Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce dendrite spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

InactiveCN106834795ASolve segregationImprove plastic processing performanceIncreasing energy efficiencyWear resistantWater cooling

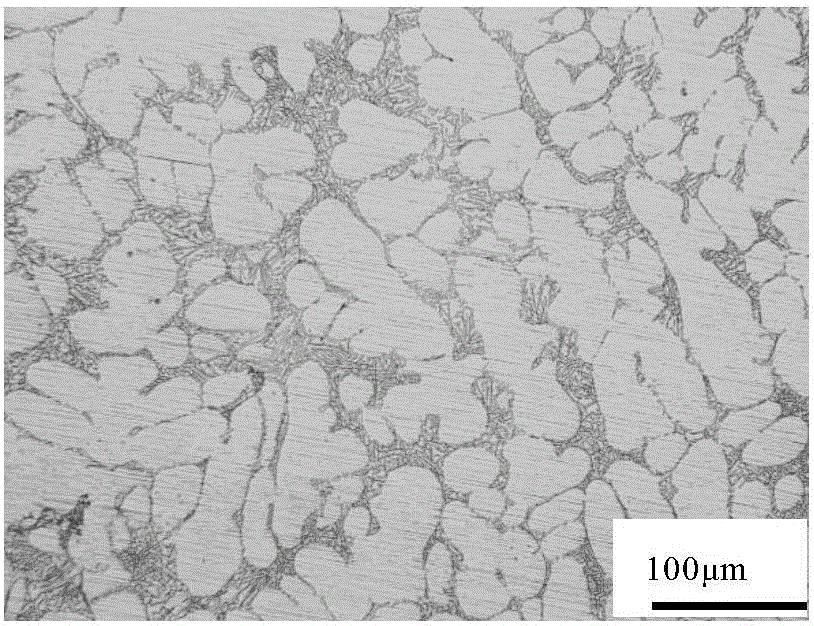

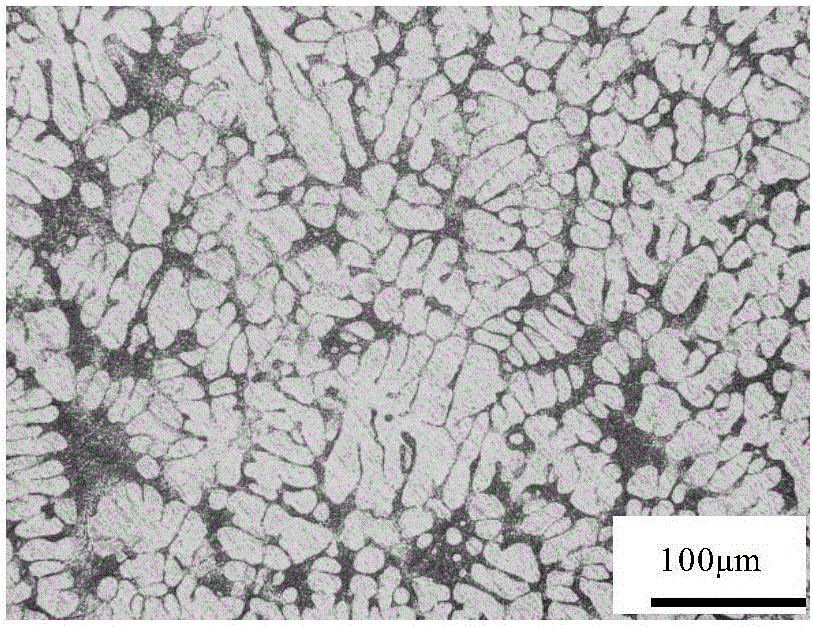

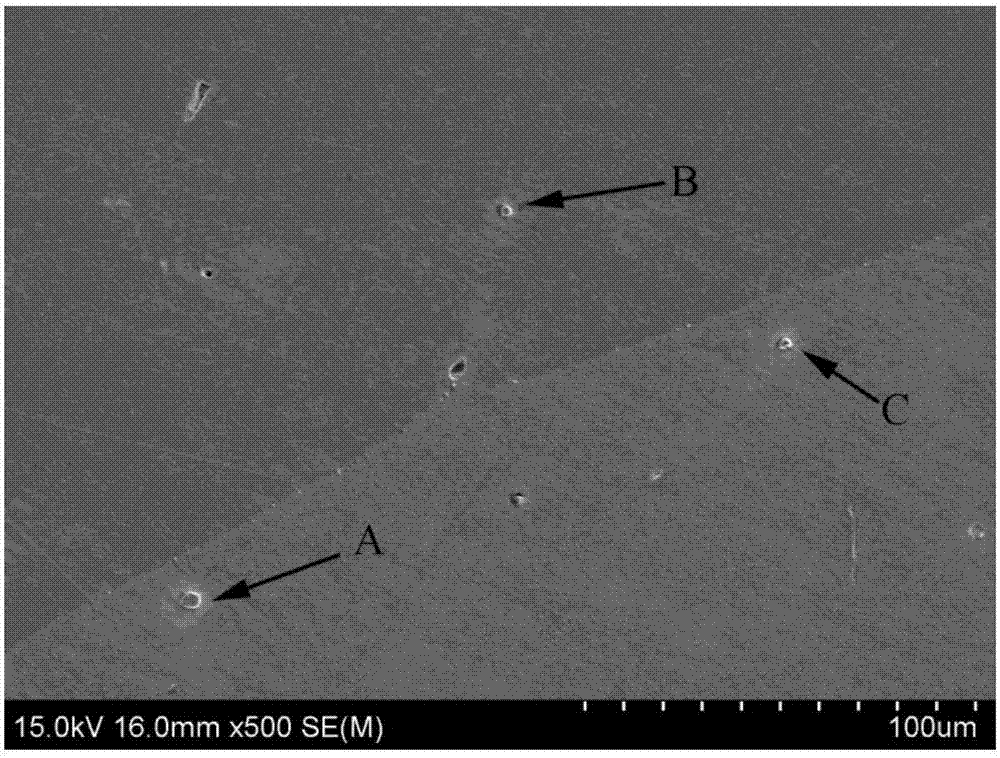

The invention relates to a preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The preparation method comprises the following steps: vacuum induction melting or covering protection type non vacuum melting of a Cu-Ni-Sn ternary alloy, application of electromagnetic stirring until alloy melt is solidified completely in the subsequent solidification process, and homogenization annealing-water cooling-solid solution-cold deformation-aging treatment of as-cast alloy. Through use of the preparation method of a high-elasticity corrosion-resistant and wear-resistant Cu-Ni-Sn alloy, crystal grains can be refined, dendrite spacing can be reduced, macrosegregation and microsegregation of the series of alloy can be eliminated, aging strengthening effect is excellent, plastic processing property of the series of alloy can be improved, the service life of the alloy can be improved, by the application of electromagnetic stirring in the solidification process, the segregation degree of the obtained as-cast structure is small, the segregation is easy to remove, and the method has the advantages of saving energy, improving production efficiency and reducing production cost.

Owner:JIANGYIN SANLING METAL PROD

Magnesium-zinc-zirconium-yttrium-magnesium alloy

InactiveCN101812620AImprove heat deformation plasticityReduce extrusion deformation resistanceHeat deflection temperatureYttrium

The invention provides a magnesium-zinc-zirconium-yttrium-magnesium alloy which comprises the following components in percentage by weight: 2.0-4.0% of zinc, 0.2-0.5% of zirconium and 0.9-5.8% of yttrium and the balance magnesium and impurity. The invention improves optional heat deflection temperature range of the alloy by controlling zinc content in the magnesium-zinc-zirconium series magnesium alloy and adding yttrium element with a proper proportion; higher deflection temperature is favorable for improving the heat deflection plasticity of magnesium alloy and improving extrusion rate; and meanwhile, alloy crystalline grain is refined by the action that high melting point second phase containing yttrium prevents crystalline grains from growing in the heat extrusion deformation recrystallization process so as to obtain magnesium alloy with moderate strength and favorable plasticity. The magnesium-zinc-zirconium-yttrium-magnesium alloy with the optimal proportion has the room-temperature tensile strength of 279 MPa, yield strength of 184 MPa and elongation percentage of 28%.

Owner:CHONGQING UNIV

Rare earth aluminum alloy material and preparation method thereof

ActiveCN110885940AGood casting performanceReduce dendrite spacingCastabilityUltimate tensile strength

On one hand, the invention provides a rare earth aluminum alloy material comprising the following components by mass: 6%-8% of Si, 1.5%-4.5% of Cu, 0.2%-0.5% of Mg, 0.3%-0.8% of Mn, 0.2%-0.5% of Re, 0.1%-0.2% of Ti, 0.01%-0.05% of Sr and 80%-89% of Al; the Re is mischmetal containing Ce and La, and the Ti, Si, Ce and La rare earth elements are introduced into aluminum alloy; the castability of thealuminum alloy is improved effectively, and the freezing range and dendrite arm spacing of the alloy are reduced; the rare earth aluminum alloy material is higher in strength and plasticity; the component requirements of the rare earth aluminum alloy material are lower, and high purity Al ingots and expensive Zr, V and Y alloys are not required; the production cost is low, and the rare earth aluminum alloy material is high in industrial value. On the other hand, the invention provides a preparation method of the rare earth aluminum alloy material, and an indirect extrusion casting process isadopted; and the industrial production is achieved, and the preparation method has huge development potential in the fields of lightweight automobiles, intelligent robots, aerospace and the like.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

Aluminum alloy sodium-free refining agent and application thereof

The invention provides an aluminum alloy sodium-free refining agent and belongs to the technical field of casting of aluminum alloys. The sodium-free refining agent comprises the following raw materials in parts by weight: 30-35 parts of K2CO3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 12-18 parts of LiCl, 3-5 parts of calcium oxide, 30-35 parts of BalF3, 5-10 parts of K2SiF6, 10-15 parts of C6Cl6, 5-10 parts of TiO2 and 3-8 parts of CaCl. The aluminum alloy sodium-free refining agent is free of impurity sodium; meanwhile, rare-earth metals are added into the sodium-free refining agent; the rare-earth metals have high chemical affinity with impurity elements such as H2 and S and the like; the rare-earth metals and various impurity elements form compounds; the influence of harmful impurities can be eliminated; the rare-earth metals have the functions of modifying and refining the aluminum alloy structure; the dendrite spacing of the aluminum alloy is effectively reduced; the as-cast grains are refined; the mechanical performance of the alloy is improved; meanwhile, the smelting temperature of the aluminum alloy is maintained at 710-730 DEG C in the process of using the aluminum alloy sodium-free refining agent, so that the effect of removing impurity elements such as H2 and S and the like is more significant.

Owner:贵州航天风华精密设备有限公司

Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

The invention relates to a preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The Cu-Ni-Sn multi-element alloy is obtained through vacuum induction melting or covering protection type non-vacuum smelting. In the casting forming process, electromagnetic stirring is applied until alloy liquid is complete solidified, and then the as-cast alloy is subjected to homogenization annealing, hot rolling and cogging, solid solution treatment, cold deformation, spinodal decomposition and other processes. The preparation method of the Cu-Ni-Sn alloy is capable ofrefining crystalline grains, reducing dendritic spacing and eliminating alloy microscopic and macroscopic structure and component segregation, provides implementation conditions for follow-up alloy plastic processing, spinodal decomposition and other processes, and has the beneficial effects that energy is saved, the production efficiency is improved, the service life of the alloy is prolonged, and the production cost is reduced.

Owner:JIANGYIN SANLING METAL PROD

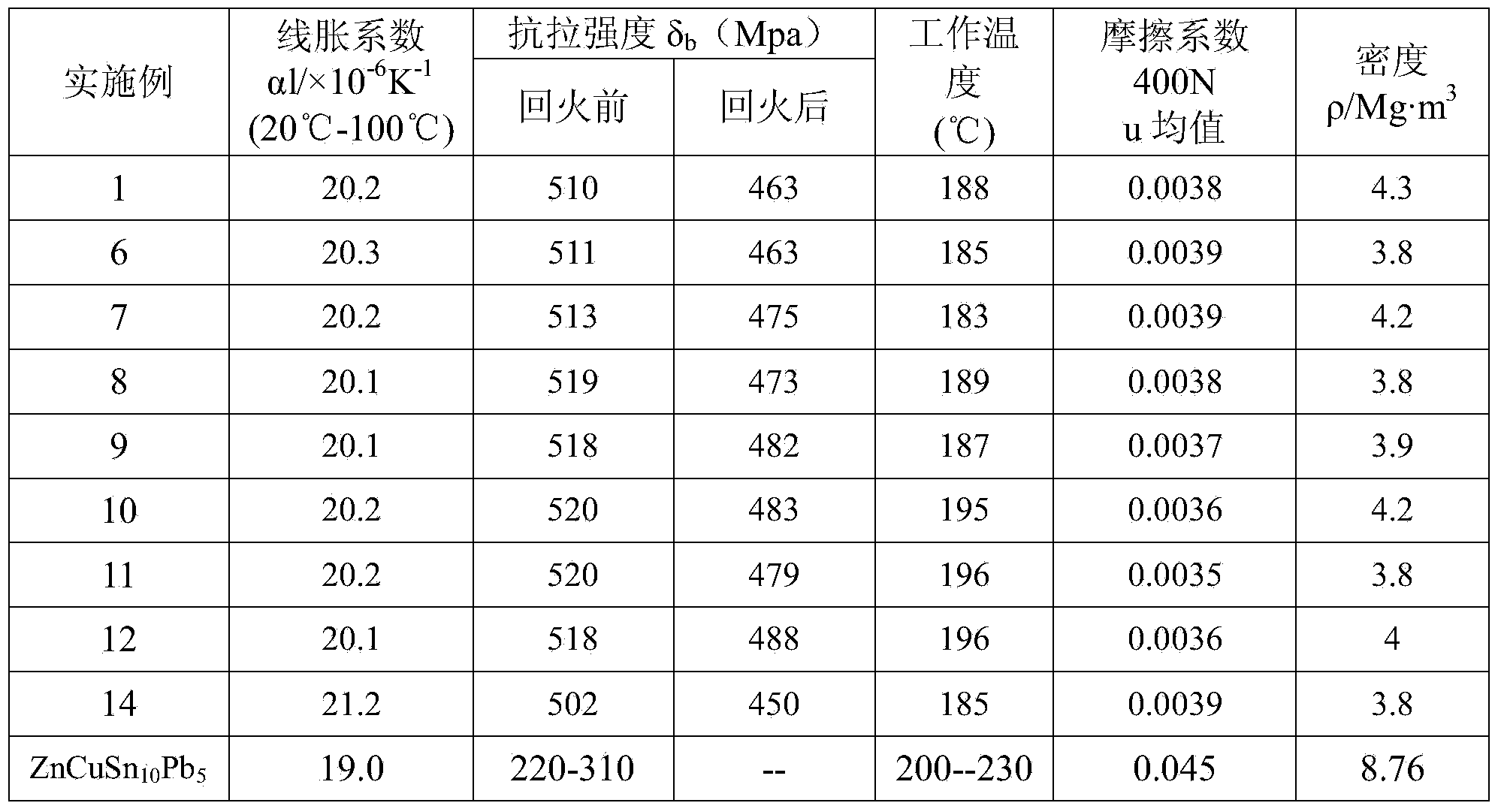

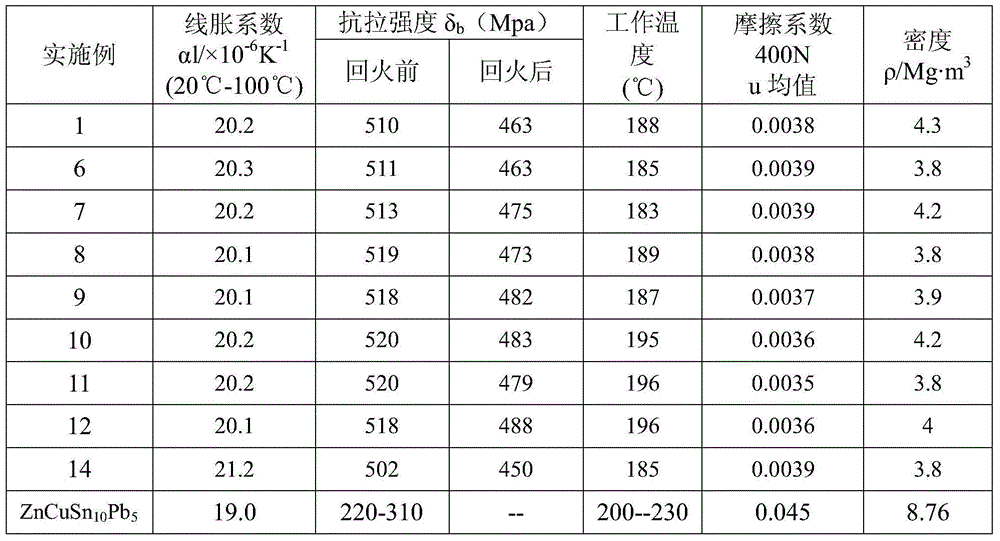

Highly wear-resisting axle-hang free aluminum base alloy and preparation method thereof

InactiveCN103436756AGrain refinementImprove wear resistance and antifriction performanceRheniumManganese

The invention discloses an aluminum base alloy which comprises the following components in percent by weight: 38-40% of zinc, 0.5-5% of silicon, 3.0-5% of copper, 0.5-1% of manganese, 0.3-0.5% of chromium, 1.2-1.8% of rhenium, 1-1.5% of boron, 0.038-0.048% of magnesium, 0.015-0.02% of titanium and the balance of aluminum. The invention further discloses a preparation method thereof. The aluminum base alloy disclosed by the invention has the advantages of high wear resistance, no axle-hang, low expansion rate, self-lubrication, anti-occluding function and high work temperature, and the low expansion rate of the alloy is realized, so that the aluminum base alloy is suitable for manufacturing various precise friction pair parts of mechanical equipment.

Owner:四川超耐磨高科技有限公司

Aluminum alloy sodium-free refining agent containing rare earth

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

Welding wire matched with AI-Mg-Si series aluminum alloy during use and preparation process of welding wire

InactiveCN106271192AGuaranteed performanceQuality assuranceWelding/cutting media/materialsSoldering mediaRare-earth elementSurface oxidation

The invention discloses a welding wire matched with AI-Mg-Si series aluminum alloy during use. The welding wire is prepared from the following main chemical components in percentage by weight: 1.2-1.5 percent of Mg, 0.8-1.0 percent of Si, 0.2-0.3 percent of Cu, 0.4-0.5 percent of Fe, 0.1-0.15 percent of Cr, 0.15-0.2 percent of Ce, 0.1-0.2 percent of Er and the balance of Al. A preparation process of the welding wire comprises the following steps: mixing the raw materials in proportion, smelting by adopting a medium-frequency induction resistance furnace and casting under the protection of argon gas into a cast ingot; beheading and milling the homogenized cast ingot and then extruding to prepare an alloy wire rod; performing coarse, medium and fine wire drawing on the alloy wire rod and then performing scraping and cleaning treatment to obtain the welding wire. The welding wire prepared by the preparation process disclosed by the invention has the following advantages that a smelting process is stable and easy to realize, the drawing performance of the welding wire is good, and a drawing device is subjected to sealing treatment to prevent the surface oxidation of the welding wire; as rare earth elements are added, the welding wire structure is refined; impurities in the welding wire are less and low in content, so that the toughness of the welding wire is promoted to be improved; scraping and ultrasonic cleaning are adopted for surface treatment, so that the simplicity and no pollution are realized; the welding wire is low in burn rate, difficult to break and good in mechanical property.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

Modification treatment method of aluminium alloy

The invention belongs to the technical field of aluminium alloys, and relates to a modification treatment method of an aluminium alloy. The modification treatment method is characterized in that Al-10Zr and Al-12Er intermediate alloys are adopted as an alterant, an A356 aluminium alloy is adopted as a modification object; 0.20% of Zr and 0.40% of Er are added, and the microstructure and performance of the A356 aluminium alloy are remarkably improved through the technological processes like batching, smelting and modification treatment; and tensile strength of the A356 aluminium alloy subjected to modification treatment of the Al-10Zr intermediate alloy and the Al-12Er intermediate alloy is 225 MPa, elongation is 6.4%, and tensile strength and elongation are respectively improved by 52.8% and 36.2% compared with tensile strength and elongation of the A356 aluminium alloy which is not subjected to modification treatment.

Owner:JIANGSU UNIV OF TECH

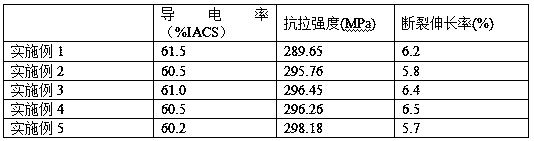

A high-strength and high-conductivity aluminum-based wire and its preparation method

ActiveCN107841658BImprove conductivityHigh strengthConductive materialMetal/alloy conductorsYttriumDislocation

The invention relates to a high-strength and high-conductivity aluminum-based wire and a preparation method thereof and belongs to the technical field of materials. The intermediate-strength, high-heat-resistance and high-conductivity aluminum-based wire is prepared from the following metallic elements and non-metallic elements of, with the mass percentage of aluminum as 1, 0.3-0.4% of yttrium, 0.2-0.5% of germanium, 0.2-0.4% of erbium, 0.3-0.5% of copper, 0.5-0.6% of magnesium, 0.2-0.4% of boron, 0.5-0.8% of silicon and 0.5-0.8% of iron. Erbium, yttrium, germanium and copper are added into aluminum, thus as-cast grains can be refined, dendrite spaces and dislocation are reduced, structure homogenization is achieved, impurity elements in the aluminum are removed, and the conductivity of analuminum alloy is improved; and the structure is refined, forming of a theta (CuAl2) strengthening phase is promoted, and the alloy strength is improved.

Owner:KUNMING UNIV OF SCI & TECH

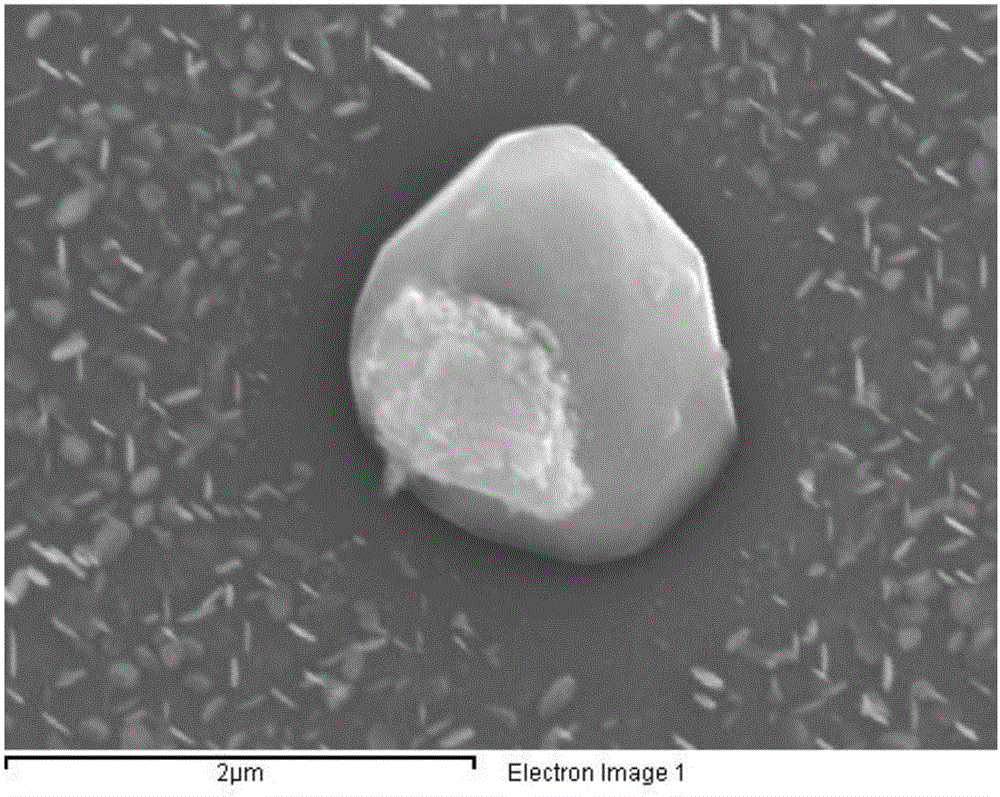

Rare earth oxide modified copper-nickel-silicon alloy material and preparation method and application thereof

InactiveCN106011535APromote formationGuaranteed tensile strengthMagnetic circuit characterised by magnetic materialsSilicon alloyRare earth

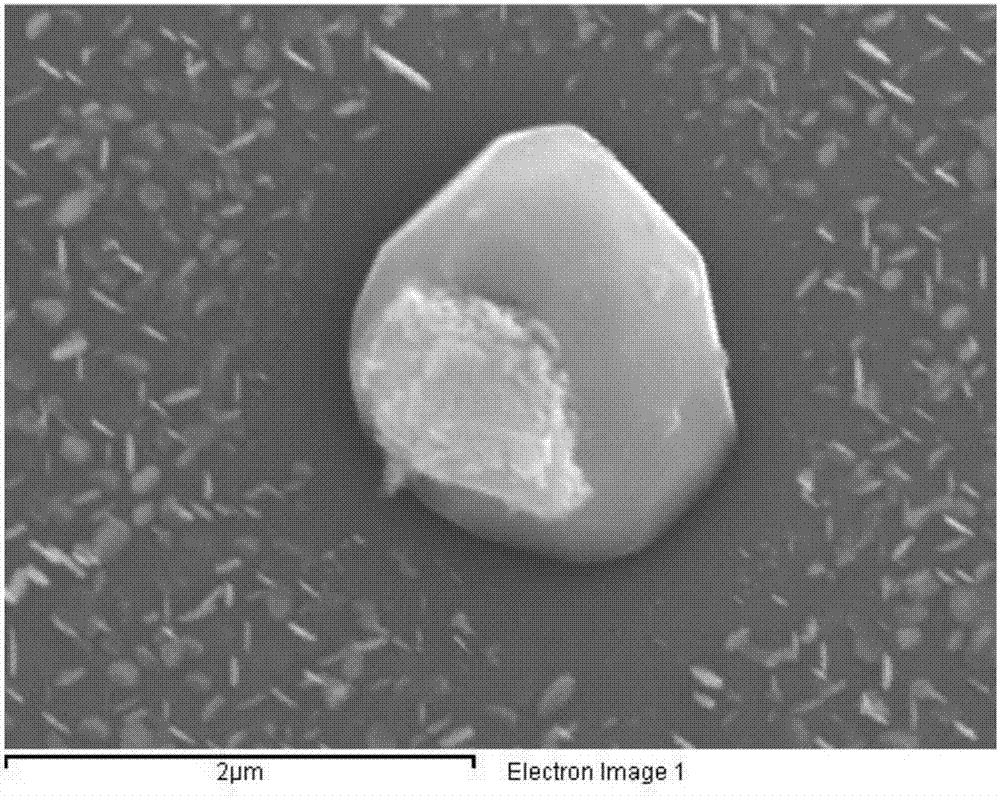

The invention belongs to the technical field of high-performance copper alloy materials, and discloses a rare earth oxide modified copper-nickel-silicon alloy material and a preparation method and application thereof. All the components include, by weight percentage, 1.1%-4.1% of nickel, 0.1%-2.1% of silicon, 0.01%-1.2% of rare earth oxide, and the balance copper and unavoidable impurities, wherein the rare earth oxide is strontium lanthanum manganese oxide (the atomic ratio of strontium is 0.01-0.29, and the atomic ratio of lanthanum is 0.01-0.59), and a vacuum induction smelting method is adopted. Part of the rare earth oxide in the rare earth oxide modified copper-nickel-silicon alloy material focuses in front of a solid-liquid interface, constitutional supercooling is caused, the cast structure is refined, and the dendrite arm spacing is reduced. Part of fine rare earth oxide particles enter grains to serve as heterogeneous nucleation points, and formation of isometric crystal is promoted. The rare earth oxide has a doping effect, thereby playing a role as modificator and affecting the separating-out number and distribution of a second phase. Finally, on the premise of guaranteeing the tensile strength of the cast alloy, the elongation is greatly improved, and the cast alloy has good plasticity.

Owner:SHANDONG UNIV +1

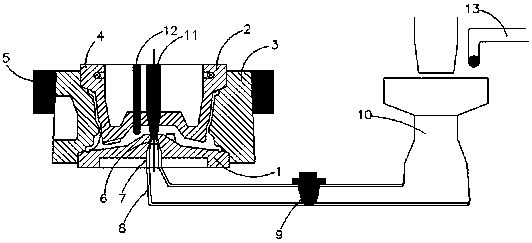

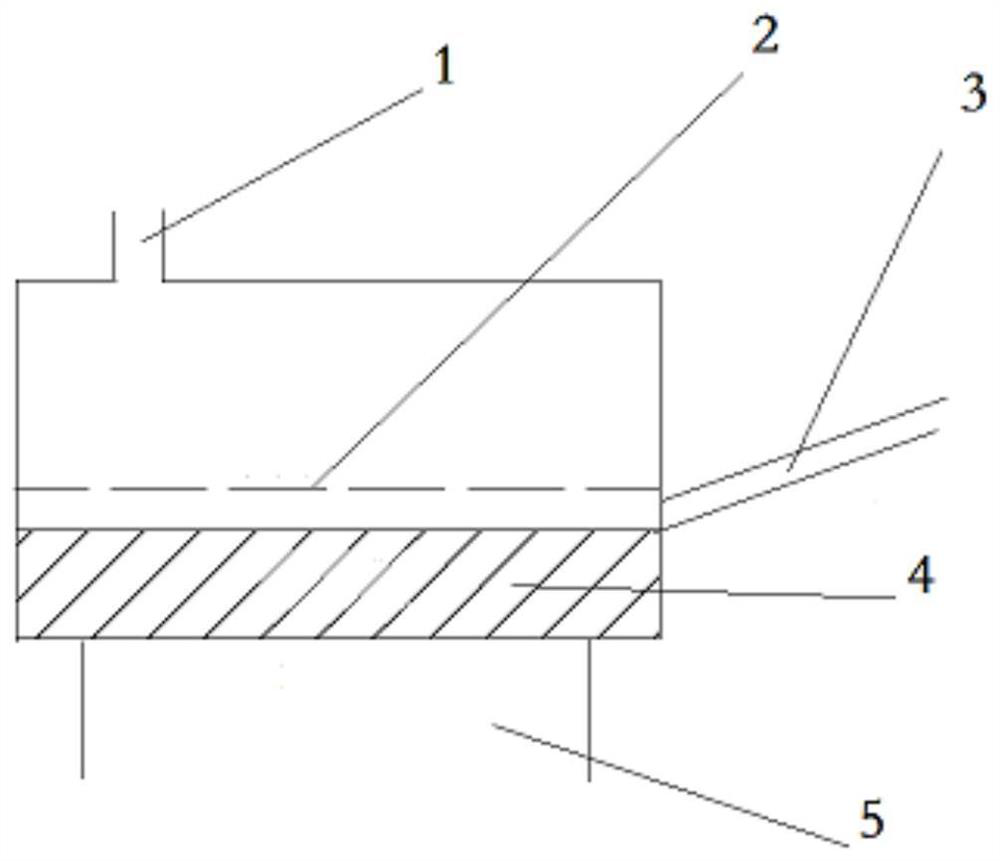

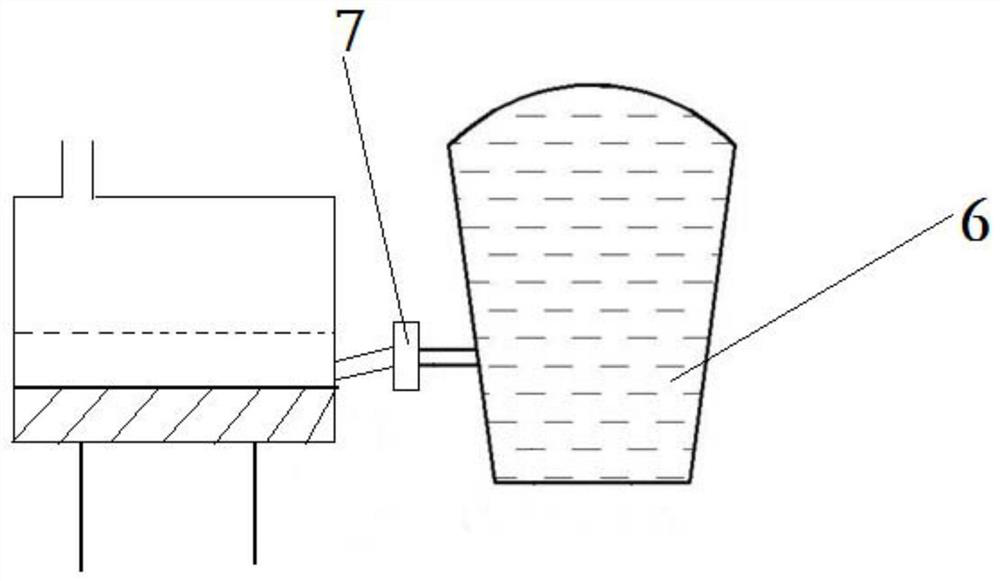

Aluminum wheel extrusion casting process and device thereof

ActiveCN108237212AIncreased mechanical elongationReduce dendrite spacingFoundry mouldsFoundry coresDeformation effectMold filling

The invention discloses an aluminum wheel extrusion casting process and a device thereof. A U-shaped pipe is adopted to realize injection of molten aluminum into a molding cavity of a mold at a low-pressure lower bottom part, so that the mold filling is stable, and the quality problem of the rim air hole defect caused by extrusion casting is solved; through application of a mold locking ring, therim extrusion deformation effect is improved; and through a secondary pressing process of center parts of aluminum wheels, internal structure dendritic crystal gaps of aluminum wheel castings are reduced, the yield strength and the ductility index in the mechanical performances of casting materials are improved, and necessary technical basis is provided for overall lightening of the aluminum wheels.

Owner:CITIC DICASTAL

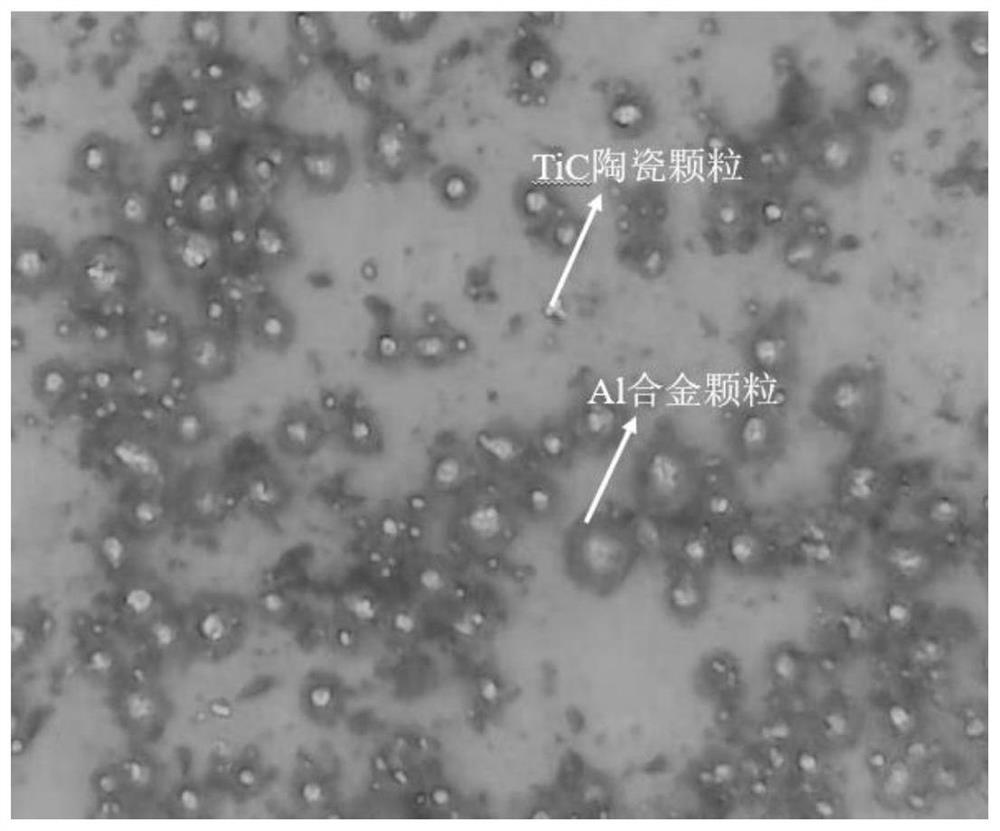

Aluminum alloy mixed powder, and method and product for improving density of aluminum alloy product

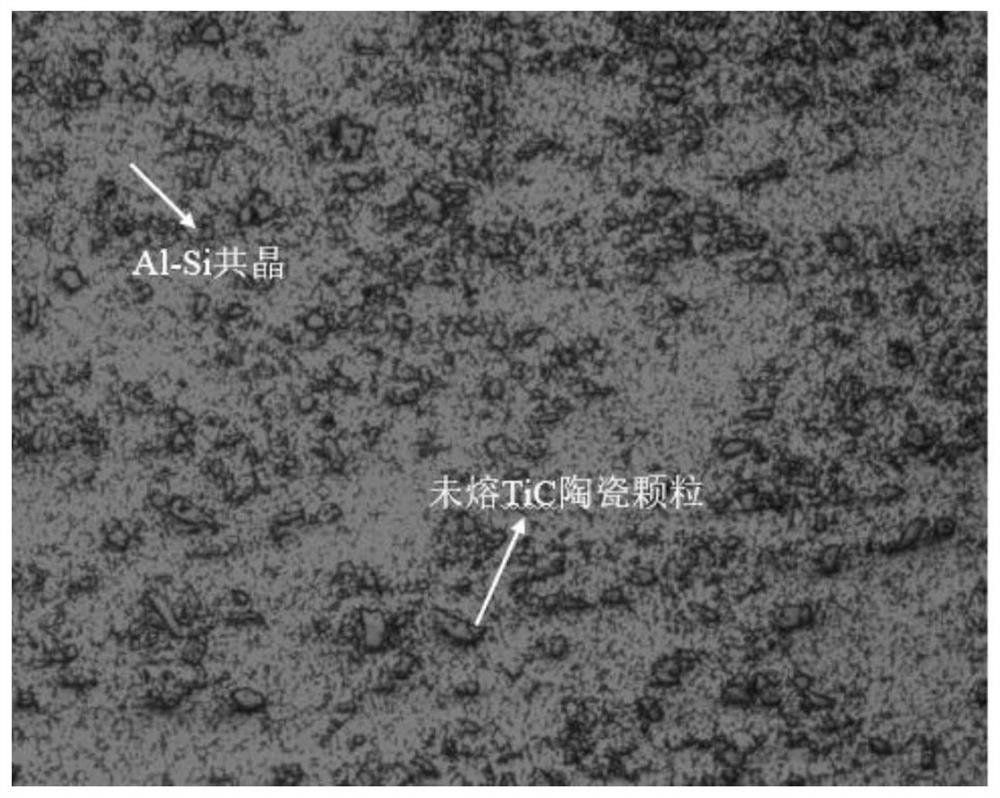

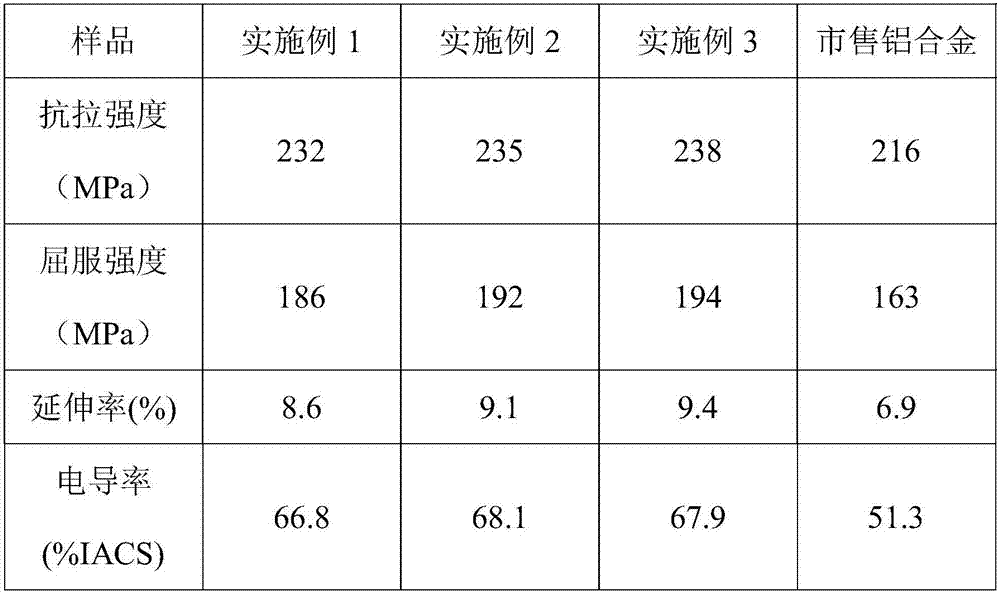

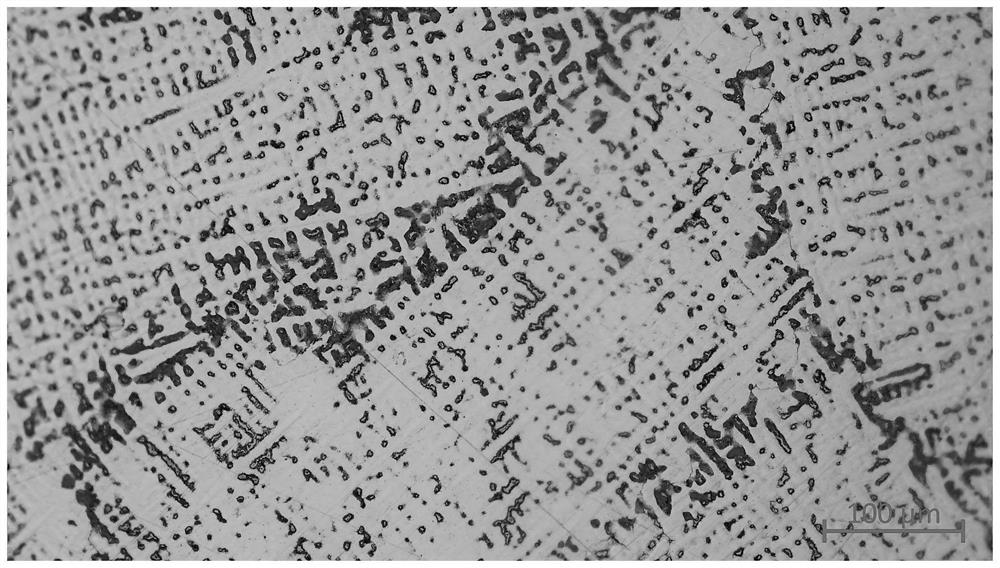

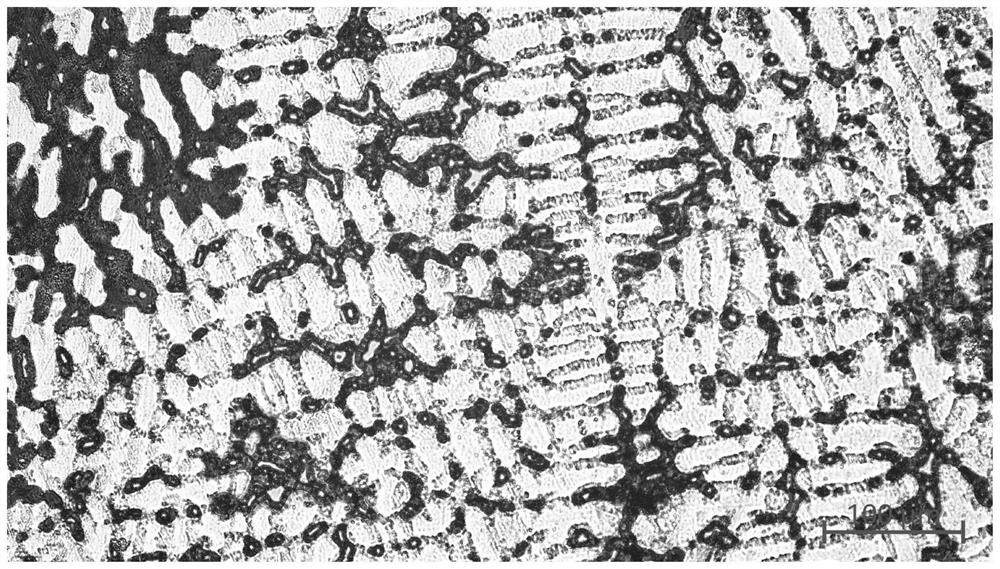

PendingCN112708805AHigh strengthImprove mechanical propertiesAdditive manufacturing apparatusCarbideLaser additive manufacturing

The invention belongs to the related technical field of laser additive manufacturing, and discloses aluminum alloy mixed powder, and a method and product for improving the density of an aluminum alloy product. The mixed powder comprises aluminum alloy powder and transition element carbide ceramic powder, wherein the aluminum alloy powder serves as matrix powder, and the mass fraction of the transition element carbide ceramic powder in the mixed powder does not exceed 10%. The mixed powder is used for laser additive manufacturing; when the mixed powder is molten by laser, the aluminum alloy powder and the transition element carbide ceramic powder are metallurgically bonded, and due to the difference of melting points, the aluminum alloy powder is molten while the transition element carbide ceramic powder is not molten; and thus, the transition element carbide ceramic powder forms similar pinning in the aluminum alloy powder, and strengthening of the aluminum alloy matrix powder is achieved. By means of the mixed powder, the mechanical property of the aluminum alloy product is improved, pores are reduced, and the density is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

High-strength and high-conductivity aluminum alloy and preparation method thereof

InactiveCN108004441AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsRare-earth elementElectro conductivity

The invention relates to a high-strength and high-conductivity aluminum alloy and a preparation method thereof. The aluminum alloy is prepared from the following components, by weight percentage (wt%), 0.5-0.54wt% of Mg, less than or equal to 0.01wt% of Mn, less than or equal to 0.01wt% of Zn, 0. 41-0.45wt% of Si, 0.09-0.18wt% of Fe, less than or equal to 0.01wt% of Cu, 0.31-0.5wt% of misch metalRE, and the balance Al and inevitable impurities. Compared with the prior art, the aluminum alloy and the preparation method thereof have the following advantages that a proper amount of rare earth element Re is added in the preparation process so that the dendritic crystal spacing can be reduced in the solid-liquid process of the aluminum alloy, the crystal grains can be refined, the content ratio of the Mg to the Si is controlled so that the strength of the aluminum alloy can be improved, and meanwhile, the rare earth element and the harmful impurities form a polycompound so that the adverseeffect of the aluminum alloy can be effectively overcome, and the conductivity of the aluminum alloy can be improved.

Owner:JIANGYIN EAST CHINA ALUMINUM TECH

Processing method of improved 5052 aluminum alloy refrigerator foaming die cast

The invention discloses a processing method of an improved 5052 aluminum alloy refrigerator foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements Pr, Ce, and Y are added to the improved 5052 aluminum alloy, so that the dendritic crystal distance of the aluminum alloy can be effectively reduced, as-cast grains are refined, and the mechanical property of the aluminum alloy is improved. The processed aluminum alloy refrigerator foaming mold die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州佳诚模具制造有限公司

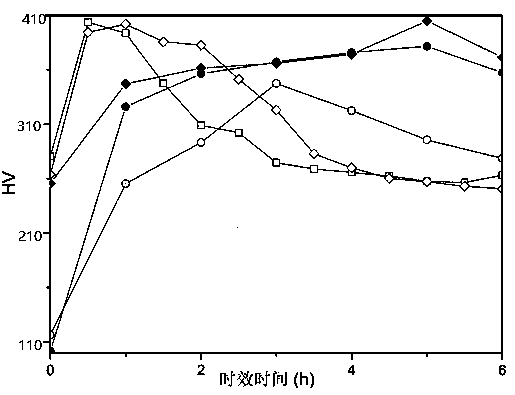

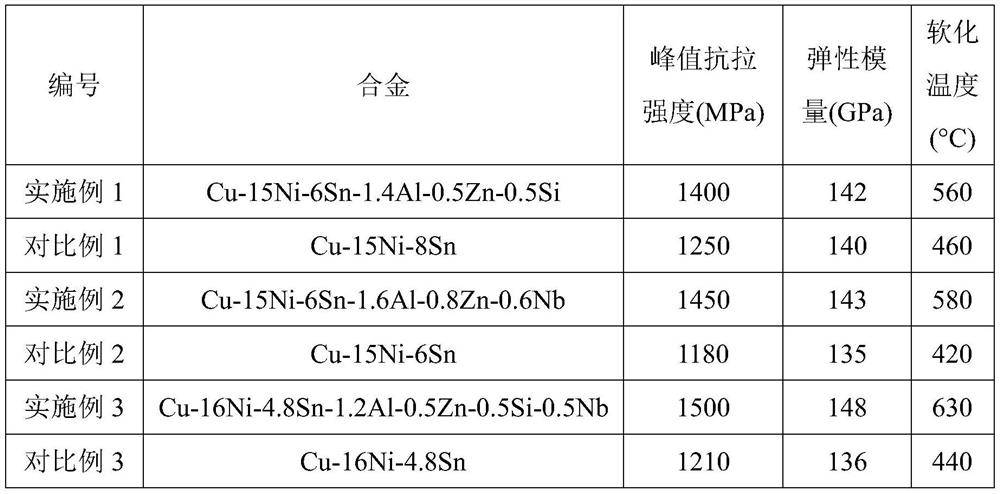

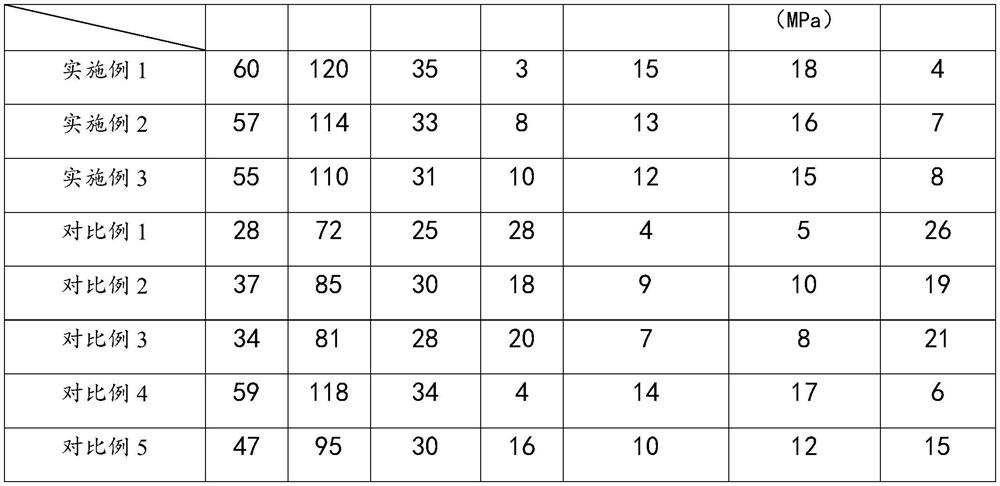

High-temperature softening resistant Cu-Ni-Sn series high-strength and high-elasticity copper alloy and preparation method thereof

InactiveCN114086027AImprove performanceImprove the problem of insufficient resistance to high temperature softeningSolution treatmentHigh wear resistance

The invention discloses a high-temperature softening resistant Cu-Ni-Sn series high-strength and high-elasticity copper alloy and a preparation method thereof. The alloy comprises the following components such as Cu, Ni, Sn, Al, Zn, Si or Nb and inevitable impurity elements, and the contents of Ni, Sn, Al, Zn, Si or Nb elements are as follows: 12-18 wt% of Ni; 4.5-8.5 wt% of Sn; 0.5-2 wt% of Al; 0.3-1.0 wt% of Zn; 0.3-1.0 wt% of Si; and 0-1.0 wt% of Nb. The alloy preparation process comprises the steps of smelting, up-drawing continuous casting, homogenization and solution treatment, cold deformation treatment and aging treatment. The multi-component Cu-Ni-Sn series copper alloy prepared through adopting a short-process up-drawing continuous casting method is small in dendritic crystal spacing, high-melting-point second-phase particles can be separated out to occupy a nucleation position of discontinuous precipitation after large-deformation cold machining and combined deformation heat treatment processes, recrystallization reaction is promoted, and growth of the discontinuous precipitation is remarkably inhibited; therefore, the copper alloy with excellent high-temperature softening resistance, high strength, high elasticity and high wear resistance is prepared.

Owner:JIANGXI UNIV OF SCI & TECH

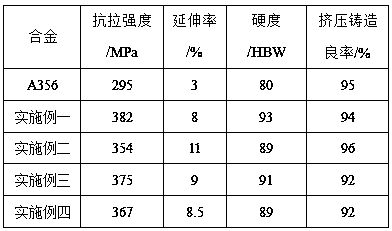

High-ductility high-strength rare earth aluminum alloy material and preparation method thereof

On the one hand, the invention provides a high-ductility high-strength rare earth aluminum alloy material. The rare earth aluminum alloy material comprises the following components of, in percentage by mass, 2.0% - 3.5% of Si, 3.5% - 5.0% of Cu, 0.5% - 0.9% of Mn, 0.1% - 0.5% of Re, 0.1% - 0.2% of Ti, 0.005% - 0.05% of Sr and 80% - 92% of Al, wherein the Re is mixed rare earth containing Ce and La. According to the high-ductility high-strength rare earth aluminum alloy material, the rare earth element is introduced into an aluminum alloy, so that the fluidity of the aluminum alloy is improved,and the initiation of shrinkage porosity, shrinkage and crack is reduced. On the other hand, the invention provides a preparation method of the high-ductility high-strength rare earth aluminum alloymaterial. An indirect squeeze casting process is adopted, industrial scale production is realized, and the rare earth aluminum alloy material has great development potential in the fields of automobile light weight, intelligent robots, aerospace and the like.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

Local vacuum casting method for aluminum alloy

The invention provides a local vacuum casting method for aluminum alloy. A raw material is sequentially added step by step, and ultrasonic vibration treatment and mechanical stirring treatment are combined, so refinement of a melt structure can be remarkably promoted, the dendritic crystal spacing is reduced, and the dendritic crystal spacing is stable; an alloy casting is formed under the actionof vacuum and pressure formed at the upper part of a crystallizer through the local vacuumizing casting method, the grain diameter is small, the structure is compact, and the hole defects are few; theconnection among a filter chamber box, a molten aluminum inlet and a crystallizer is always kept in a vacuum state, so the situations of segregation, turbulence, easy gas entrapment and oxidation ofthe aluminum alloy in the production process are reduced, the shifting amplitude of the liquid level of the aluminum alloy is stable, and the slag entrapment phenomenon can be obviously improved; andthe local vacuumizing casting method for aluminum alloy has the advantages of simple device, and easiness in operation, and the prepared aluminum alloy has no obvious defects such as cracks, pits andslag inclusion on the surface, and has the advantages of large tensile strength, good yield strength and high extrudability.

Owner:佛山市三水凤铝铝业有限公司 +1

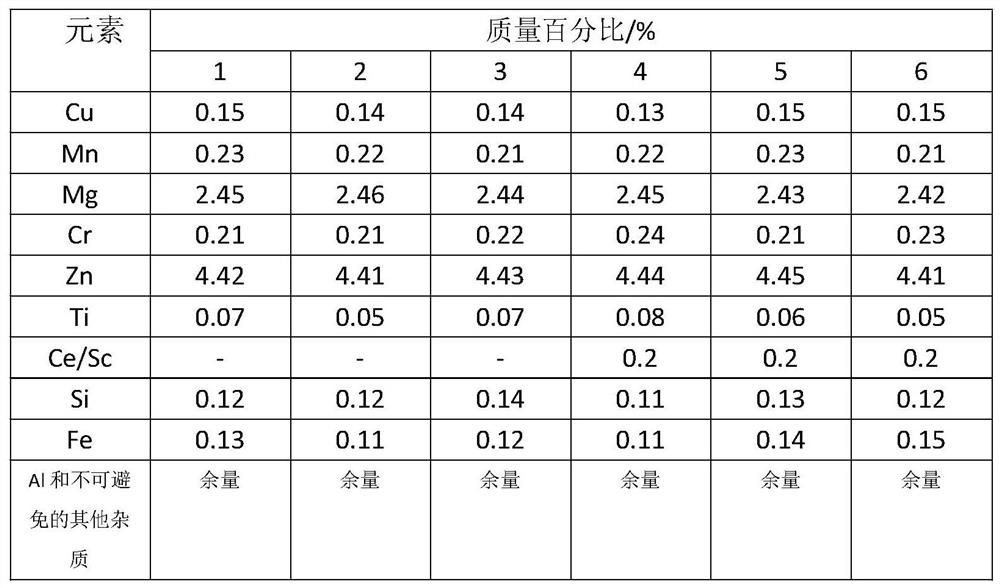

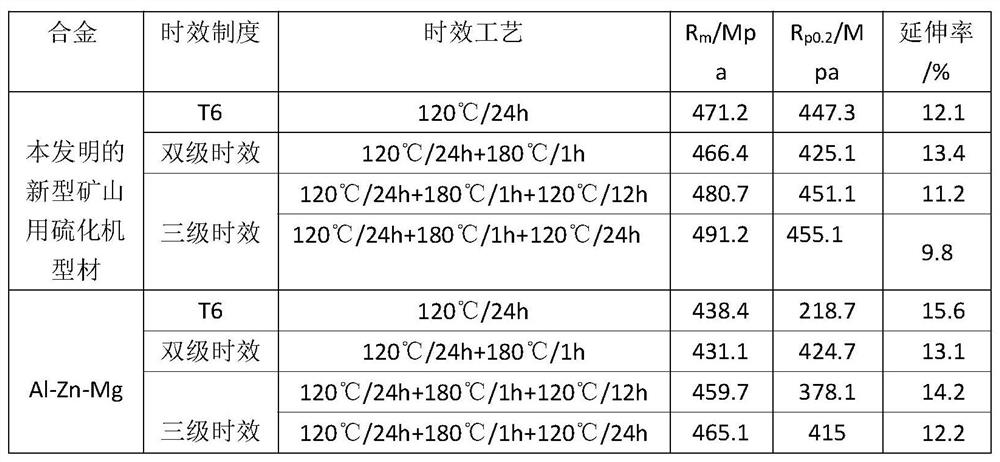

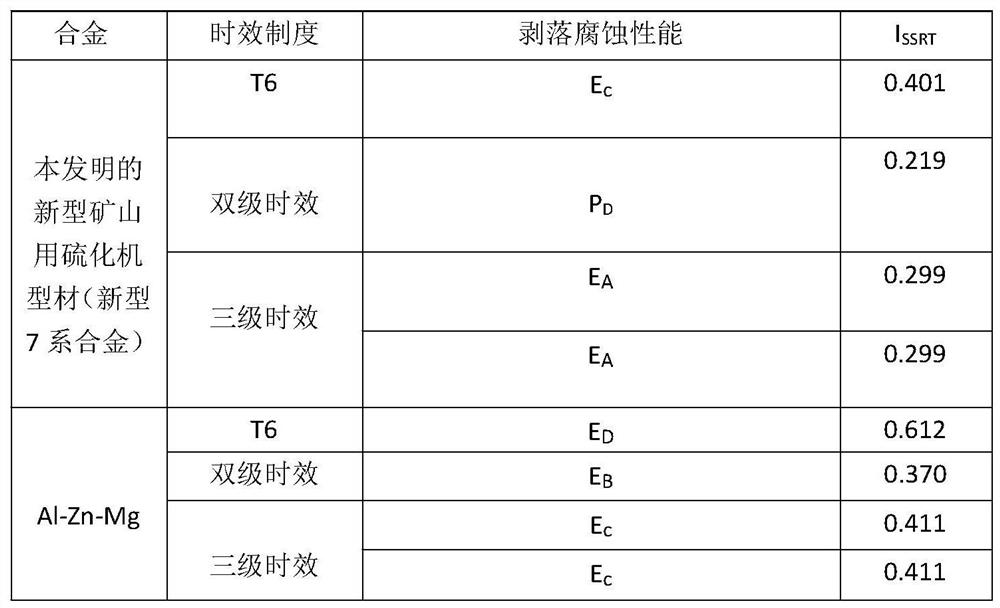

Novel mine vulcanizing machine profile and preparation method thereof

ActiveCN112853138AImprove mechanical propertiesAccelerated corrosionUltimate tensile strengthMechanical property

The invention relates to the technical field of vulcanizing machine profiles, and provides a novel mine vulcanizing machine profile and a preparation method thereof. The alloy content of an aluminum alloy is adjusted, and corresponding trace elements, rare earth elements and modifiers are added under specific conditions, so that the microstructure of the alloy is optimized, the corrosion resistance of the alloy is improved while the strength and hardness of the material are ensured, and the alloy has relatively high mechanical property and good corrosion resistance; the purpose of reducing the weight of the vulcanizing machine is achieved, meanwhile, the corrosion resistance of the alloy is improved, the stress corrosion susceptibility of the alloy is reduced, and service of the vulcanizing machine under a mine is facilitated; and on the premise of not increasing the production cost of the mine vulcanizing machine, the wall thickness of the aluminum alloy is reduced, the unit weight of an aluminum alloy profile used by the vulcanizing machine is reduced, the equipment weight of the vulcanizing machine are reduced, and meanwhile, the corrosion resistance of the alloy is improved, so that the alloy has matched comprehensive performance of relatively high mechanical property and good corrosion resistance.

Owner:中色创新研究院(天津)有限公司

A kind of A356.2 aluminum alloy casting method

The invention relates to an A356.2 aluminum alloy casting method. The method includes the steps that 1, raw material required by A356.2 aluminum alloy is fed according to the standard requirement proportion, the fed raw material does not contain the raw material containing strontium, then smelting is conducted, casting is conducted after purifying is conducted, in the casting process, and Al-Sr intermediate alloy is added to A356.2 aluminum alloy melt; according to the feeding mode, the required Al-Sr intermediate alloy is equally divided into multiple parts and is added to the aluminum alloy melt in different time frames according to the divided parts; 2, in the casting process, at a joint where aluminum alloy ingots in a die are converted into solid from liquid, cooling water mist is sprayed to the die from the bottom of the die, and the cooling water mist spraying range is extended backwards by 4-5 m from the starting point.

Owner:隆达铝业(烟台)有限公司

Motor rotor aluminum alloy for new energy automobile and preparation method of motor rotor aluminum alloy

The invention discloses a motor rotor aluminum alloy for a new energy automobile and a preparation method of the motor rotor aluminum alloy, and belongs to the technical field of new energy automobile motor rotor materials. The motor rotor aluminum alloy for the new energy automobile comprises the following components in percentage by mass: 0.4-0.6 wt% of Fe, 0.1-0.3 wt% of Cu, 0.02-0.23 wt% of heavy rare earth elements and the balance of Al. The motor rotor aluminum alloy for the new energy automobile, provided by the invention, has excellent mechanical properties.

Owner:聊城市博源节能科技有限公司

A high wear-resistant shaft-free aluminum-based alloy and its preparation method

InactiveCN103436756BGrain refinementImprove wear resistance and antifriction performanceRheniumWear resistant

The invention discloses an aluminum base alloy which comprises the following components in percent by weight: 38-40% of zinc, 0.5-5% of silicon, 3.0-5% of copper, 0.5-1% of manganese, 0.3-0.5% of chromium, 1.2-1.8% of rhenium, 1-1.5% of boron, 0.038-0.048% of magnesium, 0.015-0.02% of titanium and the balance of aluminum. The invention further discloses a preparation method thereof. The aluminum base alloy disclosed by the invention has the advantages of high wear resistance, no axle-hang, low expansion rate, self-lubrication, anti-occluding function and high work temperature, and the low expansion rate of the alloy is realized, so that the aluminum base alloy is suitable for manufacturing various precise friction pair parts of mechanical equipment.

Owner:四川超耐磨高科技有限公司

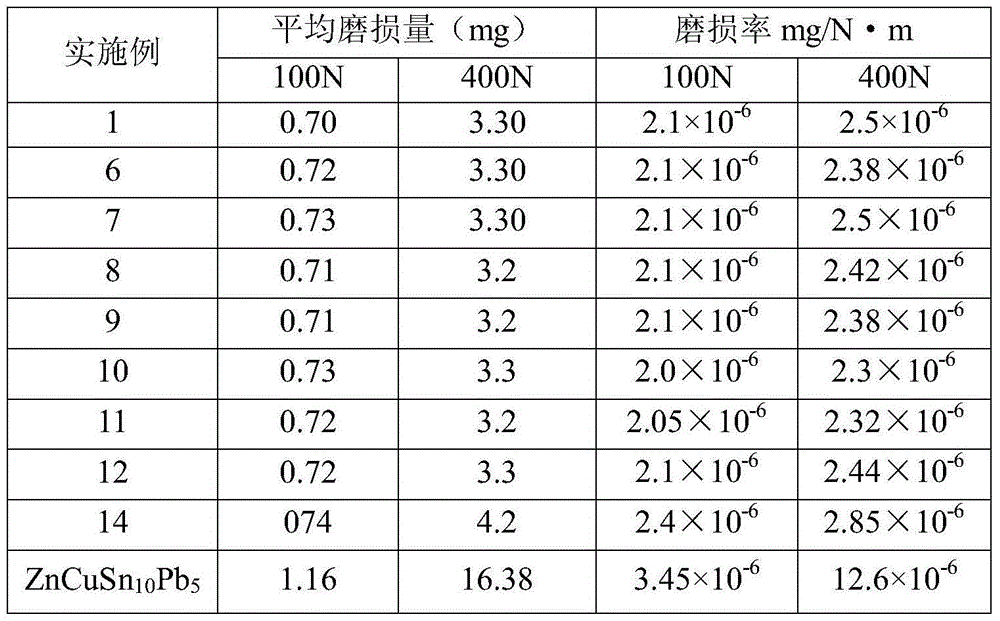

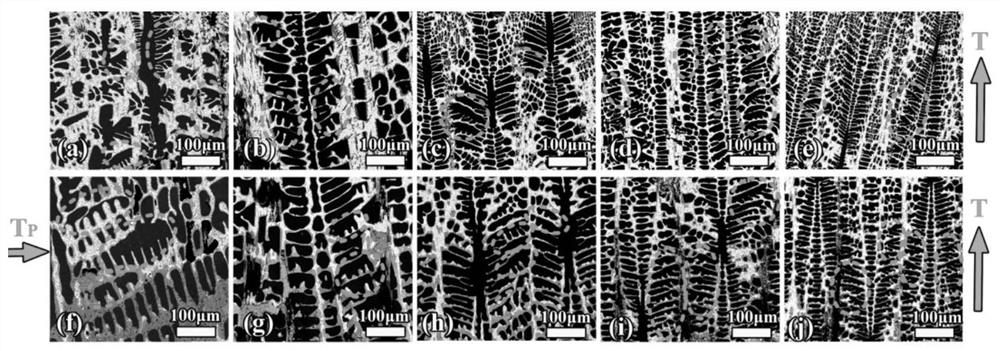

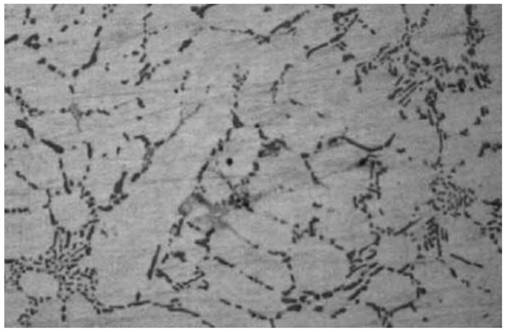

Method for growing atypical tertiary dendrites in directionally solidified peritectic alloy

ActiveCN111681714AImprove mechanical propertiesImproved specific mechanical propertiesIncreasing energy efficiencyComputational theoretical chemistryTheory modelDirectional solidification

The invention discloses a method for growing atypical tertiary dendrites in directionally solidified peritectic alloy, comprising the following steps of: firstly establishing a theoretical model according to the characteristics of the atypical tertiary dendrites for analysis and calculation; then obtaining a result according to the analysis and calculation; and finally selecting the peritectic alloy meeting conditions, and combining the calculation of the solidification speed and the remelting speed of the lower edge of the rough secondary dendrite arm to select proper directional solidification process parameters to realize the growth of the atypical tertiary dendrite arm. According to the invention, a relevant model is established for analysis and calculation, the mechanism of atypical tertiary dendrite formation is explained, and the directional solidification process parameters are improved by combining the analysis and calculation results to realize the improvement of the specificmechanical properties of the material.

Owner:LANZHOU UNIVERSITY

A kind of modification treatment method of aluminum alloy

The invention belongs to the technical field of aluminum alloys, and relates to a modification treatment method for aluminum alloys. In the present invention, Al-10Zr and Al-12Er master alloys are used as modifying agents, and A356 aluminum alloy is used as the object of modification; 0.20% Zr and 0.40% Er are added, and the A356 aluminum alloy is significantly improved through processes such as batching, smelting, and modification treatment. The microstructure and performance of Al-10Zr master alloy and Al-12Er master alloy modified A356 aluminum alloy have a tensile strength of 225MPa and an elongation of 6.4%, which is higher than that of the unmodified A356 aluminum alloy. , elongation were increased by 52.8%, 36.2%.

Owner:JIANGSU UNIV OF TECH

A kind of sodium-free refining agent for aluminum alloy containing lanthanum, erbium and zirconium

The invention discloses a sodium-free refining agent for aluminum alloy containing lanthanum, erbium and zirconium, which includes material A and material B, wherein the material A includes the following raw materials in parts by weight: 50-60 parts of KCl, 20-25 parts of K2CO3, 10-25 parts of LiCl 15 parts, 30 to 35 parts of AlF, 10 to 12 parts of potassium fluoroaluminate, 25 to 10 parts of CaF, 5 to 10 parts of carbon powder, 15 to 25 parts of light calcium carbonate, and 8 parts of CaO2; the B material is composed of C2Cl6, The composition of TiO2 and metal is 5:1.5-2:1-1.5 by weight, and the metal is a mixed metal including Mg, La, Er and Zr; material A and material B are used together, and the weight ratio is 2-3:1. Using the refining agent of the present invention does not introduce impurity sodium in the refining process, and adds Mg, La, Er and Zr elements to modify and refine the aluminum alloy structure and improve the mechanical properties of the alloy.

Owner:广西平果铝合金精密铸件有限公司

A kind of rare earth-containing aluminum alloy sodium-free refining agent

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

High-strength and high-conductivity aluminum-based wire and preparation method thereof

ActiveCN107841658AImprove conductivityHigh strengthConductive materialMetal/alloy conductorsYttriumDislocation

The invention relates to a high-strength and high-conductivity aluminum-based wire and a preparation method thereof and belongs to the technical field of materials. The intermediate-strength, high-heat-resistance and high-conductivity aluminum-based wire is prepared from the following metallic elements and non-metallic elements of, with the mass percentage of aluminum as 1, 0.3-0.4% of yttrium, 0.2-0.5% of germanium, 0.2-0.4% of erbium, 0.3-0.5% of copper, 0.5-0.6% of magnesium, 0.2-0.4% of boron, 0.5-0.8% of silicon and 0.5-0.8% of iron. Erbium, yttrium, germanium and copper are added into aluminum, thus as-cast grains can be refined, dendrite spaces and dislocation are reduced, structure homogenization is achieved, impurity elements in the aluminum are removed, and the conductivity of analuminum alloy is improved; and the structure is refined, forming of a theta (CuAl2) strengthening phase is promoted, and the alloy strength is improved.

Owner:KUNMING UNIV OF SCI & TECH

A kind of rare earth oxide modified copper-nickel-silicon alloy material and its preparation method and application

InactiveCN106011535BPromote formationGuaranteed tensile strengthMagnetic circuit characterised by magnetic materialsSilicon alloyRare earth

Owner:SHANDONG UNIV +1

A kind of method of partial vacuum casting of aluminum alloy

The invention provides a method for partial vacuum casting of aluminum alloy. The raw materials are added step by step, combined with ultrasonic vibration treatment and mechanical stirring treatment, which can significantly promote the refinement of the melt structure, reduce the distance between dendrites, and the distance between dendrites Steady; alloy castings are formed under the action of vacuum and pressure on the upper part of the crystallizer by partial vacuum casting method. The connection between the aluminum alloys is always kept in a vacuum state, which reduces the occurrence of segregation, turbulence, gas entrainment and oxidation of the aluminum alloy during production, and the fluctuation range of the aluminum alloy liquid level is stable, which can significantly improve the phenomenon of slag entrainment; in addition, the aluminum alloy of the present invention The alloy partial vacuum casting method has simple equipment and simple operation, and the surface of the prepared aluminum alloy has no defects such as obvious cracks, pits and slag inclusions, and has the advantages of high tensile strength, good yield strength and high extrudability.

Owner:佛山市三水凤铝铝业有限公司 +1

A rare earth-containing aluminum alloy refining agent

The invention discloses a rare earth-containing aluminum alloy refining agent, which comprises the following raw materials in parts by weight: 70-80 parts of NaCl, 50-56 parts of KCl, 10-15 parts of MgCl, 5-8 parts of LiCl, 30-36 parts of NaF, and 10-12 parts of AlF , 10-12 parts of sodium fluoroaluminate, 5-10 parts of carbon powder, 25-35 parts of light calcium carbonate, 10-15 parts of marble powder, 8-12 parts of CaO, 2-5 parts of fluorite, 5-10 parts of rare earth . Using the aluminum alloy refining agent of the present invention not only can obtain a good hydrogen removal effect, but also has a good modification effect on the aluminum alloy melt, can obviously reduce the grain size, and improve the uniformity of aluminum products.

Owner:广西平果铝合金精密铸件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com