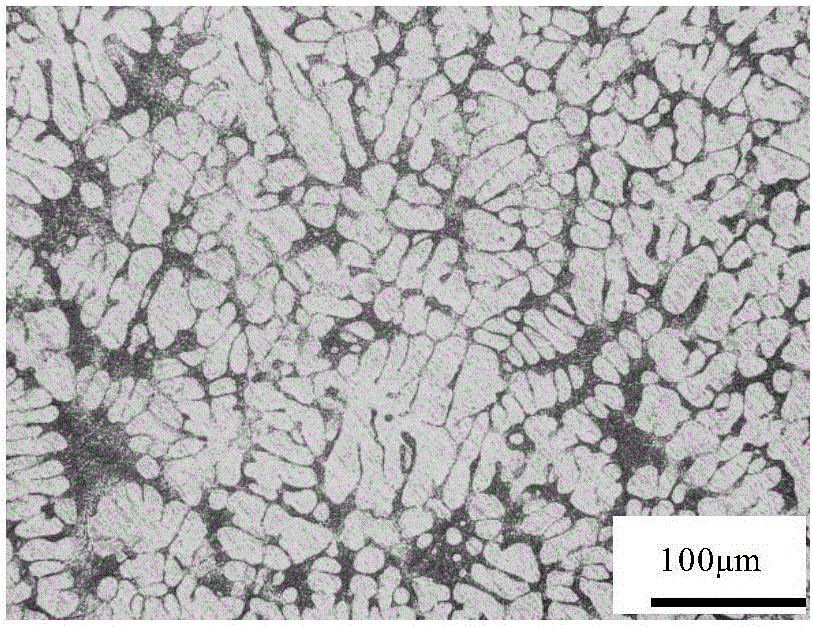

[0031] Put the A356 aluminum alloy (Al-7Si-0.6Mg) in a graphite crucible that has been cleaned and preheated to 500°C, and placed in a SG2-7.5-12 resistance furnace to heat up to 750°C to melt, and the A356 aluminum alloy ( After Al-7Si-0.6Mg) is completely melted, when the temperature is 720°C-750°C, use a bell jar to press into the Al-12Er master alloy, so that the Er content reaches 0.40%. Use a graphite rod to stir evenly for 1 minute, keep warm for 4-6 minutes, so that the elements are evenly distributed, and when the temperature of the melt drops to 700 ° C ~ 720 ° C, use a bell jar to press 0.10% of the mass of hexacyanoethane into the melt for degassing and degassing Let the slag stand for 10 minutes, remove the slag, filter, and pour it into a metal mold preheated to 220°C to make a metallographic sample and observe the metallographic structure. In the solidification structure of A356 alloy (Al-7Si-0.6Mg) without adding refiner, the primary aluminum dendrites are thic...

Embodiment 3

[0034] Put the A356 aluminum alloy (Al-7Si-0.6Mg) in a graphite crucible that has been cleaned and preheated to 500°C, and placed in a SG2-7.5-12 resistance furnace to heat up to 750°C to melt, and the A356 aluminum alloy ( After Al-7Si-0.6Mg) is completely melted, the Al-10Zr master alloy is pressed into the Al-10Zr master alloy with a bell jar at a temperature of 720° C. to 750° C., so that the Zr content reaches 0.10%. Use a graphite rod to stir evenly for 1 minute, keep warm for 4-6 minutes, so that the elements are evenly distributed, and when the temperature of the melt drops to 700 ° C ~ 720 ° C, use a bell jar to press 0.10% of the mass of hexacyanoethane into the melt for degassing and degassing Let the slag stand for 10 minutes, remove the slag, filter, and pour it into a metal mold preheated to 220°C to make a metallographic sample and observe the metallographic structure. In the solidification structure of A356 alloy (Al-7Si-0.6Mg) without adding refiner, the prima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com