Concrete with common strength and high elastic modulus and preparation method thereof

A technology with high elastic modulus and high strength, applied in the field of building materials, can solve the problems of poor resistance to deformation, low elastic modulus, poor shrinkage deformation, etc., and achieve the effect of improving interface performance, improving compactness and reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

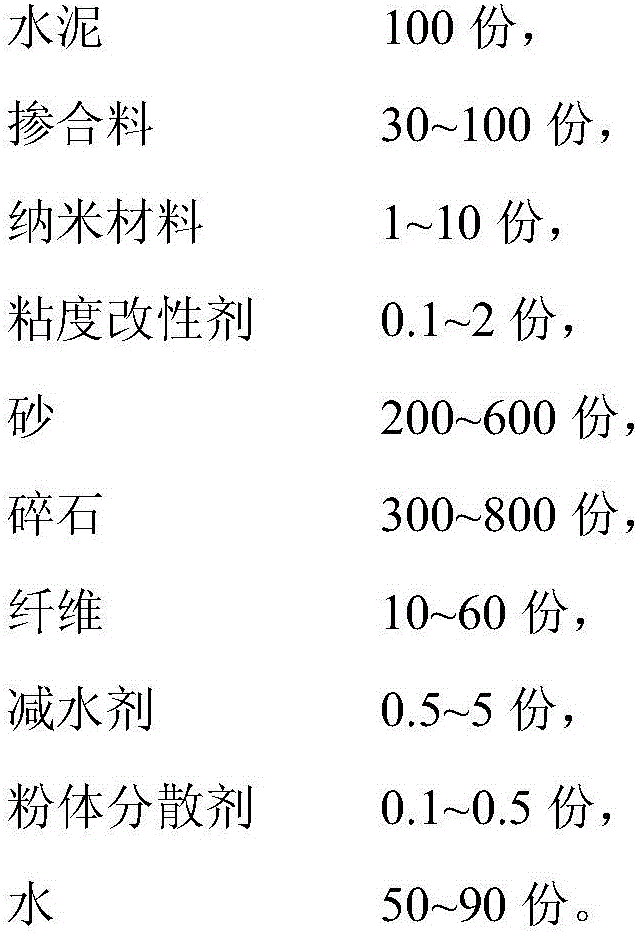

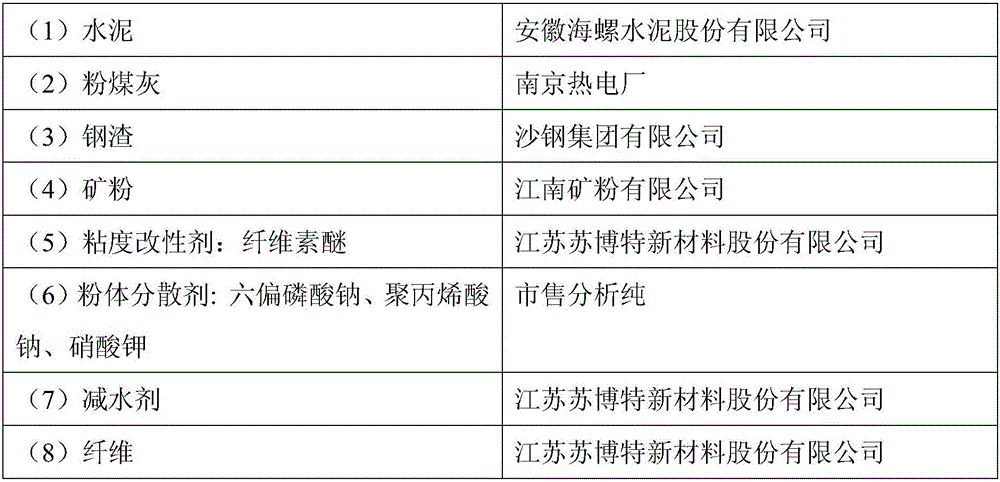

Method used

Image

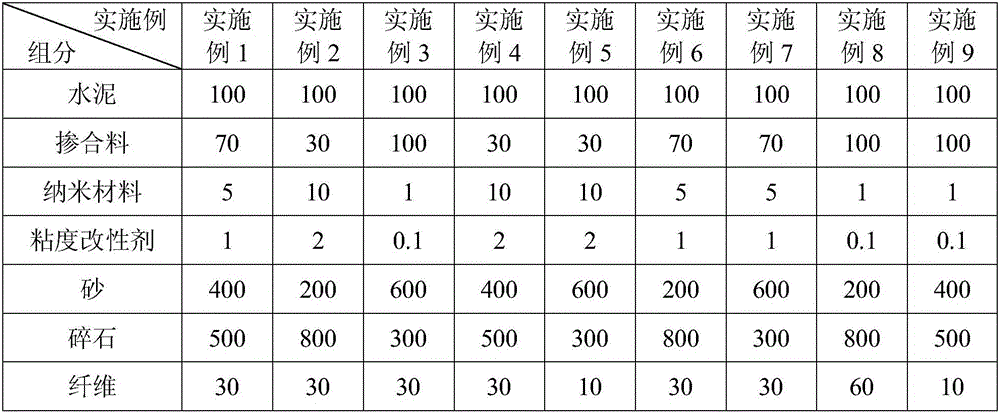

Examples

Embodiment 1

[0040] In Example 1, the nanomaterial is composed of graphene and nano whiskers, and the mass ratio is 20:80; the sand is composed of quartz sand and silicon carbide, and the mass ratio is 40:60; the crushed stone is composed of granite and brown corundum. Composition, the mass ratio is 40:60; the water reducer is a carboxylic acid type water reducer.

Embodiment 2

[0041] In Example 2, the nanomaterial is composed of carbon nanotubes and nano-calcium carbonate, and the mass ratio is 10:90; the sand is quartz sand; the gravel is composed of basalt and brown corundum, and the mass ratio is 25:75; The water agent is a carboxylic acid water reducer.

Embodiment 3

[0042] In Example 3, the nanomaterial is composed of nano-calcium carbonate and nano-whiskers, and the mass ratio is 90:10; the sand is composed of river sand and brown corundum, and the ratio is 20:80; the crushed stone is granite; the water reducing agent It is an aliphatic water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com