Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Guarantee organization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of spring steel 60Si2Mn hot-rolled wire rod for automotive suspension

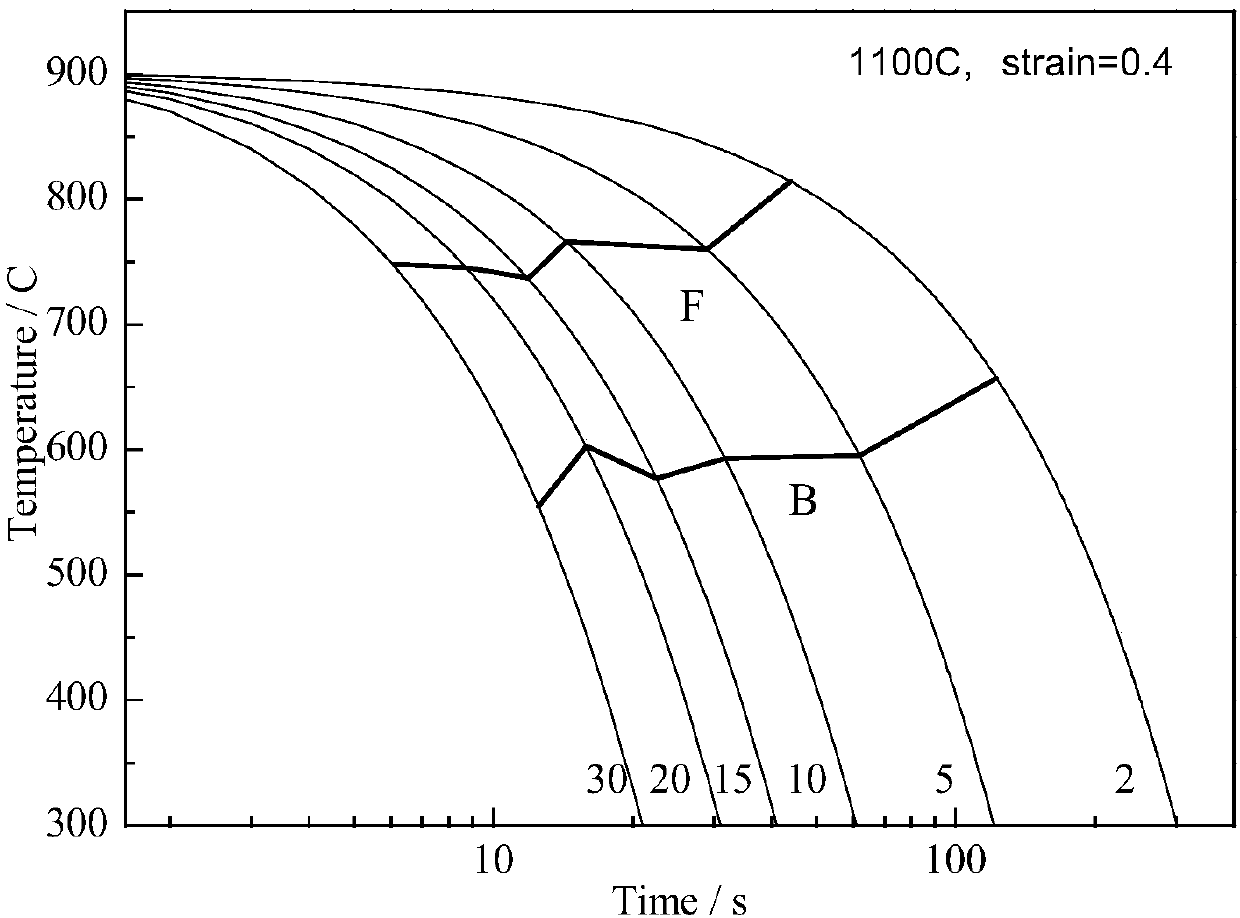

ActiveCN109023059AGuarantee organizationGuaranteed performanceProcess efficiency improvementSlagDeoxygenation

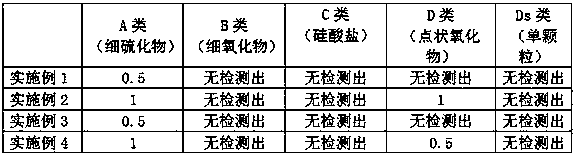

The invention discloses a production technology of a spring steel 60Si2Mn hot-rolled wire rod for an automotive suspension. The production technology comprises the steps of a hot metal pretreatment working procedure, a converter smelting working procedure, an LF refining working procedure, an RH vacuum treatment working procedure, a continuous casting working procedure, a cogging working procedure, an ingot blank polishing working procedure and a wire rod rolling working procedure. According to the production technology, the generation of AL2O3 inclusion is controlled from the source by meansof hot metal pretreatment desulfurization, silicon iron deoxygenation, silicon carbide diffusion deoxygenation and wollastonite and active lime slag formation; by the adoption of special carburant andspecial silicon iron, the content of nitrogen and the content of titanium in steel are controlled, argon protection in the whole process and the sufficient standing time are adopted, the situation that the inclusion fully and upwards floats is guaranteed, and D and Ds inclusion in the molten steel is controlled; by means of large ladle slag detection and special covering slag, the phenomenon thatthe molten steel is subjected to secondary pollution can be completely eradicated, and a good effect of thermal-insulating adsorption of the inclusion can be achieved; by means of the stir and soft press operation of a large rectangular blank crystallizer, the internal quality of an ingot blank is ensured; and in the rolling process, due to the optimization of the rolling speed and the control over the rolling temperature, the structure and the performance of a finished product are guaranteed.

Owner:HANDAN IRON & STEEL GROUP +1

Titanium alloy seamless tube and manufacturing method thereof

The present invention belongs to the technical field of titanium alloy and the manufacturing method thereof and discloses a titanium alloy seamless tube and the manufacturing method thereof. The invention is mainly characterized by comprising a tube body. The tube body comprises the following components by weight: 90 parts of Ti, 3.5-4.5 parts of V, 5.5-6.5 parts of Al, 0.08-0.12 parts of Ru, 0.28 or fewer parts of Fe, 0.13 or fewer parts of O, 0.07 or fewer parts of C, 0.03 or fewer parts of N, and 0.015 or fewer parts of H. An anti-oxidation coating layer is repeatedly and uniformly coated on the blank material, and then is subjected to the operations of heating, skew-rolling, perforating, deforming, heating, tube-rolling and deforming at the temperature of 850-780 DEG C. Meanwhile, the multi-pass reducing and sizing deformation is conducted at the temperature of 850-780 DEG C, and then the straightening and shot-blasting treatment is finally conducted to obtain the finished products of titanium alloy tubes. The titanium alloy seamless tube and the manufacturing method are simple in process, more environmentally-friendly in manufacturing process, and wider in the dimension range of manufactured titanium alloy tubes. Manufactured products are good in microstructure and mechanical properties, and manufactured titanium alloy tubes have fewer surface defects. Manufactured titanium alloy seamless tubes are good in machining performance, such as low cost, easy forging and corrosion resistance, thus being widely applicable to complex corrosion environments.

Owner:HEBEI HENGXIANG TITANIUM ALLOY PROD CO LTD

Corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe and method for manufacturing same

ActiveCN103722346AHigh strengthStrong integrityArc welding apparatusMetal rolling arrangementsSteel tubeSteel plates

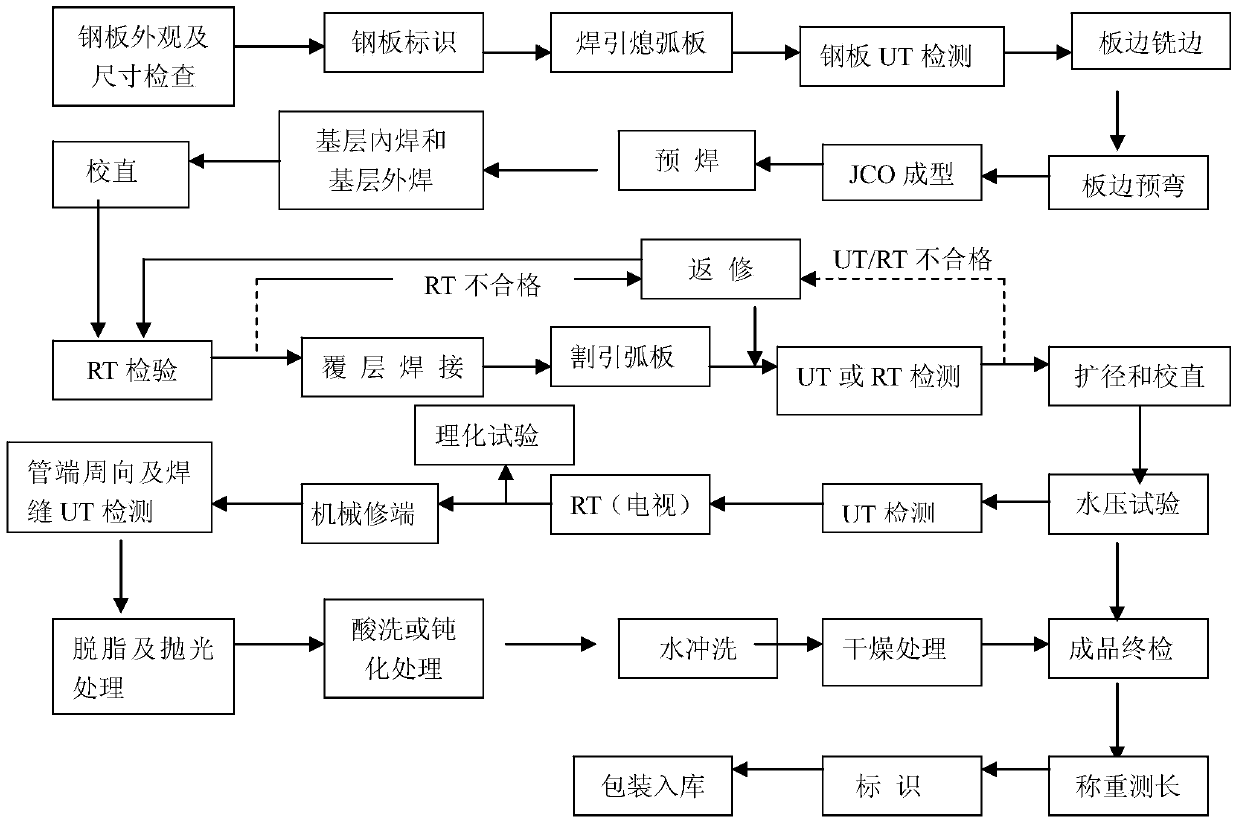

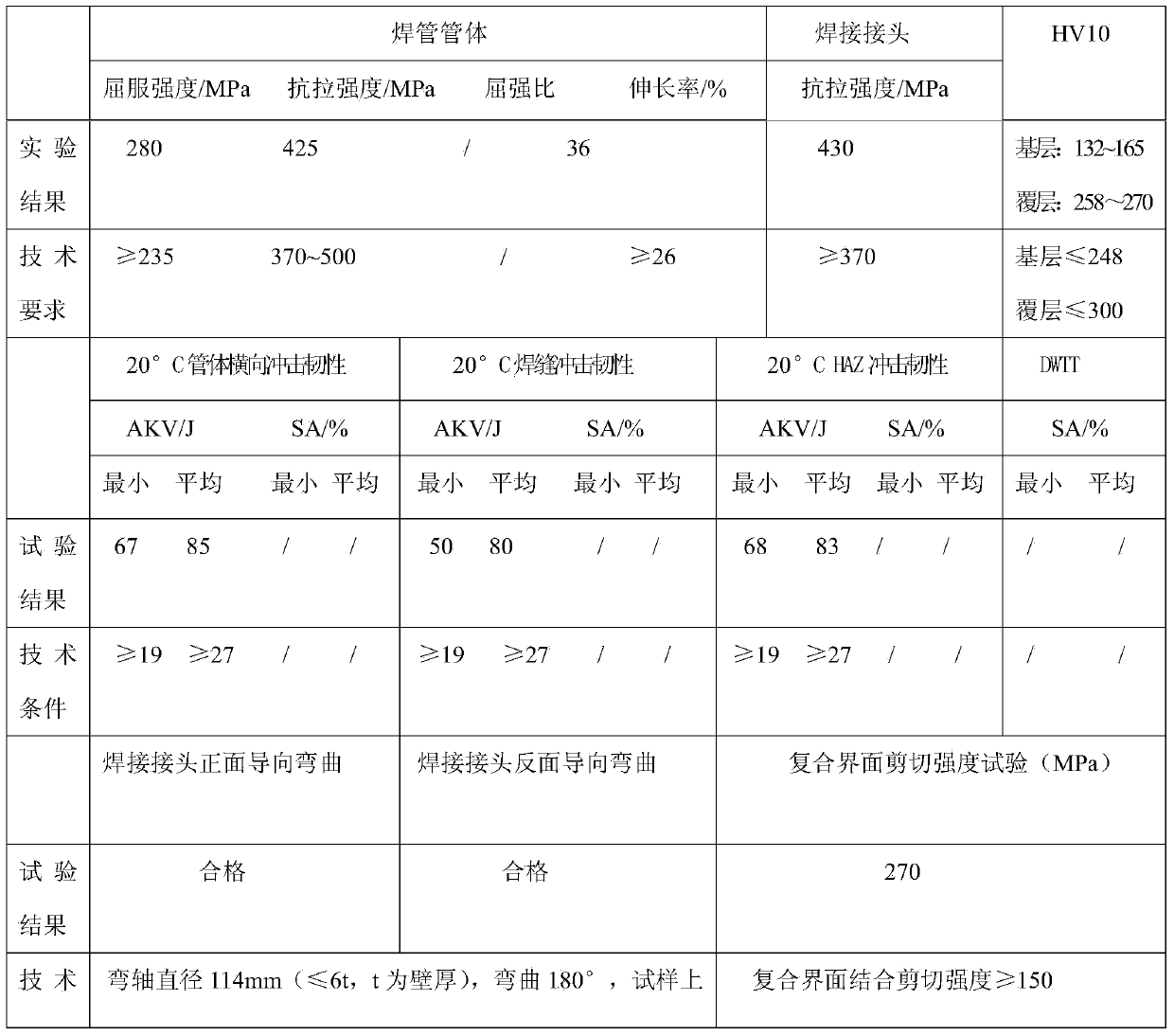

The invention provides a corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and a method for manufacturing the same. The method includes steps of (1), manufacturing bimetal composite steel plates by a hot rolling process; (2), carrying out edge milling, pre-bending, JCO forming and pre-welding on the bimetal composite steel plates manufactured in the step (1); (3), welding weld joints of a steel pipe by a submerged-arc welding process, particularly, welding a carbon steel layer of a base layer at first when the weld joints are welded, and then welding metal of a clad layer of a corrosion-resistant layer. The steel pipe is obtained after JCO forming and pre-welding are carried out on the bimetal composite steel plates. The corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and the method have the advantages that the corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe is manufactured by a hot rolling metallurgical composite bimetal steel plate and JCOE pipe manufacturing process and the efficient automatic submerged-arc welding process, double layers of metal of the steel pipe can be metallurgically combined with each other, and accordingly the steel pipe is high in strength, integrity and corrosion resistance; the JCOE pipe manufacturing process is adopted, so that the steel pipe is high in mechanical degree, production efficiency and overall dimensional accuracy, and steel pipes with the lengths of 12 meters can be produced by the method.

Owner:江苏玉龙钢管科技有限公司

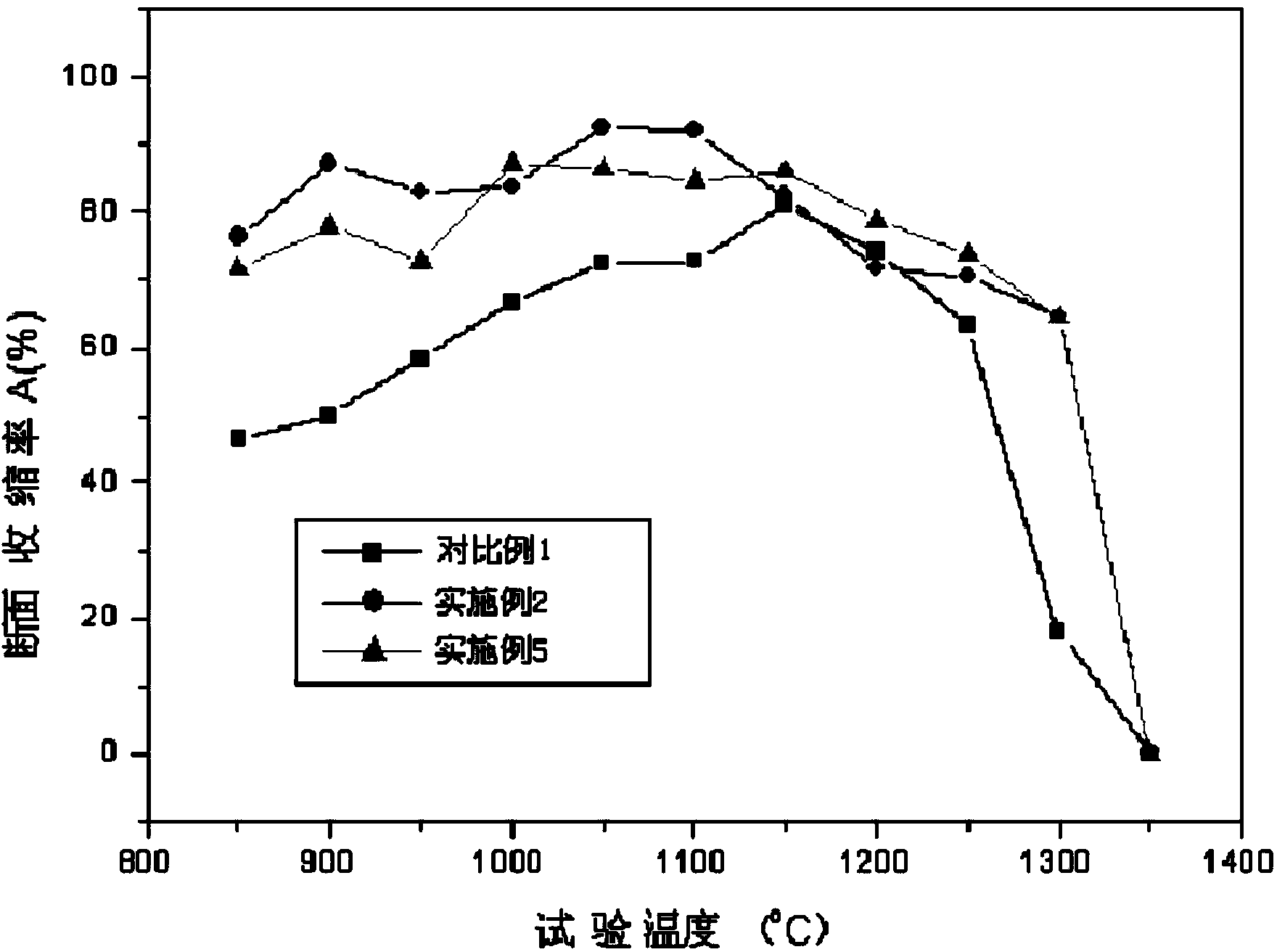

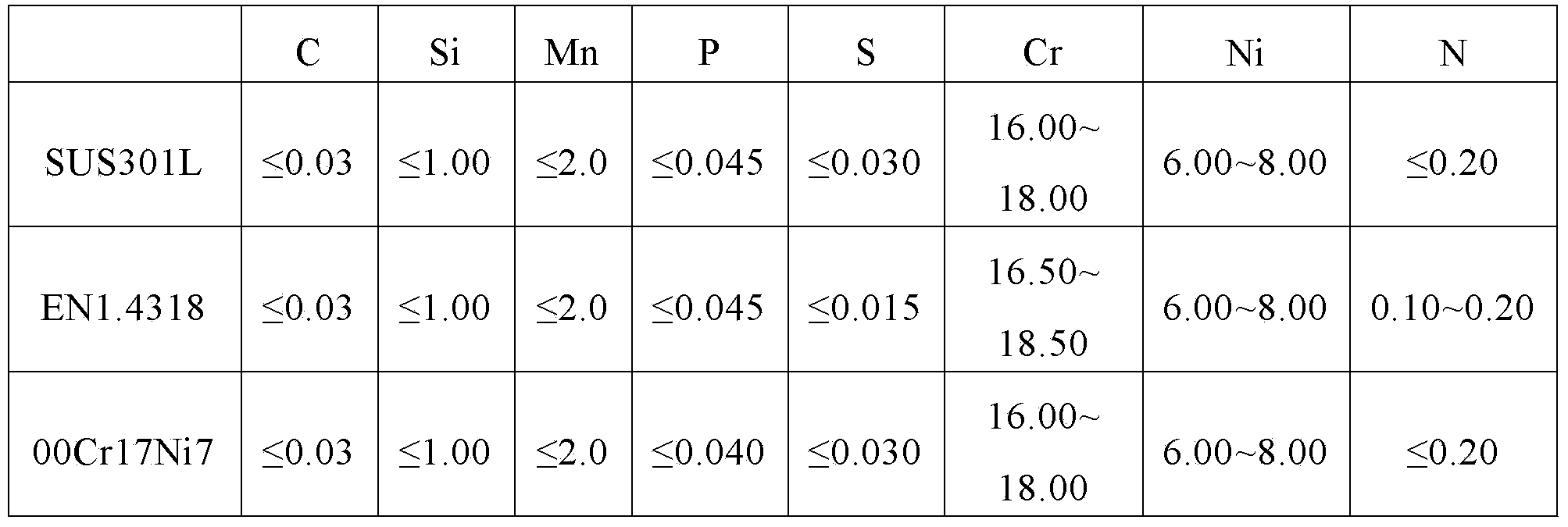

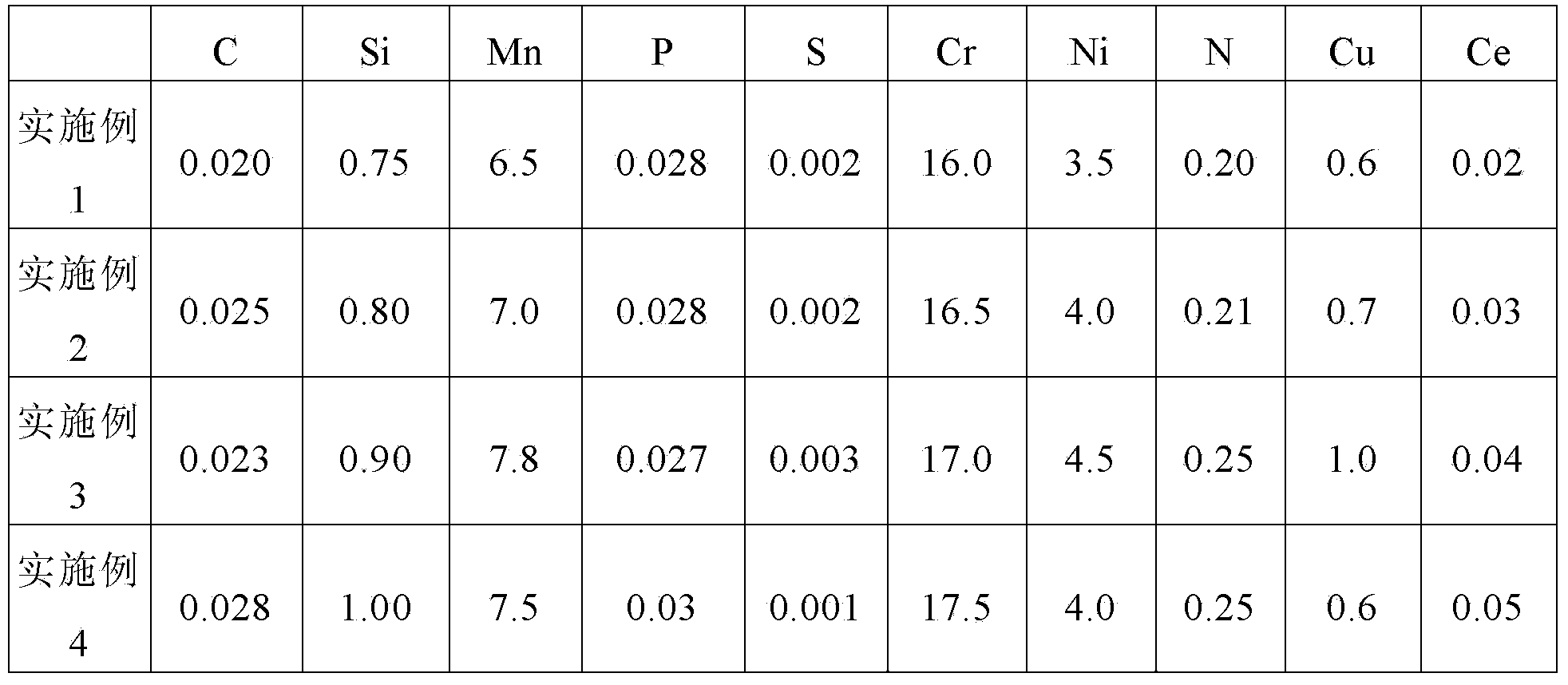

Austenitic stainless steel for urban rail vehicle face plates and manufacturing method of austenitic stainless steel

The invention discloses austenitic stainless steel for urban rail vehicle face plates and a manufacturing method of the austenitic stainless steel. The austenitic stainless steel comprises the following chemical compositions inpercentage by weight: less than 0.03% of C, 0.75-1.0% of Si, 6.5-8.0% of Mn, 16.0-17.5% of Cr, 3.0-4.5% of Ni, 0.15-0.25% of N, 0.5-1.0% of Cu, 0.02-0.05% of Ce, no greater than 0.040% of P, no greater than 0.03% of S, and the balance of Fe and inevitable impurities; the manufacturing method of the austenitic stainless steel comprises the following steps: through the operations of smelting, continuous casting, refining, tombarthite mixture block feeding, and soft stirring, continuous casting slabs are obtained by continuous casting, and the continuous casting slabs are heated; after hot rolling, cooling, reeling, air cooling, solution treating, shot blasting, acid cleaning, cold rolling and annealing acid cleaning are conducted, the finished product austenitic stainless steel is manufactured. According to the austenitic stainless steel for the urban rail vehicle face plates and the manufacturing method of the austenitic stainless steel, the oxidation of the edge part grain boundary caused by overheating of the slab edge part can be avoided; in the process of heating, a layer of dense chromium oxidation film with high adhesion is formed on the surface, the surface quality of the continuous casting slabs is protected, and the guarantee about surface quality control of stainless steel material used for the urban rail vehicle face plates can be provided.

Owner:BAOSTEEL STAINLESS STEEL

High-strength steel bar with high corrosion resistance and preparation method thereof

The invention discloses a high-strength steel bar with high corrosion resistance. The high-strength steel bar comprises the components of C, Si, Mn, P, S, Cr, Ni, Al, Cu, Mo, Ti and Fe. The invention further provides a preparation method of the high-strength steel bar with high corrosion resistance. The steel bar is stable in performance, has excellent corrosion resistance and high mechanical property, and can be widely applied to building engineering of coast and salt lake areas.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

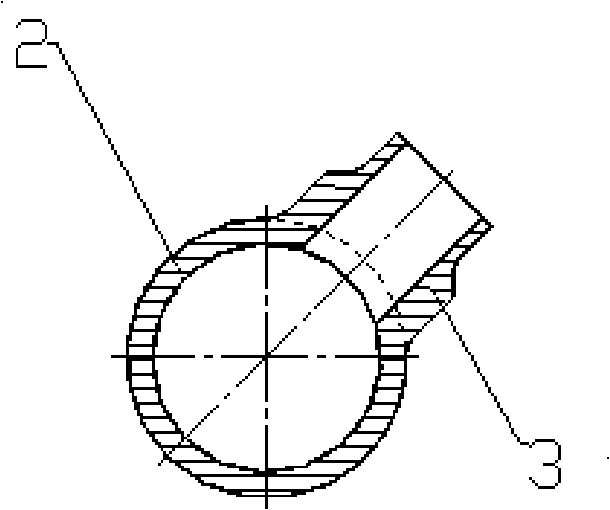

Combined shaping mold

ActiveCN101244443AMeet the technical requirements of productionReduce the amount of cuttingShaping toolsFilling rateMetal cutting

The invention discloses a composite forming die for production of elbow, satisfying the high requirements of shape and position dimensions of superior elbow, which comprises an upper die, a bottom die and a core die; wherein, the core die is made by metal; the spatial filling rate of core die filling tube interior is above 95%. The composite forming die has the advantages of satisfying the high technical requirements of shape and position dimensions of superior elbow, good performance and metal structure of tube body, low machining difficulty, small amount of metal cutting, light weight of semifinished product piece, circular bending part of elbow, good feature of bending back arc thickness reduction, good feature of nominal wall thickness, good feature of minimum wall thickness, preventing non-roundness and thickness reduction of bending part, and being applicable to a plurality of superior elbows requiring the high demands of shape and position dimensions, compared with the prior elbow made by the method of machining.

Owner:ERZHONG GROUP DEYANG HEAVY EQUIP

Method for implementing resource scheduling of video conference

ActiveCN1992878AGuarantee organizationJoin normallyTelevision conference systemsTwo-way working systemsResource schedulingAssignment methods

The invention relates to a method for calculating and distributing the resource needed by video conference, wherein said method comprises that: ordering conference, terminal accesses into conference, terminal takes back from conference; the ordering command of terminal comprises conference capacity, type; the invention analyzes the ordering command, when it is common conference, executing the order process of common conference, when it is virtual conference, based on its capacity calculating needed resource, when the left resource can satisfy the conference, distributing it to the conference. The invention can be processed without knowing the terminal amounts but only appointing the conference capacity; and when the conference order is successful, it can confirm the allowed terminals to enter into conference successfully; when there are terminal moves back at the process, and when the terminal amount is under the capacity, new terminal can access successfully.

Owner:ZTE CORP

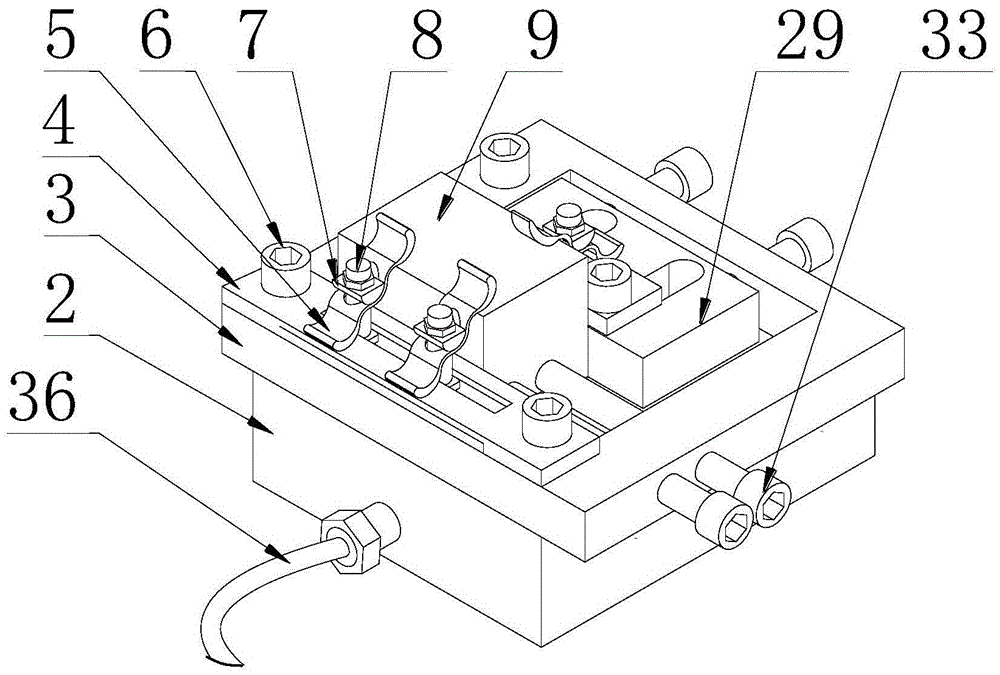

Nano-fluid minimal quantity lubrication grinding equipment coupled with electrocaloric internal cooling grinding wheel and electrostatic technology and use method thereof

ActiveCN105522487ALower grinding zone temperatureImprove processing efficiency and qualityBonded abrasive wheelsGrinding/polishing safety devicesLubricationMicrometer

The invention discloses nano-fluid minimal quantity lubrication grinding equipment coupled with an electrocaloric internal cooling grinding wheel and an electrostatic technology and a use method thereof. Nanometer-level or micrometer-level powder prepared from materials capable of generating the electrocaloric effect is added into a grinding wheel binding agent to form the electrocaloric grinding wheel, and in combination with electrostatic atomization, magnetically enhanced electrostatic neutralizing cleaning and electrostatic deposition, the grinding equipment coupled with grinding wheel internal cooling and the electrostatic technology is obtained. The temperature of a grinding area is obviously lowered, and the grinding surface of the grinding wheel is cleaned, so that the blockage of the grinding wheel is avoided. The amount of oil mist in the surroundings is obviously reduced in the grinding process. The nano-fluid minimal quantity lubrication grinding equipment obviously improves machining efficiency and meets the environmental protection requirement. The nano-fluid minimal quantity lubrication grinding equipment can effectively lower the temperature of the grinding area, improve the machining efficiency and quality, reduce oil mist pollution to the environment and reduce injuries to the health of the human body, thereby meeting the machining requirements and the requirements for energy saving and environment protection.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Isothermal die forging forming die and method for rare earth magnesium alloy thin webbed supporting fork

ActiveCN105397010AQuality improvementExtended service lifeForging/hammering/pressing machinesEngine componentsRare earthMagnesium alloy

The invention relates to a forming die and method for magnesium alloy thin webbed supporting fork forgings, in particular to an isothermal die forging forming die and method for a rare earth magnesium alloy thin webbed supporting fork. The problems that rare earth magnesium alloy thin webbed supporting fork forgings are prepared through conventional forging, blank manufacturing and forming are hard, forming defects are prone to occurring, the structure performance of the magnesium alloy forgings is hard to control, and the performance is low are solved. The forming method comprises the main steps that 1, blank manufacturing is carried out; 2, forging forming is carried out; 3, cooling is carried out; 4, primary acid pickling is carried out; 5, damage repairing is carried out; 6, final forging is carried out; 7, secondary acid pickling is carried out, wherein a magnesium alloy forging obtained in the sixth step is subjected to acid pickling, graphite on the surface is cleaned away, and a formed forging with the treated surface is obtained; and 8, the formed forging with the treated surface obtained in the seventh step is put into an aging oven to be subjected to aging treatment, and the finished rare earth magnesium alloy thin webbed supporting fork is manufactured. The forming die and method are used for preparing of the magnesium alloy thin webbed supporting fork.

Owner:HARBIN INST OF TECH

Hot continuous rolling production line of titanium and titanium alloy wire rod and production process

ActiveCN103008340AGuarantee organizationGuaranteed performanceRoll mill control devicesMetal rolling arrangementsProduction lineWire rod

The invention relates to a hot continuous rolling production line of titanium and a titanium alloy wire rod and a production process. An axial rolling production line of titanium and the titanium alloy wire rod is formed by vertically and sequentially connecting a heating furnace, a transverse two-roller roughing rolling unit, a high rigidity short stress line vertical two-roller intermediate rolling unit, a high rigidity short stress line vertical two-roller pre-finishing rolling unit, a Morgan type finishing rolling unit and a low speed active wire coil collecting barrel. Heat by deformation generated by resistance to deformation during rolling is reduced with the adoption of a low speed continuous rolling process, so that the microstructure and properties of a rolled piece are ensured, and qualified wire rods are directly produced. The production line provided by the invention can roll all titanium and titanium alloy wire rods with a diameter of 5-12mm, so that production of high precision, large rolled heavy titanium and titanium alloy wire rods can be realized, and the production efficiency is high and the production cost is low.

Owner:BAOJI TITANIUM IND

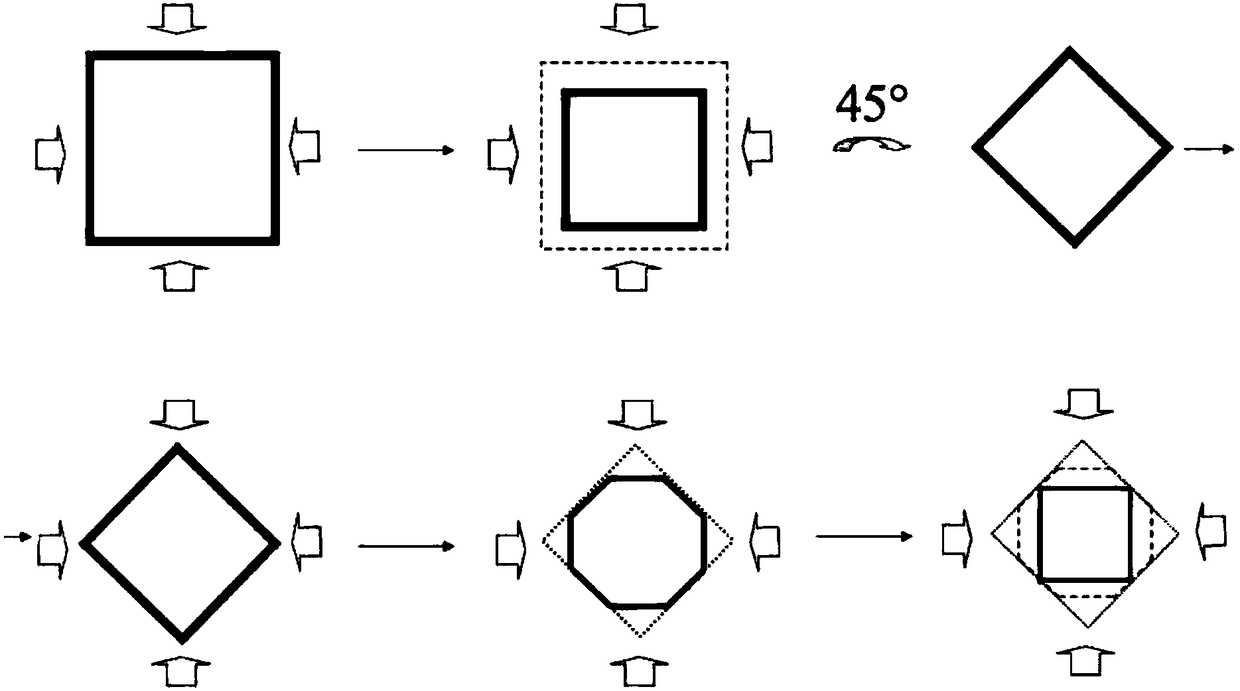

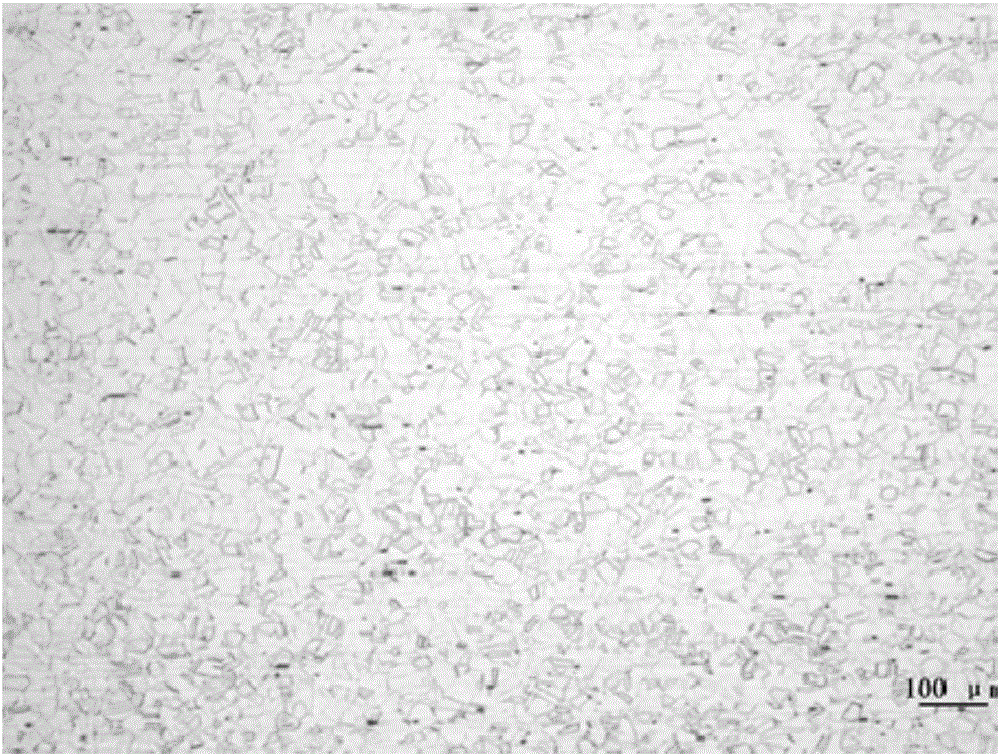

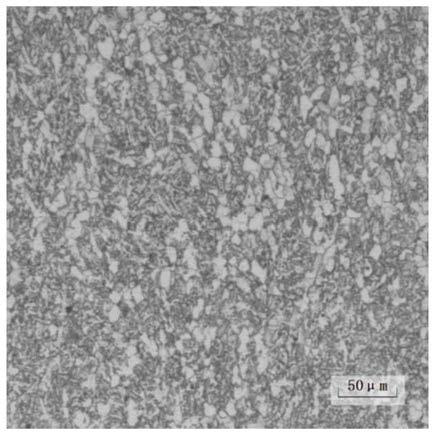

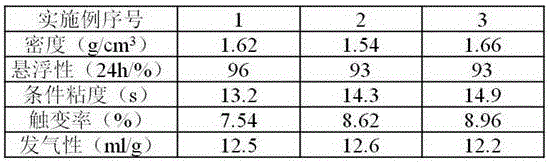

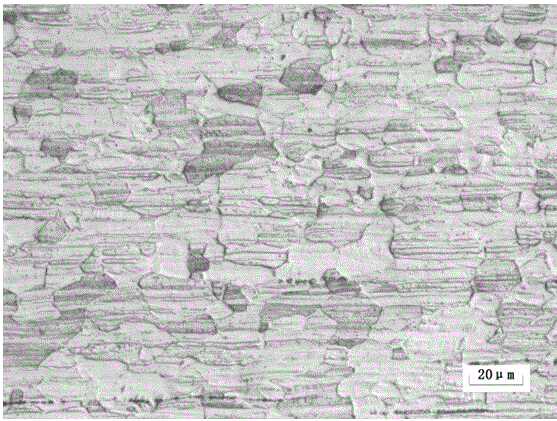

Forging method capable of improving structure uniformity of titanium alloy forging stock

ActiveCN108057829AClear grain boundariesGuarantee organizationMetal-working apparatusTitanium alloyTransition temperature

The invention discloses a forging method capable of improving structure uniformity of a titanium alloy forging stock. Differential thermal analyzing is used for measuring the phase transformation temperature beta t of a titanium alloy blank to be forged; under the temperature from (beta t+100) DEG C to (beta t+150) DEG C, heat preservation is carried out for 4 hours to 6 hours, and the blank to beforged is forged into a square blank; the obtained square blank is subject to heat preservation for 2 hours to 4 hours at the temperature from (beta t-20) DEG C to (beta t-10) DEG C, second-heating forging is carried out, the obtained square blank is subject to free drawing until the deformation amount reaches 50% to 60% of the total deformation amount, and the square blank obtained after free drawing is obtained; the obtained square blank obtained after free drawing rotates by 45 degrees around the center axis of the length direction of the square blank, pressing is carried out, and the final square blank is obtained; and the macrostructure of the cross section of the forge blank obtained after machining is uniform, the grain boundary is clear, no special-shaped piebald defects exist, the microstructure is uniform and consistent, the whole is of a net basket structure or equal-axis structure, and the edge and heart structures have no difference.

Owner:西安赛特思迈钛业有限公司

Heat treatment distortion control method for leaf spring parts

InactiveCN107058708AFit tightlyEven by forceFurnace typesHeat treatment process controlHardnessMaterials science

The invention discloses a heat treatment deformation control method for spring sheet parts, which belongs to the field of heat treatment deformation control. The method is as follows: ①Quenching the parts after cold forming; ②Put the spring piece into the shape-correcting fixture, fix it with appropriate pre-tightening bolts, and temper them together at the specified temperature; ③Tighten the bolts fully after half the tempering time, Put it into the furnace again and heat until the tempering process is over. The invention has the advantages that the method of fixture shape maintenance and heat correction can effectively correct the distortion and deformation of the spring sheet after quenching, ensure the corresponding structure and hardness requirements, and achieve the purpose of heat treatment shape control.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

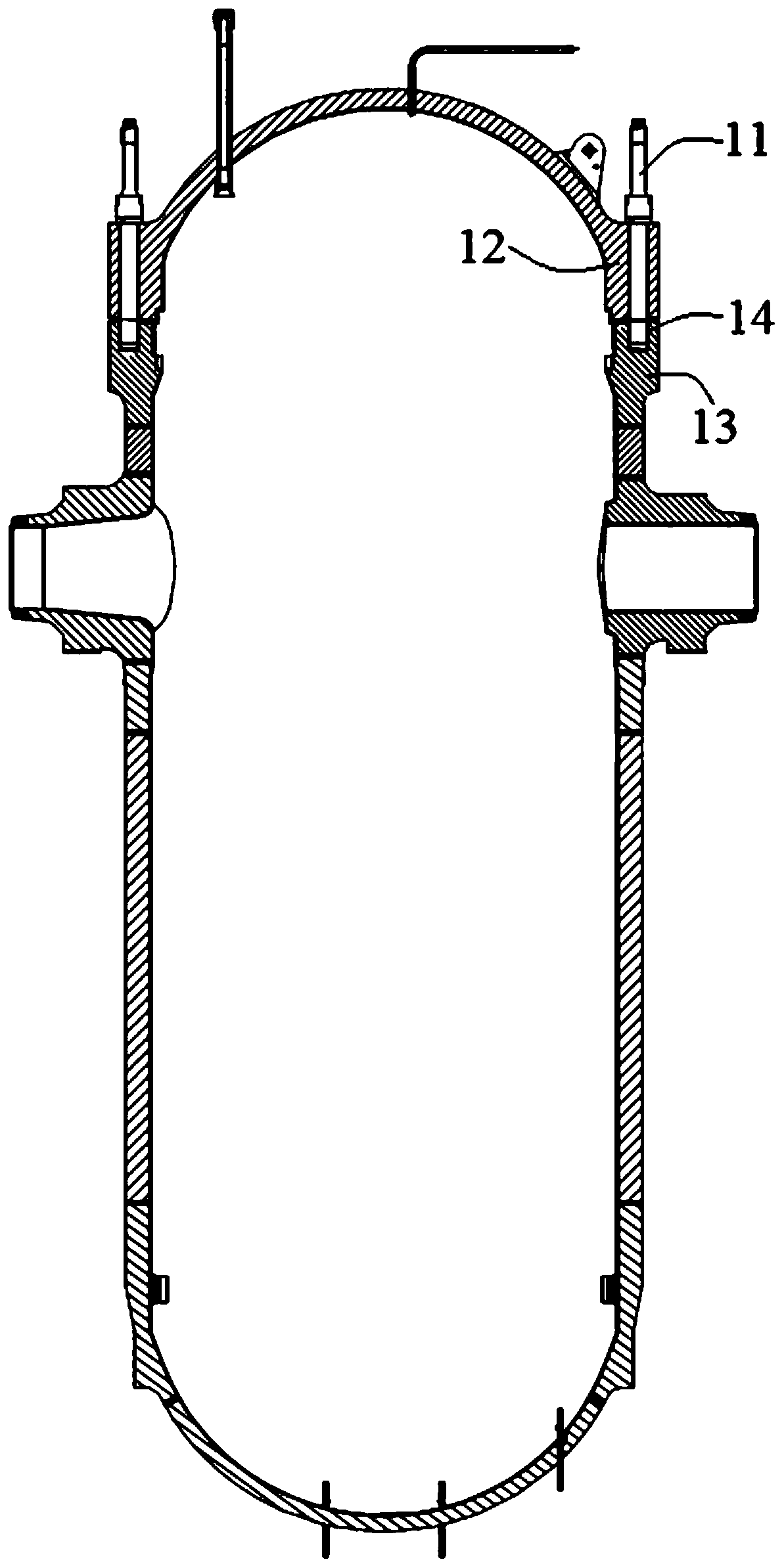

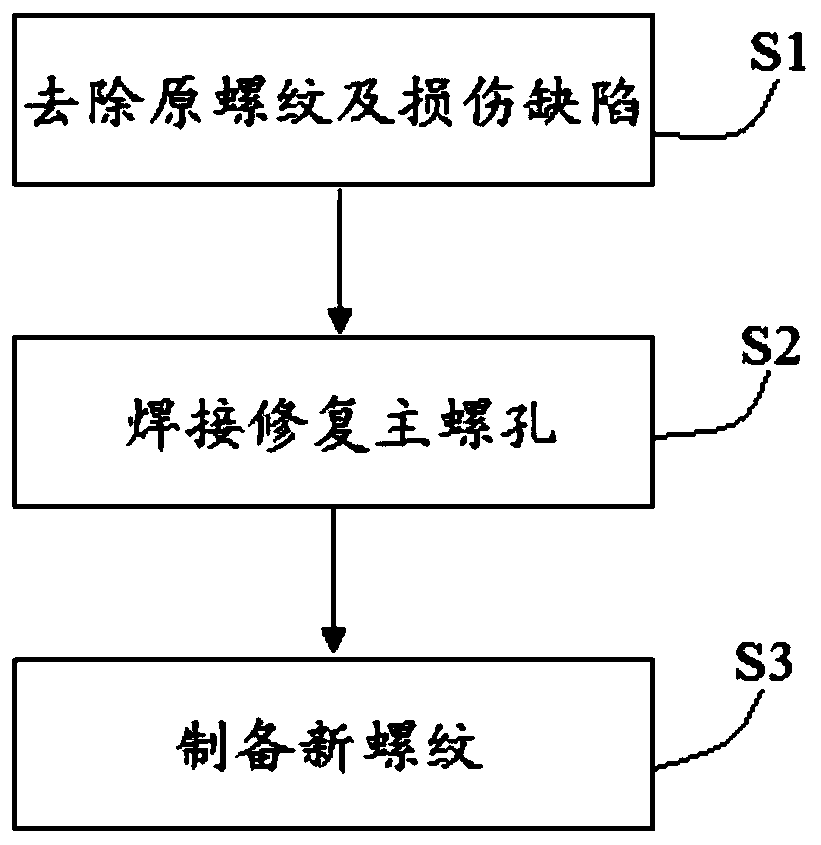

Main screw hole damage repairing method for nuclear power plant reactor pressure vessel

ActiveCN110253206ARepair serious damageGuarantee organizationReactor pressure vesselNuclear power plant

The invention discloses a main screw hole damage repairing method for a nuclear power plant reactor pressure vessel (RPV). The method comprises the follow steps of 1), carrying out hole expansion treatment on the damaged RPV main screw hole to remove the original thread and the damage defect; 2), adopting automatic pulse tungsten inert gas shielded welding to continuously implement horizontal welding position multi-bead multi-layer welding from bottom to top along the inner wall at the bottom of an RPV main screw hole; and 3), mechanical machining is carried out on the weld metal on the inner wall of the main screw hole, redundant weld metal is completely removed, and after removal is completed, carrying out new thread machining on the weld metal on the inner wall of the main screw hole to obtain a main screw hole meeting the design size requirement. According to the method, the new thread is prepared through welding and machining, so that the severe damage of the main screw hole thread of the RPV can be effectively repaired, and the application prospect and the economic benefit are huge.

Owner:中广核工程有限公司 +2

Preparation method of plasma-sprayed ceramic coating for strengthening surface of water pump impeller

InactiveCN107299310AExtend the life cycleHigh temperature resistantMolten spray coatingThermal sprayingChemical plating

The invention relates to a preparation method of a plasma-sprayed ceramic coating for strengthening surface of a water pump impeller. The preparation method comprises the following steps: ultrasonically washing the surface of the water pump impeller with acetone, and drying; processing the surface of the water pump impeller through sand-blasting roughening by brown aluminum oxide; preheating the surface of a base body; and spraying ceramic powder onto the surface of the base body of the water pump impeller to obtain a durable and corrosion-resistant ceramic coating, wherein the ceramic coating on the surface of the impeller is obtained by being spraying for a plurality of times. The preparation method overcomes shortages of laser surface modification, thermal spraying, chemical plating and electroplating. The preparation method has the advantages that the use cycle of a water pump is obviously prolonged; requirements of the water pump impeller surface on corrosion resistance and cavitation resistance are met; workpieces are recycled repeatedly; processes are simple and feasible; the production efficiency is high; the automation degree is high; the sustainable development strategy is met; and the method has market economic benefits.

Owner:YANGZHOU UNIV

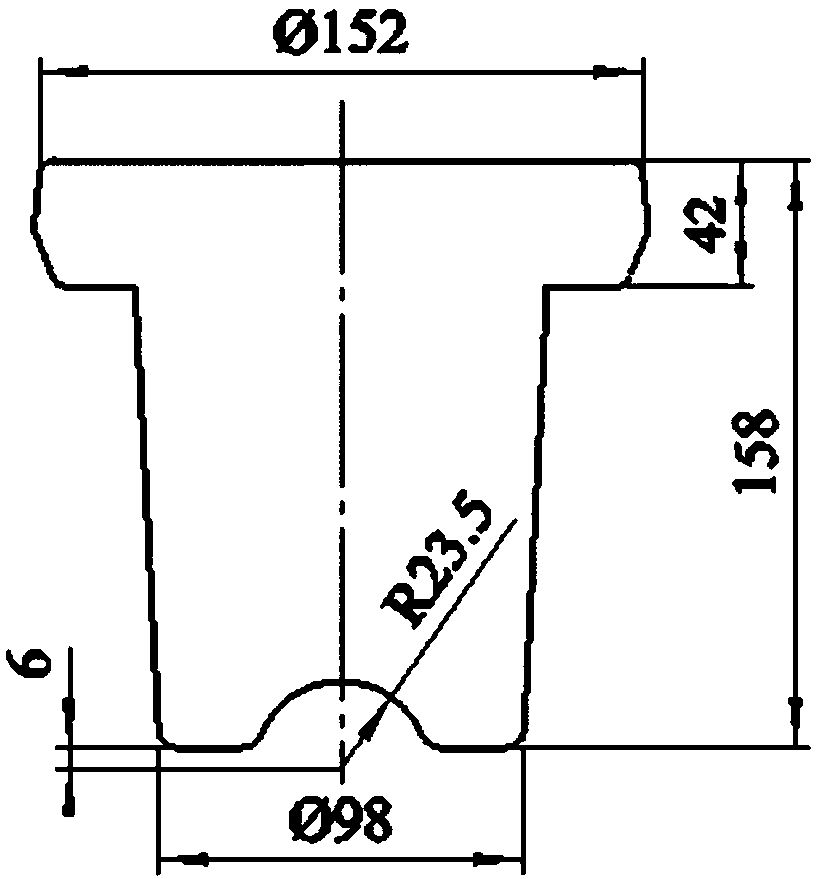

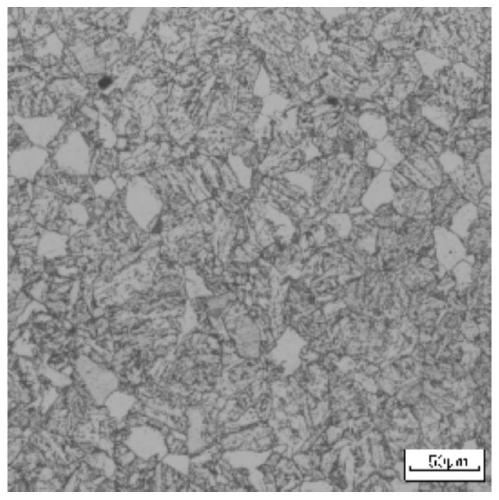

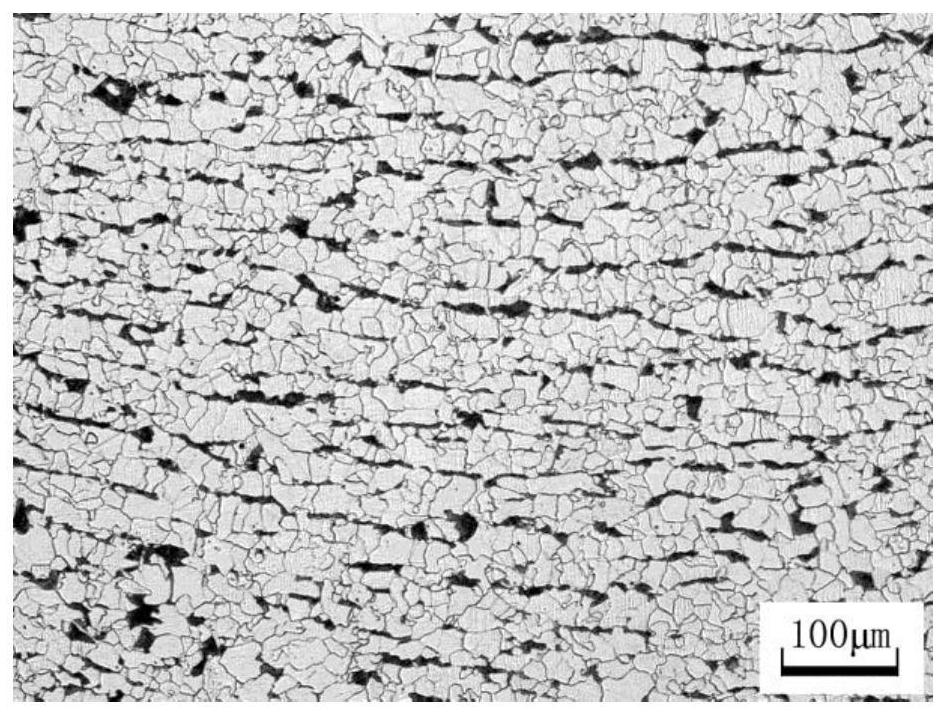

Die forging forming method of TC4 titanium alloy round-T-shaped forge piece

InactiveCN109352279AOptimizing the shape of the bottomGuaranteed flowHeating/cooling devicesMetal formingTitanium alloy

The invention discloses a die forging forming method of a TC4 titanium alloy round-T-shaped forge piece. The primary alpha phase of an adopted blank is 55 to 90%, heating before blank forging is carried out, and the process of one-time temperature rise and two-time heat preservation is carried out in an electric furnace. According to the method, raw materials are strictly controlled, according tothe proportion range of the blank primary alpha phase, the forging temperature is determined, the bottom shape of the force piece is optimized, metal forming is facilitated, precise control over the forge piece structure is achieved, fire forming is adopted, the streamline, the structure and the performance of the forge piece are ensured, and the forge piece structure and performance consistency are improved.

Owner:AECC AVIATION POWER CO LTD

High-strength austenitic stainless steel for economical railway vehicle and manufacturing method thereof

The invention discloses high-strength austenitic stainless steel for an economical railway vehicle and a manufacturing method thereof. The high-strength austenitic stainless steel comprises the following chemical components in percentage by mass: 0.03-0.12% of C, 0.4-0.8% of Si, 8.5-14.5% of Mn, 14.0-15.5% of Cr, 1.2-1.8% of Ni, 0.15-0.25% of N, V not more than 0.15%, Ti not more than 0.10%, V+Ti not less than 0.05%, Cu not more than 0.60%, P not more than 0.03%, S not more than 0.01%, and the balance of Fe and inevitable impurities; the room-temperature yield strength is not less than 400 MPa; the tensile strength is not less than 700 MPa; and the ductility is not less than 35%. The stainless steel is applied to the railway vehicle, and can reduce the manufacturing cost under the precondition of satisfying the safety requirement; and the stainless steel is applied to a railway truck, can improve the strength when guaranteeing the economy and the service life, and improves the vehicle lightness level.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

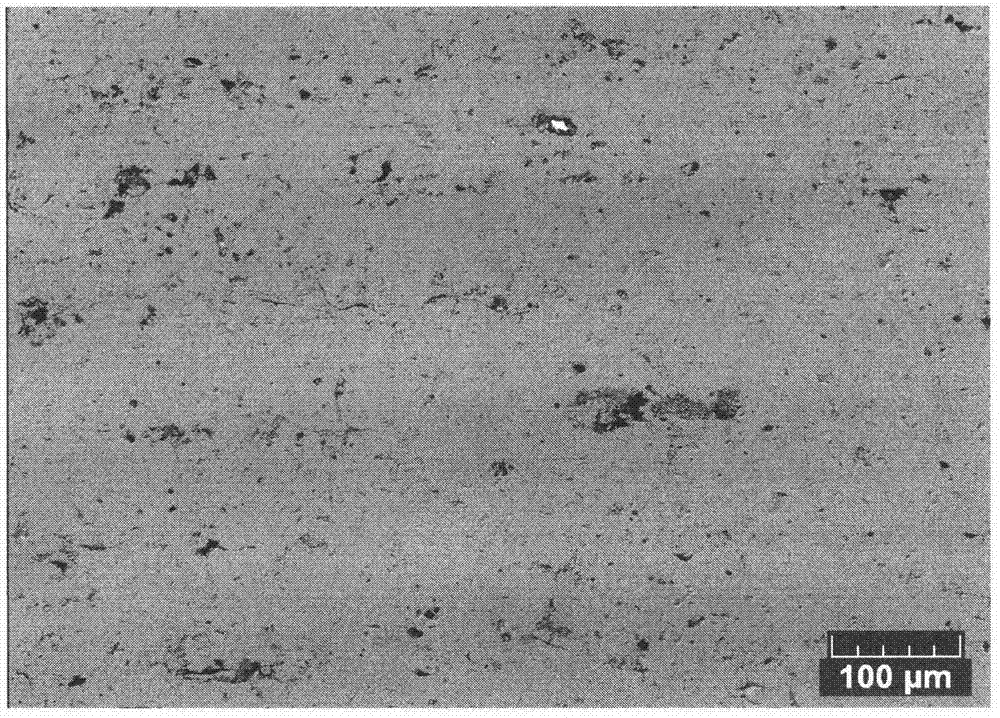

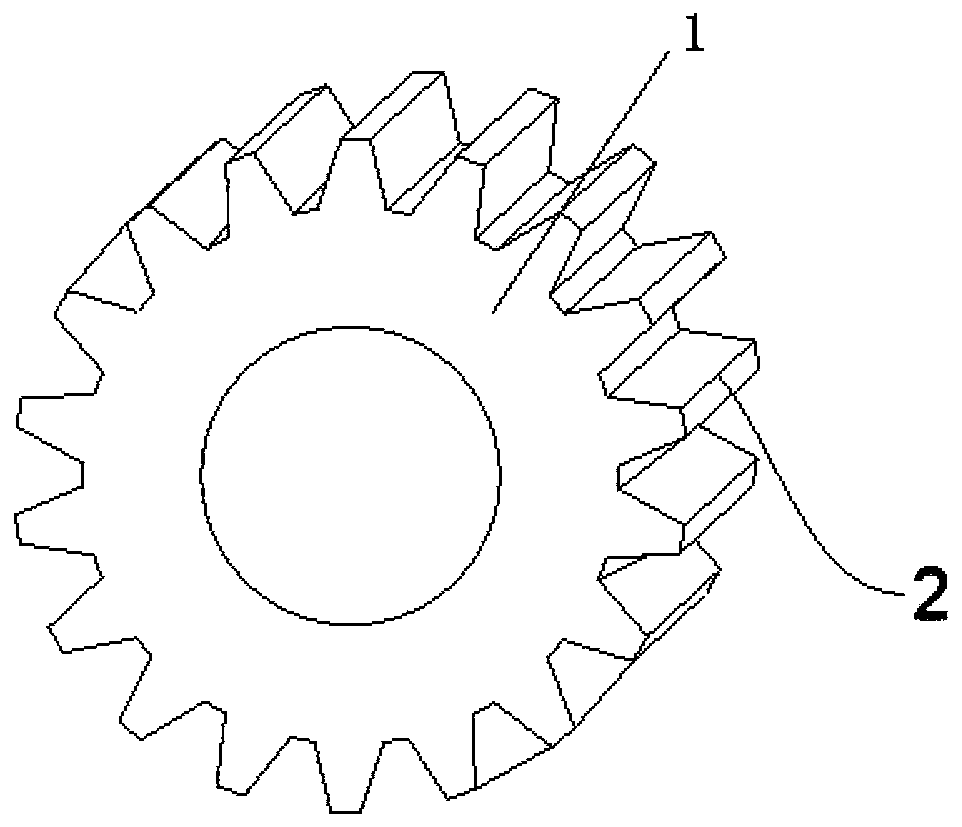

Low-noise self-lubrication small and medium modulus cylindrical gear and preparation method thereof

ActiveCN109877550AUniform mechanical propertiesOvercome the effect of non-uniformityFurnace typesHeat treatment furnacesLow noiseHobbing

The invention discloses a preparation method of a low-noise self-lubrication small and medium modulus cylindrical gear. The preparation method comprises the following steps of molten iron melting, pouring and condensation, proximate matter drawing, proximate matter performance detecting, annealing treatment, sawing and turning, aging treatment, gear hobbing or gear milling, high-frequency induction and isothermal quenching, and rough grinding and fine grinding to a preset assembly size. The graphite nodule diameter of the gear part of the obtained cylindrical gear is less than or equal to 20 [mu]m, the nodule density is greater than or equal to 300 per mm2, and the rate of spheroidization is 100%; and the graphite nodule diameter of the root part is less than or equal to 30 [mu]m, the nodule density is greater than or equal to 200 per mm2, and the rate of spheroidization is 100%. According to the preparation method, the surface contact fatigue strength and the gear root bending fatiguestrength of the prepared cylindrical gear are improved, hardness of other parts of a basal body is increased to resist abrasion, adhesive abrasion caused by sliding friction among gear surfaces is effectively prevented, the service life is prolonged, and dispersed distribution ultra-fine graphite nodules also make the gear have the outstanding sound absorption and shock absorption effects.

Owner:XIAN UNIV OF TECH

Low-temperature toughness chromium-molybdenum steel plate and production method

PendingCN111286667AGuaranteed toughnessModerate performanceFurnace typesHeat treatment furnacesTemperature controlTempering

The invention provides a low-temperature toughness chromium-molybdenum steel plate and a production method. The low-temperature toughness chromium-molybdenum steel plate comprises the chemical components: 0.14%-0.17% of C, 0.40%-0.55% of Mn, 0.50%-0.60% of Si, not greater than 0.008% of S, not greater than 0.015% of P, 1.15%-1.35% of Cr, 0.45%-0.55% of Mo, 0.02%-0.04% of Alt and the balance Fe andinevitable impurities. According to the low-temperature toughness chromium-molybdenum steel plate, a noble metal is not added, and a special process does not need to be employed to reduce the contentof sulfur and phosphorus in steel, so that cost is low; a ferrite + pearlite + bainite structure is obtained by final rolling temperature control and cooling after rolling through a normalizing + tempering process; and the tensile strength Rm is 550-650 MPa, the yield strength Rel is 350-450 MPa, the elongation A (L0 = 200mm) is not less than 22%, and the lateral V-shaped impact average value at-29 DEG C is not less than 47J.

Owner:新余钢铁股份有限公司

Titanium and titanium alloy bar hot continuous rolling production line and production process

InactiveCN103008341AGuarantee organizationGuaranteed performanceMetal rolling arrangementsProduction lineTitanium

The invention relates to a titanium and titanium alloy bar hot continuous rolling production line and a production process. The titanium and titanium alloy bar hot continuous rolling production line consists of a heating furnace, a transverse two-roll rough rolling unit, a high-rigidity short-stress-line longitudinal two-roll intermediate rolling unit, a high-rigidity short-stress-line longitudinal two-roll finish rolling unit and a small bar cooling bed. A low-speed continuous rolling process is adopted to reduce deformation heat produced by deformation resistance during rolling, guarantee the internal structure and the properties of rolled pieces and directly produce qualified bars. The titanium and titanium alloy bar hot continuous rolling production line can be used for rolling titanium and titanium alloy bars with specifications from phi 12mm to phi 140mm, the production of high-precision and heavy-piece-weight titanium and titanium alloy bars is realized, the production efficiency is high and the production cost is low.

Owner:BAOJI TITANIUM IND

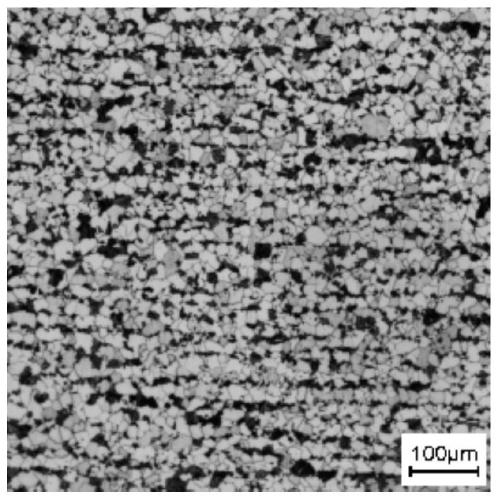

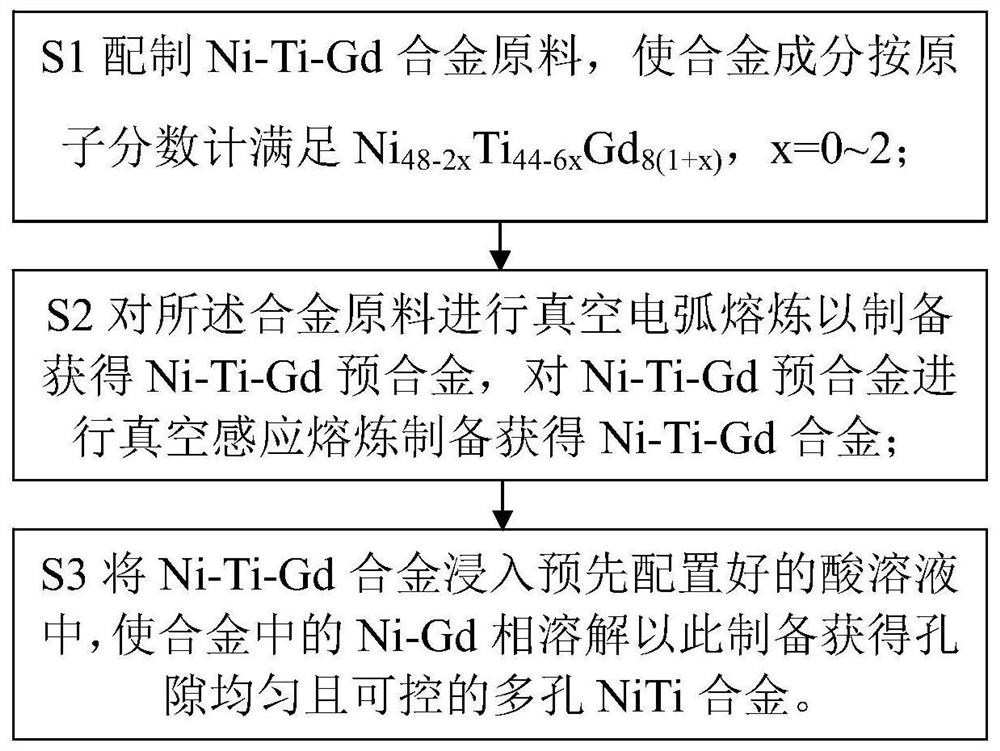

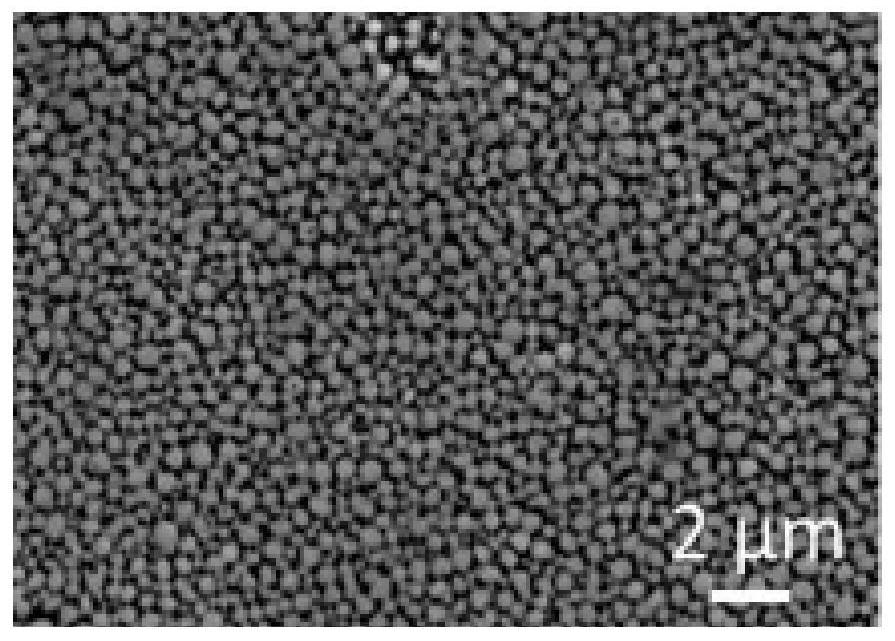

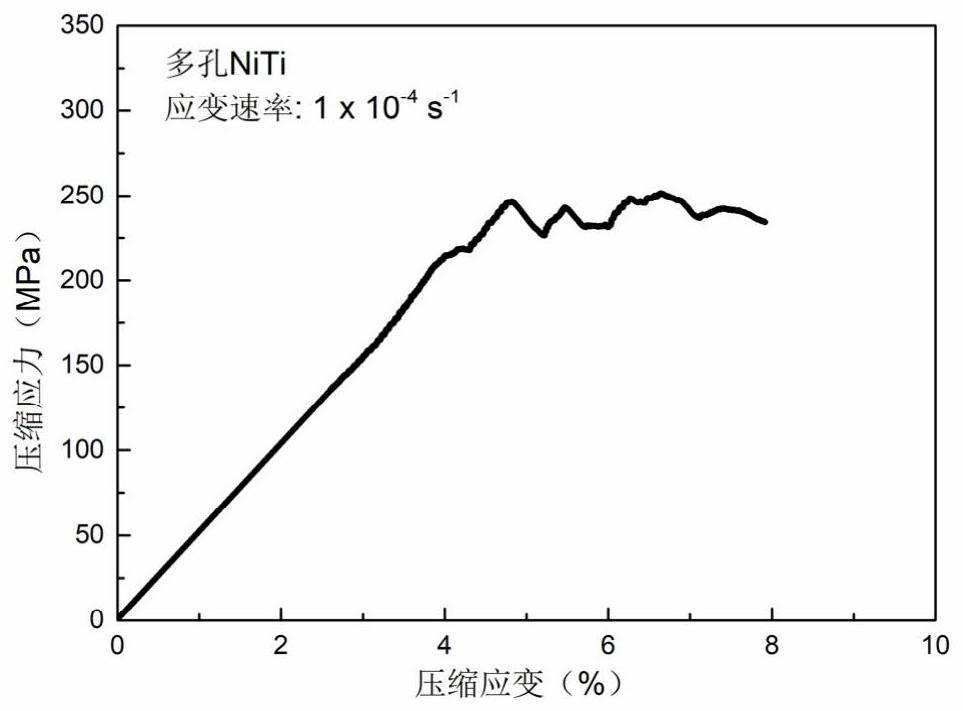

Preparation method for porous NiTi alloy based on selective dissolution and product

The invention belongs to the field of porous alloy preparation, and particularly discloses a preparation method for a porous NiTi alloy based on selective dissolution and a product. The preparation method comprises the following steps: adding a Gd element into a Ni-Ti binary alloy, based on the characteristic that the Gd element can react with the Ni element but not react with the Ti element, onlyNi-Ti and Ni-Gd phases are generated in the alloy, and then removing the Ni-Gd phases based on selective corrosion by using an acid solution to obtain the porous NiTi alloy with uniform and controllable pores. The method can be used for preparing the porous NiTi alloy with small pore size and uniform distribution, and has the advantages of simple and convenient operation process and lower cost.

Owner:HUAZHONG UNIV OF SCI & TECH

Production method of 540 MPa grade hot-rolled pickled plate with low cost and high hole expansion rate

ActiveCN107663609AGuaranteed organization and mechanical propertiesGuaranteed surface qualityManganese sulfideChemical composition

The invention relates to the field of hot-rolled pickled plates, in particular to a production method of a 540 MPa grade hot-rolled pickled plate with a low cost and a high hole expansion rate. According to the production method, through reasonable design of chemical components, a rolling process and a pickling and leveling process, the good performance and surface quality of the product are guaranteed. By adopting the production method provided by the invention, the quality problems that a 540 MPa grade hot-rolled pickled plate produced in the prior art is prone to surface peeling, internal banded structures are severe, and manganese sulfide occluded foreign substances are high in grade can be solved, and the problems that during application of the hot-rolled pickled plate, the yield is low, the moldability is poor, and the welding performance is poor can be solved.

Owner:BENGANG STEEL PLATES

Turbine blade thermal barrier coating finishing protection device and method

ActiveCN113001339AAvoid overglazing problemsGuarantee organizationEdge grinding machinesVacuum evaporation coatingSpoilerTurbine blade

The invention discloses a turbine blade thermal barrier coating finishing protection device and a method. The turbine blade thermal barrier coating finishing protection device comprises a pull rod, an air inlet edge spoiler, a protection box and an exhaust edge spoiler; the protection box is of an open structure, a through hole is formed in the open bottom face of the protection box, a clamping groove is formed in one end of the pull rod and used for fixing a tenon of a blade to be finished, and the other end of the pull rod penetrates through the through hole in the bottom face of the protection box to fix the tenon of the blade to be finished into the protection box; the air inlet edge spoiler is arranged on one side wall of the protection box and used for protecting an air inlet edge of the blade to be finished; and the exhaust edge spoiler is arranged on one side wall of the protection box and used for protecting the exhaust edge of the blade to be finished. Firstly, wax seal is adopted to block an air film hole, a top cover hole and a tail crack of a turbine blade, and then the air inlet edge spoiler, the exhaust edge spoiler and the protection box are arranged to carry out finishing protection on the air inlet edge, the exhaust edge and the tenon.

Owner:AECC AVIATION POWER CO LTD +1

Welding method of high-strength steel

InactiveCN113118597AGuarantee organizationGuaranteed Grain SizeWelding accessoriesTemperature controlWeld seam

The invention provides a welding method for high-strength steel. The welding method comprises the following steps that a high-strength welding wire is used at a welded junction of a steel plate to carry out gas shielded welding, and the gas shielded welding comprises the step of sequentially carrying out priming layer welding and capping layer welding at the welded junction, wherein the heat input of the gas shielded welding is 0.8-1.5 kJ / mm, the gas flow is 15-25 L / min, and the interlayer temperature between the priming layer welding and the capping layer welding is controlled to be 120-200 DEG C. According to the welding method of the high-strength steel, the heat input and the interlayer temperature are strictly controlled to be within a proper range, the structure and grain size are guaranteed, and therefore it is guaranteed that a weld joint obtains good obdurability matching; the certain toughness is achieved while the strength of the welding wire is ensured; and a welding joint with high strength and good toughness and plasticity is obtained. Moreover, the welding method for the high-strength steel produced by the method adopts the same high-strength steel welding wire in the whole process, so that the welding wire is prevented from being switched back and forth, operation is simple, the implementation is easy in production, the method can be popularized to automatic robot welding, and efficient production is realized.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Forming method for improving structure performance of rare-earth magnesium alloy conical cylindrical part

ActiveCN109594000AGive full play to the effect of deformation dynamic recrystallization strengtheningGuarantee organizationExtrusion diesForging/hammering/pressing machinesHeat resistanceRare earth

The invention relates to a forming method for improving the structure performance of a rare-earth magnesium alloy conical cylindrical part, belongs to the field of non-ferrous metal materials and technologies, and particularly relates to a forming method for improving the small-end structure performance of a Mg-9Gd-3RE heat-resistant rare-earth magnesium alloy conical cylindrical part. According to the forming method, for the heat resistance, the tensile strength of the mechanical property at 200 DEG C is not lower than 330 MPa, for the conical cylindrical part, the large-end diameter size (outer diameter ) is not lower than phi 200 mm, the small-end diameter size (outer diameter) is not lower than phi 80 mm, in case of the improvement on the structure performance of the rare-earth magnesium alloy cylindrical part, the mechanical property is improved, and the grain size is refined; and for the ratio of the height of the conical cylindrical part to the small-end outer diameter is not less than 7, in case of the improvement on the structure performance of the rare-earth magnesium alloy conical cylindrical, the mechanical property is improved, and the grain size is refined.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

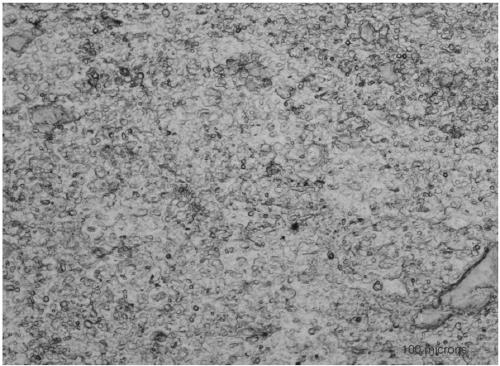

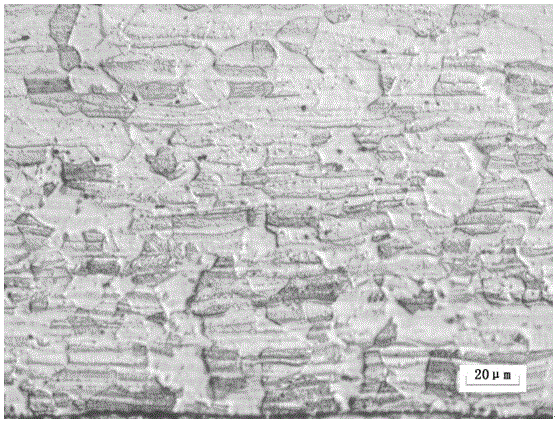

Casting coating and preparation method thereof

InactiveCN106513570AGood heat insulationReduce thermal shockFoundry mouldsFoundry coresRefractoryCohesive strength

The invention provides a casting coating. The casting coating comprises, by mass, 65-90 parts of a component A, 100-130 parts of a component B, and 8-12 parts of a component C. The component A is a refractory material component, the component B is a carrier liquid and bonding agent component, and the component C is an additive and assistant component. The casting coating is good in heat-insulation performance, thermal shock borne by metal can be reduced, and the service life of the metal is prolonged; the thermal resistance of a system can be adjusted, and the cooling speed can be controlled, so that it is guaranteed that the structure and performance of a casting meet requirements; and the casting coating has certain adhesive strength and cohesive strength, and thus the situation that molten liquid scours the coating under the effect of centrifugal force can be prevented.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Production method for improving whole-section residual stress uniformity of F-shaped rail

ActiveCN111635987AImprove residual stress uniformityReduce temperature differenceTemperature control deviceFurnace typesTemperature controlEngineering

The invention discloses a production method for improving whole-section residual stress uniformity of an F-shaped rail. The production method comprises the following steps: dividing the F-shaped railinto three cooling areas according to different positions of a section, cooling the three cooling areas of the rolled F-shaped rail at different cooling rates, wherein the initial cooling temperatureis controlled to be 520-600 DEG C, the cooling rate of the first cooling area is 0.2-0.7 DEG C / s, the cooling rate of the second cooling area is 0.8-1.3 DEG C / s, and the cooling rate of the third cooling area is 1.4-2.0 DEG C / s, stopping accelerated cooling when the surface temperature of the first cooling area is reduced to 60-100 DEG C, and carrying out straightening and finishing. According tothe method provided by the invention, by reasonably controlling the cooling strength of each position of the section of the rolled F-shaped rail, the temperature difference of the whole section of theF-shaped rail is reduced, and the absolute value of the whole-section residual stress fluctuation is controlled within 100MPa.

Owner:武汉钢铁有限公司

Environment friendly casting coating as well as preparation method and using method thereof

InactiveCN106513568AGood heat insulationImprove stabilityFoundry mouldsFoundry coresEnvironmental resistanceThermal insulation

The invention discloses an environment friendly casting coating as well as a preparation method and a using method thereof. The environment friendly casting coating comprises the followings in parts by mass: 100-120 parts of a component A, 130-150 parts of a component B and 15-25 parts of a component C, wherein the component A is fireproof material; the component B is carrier liquid and a binder; and the component C is an additive and an assistant. The environment friendly casting coating has the advantages of excellent thermal insulation property, high strength, low gas evolution amount and excellent rheological property and suspendability, is environment friendly and non-poisonous, does not generate toxic and harmful substances during the manufacturing and using processes, and can well protect operators and atmospheric environment in the casting flow.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Pre-weld and post-weld heat treatment methods for inertial friction welded rotor assemblies

ActiveCN110158002BUnified post-weld heat treatment systemGuarantee organizationWelding/cutting auxillary devicesFurnace typesFriction weldingMaterials science

The invention provides a heat treatment method of an inertia friction welding rotor module before and after welding. The method comprises the following steps: (1) a before-welding heat treatment stateof parts to be welded is determined; (2) the surfaces of all the parts to be welded are cleaned; and the cleaned surfaces show the metal luster; (3) two welded parts are fixed and welded; (4) weldedmodules are fixed after welding, and are loaded in another welded part for welding; (5) all welding flanges are removed after the module welding, and are loaded in a vacuum heat treatment furnace forafter-welding heat treatment; (6) the air cooling or the atmosphere cooling is performed on the modules after the after-welding heat treatment; and (7) all inertia friction welding rotor modules are detected and machined. On the basis of guaranteeing material structures and performances, the unified after-welding heat treatment regime of the modules is guaranteed, and the support is provided for application of the inertia friction welding process to aero-engine welding robot modules.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

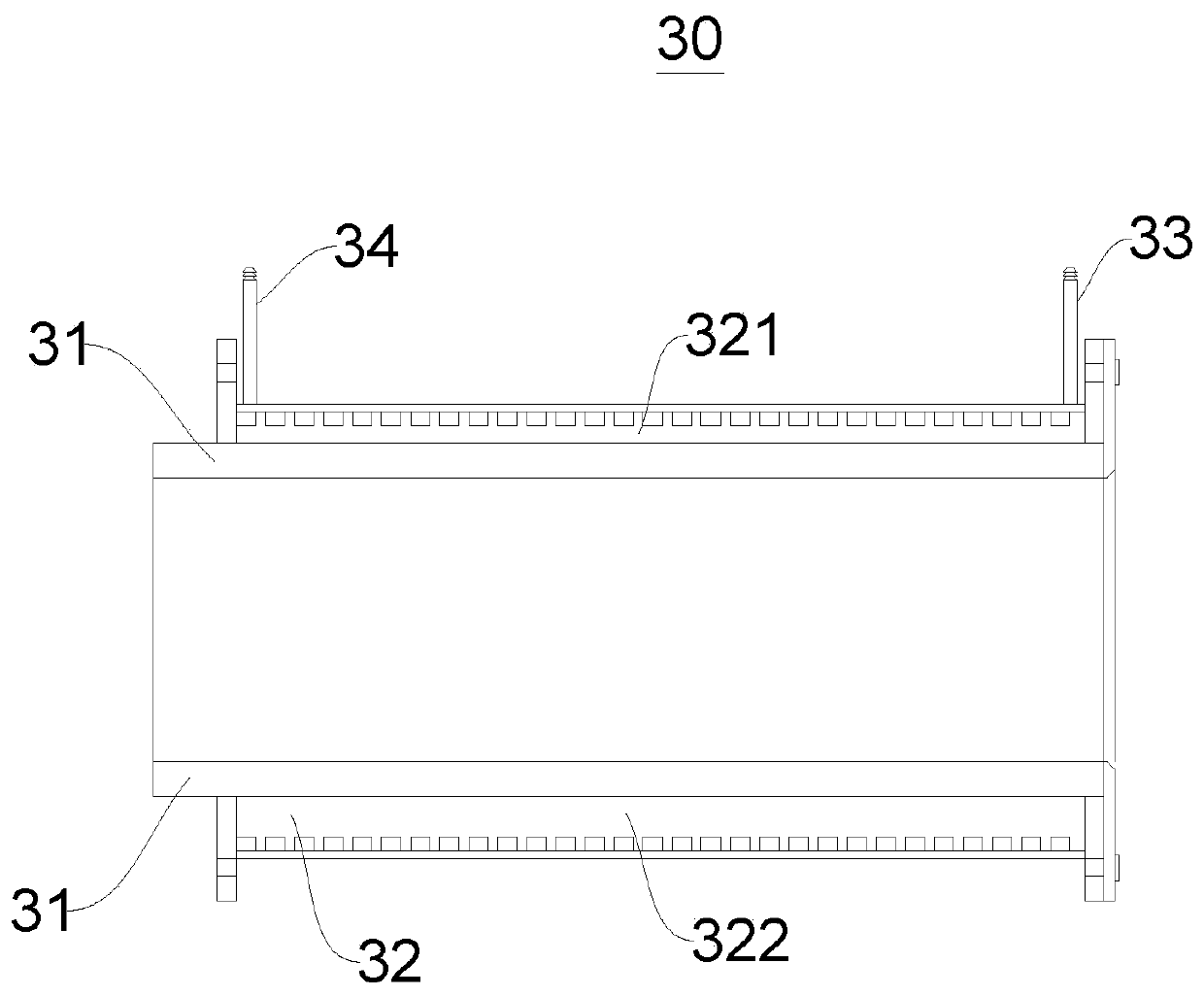

Water-based quenching equipment and quenching method for phi76.2mm steel balls made of GCr15SiMn steel

InactiveCN109161675AIncreases heart cooling speedGuaranteed cardiac tissueFurnace typesQuenching agentsQuenchingCore cooling

The invention discloses water-based quenching equipment and a water-based quenching method for phi76.2mm steel balls made of GCr15SiMn steel. By the water-based quenching method for the phi76.2mm steel balls made of the GCr15SiMn steel, water-based quenching liquid obtained through reasonable formulation of a water-based quenching agent and water is used as a cooling medium to control the steel ball quenching cooling time and the liquid discharging temperature, and for such steel balls with relatively large specifications, the core cooling rate can be obviously increased, the core structure isguaranteed and the core hardness is improved.

Owner:LUOYANG LYC BEARING

Heat treatment technique of stainless steel for 410L containers

InactiveCN104911320AGuaranteed product organizationGuaranteed performanceTemperature controlLaminar cooling

The invention provides a heat treatment technique of stainless steel for 410L containers. The technical scheme is as follows: the heat treatment technique comprises the following steps: dephosphorizing, AOD (argon oxygen decarburization) refining, LF (ladle furnace) refining, continuous casting, trimming, hot rolling, hot pickling, cold rolling, cold wire annealing pickling and straightening, wherein in the hot rolling process, laminar cooling is not performed, the coiling temperature is controlled at 800-840 DEG C, the sheet strip is blown from the side, and the black coil drop adopts a pile cooling technique; and the cold wire annealing TV value is 40+ / -5 mm*m / minute, the target TV value is 40mm*m / minute, and the material temperature is 840+ / -10 DEG C. The technique cancels the hood-type annealing technique, and lowers the production cost and accelerates the production rhythm on the premise of ensuring the product structure and properties.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com