Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

A cu-ni-sn, corrosion-resistant technology, which is used in the preparation of corrosion-resistant and wear-resistant Cu-Ni-Sn alloys, and in the field of high elasticity, can solve the problem of reducing product fatigue life, increasing the difficulty of plastic forming of materials, and microscopic cracks in structures and other problems, to achieve the effect of improving service life, obvious synergy, and alleviating alloy segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

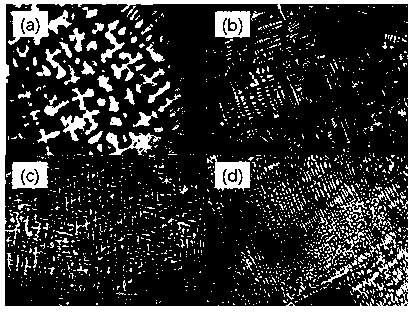

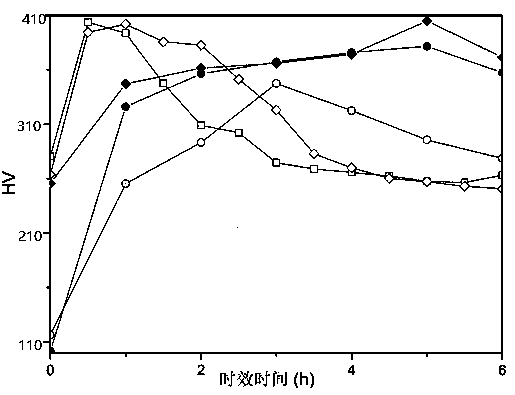

Image

Examples

Embodiment 1

[0037] A kind of highly elastic, corrosion-resistant, wear-resistant Cu-Ni-Sn alloy preparation method, the steps of described preparation method are:

[0038] Step 1: The weight percentage of each component to prepare Cu-Ni-Sn alloy is: Ni 15.6%, Sn8.7%, Mn0.5%, trace elements Cr0.03%, Nb0.03%, Si0.03% , Zr0.03% and Ti0.03%, the balance is Cu.

[0039] Step 2: The above-mentioned alloy is smelted by vacuum induction smelting or non-vacuum smelting with covering protection. The feeding materials are Cu and Ni at the same time, and Sn, Mn and trace elements are added after Cu and Ni are melted and refined, and melted. Afterwards, casting is carried out, and the furnace temperature is controlled to be 1100°C.

[0040] Step 3: Apply electromagnetic stirring during the solidification process until the alloy liquid is completely solidified, the electromagnetic stirring power: 100KW, and the stirring time is 50s.

[0041] Step 4: The above-mentioned cast alloy is subjected to homo...

Embodiment 2

[0044] A kind of highly elastic, corrosion-resistant, wear-resistant Cu-Ni-Sn alloy preparation method, the steps of described preparation method are:

[0045] Step 1: The percentage by weight of each component to prepare Cu-Ni-Sn alloy is: Ni16%, Sn9.5%, Mn0.7%, trace elements Cr0.03%, Nb0.03%, Si0.03%, Zr0.03% and Ti0.03%, the balance is Cu.

[0046] Step 2: The above-mentioned alloy is smelted by vacuum induction smelting or non-vacuum smelting with covering protection. The feeding materials are Cu and Ni at the same time, and Sn, Mn and trace elements are added after Cu and Ni are melted and refined, and melted. Afterwards, casting is carried out, and the furnace temperature is controlled to be 1200°C.

[0047] Step 3: Apply electromagnetic stirring during the solidification process until the alloy liquid is completely solidified, the electromagnetic stirring power: 200KW, and the stirring time is 80s.

[0048] Step 4: The above-mentioned cast alloy is subjected to homogen...

Embodiment 3

[0051] The only difference from Example 1 is that the electromagnetic stirring power is 250KW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com