Method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with method

A high specific surface area, ultra-fine silver technology, which is applied in the field of high specific surface area flocculent ultra-fine silver powder preparation and the obtained silver powder, can solve the problem that the stability of copper paste cannot be achieved, the anti-oxidation performance of copper powder is difficult, and there is no obvious cost advantage and other problems, to achieve the effects of high production efficiency, good dispersion, and excellent particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

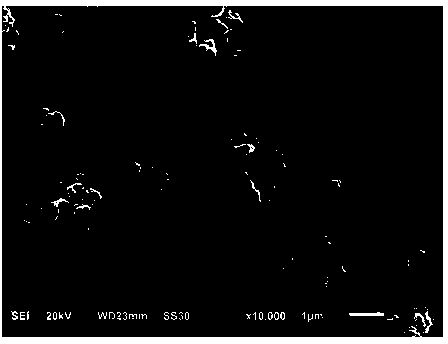

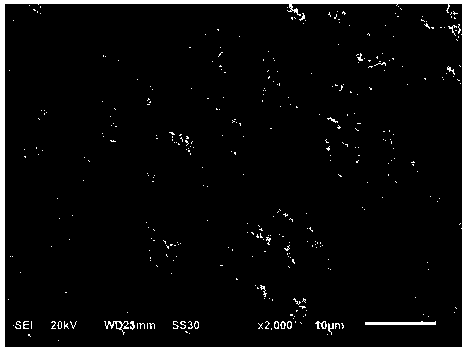

Image

Examples

Embodiment 1

[0033] Example 1: It is a basic embodiment of the preparation method of high specific surface area flocculent ultrafine silver powder of the present invention. The preparation method of flocculent ultrafine silver powder with high specific surface area comprises the following steps:

[0034] A. Prepare the first aqueous solution: add ammonia solution to the silver nitrate solution and stir until the solution is clear, then add the dispersant solution to obtain the first aqueous solution; B. Prepare the second aqueous solution: dissolve or dilute the organic reducing agent, then add ammonia water to adjust pH value, to obtain the second aqueous solution; C, reduction treatment: the first aqueous solution and the second aqueous solution are mixed into a mixed solution, and the two solutions directly undergo a reduction reaction; D, washing: the mixed solution in the reduction reaction is fully reacted , and then lowered to the washing tank for washing, filtering to obtain the ...

Embodiment 2

[0035] Example 2:It is a further embodiment of the preparation method of the high specific surface area flocculent ultrafine silver powder of the present invention. In the preparation method of high specific surface area flocculent ultrafine silver powder, the concentration of the first aqueous solution in the step A is measured as 200-400g / L by silver, that is, the silver content in the silver salt is the concentration of silver in the silver ion-containing aqueous solution calculate. When the concentration of silver in the first aqueous solution was lower than 200g / L, the silver content in the solution was too low, and the particle diameter of the silver powder particles was difficult to reach uniform; on the other hand, when the concentration of silver in the first aqueous solution exceeded 400g / L, the concentration of silver in the solution was not High, the aggregation of the reduced and precipitated silver particles is obvious. The ammonia water used in preparing the ...

Embodiment 3

[0036] Example 3: It is a preferred embodiment of the preparation method of high specific surface area flocculent ultrafine silver powder of the present invention. The difference from Example 2 is: the dispersant in the step A is polyvinyl alcohol and its chelating agent; the concentration of the first aqueous solution in the step A is 300-350 g / L measured by silver. In the step A, the weight ratio of the dispersant to the silver ion is 1-2:100. In the described B step, the organic reducing agent is selected as a reducing agent with strong reducibility in alkaline solution, at this time, the pH value is 8 to 10; Compared with the theoretical value of the reducing agent, the reducing agent with stronger reducing ability in alkaline solution, the selected excess range is 5% to 15%; the reducing agent with stronger reducing ability in alkaline solution is selected as formaldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com